Birta aan Lahayn HI Beam

Sharaxaad Gaaban:

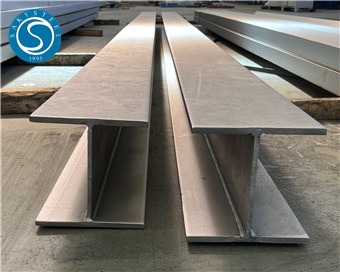

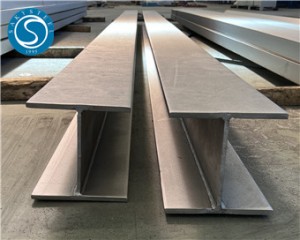

"H Beam" waxay tixraacaysaa qaybaha qaabdhismeedka ee u qaabaysan xarafka "H" ee sida caadiga ah loo isticmaalo dhismaha iyo codsiyada qaabdhismeedka ee kala duwan.

Birta Aan Aan Lahayn H Beam:

Birta aan birta lahayn H Beam waa qaybo dhismeed oo lagu garto qaybtooda H-qaabeeya. Kanaaladan waxa laga sameeyay bir aan-xawaag lahayn, alloy adkaysi u leh daxalka oo caan ku ah adkaysigeeda, nadaafadeeda, iyo bilicdeeda. Kanaalada H ee birta ah waxay ka helaan codsiyada warshadaha kala duwan, oo ay ku jiraan dhismaha, naqshadeynta, iyo wax soo saarka, halkaas oo iska caabintooda daxalka iyo xoogga ay ka dhigaan doorashada la doorbido ee taageerada qaabdhismeedka iyo naqshadeynta. Qaybahaas waxaa badanaa loo isticmaalaa dhismaha qaabdhismeedka, taageerada, iyo walxaha kale ee dhismaha halkaas oo labadaba xoogga iyo muuqaalka dhalaalaya ay muhiim yihiin.

Tilmaamaha I Beam:

| Darajo | 302 304 304L 310 316 316L 321 2205 2507 iwm. |

| Heerka | GB T33814-2017,GBT11263-2017 |

| Dusha sare | Bacaad qarxinta, turxaan bixinta, qarxinta rasaasta |

| Farsamada | Kulul duuban , Alxan |

| Dhererka | 1 ilaa 12 Mitir |

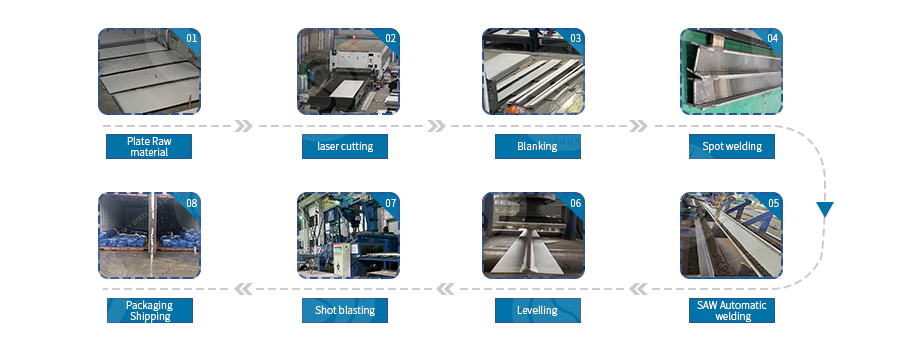

I-beam shaxda socodka socodka:

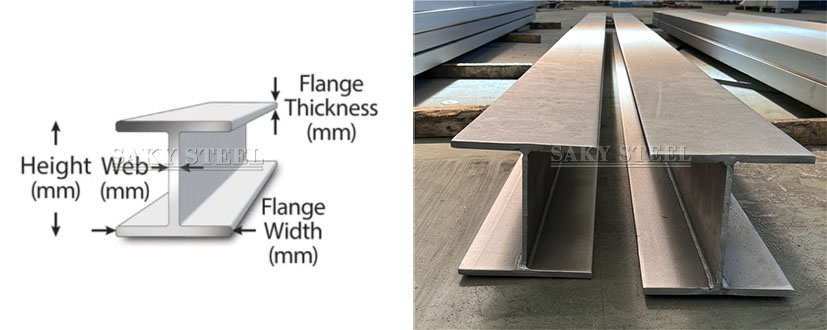

Shabakadda

Shabakaddu waxay u adeegtaa sidii udub dhexaadka udub dhexaadka u ah laydhka, sida caadiga ah lagu qiimeeyay dhumucdeeda. U shaqaynta sidii isku xidhka qaabdhismeedka, waxa ay door muhiim ah ka ciyaartaa ilaalinta hufnaanta laydhka iyada oo isku xidhaysa oo midaynaysa labada garab, si wax ku ool ah u qaybinaysa una maaraynaysa cadaadiska.

