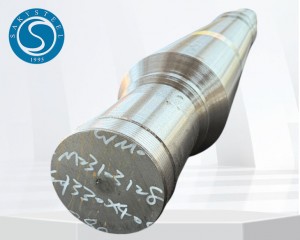

316 Ho Beha Mokotla oa Tšepe Roller

Tlhaloso e Khutšoanyane:

Fumana Forging Steel Roller Shafts bakeng sa lits'ebetso tsa indasteri. E entsoe ho latela lintlha tsa hau, e nang le ts'ebetso e tšoarellang le ho qhekella hantle.

Shaft ea tšepe e entsoeng ka tšepe

Shaft ea tšepe e entsoeng ka tšepeke karolo ea matla a holimo, e tšoarellang e sebelisoang lits'ebetsong tse fapaneng tsa indasteri, haholo ha ho etsoa le ho lokisa thepa e kang tšepe, pampiri le masela. Li entsoe ka mokhoa oa ho forging, li-shafts tsena li fana ka lisebelisoa tse phahameng tsa mochini, ho kenyelletsa le ho tiea ho ntlafetseng, ho hanyetsa ho apara, le bokhoni bo phahameng ba ho jara thepa ha bo bapisoa le li-shafts tse entsoeng ka mechine. Forged Steel Roller Shafts e entsoe ka tloaelo ho fihlela litlhoko tse ikhethang tsa boholo, sebopeho, le ts'ebetso, ho netefatsa ts'ebetso e tšepahalang le bophelo bo atolositsoeng ba ts'ebeletso libakeng tse boima. E loketse ho sebelisoa ho lirolara, li-conveyors le mechini e meng, li fana ka ts'ebetso e ikhethang maemong a khatello e phahameng ea maikutlo.

Litlhaloso tsa Forged Steel Rolls:

| Litlhaloso | ASTM A182,ASTM A105,GB/T 12362 |

| Lintho tse bonahalang | Tšepe ea motsoako, tšepe ea carbon, tšepe ea Carburizing, tšepe e tingoeng le e halefileng |

| Kereiti | Carbon Steel:4130,4140,4145,S355J2G3+N,S355NL+N,C20,C45,C35, joalo-joalo. |

| Tšepe e se nang Mokelikeli: 17-4 PH, F22,304,321,316/316L, joalo-joalo. | |

| Tool Steel: D2 / 1.2379, H13 / 1.2344, 1.5919, joalo-joalo. | |

| Surface Finish | E ntšo, e Khanyang, joalo-joalo. |

| Phekolo ea mocheso | Ho tloaeleha, Ho Aneha, Ho tima le ho halefisa, ho tima holim'a metsi, ho thatafatsa linyeoe |

| Mochini | CNC Turning,CNC Milling,CNC Boring,CNC Grinding,CNC Drilling |

| Mochini oa Gear | Gear Hobbing,Gear Milling,CNC Gear Milling,Gear Cutting,spiral gear cutting,Gear Cutting |

| Setifikeiti sa Tlhahlobo ea Mill | EN 10204 3.1 kapa EN 10204 3.2 |

Lisebelisoa tsa ho theha Shaft ea tšepe:

1.Indasteri ea Litšepe: Li-Forged Steel Roller Shafts li sebelisoa haholo ho liloala, moo li bapalang karolo ea bohlokoa ho bopeng le ho etsa lihlahisoa tsa tšepe. Li-shafts tsena li mamella matla le mocheso o phahameng, li netefatsa ts'ebetso ea tšepe e boreleli le e tsitsitseng.

2.Indasteri ea Lipampiri le ea Pulp: Liindastering tsa pampiri, li-shaft tsena li sebelisoa li-calender, mechine ea khatiso le lirolara, tse hlokahalang bakeng sa tlhahiso ea pampiri le khateboto. Ho tšoarella ha bona le ho hanyetsa ho apara ho etsa hore e be tse loketseng bakeng sa ho sebetsana le ts'ebetso e phahameng ea khatello le lebelo le phahameng.

3.Indasteri ea Textile: Li-Forged Steel Roller Shafts li sebelisoa mecheng ea masela, joalo ka thepa ea ho loha le ea ho ohla, ho tšehetsa lirolara le ho fana ka motsamao o nepahetseng le botsitso nakong ea tlhahiso ea masela.

4.Mining le Quarrying: Li-shafts tsena li bohlokoa haholo mecheng e sebetsanang le liminerale, moo li mamellang meroalo e boima le maemo a thata a ts'ebetso. Matla a bona a netefatsa ts'epo ea nako e telele le ts'ebetso e nepahetseng ho li-crusher, li-mill le li-conveyors.

