2507 S32750 Super Duplex Round Bar

Tlhaloso e Khutšoanyane:

2507 tšepe e sa jeleng paate ke tšepe e sa tsitsang e habeli e tsebahalang ka ho hanyetsa kutu le matla a eona a holimo.

Super Duplex 2507 Round Bar:

2507 tšepe e sa hloekang e ithorisa ka chai e ngata haholo le matla a tsitsitseng, e leng se etsang hore e tšoanele maemo a phahameng a khatello ea maikutlo. tlhahiso.2507 tšepe e sa hloekang e boloka thepa ea eona ea mochine le ho hanyetsa ho bola esita le libakeng tse phahameng tsa mocheso.E sebelisoa bakeng sa likarolo tsa mehaho ea leoatle, likepe le liforomo tsa oli tse lebōpong la leoatle.

Litlhaloso tsa 2507 steel bar:

| Kereiti | S32760 S31254 2507 S32750 |

| Litlhaloso | ASTM A276 |

| Bolelele | 2.5M, 3M, 6M & Bolelele bo Hlokehang |

| Diameter | 4.00 limilimithara ho 500 limilimithara |

| Boholo | 6 limilimithara ho 120 limilimithara |

| Botenya | 100 ho isa ho 6000 limilimithara |

| bokahodimo | E khanyang, e Ntšo, Sepolishe |

| Mofuta | Round, Square, Hex (A/F), Rectangle, Billet, Ingot, Forging jj. |

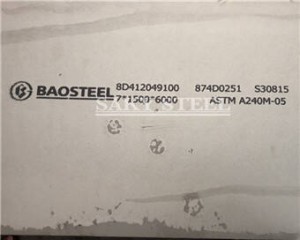

| Lintho tse tala | POSCO, Baosteel, TISCO, Saky Steel, Outokumpu |

S32750 Bar Limaraka tse lekanang:

| Kereiti | UNS | Werkstoff Nr. |

| 2507 | S32750 | 1.4410 |

Sebopeho sa S32750 Duplex Bar Chemical:

| Kereiti | C | Si | Mn | S | P | Cr | Mo | Ni |

| S32750 | 0.03 | 0.8 | 1.2 | 0.02 | 0.035 | 24.0-26.0 | 3.0-5.0 | 6.0-8.0 |

2507 Duplex Bar Mechanical & Thepa ea 'Mele:

| Matla a Hlahisa (0.2%Offset) | Matla a tšepe | Elongation |

| 550Mpa | 800Mpa | 15% |

Ke Hobane'ng ha U Re Khetha:

1. U ka fumana boitsebiso bo phethahetseng ho ea ka tlhokahalo ea hau bonyane theko e ka khonehang.

2. Re boetse re fana ka Reworks, FOB, CFR, CIF, le litheko tsa ho fana ka ntlo le ntlo. Re fana ka tlhahiso ea hore u etse tumellano ea ho tsamaisa thepa e tla u baballa haholo.

3. Thepa eo re fanang ka eona e ka netefatsoa ka botlalo, ho tloha ho setifikeiti sa tlhahlobo ea thepa e tala ho isa polelong ea ho qetela.(Litlaleho li tla hlaha ho latela tlhoko)

4. Re netefatsa ho fana ka karabo nakong ea lihora tse 24 (hangata ka hora e tšoanang)

5. Fana ka tlaleho ea SGS TUV.

6. Re inehetse ka ho feletseng ho bareki ba rona. Haeba ho ke ke ha khoneha ho finyella litlhoko tsa hau ka mor'a ho hlahloba likhetho tsohle, re ke ke ra u khelosa ka ho etsa litšepiso tsa bohata tse tla theha likamano tse ntle tsa bareki.

7.Fana ka tšebeletso ea sebaka se le seng.

8.Lihlahisoa tsa rona li tsoa ka ho toba fekthering ea tlhahiso, ho netefatsa boleng ba pele le ho felisa litšenyehelo tse eketsehileng tse amanang le baemeli.

9.Re ikemiselitse ho fana ka litheko tse nang le tlhōlisano e kholo, e leng se u lumellang ho thabela melemo ea bohlokoa ea litšenyehelo ntle le ho sekisetsa boleng.

Litšebeletso tsa Rōna

1. Ho khutsisa le ho khutsisa

2.Ho phekola mocheso oa vacuum

3.Bokaholimo bo pentiloeng ka seipone

4.Precision-milled finish

5.CNC mechine

6.Ho cheka ka mokhoa o nepahetseng

7.Khaola likarolo tse nyane

8.Fihlella ho nepahala ha hlobo

Sephutheloana sa SAKY STEEL'S:

1. Ho paka ke habohlokoa haholo-holo tabeng ea thepa ea machaba eo thepa e fetang ka litsela tse fapa-fapaneng ho fihla moo e eang teng, kahoo re amehile haholo ka ho paka.

2. Saky Steel e paka thepa ea rona ka mekhoa e mengata ho latela lihlahisoa. Re paka lihlahisoa tsa rona ka mekhoa e mengata, joalo ka,