Flange:

Qaybaha hoose ee sare iyo kuwa siman ee birta waxay wataan culayska aasaasiga ah. Si loo hubiyo qaybinta cadaadiska isku midka ah, waxaan ku dhejineynaa geesaha. Labadan qaybood ayaa is barbar socda, marka la eego macnaha I-beams, waxay muujinayaan baal-ballaadhineed oo kale ah.

H Beam Alxanka Dhumucda Xadhkaha Cabbirka:

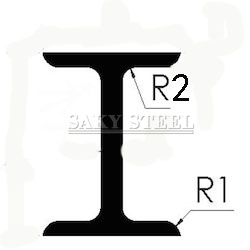

Birta Aan-la-laawaha lahayn I Beam Beveling Process:

Xagasha R ee I-beam waa la dhalaaliyay si ay dusha uga dhigto mid siman oo aan dabo lahayn, taas oo ku habboon ilaalinta badbaadada shaqaalaha. Waxaan ka baaraandegi karnaa xagasha R ee 1.0, 2.0, 3.0. 304 316 316L 2205 IH Biamyada aan Alaabta lahayn. Xagasha R ee 8-da sadar dhamaantood waa la silcay.

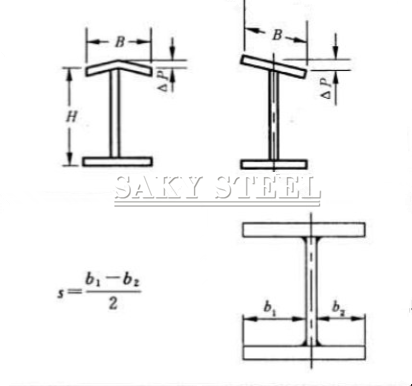

Birta Aan Lahayn I Beam Wing/Flange toosinta:

Tilmaamaha & Faa'iidooyinka:

•Naqshadaynta qaybta iskutallaabta ee qaabaysan ee "H" ee birta I-beam waxay siinaysaa awood heersare ah oo qaadis ah culaysyo toosan iyo kuwo toosan labadaba.

•Naqshadeynta qaabdhismeedka birta I-beam waxay bixisaa xasillooni heer sare ah, ka hortagga qallafsanaanta ama foorarsiga cadaadiska.

•Sababtoo ah qaabkeeda gaarka ah, birta I-beam waxaa si dabacsan loogu dabaqi karaa qaabab kala duwan, oo ay ku jiraan alwaaxyada, tiirarka, buundooyinka, iyo in ka badan.

•Birta I-beam waxay si gaar ah u qabataa foorarsiga iyo isku-buufinta, hubinta xasiloonida xaaladaha culeyska adag.

•Naqshadeeda hufan iyo xoogga sare, I-beam steel inta badan waxay bixisaa wax ku ool wanaagsan.

•Birta I-beam waxay ka heleysaa isticmaalka ballaaran ee dhismaha, buundooyinka, qalabka warshadaha, iyo meelo kale oo kala duwan, oo muujinaya kala duwanaanshaheeda mashaariicda injineernimada iyo dhismaha ee kala duwan.

•Naqshadeynta birta I-beam waxay u oggolaaneysaa inay si fiican ula qabsato shuruudaha dhismaha iyo naqshadeynta waara, iyada oo siinaya xal qaabaysan oo waxtar leh oo loogu talagalay hababka dhismaha deegaanka iyo cagaarka.