5. Thepa ea Temo: Mecheng ea temo, joalo ka ba kotulang le ba polang, Mechini ea Forged Steel Roller Shafts e thusa ho tsamaisa thepa le ho tsamaisa thepa, ho netefatsa hore lisebelisoa li sebetsa hantle tlas'a maemo a thata a masimong.

6.Automotive and Conveyor Systems: Forged Steel Roller Shafts e sebelisoa mehala ea tlhahiso ea likoloi le mekhoa ea ho tsamaisa likoloi, moo e fanang ka tšehetso e matla bakeng sa li-roller tse boima tse tsamaisang lihlahisoa haufi le mohala oa kopano.

7.Plastiki le Rubber Manufacturing: Li-shafts tsena li sebelisoa ka mechine ea extrusion le lisebelisoa tse ling tsa ho sebetsana le liindasteri tsa polasetiki le rabara, ho netefatsa hore ho na le ts'ebetso e phahameng libakeng tseo ho tsona ho hlokahalang lebelo le ho jara mojaro.

Likarolo tsa Bright Shaft Forgings:

1.Matla a Phahameng le Matla: Ts'ebetso ea ho forging e ntlafatsa sebopeho sa lijo-thollo tse ka hare tsa tšepe, ho etsa hore shaft e be matla haholo le ho mamella khatello ea maikutlo le tšusumetso.

2.Improved Wear Resistance: Forged Steel Roller Shafts e hanyetsana haholo le ho roala le ho abrasion, e leng se etsang hore e be tse loketseng bakeng sa lisebelisoa tse boima moo khohlano e lulang e le teng.

3. Ho hanyetsa Mokhathala ho Matlafalitsoeng: Ka lebaka la microstructure ea bona e hloekisitsoeng, li-shafts tsena li khona ho mamella lipotoloho tse pheta-phetoang tsa ho laela le ho laolla ntle le ho robeha kapa ho lahleheloa ke botšepehi.

4.Superior Load-Bearing Capacity: Forged Steel Roller Shafts e etselitsoe ho sebetsana le meroalo e boima ntle le deformation.

5.Corrosion Resistance: Ho ipapisitse le boemo ba tšepe e sebelisitsoeng le liphekolo life kapa life tse ling tse eketsehileng tsa holim'a metsi (mohlala, ho roala kapa ho futhumatsa mocheso).

6.Customizability: Forged Steel Roller Shafts e ka etsoa hore e finyelle litlhoko tse khethehileng tsa boholo, sebōpeho le tshebetso.

7.High Temperature Resistance: Li-shafts tsena li ka sebetsa maemong a feteletseng a mocheso.

Ho nepahala ha 8.Dimensional: Ts'ebetso ea ho theha e lumella ho mamellana ka thata le ho nepahala ho phahameng.

9.Durability le Bophelo bo Bolelele: Forged Steel Roller Shafts e na le nako e telele ea tšebeletso ha e bapisoa le lisebelisoa tse ling kapa mekhoa ea tlhahiso ka lebaka la matla a bona a phahameng le ho tšoarella.

10.Impact Resistance: Ts'ebetso ea ho forging e ntlafatsa bokhoni ba shaft ba ho hanela ts'isinyeho ea tšohanyetso kapa litlamorao.

Ke Hobane'ng ha U re Khetha?

•U ka fumana thepa e phethahetseng ho latela tlhoko ea hau bonyane theko e ka khonehang.

•Re boetse re fana ka Reworks, FOB, CFR, CIF, le litheko tsa ho fana ka ntlo le ntlo. Re fana ka tlhahiso ea hore u etse tumellano ea ho tsamaisa thepa e tla u baballa haholo.

•Thepa eo re fanang ka eona e ka netefatsoa ka botlalo, ho tloha ho setifikeiti sa tlhahlobo ea thepa e tala ho isa polelong ea ho qetela. (Litlaleho li tla hlaha ho latela tlhoko)

•Re netefatsa ho fana ka karabo nakong ea lihora tse 24 (hangata ka hora e tšoanang)

•Fana ka tlaleho ea SGS ,TUV,BV 3.2.

•Re inehetse ka ho feletseng ho bareki ba rona. Haeba ho ke ke ha khoneha ho finyella litlhoko tsa hau ka mor'a ho hlahloba likhetho tsohle, re ke ke ra u khelosa ka ho etsa litšepiso tsa bohata tse tla theha likamano tse ntle tsa bareki.

•Fana ka tšebeletso ea sebaka se le seng.

Ho Paka Litšepe Tsa Forged Steel:

1. Ho paka ke habohlokoa haholo-holo tabeng ea thepa ea machaba eo thepa e fetang ka litsela tse fapa-fapaneng ho fihla moo e eang teng, kahoo re amehile haholo ka ho paka.

2. Saky Steel e paka thepa ea rona ka mekhoa e mengata ho latela lihlahisoa. Re paka lihlahisoa tsa rona ka mekhoa e mengata, joalo ka,