Rolled Ring Forging

Tlhaloso e Khutšoanyane:

Rolled ring forging ke ts'ebetso ea ts'ebetso ea tšepe e hlahisang mehele e matla, e tšoarellang e nang le lisebelisoa tse fapaneng ho pholletsa le liindasteri tse ngata.

Rolled Ring Forging:

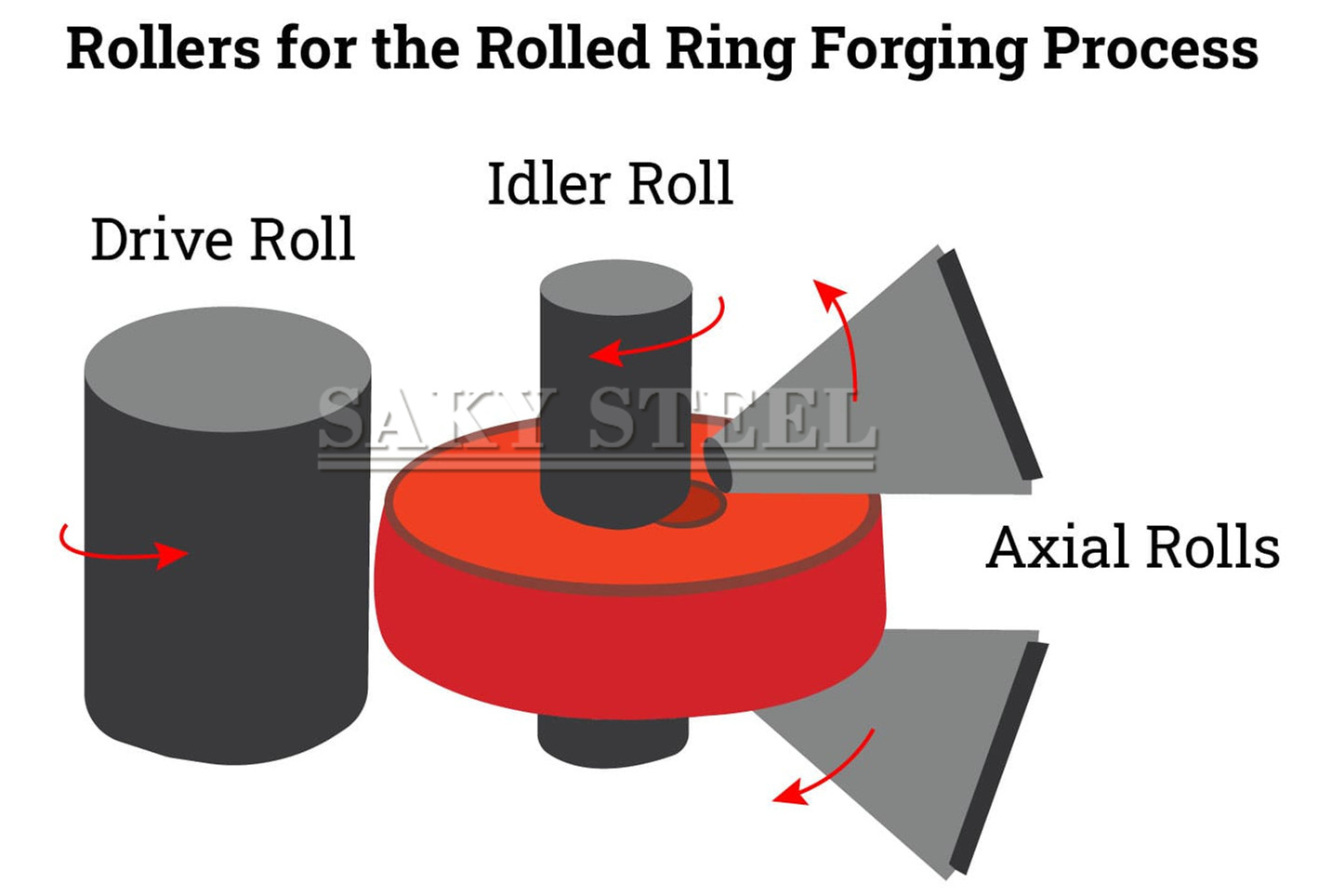

Li-ringless forged ringless li entsoe ka mokhoa o tsejoang e le ring rolling. Ts'ebetso ena e qala ka preform ea tšepe e chitja, e hlajoang ho sebelisoa forging e bulehileng ho theha "ring blocker." Ka nako eo, "ring blocker" e khutlisetsoa mocheso o loketseng bakeng sa boemo ba eona ba thepa. Hang ha e futhumetse, e behoa holim'a mandrel. Joale mandrel e isoa moqolong oa koloi, oo hape o bitsoang morena roll, o potolohang tlas'a khatello. Khatello ena e fokotsa botenya ba lerako la lesale, ha ka nako e le 'ngoe e eketsa bophara ba eona ba ka hare le ba ka ntle.