Halabuurka Kiimikada H Beam:

| Darajo | C | Mn | P | S | Si | Cr | Ni | Mo | Nitrojiin |

| 302 | 0.15 | 2.0 | 0.045 | 0.030 | 1.0 | 17.0-19.0 | 8.0-10.0 | - | 0.10 |

| 304 | 0.08 | 2.0 | 0.045 | 0.030 | 1.0 | 18.0-20.0 | 8.0-11.0 | - | - |

| 309 | 0.20 | 2.0 | 0.045 | 0.030 | 1.0 | 22.0-24.0 | 12.0-15.0 | - | - |

| 310 | 0.25 | 2.0 | 0.045 | 0.030 | 1.5 | 24-26.0 | 19.0-22.0 | - | - |

| 314 | 0.25 | 2.0 | 0.045 | 0.030 | 1.5-3.0 | 23.0-26.0 | 19.0-22.0 | - | - |

| 316 | 0.08 | 2.0 | 0.045 | 0.030 | 1.0 | 16.0-18.0 | 10.0-14.0 | 2.0-3.0 | - |

| 321 | 0.08 | 2.0 | 0.045 | 0.030 | 1.0 | 17.0-19.0 | 9.0-12.0 | - | - |

Qalabka makaanikada ee I Beams:

| Darajo | Xoogga Jilitaanka ksi[MPa] | Yiled Strengtu ksi[MPa] | Kordhinta % |

| 302 | 75[515] | 30[205] | 40 |

| 304 | 95[665] | 45[310] | 28 |

| 309 | 75[515] | 30[205] | 40 |

| 310 | 75[515] | 30[205] | 40 |

| 314 | 75[515] | 30[205] | 40 |

| 316 | 95[665] | 45[310] | 28 |

| 321 | 75[515] | 30[205] | 40 |

Maxaa noo doora ?

•Waxaad ka heli kartaa alaabta ugu fiican iyadoo loo eegayo shuruudahaaga qiimaha ugu yar ee suurtogalka ah.

•Waxaan sidoo kale bixinaa Reworks, FOB, CFR, CIF, iyo albaabka ilaa albaabada qiimaha gaarsiinta. Waxaan kugula talineynaa inaad wax ka qabato dhoofinta kaas oo noqon doona mid aad dhaqaale.

•Agabka aanu bixino gabi ahaanba waa la xaqiijin karaa, laga bilaabo shahaadada tijaabada alaabta ceyriinka ilaa bayaanka cabbirka kama dambaysta ah.

•Waxaan dammaanad qaadaynaa inaan ku bixinno jawaab 24saac gudahood (badanaa isla saacada)

