ER385 Stainless Steel Welding Rod

Tlhaloso e Khutšoanyane:

ER385 ke mofuta oa tšepe ea li-welding filler, haholo-holo eleketrode ea tšepe e sa hloekang. "ER" e emetse "Electrode kapa Rod," 'me "385" e bontša sebopeho sa lik'hemik'hale le litšobotsi tsa tšepe ea ho tlatsa. Tabeng ena, ER385 e etselitsoe ho cheselletsa litšepe tsa austenitic stainless.

Molamu oa Welding oa ER385:

Litšepe tsa Austenitic, tse kang Mofuta oa 904L, li na le chromium, nickel, le molybdenum tse ngata, tse etsang hore li se ke tsa bola 'me li loketse ho sebelisoa libakeng tse thata. Li-welding rods tsa ER385 li atisa ho sebelisoa lits'ebetsong moo ho hanyetsa ha kutu e leng ntho ea bohlokoa haholo, joalo ka lik'hemik'hale, petrochemical, le marine industries.ER385 li-welding rods li loketse bakeng sa mekhoa e sa tšoaneng ea ho tjheseletsa, ho akarelletsa le shielded metal arc welding (SMAW), gas tungsten arc welding (GTAW kapa TIG) kapa MIGGMA metal welding (MIGGMA).

Litlhaloso tsa ER385 Welding Wire:

| Kereiti | ER304 ER308L ER309L,ER385 joalo-joalo. |

| Standard | AWS A5.9 |

| Bokaholimo | E khanyang, e koahetsoeng ke maru, e thota, e ntšo |

| Diameter | MIG - 0.8 ho 1.6 limilimithara, TIG - 1 ho 5.5 limilimithara, Core terata - 1.6 ho 6.0 |

| Kopo | E atisa ho sebelisoa ho hlahisa le ho lokisa litora, litanka, liphaephe le lijana tsa polokelo le tsa lipalangoang bakeng sa li-acid tse sa tšoaneng tse matla. |

E lekana le Stainless Steel ER385 Wire:

| TS'ELISO | WERKSTOFF NR. | UNS | JIS | BS | KS | HLOMPHO | EN |

| ER-385 | 1.4539 | N08904 | SUS 904L | 904S13 | STS 317J5L | Z2 NCDU 25-20 | X1NiCrMoCu25-20-5 |

Sebopeho sa Lik'hemik'hale SUS 904L Mohala oa Welding:

Ho latela maemo a AWS A5.9

| Kereiti | C | Mn | P | S | Si | Cr | Ni | Mo | Cu |

| ER385(904L) | 0.025 | 1.0-2.5 | 0.02 | 0.03 | 0.5 | 19.5-21.5 | 24.0-36.0 | 4.2-5.2 | 1.2-2.0 |

1.4539 Welding Rod Mechanical thepa:

| Kereiti | Tensile Strength ksi[MPa] | Elongation % |

| ER385 | 75[520] | 30 |

Ke Hobane'ng ha U re Khetha?

•U ka fumana thepa e phethahetseng ho latela tlhoko ea hau bonyane theko e ka khonehang.

•Re boetse re fana ka Reworks, FOB, CFR, CIF, le litheko tsa ho fana ka ntlo le ntlo. Re fana ka tlhahiso ea hore u etse tumellano ea ho tsamaisa thepa e tla u baballa haholo.

•Thepa eo re fanang ka eona e ka netefatsoa ka botlalo, ho tloha ho setifikeiti sa tlhahlobo ea thepa e tala ho isa polelong ea ho qetela. (Litlaleho li tla hlaha ho latela tlhoko)

•Re netefatsa ho fana ka karabo nakong ea lihora tse 24 (hangata ka hora e tšoanang)

•Fana ka tlaleho ea SGS TUV.

•Re inehetse ka ho feletseng ho bareki ba rona. Haeba ho ke ke ha khoneha ho finyella litlhoko tsa hau ka mor'a ho hlahloba likhetho tsohle, re ke ke ra u khelosa ka ho etsa litšepiso tsa bohata tse tla theha likamano tse ntle tsa bareki.

•Fana ka tšebeletso ea sebaka se le seng.

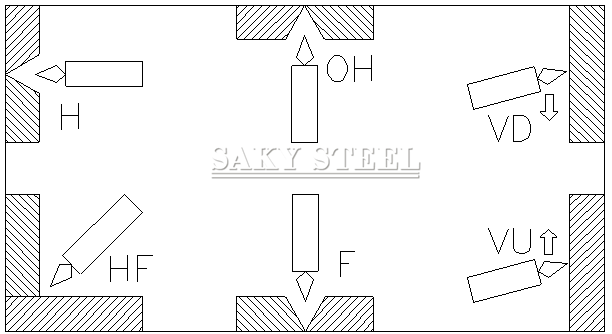

Mekhoa ea hona joale ea ho cheselletsa: DCEP (DC+)

| Tlhaloso ea bophara ba terata (mm) | 1.2 | 1.6 |

| Motlakase (V) | 22-34 | 25-38 |

| Hona joale (A) | 120-260 | 200-300 |

| Elong e ommeng (mm) | 15-20 | 18-25 |

| Phallo ea khase | 20-25 | 20-25 |

Litšobotsi tsa ER385 Welding Wire ke life?

1. Ho hanyetsa kutu e ntle haholo, ho ka hanela kutu e ts'oanang ea asiti ea sulfuric le asiti ea phosphoric, ho hanela kutu ea asiti ea acetic ka mocheso ofe kapa ofe le mahloriso tlas'a khatello e tloaelehileng, 'me e ka rarolla ka katleho kutu ea likoti, kutu ea likoti, kutu ea mokokotlo, kutu ea khatello ea maikutlo le mathata a mang a halide.

2. Arc e bonolo ebile e tsitsitse, e na le spatter e fokolang, sebōpeho se setle, ho tlosoa ha slag hantle, ho fepa ka terata e tsitsitseng, le ts'ebetso e babatsehang ea ts'ebetso ea welding.

Maemo a welding le lintho tsa bohlokoa:

1. Sebelisa litšitiso tse thibelang moea ha u cheselletsa libakeng tse nang le moea ho qoba masoba a bakoang ke moea o matla.

2. Mocheso o pakeng tsa ho feta o laoloa ho 16-100 ℃.

3. Mongobo, mafome a mafome le matheba a oli holim'a tšepe ea motheo e tlameha ho tlosoa ka ho feletseng pele ho tjheseletsa.

4. Sebelisa khase ea CO2 bakeng sa welding, bohloeki bo tlameha ho ba bo boholo ho feta 99.8%, 'me phallo ea khase e lokela ho laoloa ho 20-25L / min.

5. Bolelele bo omeletseng ba terata ea welding bo lokela ho laoloa ka har'a sebaka sa 15-25mm.

6. Ka mor'a ho manolla terata ea ho tjheseletsa, ka kopo hlokomela: nka mehato e thibelang mongobo, e sebelise kapele kamoo ho ka khonehang, 'me u se ke ua tlohela terata e sa sebelisoang e pepesehileng moeeng ka nako e telele.

Bareki ba Rona

Stainless Steel I Beams Packing:

1. Ho paka ke habohlokoa haholo-holo tabeng ea thepa ea machaba eo thepa e fetang ka litsela tse fapa-fapaneng ho fihla moo e eang teng, kahoo re amehile haholo ka ho paka.

2. Saky Steel e paka thepa ea rona ka mekhoa e mengata ho latela lihlahisoa. Re paka lihlahisoa tsa rona ka mekhoa e mengata, joalo ka,