Stainless Simbi HI Beam

Tsanangudzo Pfupi

"H Beam" inoreva zvikamu zvezvimiro zvakaumbwa sebhii rekuti "H" izvo zvinowanzoshandiswa mukuvaka uye zvakasiyana-siyana zvimiro zvekushandisa.

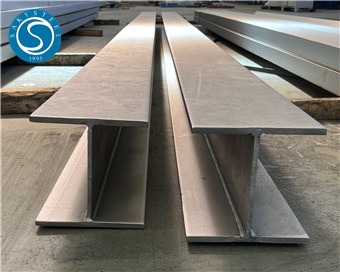

Stainless Simbi H Beam:

Simbi isina Stainless H Beam zviumbwa zvinoratidzwa neH-shaped cross-section yavo. Aya machani akagadzirwa kubva kusimbi isina tsvina, alloy-resistant alloy inozivikanwa nekusimba kwayo, hutsanana, uye aesthetic kukwezva. Stainless steel H channels dzinowana kushandiswa mumaindasitiri akasiyana-siyana, anosanganisira kuvaka, zvivakwa, uye kugadzira, uko kushora kwavo kusimba uye simba rinovaita sarudzo inosarudzika yerutsigiro rwechimiro uye dhizaini.Zvikamu izvi zvinowanzoshandiswa pakuvaka mapuranga, zvitsigiro, uye zvimwe zvinhu zvekugadzirisa apo zvose simba uye chitarisiko chinopenya zvakakosha.

Zvinotsanangurwa zveI Beam:

| Giredhi | 302 304 304L 310 316 316L 321 2205 2507 nezvimwewo. |

| Standard | GB T33814-2017,GBT11263-2017 |

| Surface | Kuputika kwejecha, kukwenenzvera, kuputika kwepfuti |

| Vadivelu Comedy Technology | Inopisa Yakakungurutswa, Yakaputirwa |

| Urefu | 1 kusvika 12 Mamita |

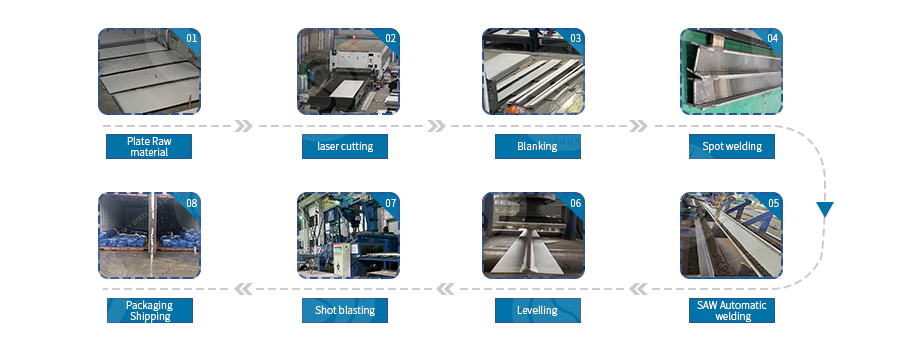

I-beam yekugadzira kuyerera chati:

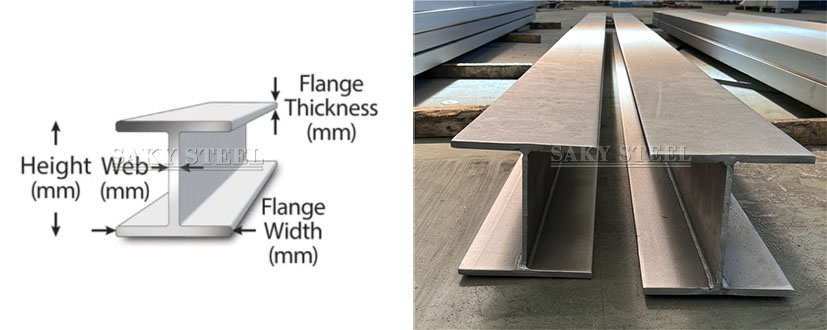

Webhu

Iyo dandemutande inoshanda sepakati pepakati pedanda, rinowanzo kugirwa zvichienderana nekukora kwayo. Ichishanda sechinhu chekubatanidza, inoita basa rakakosha mukuchengetedza kutendeseka kwedanda nekubatanidza nekubatanidza maflange maviri, kugovera zvinobudirira uye kutonga kudzvanywa.

Flange:

Nzvimbo dzepamusoro uye dzakatsetseka dzepasi dzesimbi dzinotakura mutoro wekutanga. Kuti tive nechokwadi chekugovera yunifomu yekumanikidza, tinoisa flat flanges. Izvi zvikamu zviviri zvinomhanya zvakafanana kune mumwe nemumwe, uye mumamiriro ezvinhu eI-matanda, anoratidza mapapiro-sekuwedzera.