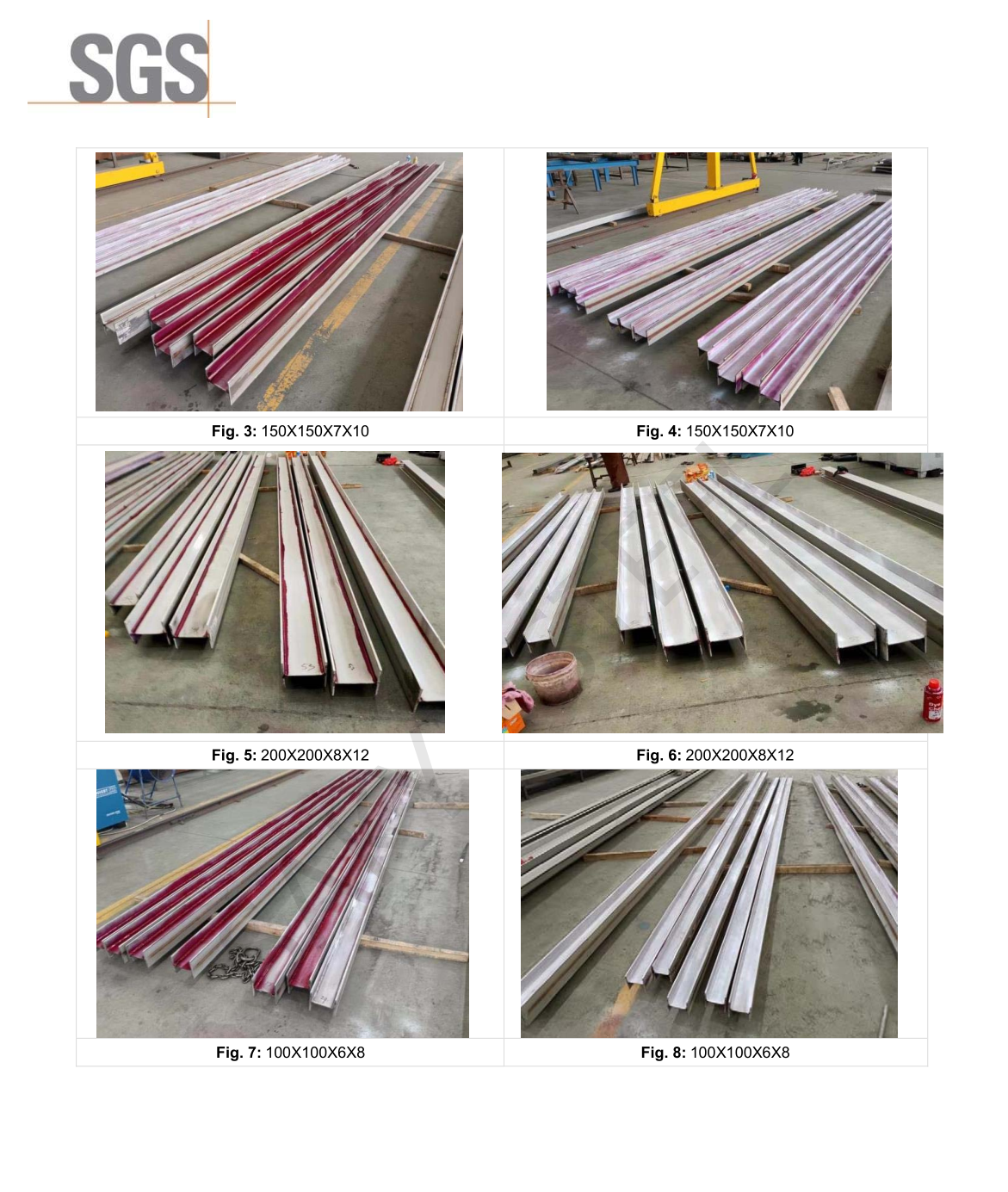

•Bixi warbixinta SGS TUV

•Waxaan si buuxda ugu heellan nahay macaamiishayada. Haddii ay suurtagal noqon waydo inaad buuxiso shuruudahaaga ka dib markaad eegto dhammaan fursadaha, kuma marin habaabin doonno ballanqaadyo been abuur ah oo abuuraya xiriir wanaagsan oo macaamiisha ah.

•Bixi adeeg hal joogsi ah.

316L oo ah birta welded H Beam Penetration Test (PT)

Ku salaysan JBT 6062-2007 Tijaabooyin aan burburin - Tijaabada dhex-galka ah ee alxanka 304L 316L birta alxanka H Beam.

Waa maxay hababka alxanka?

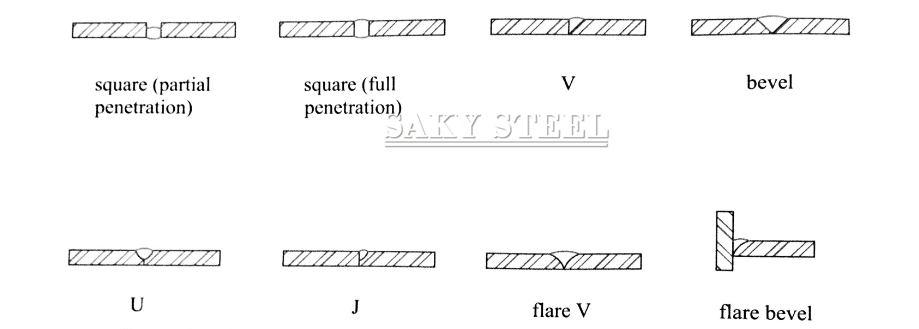

Hababka alxanka waxaa ka mid ah alxanka arc, alxanka gaashaanka gaaska (MIG / MAG alxanka), alxanka iska caabin ah, alxanka laser, alxanka arc plasma, alxanka walaaq khilaaf, alxanka cadaadiska, alxanka alxanka alxanka, iwm Hab kastaa wuxuu leeyahay codsiyada iyo sifooyinka gaarka ah, ku haboon noocyada kala duwan ee workpieces iyo shuruudaha wax soo saarka. Hababka alxanka ee caadiga ah waxaa ka mid ah alxanka qaanso-gacmeedka, alxanka argon, alxanka arc hoostiisa, iwm. Kulaylka ay dhaliso caabbinta waxaa loo isticmaalaa in lagu dhalaaliyo birta dusha sare ee workpiece si ay u sameeyaan xiriir. Alxanka iska caabinta waxaa ka mid ah alxanka barta, alxanka tolleynta iyo alxanka birta.

