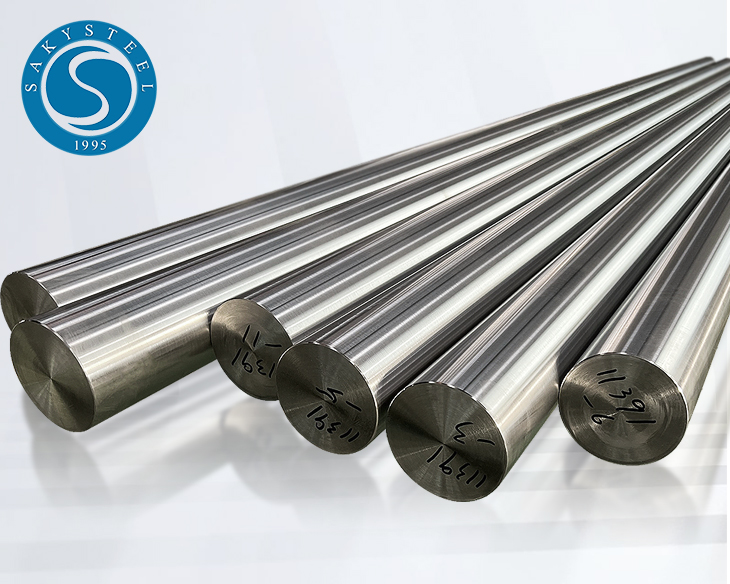

321 321H Stainless Steel bar

Tlhaloso e Khutšoanyane:

Lekola liphapano tsa bohlokoa lipakeng tsa 321 le 321H tsa tšepe e sa jeleng paate. Ithute ka ho hanyetsa ha tsona mocheso o phahameng, thepa le lisebelisoa tse loketseng.

321 tšepe e sa hloekang:

The 321 stainless steel bar ke motsoako oa austenitic stainless steel alloy e nang le titanium, e fanang ka khanyetso e ntle ea ho bola ha intergranular esita le ka mor'a ho pepesehela mocheso sebakeng sa chromium carbide sa 800 ° F ho 1500 ° F (427 ° C ho 816 ° C). Sena se etsa hore e be se loketseng bakeng sa ho sebelisoa libakeng tse phahameng tsa mocheso moo tšepe e lokelang ho boloka matla a eona le ho hanyetsa ho bola. Lisebelisoa tse tloaelehileng li kenyelletsa li-exhaust manifolds, lisebelisoa tsa mocheso, le likarolo tsa enjene ea sefofane. Ho eketsoa ha titanium ho tsitsisa alloy, ho thibela sebopeho sa carbide le ho netefatsa nako e telele ea nako e telele.

Litlhaloso tsa SS 321 round bar:

| Kereiti | 304,314,316,321,321H joalo-joalo. |

| Standard | ASTM A276 |

| Bolelele | 1-12m |

| Diameter | 4.00 limilimithara ho 500 limilimithara |

| Boemo | Cold Drawn & polished Cold Drawn, E peeled & Forged |

| Surface Finish | E Ntšo, E Khanyang, E bentšitsoeng, E Makhulo E Fetohileng, NO.4 Qetella, Matt Qetella |

| Sebopeho | Round, Square, Hex (A/F), Rectangle, Billet, Ingot, Forged jj. |

| QETA | Qetello e Ntle, Qetello e Beveled |

| Setifikeiti sa Tlhahlobo ea Mill | EN 10204 3.1 kapa EN 10204 3.2 |

Mephato e Tšoanang ea Stainless Steel 321/321H:

| TS'ELISO | WERKSTOFF NR. | UNS | JIS | EN |

| SS321 | 1.4541 | S32100 | SUS 321 | X6CrNiTi18-10 |

| SS 321H | 1.4878 | S32109 | SUS 321H | X12CrNiTi18-9 |

Sebopeho sa SS 321 / 321H Bar Chemical:

| Kereiti | C | Mn | Si | P | S | Cr | N | Ni | Ti |

| SS321 | 0.08 max | 2.0 boholo | 1.0 max | 0.045 boholo | 0.030 boholo | 17.00 - 19.00 | 0.10 max | 9.00 - 12.00 | 5(C+N) - 0,70 max |

| SS 321H | 0.04 - 0.10 | 2.0 boholo | 1.0 max | 0.045 boholo | 0.030 boholo | 17.00 - 19.00 | 0.10 max | 9.00 - 12.00 | 4(C+N) - 0,70 max |

Lisebelisoa tse 321 tsa tšepe e sa hloekang

1.Aerospace: Likarolo tse kang litsamaiso tsa mosi, manifolds, le likarolo tsa enjene ea turbine moo ho pepesehela mocheso o phahameng le tikoloho e senyang khafetsa.

2.Chemical Processing: Lisebelisoa tse kang mocheso oa mocheso, lik'hemik'hale tsa lik'hemik'hale, le litanka tsa polokelo, moo ho hanyetsanang le lintho tse nang le acidic le tse senyang li leng bohlokoa.

3.Petroleum Refining: Liphaephe, lisebelisoa tsa mocheso, le lisebelisoa tse ling tse pepesehetseng mocheso o phahameng oa peterole le mekhoa ea petrochemical.

4.Moloko oa Matla: Li-boilers, lijana tsa khatello, le likarolo tse ling tsa limela tsa matla tse sebetsang tlas'a mocheso o phahameng le khatello.

5.Automotive: Lisebelisoa tsa ho ntša metsi, li-mufflers, le li-converter tsa catalytic tse hlokang ho hanyetsa mocheso o phahameng le oxidation.

6.Tlhahiso ea Lijo: Lisebelisoa tse tlamehang ho mamella lipotoloho tse pheta-phetoang tsa ho futhumatsa le ho pholile, ha li ntse li boloka maemo a bohloeki, joalo ka mochini oa lebese le o lokisang lijo.

Ke Hobane'ng ha U re Khetha?

•U ka fumana thepa e phethahetseng ho latela tlhoko ea hau bonyane theko e ka khonehang.

•Re boetse re fana ka Reworks, FOB, CFR, CIF, le litheko tsa ho fana ka ntlo le ntlo. Re fana ka tlhahiso ea hore u etse tumellano ea ho tsamaisa thepa e tla u baballa haholo.

•Thepa eo re fanang ka eona e ka netefatsoa ka botlalo, ho tloha ho setifikeiti sa tlhahlobo ea thepa e tala ho isa polelong ea ho qetela. (Litlaleho li tla hlaha ho latela tlhoko)

•Re netefatsa ho fana ka karabo nakong ea lihora tse 24 (hangata ka hora e tšoanang)

•Fana ka tlaleho ea SGS TUV.

•Re inehetse ka ho feletseng ho bareki ba rona. Haeba ho ke ke ha khoneha ho finyella litlhoko tsa hau ka mor'a ho hlahloba likhetho tsohle, re ke ke ra u khelosa ka ho etsa litšepiso tsa bohata tse tla theha likamano tse ntle tsa bareki.

•Fana ka tšebeletso ea sebaka se le seng.

SS 321 round bar Packing:

1. Ho paka ke habohlokoa haholo-holo tabeng ea thepa ea machaba eo thepa e fetang ka litsela tse fapa-fapaneng ho fihla moo e eang teng, kahoo re amehile haholo ka ho paka.

2. Saky Steel e paka thepa ea rona ka mekhoa e mengata ho latela lihlahisoa. Re paka lihlahisoa tsa rona ka mekhoa e mengata, joalo ka,