Litlhaloso tsa Seamless Rolled Ring Forging:

| Kereiti | 304,316,321 joalo-joalo. |

| Boholo | Customized |

| Bokaholimo | Ho penta, sandblasting, electroplating, joalo-joalo |

| Lintho tse tala | POSCO, Baosteel, TISCO, Saky Steel, Outokumpu |

Rolled Ring Forging ke eng?

Ho roala lesale la forging ke mokhoa oa ho sebetsa ka tšepe o qalang ka tšepe e chitja, e entsoeng esale pele, e ferekaneng le ho phunngoa ho etsa sebopeho se kang sa donut. Sekhechana sena se bōpehileng joaloka torus se futhumatsoa ho mocheso ka holim'a ntlha ea eona ea recrystallization 'me e behoa holim'a mandrel kapa idler.Idler e lebisa torus e phunyeletsoeng ho ea ho koloi ea koloi, e potolohang ka mokhoa o ts'oanang le ho sebelisa khatello ea ho fokotsa lerako ha e ntse e atolosa bophara ba ka hare le ka ntle. Ts'ebetso ena e etsa hore ho thehoe selikalikoe se pota-potiloeng. Mehele ea tšepe e se nang seamless e hlahisoang ka ho roala lesale e ka fapana ka boholo 'me e atisa ho sebelisoa ka lisebelisoa tsa mochine, li-turbine, liphaephe le likepe tsa khatello. Mokhoa ona oa ho theha o ntlafatsa haholo lisebelisoa tsa mochini oa tšepe, o boloka sebopeho sa lijo-thollo ha o ntse o o bopa.

Ke Hobane'ng ha U re Khetha?

•U ka fumana thepa e phethahetseng ho latela tlhoko ea hau bonyane theko e ka khonehang.

•Re boetse re fana ka Reworks, FOB, CFR, CIF, le litheko tsa ho fana ka ntlo le ntlo. Re fana ka tlhahiso ea hore u etse tumellano ea ho tsamaisa thepa e tla u baballa haholo.

•Thepa eo re fanang ka eona e ka netefatsoa ka botlalo, ho tloha ho setifikeiti sa tlhahlobo ea thepa e tala ho isa polelong ea ho qetela. (Litlaleho li tla hlaha ho latela tlhoko)

•Re netefatsa ho fana ka karabo nakong ea lihora tse 24 (hangata ka hora e tšoanang)

•Fana ka tlaleho ea SGS TUV.

•Re inehetse ka ho feletseng ho bareki ba rona. Haeba ho ke ke ha khoneha ho finyella litlhoko tsa hau ka mor'a ho hlahloba likhetho tsohle, re ke ke ra u khelosa ka ho etsa litšepiso tsa bohata tse tla theha likamano tse ntle tsa bareki.

•Fana ka tšebeletso ea sebaka se le seng.

Litšebeletso tsa Rōna

1. Ho khutsisa le ho khutsisa

2.Ho phekola mocheso oa vacuum

3.Bokaholimo bo pentiloeng ka seipone

4.Precision-milled finish

4.CNC mechine

5.Ho cheka ka mokhoa o nepahetseng

6.Khaola likarolo tse nyane

7.Fihlella ho nepahala ha hlobo

Ho paka:

1. Ho paka ke habohlokoa haholo-holo tabeng ea thepa ea machaba eo thepa e fetang ka litsela tse fapa-fapaneng ho fihla moo e eang teng, kahoo re amehile haholo ka ho paka.

2. Saky Steel e paka thepa ea rona ka mekhoa e mengata ho latela lihlahisoa. Re paka lihlahisoa tsa rona ka mekhoa e mengata, joalo ka,