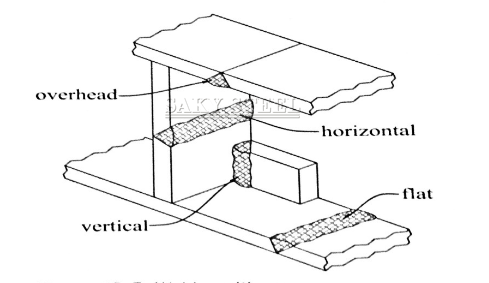

Mar kasta oo ay suurtogal tahay, alxanka waa in lagu sameeyaa dukaanka halkaas oo tayada alxanka ay caadi ahaan ka fiican tahay, alxanka dukaanka laguma sakhiro cimilada iyo gelitaanka wadajirka ayaa si cadaalad ah u furan. Alxanka waxaa loo kala saari karaa fidsan, siman, toosan, iyo sare. Waxaa la arki karaa in alxanka fidsan ay yihiin kuwa ugu fudud ee la sameeyo; waa habka la door biday. Alxanka sare, oo inta badan lagu sameeyo garoonka, waa in sidoo kale laga fogaadaa meesha ay suurtagal tahay sababtoo ah way adag yihiin oo waqti badan ayay qaataan, halkaasna waa ka qaalisan yihiin.

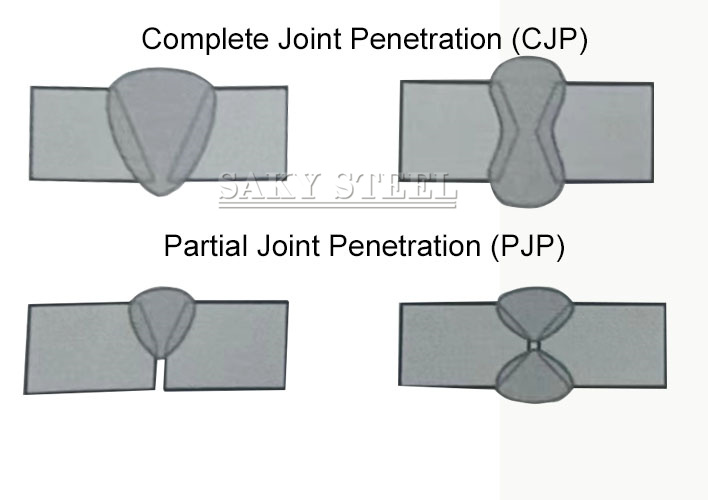

Alxannada jeexdintu waxay geli karaan xubinta ku xiran qayb ka mid ah dhumucda xubinta, ama waxay geli kartaa dhumucda buuxda ee xubinta ku xiran. Kuwaan waxaa loo yaqaannaa dhex galka qayb wadaagga ah (PJP) iyo dhexgalka wadajirka ah (CJP), siday u kala horreeyaan. Alxanka galinta dhamaystiran (sidoo kale loo yaqaan full.penetration ama "qalinka buuxa" alxanka) waxay isku xiraan dhammaan qoto dheer ee darafyada xubnaha ku xiran Alxanka gelinta qaybeed waa ka kharash badan yahay waxaana la isticmaalaa marka rarka la rakibay ay yihiin sida alxanka dhexgalka buuxa looma baahna. Waxa kale oo loo isticmaali karaa halka gelitaanka jeexdintu ay ku kooban tahay hal dhinac oo xidhiidhka ah.

Fiiro gaar ah: Tus qaabdhismeedka birta qaab-dhismeedka

Waa maxay faa'iidooyinka alxanka arc hoostiisa?

