Stainless Simbi Yakarukwa Flanges

Tsanangudzo Pfupi

Saky simbi ndiyo yakanakisa kugadzira, mutengesi, uye mutengesi kunze kwemhando yakanaka kwazvo yeStainless simbi flanges. Isu tinonyatsozivikanwa kugadzira kunobata pasirese uye kupa iyo SS flanges kune mutengi maererano nemaitiro avo uye nezvinodiwa. Flanges yatinopa ndiyo mhete yefodya kana yakakandwa inogadzirwa kubatanidza zvikamu zvepombi kana chero mimwe michina inoda nzvimbo dzepakati dzekubatanidza. Flanges anoshandiswa kubatanidza mumwe nemumwe kuburikidza nebhaudhi kana kubatanidzwa kune pombi system kuburikidza neshinda kana welding.

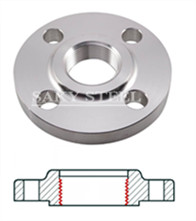

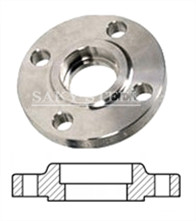

| Zvinyorwa zveSsimbi isina simbiThreadedFlanges: |

Slip-On WeldingFlangs Size:1/2″ (15 NB) kusvika 48″ (1200NB)

Specifications : ASTM A182 / ASME SA182

Standard :ANSI/ASME B16.5, B 16.47 Series A & B, B16.48, BS4504, BS 10, EN-1092, DIN, nezvimwewo.

Giredhi:304, 316, 321, 321Ti, 347, 347H, 904L, 2205, 2507

Kirasi / Pressure:150#, 300#, 600#, 900#, 1500#, 2500#, PN6, PN10, PN16, PN25, PN40, PN64 nezvimwe.

Flange Face Type :Chiso Chete (FF), Yakasimudzwa Face (RF), Mhete Rudzi Rungano (RTJ)

| ANSI b16.5 Stainless Steel Flanges / ANSI b16.5 SS Flanges: |

|  |  |

| 316 Weld Neck Forged Flange | 316 Lap Joint Forged Flange | 316 Threaded Forged Flange |

|  |  |

| 316 Bofu Forged Flange | 316 Slip paForged Flange | 316 Socket Weld Forged Flange |

| Sei Tisarudze: |

1. Unogona kuwana zvinhu zvakakwana maererano nezvinodiwa zvako pamutengo wakaderera.

2. Isu tinopawo Reworks, FOB, CFR, CIF, uye mitengo yekutumira pamusuwo kumasuo. Tinokupa zano kuti uite dhiri yekutumira iyo inove ine mari shoma.

3. Zvishandiso zvatinopa zvinonyatso zivikanwa, kubva pazvitupa zvekuedza kusvika kune yekupedzisira dimensional statement.(Mishumo icharatidza pane zvinodiwa)

4. inovimbisa kupa mhinduro mukati memaawa makumi maviri nemana (kazhinji muawa imwe chete)

5. Unogona kuwana dzimwe nzira dzemasheya, kutakura zvigayo nekuderedza nguva yekugadzira.

6. Isu takazvipira zvizere kune vatengi vedu. Kana zvisingabviri kuzadzisa zvaunoda mushure mekuongorora zvese zvingasarudzwa, isu hatizokunyengedzi nekuita zvipikirwa zvenhema izvo zvinogadzira hukama hwakanaka hwevatengi.

| Hunhu Husimbiso (kusanganisira zvese Zvinoparadza uye Zvisiri Kuparadza): |

1. Visual Dimension Test

2. Mechanical bvunzo senge tensile, Elongation uye kuderedzwa kwenzvimbo.

3. Muedzo mukuru

4. Kemikari yekuongorora kuongorora

5. Kuoma bvunzo

6. Pitting kudzivirira bvunzo

7. Flaring Testing

8. Mvura-Jet Test

9. Penetrant Test

10. X-ray test

11. Intergranular Corrosion Testing

12. Kuongorora kwemigumisiro

13. Eddy anoongorora

14. Hydrostatic analysis

15. Metallography Experimental Test

| Kurongedza: |

1. Kurongedza kwakakosha zvakanyanya muchiitiko chekutumira kune dzimwe nyika uko kutakurwa kunopfuura nemumatanho akasiyana-siyana kuti usvike kwaunoenda, saka tinoisa hanya zvakanyanya maererano nekurongedza.

2. Saky Steel inorongedza zvinhu zvedu nenzira dzakawanda zvichienderana nezvigadzirwa. Isu tinorongedza zvigadzirwa zvedu nenzira dzakawanda, senge,

Shrink-yakaputirwa

Makatoni mabhokisi

Wooden pallets

Mabhokisi emapuranga

Mabhokisi emapuranga

Applications:

1. Mechanics

2. Plumbing

3. Electronics

4. Zvizvarwa zvesimba

5. Vanopisa kupisa

6. Pharmaceuticals