Alxanka dhulka hoostiisa mara waxay ku habboon tahay automation-ka iyo deegaanka mugga sare leh. Waxay ku dhammayn kartaa tiro badan oo ah shaqada alxanka muddo gaaban gudaheed waxayna wanaajisaa waxtarka wax soo saarka. Alxanka dhulka hoostiisa mara waxay ku habboon tahay automation-ka iyo deegaanka mugga sare leh. Waxay ku dhammayn kartaa tiro badan oo ah shaqada alxanka muddo gaaban gudaheed waxayna wanaajisaa waxtarka wax soo saarka. Alxanka arc hoostiisa waxaa sida caadiga ah loo isticmaalaa in lagu alxanayo go'yaal dhumuc weyn sababtoo ah dhexgalka sare ee hadda iyo sare ayaa ka dhigaya mid waxtar leh codsiyadan. Maadaama alxanka uu daboolay qulqulka, ogsijiinta si wax ku ool ah ayaa looga hortagi karaa inay soo gasho aagga alxanka, taas oo yaraynaysa suurtogalnimada oksaydhka iyo spatter.Marka la barbar dhigo hababka alxanka gacanta, alxanka arc quuska ah ayaa inta badan si fudud loo habayn karaa, taas oo yaraynaysa baahida sare ee xirfadaha shaqaalaha. Alxanka dhulka hoostiisa ku jira, fiilooyinka alxanka badan iyo arcs ayaa isku mar la istcimaali karaa si loo gaaro alxanka kanaalka badan (lakabka badan) loona wanaajiyo waxtarka.

Waa maxay codsiyada Biraha H bim aan lahayn?

Biraha birta ah ee birta ah ayaa si weyn loogu isticmaalaa dhismaha, injineernimada badda, qalabka warshadaha, baabuurta, mashaariicda tamarta, iyo meelaha kale sababtoo ah caabbinta daxalka iyo adkeysiga. Waxay bixiyaan taageero qaabdhismeed mashaariicda dhismaha waxayna door muhiim ah ka ciyaaraan bay'ada u baahan iska caabinta daxalka, sida goobaha badda ama warshadaha. Intaa waxaa dheer, muuqaalkooda casriga ah iyo bilicda ayaa ka dhigaya inay ku habboon yihiin codsiyada naqshadaha dhismaha iyo gudaha.

Sidee u toosan tahay birta aan birta lahayn ee HI?

Toosanaanta birta H-beam, sida qayb kasta oo qaab dhismeedka ah, waa arrin muhiim u ah waxqabadkeeda iyo rakibaadda. Guud ahaan, wax-soo-saarayaashu waxay soo saaraan birta H-beams oo leh heerar toosan si ay ula kulmaan heerarka warshadaha iyo qeexitaanka.

Heerarka warshadaha ee la aqbalay ee toosnaanta birta qaab dhismeedka, oo ay ku jiraan birta H-beams, ayaa inta badan lagu qeexaa marka la eego leexinta la oggol yahay ee ka imanaysa xariiq toosan oo dhererkeedu cayiman yahay. Weecsanaantan waxa sida caadiga ah lagu muujiyaa dhinaca milimitirka ama inchs of xaaqin ama barakicin dambe.

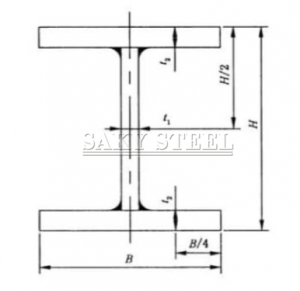

Hordhac qaabka H beam ?

Qaabka iskutallaabta ah ee birta I-beam, oo badanaa loo yaqaan "工字钢" (gōngzìgāng) ee Shiinaha, waxay u egtahay xarafka "H" marka la furo. Gaar ahaan, qaybta iskutallaabtu waxay caadi ahaan ka kooban tahay laba bir oo toosan (flanges) xagga sare iyo hoose iyo bar dhexe oo toosan (web). Qaabkan "H" wuxuu siinayaa awood sare iyo xasilloonida birta I-beam, taas oo ka dhigaysa qalab dhismeed oo caadi ah oo ku saabsan dhismaha iyo injineernimada. Qaabayntan qaabdhismeedku waxa ay awood u siinaysa birta I-beam in ay si wax ku ool ah u qaybiso culayska marka la saaro ciidamada, iyada oo siinaya taageero adag. Sababtoo ah qaabkeeda gaarka ah iyo sifooyinka qaabdhismeedka, I-beam steel waxay helaysaa isticmaalka baahsan ee dhinacyada dhismaha iyo injineernimada.

Sidee loo muujiyaa cabbirka iyo muujinta I-beam?

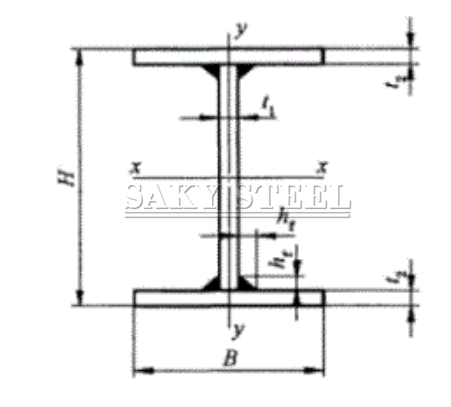

Ⅰ. Sawirka-isku-tallaabta iyo calaamadaha calaamadaynta birta 316L ee birta alxanka leh ee H-qaabeeya:

H——Dheer

B——Balac

t1—— Dhumucda shabakadda

t2-- Dhumucda saxanka Flange

h£--Xajmiga alxanka (marka la isticmaalayo isku-darka dabada iyo alxanka fillet, waa inay noqotaa cabbirka lugaha alxanka ee la xoojiyay)

Ⅱ Cabbirrada, qaababka iyo weecashooyinka la oggol yahay ee 2205 birta laba-laaban ee alxanka leh ee H-qaabeeya:

| H Beam | Dulqaad |

| Dhaleec (H) | Nalalka 300 ama ka yar: 2.0 mmIn ka badan 300:3.0mm |

| Ballaca (B) | 士2.0mm |

| Sida caadiga ah (T) | 1.2% ama ka yar wldth (B) Ogow in dulqaadka ugu yar yahay 2.0 mm |

| Dejinta xarunta (C) | 士2.0mm |

| foorarsan | 0.2096 ama ka yar oo dherer ah |

| Dhererka lugta (S) | [thlckness saxan webka (t1) x0.7]ama ka badan |

| Dhererka | 3 ~ 12m |

| Dulqaadka dhererka | + 40mm, 一0mm |

Ⅲ Cabbirrada, qaababka iyo weecashooyinka la oggol yahay ee birta alxanka leh ee H-qaabeeya

Ⅳ Cabbirada-qaybaha, aagga isdhaafka ah, miisaanka aragtida iyo cabbiraadaha sifada qaybaha ee birta alxanka leh ee H-qaabeeya

| Biraha aan birta lahayn | Cabbirka | Aagga Qaybta (cm²) | Miisaanka (kg/m) | Halbeegyada sifada | Cabbirka suufka alxanka h(mm) | ||||||||

| H | B | t1 | t2 | xx | yy | ||||||||

| mm | I | W | i | I | W | i | |||||||

| WH100X50 | 100 | 50 | 3.2 | 4.5 | 7.41 | 5.2 | 123 | 25 | 4.07 | 9 | 4 | 1.13 | 3 |

| 100 | 50 | 4 | 5 | 8.60 | 6.75 | 137 | 27 | 3.99 | 10 | 4 | 1.10 | 4 | |

| WH100X100 | 100 | 100 | 4 | 6 | 15.52 | 12.18 | 288 | 58 | 4.31 | 100 | 20 | 2.54 | 4 |

| 100 | 100 | 6 | 8 | 21.04 | 16.52 | 369 | 74 | 4.19 | 133 | 27 | 2.52 | 5 | |

| WH100X75 | 100 | 75 | 4 | 6 | 12.52 | 9.83 | 222 | 44 | 4.21 | 42 | 11 | 1.84 | 4 |

| WH125X75 | 125 | 75 | 4 | 6 | 13.52 | 10.61 | 367 | 59 | 5.21 | 42 | 11 | 1.77 | 4 |

| WH125X125 | 125 | 75 | 4 | 6 | 19.52 | 15.32 | 580 | 93 | 5.45 | 195 | 31 | 3.16 | 4 |

| WH150X75 | 150 | 125 | 3.2 | 4.5 | 11.26 | 8.84 | 432 | 58 | 6.19 | 32 | 8 | 1.68 | 3 |

| 150 | 75 | 4 | 6 | 14.52 | 11.4 | 554 | 74 | 6.18 | 42 | 11 | 1.71 | 4 | |

| 150 | 75 | 5 | 8 | 18.70 | 14.68 | 706 | 94 | 6.14 | 56 | 15 | 1.74 | 5 | |

| WH150X100 | 150 | 100 | 3.2 | 4.5 | 13.51 | 10.61 | 551 | 73 | 6.39 | 75 | 15 | 2.36 | 3 |

| 150 | 100 | 4 | 6 | 17.52 | 13.75 | 710 | 95 | 6.37 | 100 | 20 | 2.39 | 4 | |

| 150 | 100 | 5 | 8 | 22.70 | 17,82 | 908 | 121 | 6.32 | 133 | 27 | 2.42 | 5 | |

| WH150X150 | 150 | 150 | 4 | 6 | 23.52 | 18.46 | 1 021 | 136 | 6,59 | 338 | 45 | 3.79 | 4 |

| 150 | 150 | 5 | 8 | 30.70 | 24.10 | 1 311 | 175 | 6.54 | 450 | 60 | 3.83 | 5 | |

| 150 | 150 | 6 | 8 | 32.04 | 25,15 | 1 331 | 178 | 6.45 | 450 | 60 | 3.75 | 5 | |

| WH200X100 | 200 | 100 | 3.2 | 4.5 | 15.11 | 11.86 | 1046 | 105 | 8.32 | 75 | 15 | 2.23 | 3 |

| 200 | 100 | 4 | 6 | 19.52 | 15.32 | 1 351 | 135 | 8.32 | 100 | 20 | 2.26 | 4 | |

| 200 | 100 | 5 | 8 | 25.20 | 19.78 | 1 735 | 173 | 8.30 | 134 | 27 | 2.30 | 5 | |

| WH200X150 | 200 | 150 | 4 | 6 | 25.52 | 20.03 | 1916 | 192 | 8.66 | 338 | 45 | 3.64 | 4 |

| 200 | 150 | 5 | 8 | 33.20 | 26.06 | 2 473 | 247 | 8.63 | 450 | 60 | 3.68 | 5 | |

| WH200X200 | 200 | 200 | 5 | 8 | 41.20 | 32.34 | 3 210 | 321 | 8.83 | 1067 | 107 | 5.09 | 5 |

| 200 | 200 | 6 | 10 | 50.80 | 39.88 | 3 905 | 390 | 8.77 | 1 334 | 133 | 5,12 | 5 | |

| WH250X125 | 250 | 125 | 4 | 6 | 24.52 | 19.25 | 2 682 | 215 | 10.46 | 195 | 31 | 2.82 | 4 |

| 250 | 125 | 5 | 8 | 31.70 | 24.88 | 3 463 | 277 | 10.45 | 261 | 42 | 2.87 | 5 | |

| 250 | 125 | 6 | 10 | 38.80 | 30.46 | 4210 | 337 | 10.42 | 326 | 52 | 2.90 | 5 | |

Macaamiishayada

Jawaabaha Macaamiishayada

Birta aan birta lahayn H Beams waa qaybo dhismeed oo kala duwan oo laga sameeyay bir aan tayo lahayn oo tayo sare leh. Kanaalkani waxay ka kooban yihiin qaab "H" oo gaar ah, iyagoo siinaya xoog iyo xasillooni si ay u dhisaan noocyo kala duwan oo codsiyo naqshadeed ah. Dhammaystirka jilicsan ee jilicsan ee birta birta ah ayaa ku daraya taabasho casri ah, taas oo ka dhigaysa H Beam oo ku habboon labadaba naqshadaynta waxqabadka iyo muuqaalka muuqaalka leh. warshadaha, oo ay ku jiraan dhismaha, naqshadaha, iyo wax soo saarka, halkaas oo taageero dhisme oo adag lagama maarmaan tahay.

Xirmooyinka Birta Aan-Aabaha ahayn

1. Baakayntu aad bay muhiim u tahay gaar ahaan marka ay dhacdo shixnado caalami ah oo shixnaduhu ay soo maraan waddooyin kala duwan si ay u gaadhaan meesha ugu dambaysa, sidaas awgeed waxaanu walaac gaar ah saarnay baakadaha.

2. Saky Steel's waxay alaabtayada u xirtaa siyaabo badan oo ku salaysan alaabta. Waxaan u badeshaa alaabtayada siyaabo badan, sida,