H Beam Welded Line ukobvu Kuyera:

Stainless Simbi I Beam Beveling Maitiro:

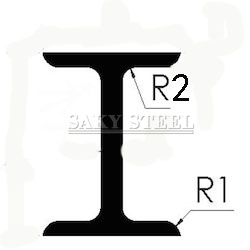

Iyo R angle yeI-beam yakakwenenzverwa kuti iite kuti nzvimbo iite mutserendende uye isina burr-isina, iri nyore kudzivirira kuchengetedza kwevashandi. Tinogona kugadzirisa R angle ye1.0, 2.0, 3.0. 304 316 316L 2205 Stainless Simbi IH Mitsipa. Makona eR emitsetse 8 ese akakwenenzverwa.

Stainless Simbi I Beam Wing/Flange kutwasanudza:

Features & Benefits:

•Iyo "H"-yakaumbwa muchinjika-chikamu dhizaini yeI-beam simbi inopa yakatanhamara-yekutakura mitoro yezvose zvakamira uye zvakachinjika mitoro.

•Chimiro chekugadzirwa kweI-beam simbi inopa kugadzikana kwepamusoro, kudzivirira deformation kana kukotama pasi pekunetseka.

•Nekuda kwechimiro chayo chakasiyana, I-beam simbi inogona kuchinjika kuiswa kune akasiyana zvimiro, kusanganisira matanda, makoramu, mabhiriji, nezvimwe.

•I-beam simbi inoita zvakanakisa mukukotama uye kudzvanya, kuve nechokwadi kugadzikana pasi pemamiriro ekutakura akaomarara.

•Nekugadzirwa kwayo kwakanaka uye simba repamusoro, I-beam simbi inowanzopa mari yakanaka.

•I-beam simbi inowana kushandiswa kwakakura mukuvaka, mabhiriji, zvishandiso zvemaindasitiri, uye zvimwe zvakasiyana siyana, ichiratidza kuchinjika kwayo mumapurojekiti akasiyana einjiniya uye zvimiro.

•Dhizaini yeI-beam simbi inobvumira kuti igadzirise zvirinani kune zvinodiwa zvekuvaka uye dhizaini, ichipa inogoneka yemaitiro mhinduro yezvakatipoteredza-inoshamwaridzika uye yakasvibira kuvaka maitiro.

Kemikari Inoumbwa H Beam:

| Giredhi | C | Mn | P | S | Si | Cr | Ni | Mo | Nitrogen |

| 302 | 0.15 | 2.0 | 0.045 | 0.030 | 1.0 | 17.0-19.0 | 8.0-10.0 | - | 0.10 |

| 304 | 0.08 | 2.0 | 0.045 | 0.030 | 1.0 | 18.0-20.0 | 8.0-11.0 | - | - |

| 309 | 0.20 | 2.0 | 0.045 | 0.030 | 1.0 | 22.0-24.0 | 12.0-15.0 | - | - |

| 310 | 0.25 | 2.0 | 0.045 | 0.030 | 1.5 | 24-26.0 | 19.0-22.0 | - | - |

| 314 | 0.25 | 2.0 | 0.045 | 0.030 | 1.5-3.0 | 23.0-26.0 | 19.0-22.0 | - | - |

| 316 | 0.08 | 2.0 | 0.045 | 0.030 | 1.0 | 16.0-18.0 | 10.0-14.0 | 2.0-3.0 | - |

| 321 | 0.08 | 2.0 | 0.045 | 0.030 | 1.0 | 17.0-19.0 | 9.0-12.0 | - | - |

Mechanical zvivakwa zveI Beams:

| Giredhi | Tensile Strength ksi[MPa] | Yiled Strengtu ksi[MPa] | Elongation % |

| 302 | 75[515] | 30[205] | 40 |

| 304 | 95[665] | 45[310] | 28 |

| 309 | 75[515] | 30[205] | 40 |

| 310 | 75[515] | 30[205] | 40 |

| 314 | 75[515] | 30[205] | 40 |

| 316 | 95[665] | 45[310] | 28 |

| 321 | 75[515] | 30[205] | 40 |

Sei Sarudza isu?

•Iwe unogona kuwana iyo yakakwana zvinhu zvinoenderana nezvinodiwa zvako pamutengo unogoneka.

•Isu tinopawo Reworks, FOB, CFR, CIF, uye mitengo yekuendesa gonhi kumusuwo. Tinokupa zano kuti uite dhiri yekutumira iyo inove ine mari shoma.

•Zvishandiso zvatinopa zvinonyatso zivikanwa, kubva pachitupa chebvunzo kusvika kune yekupedzisira dimensional statement. (Mishumo icharatidza pane zvinodiwa)

•Isu tinovimbisa kupa mhinduro mukati me24hours (kazhinji muawa imwe chete)

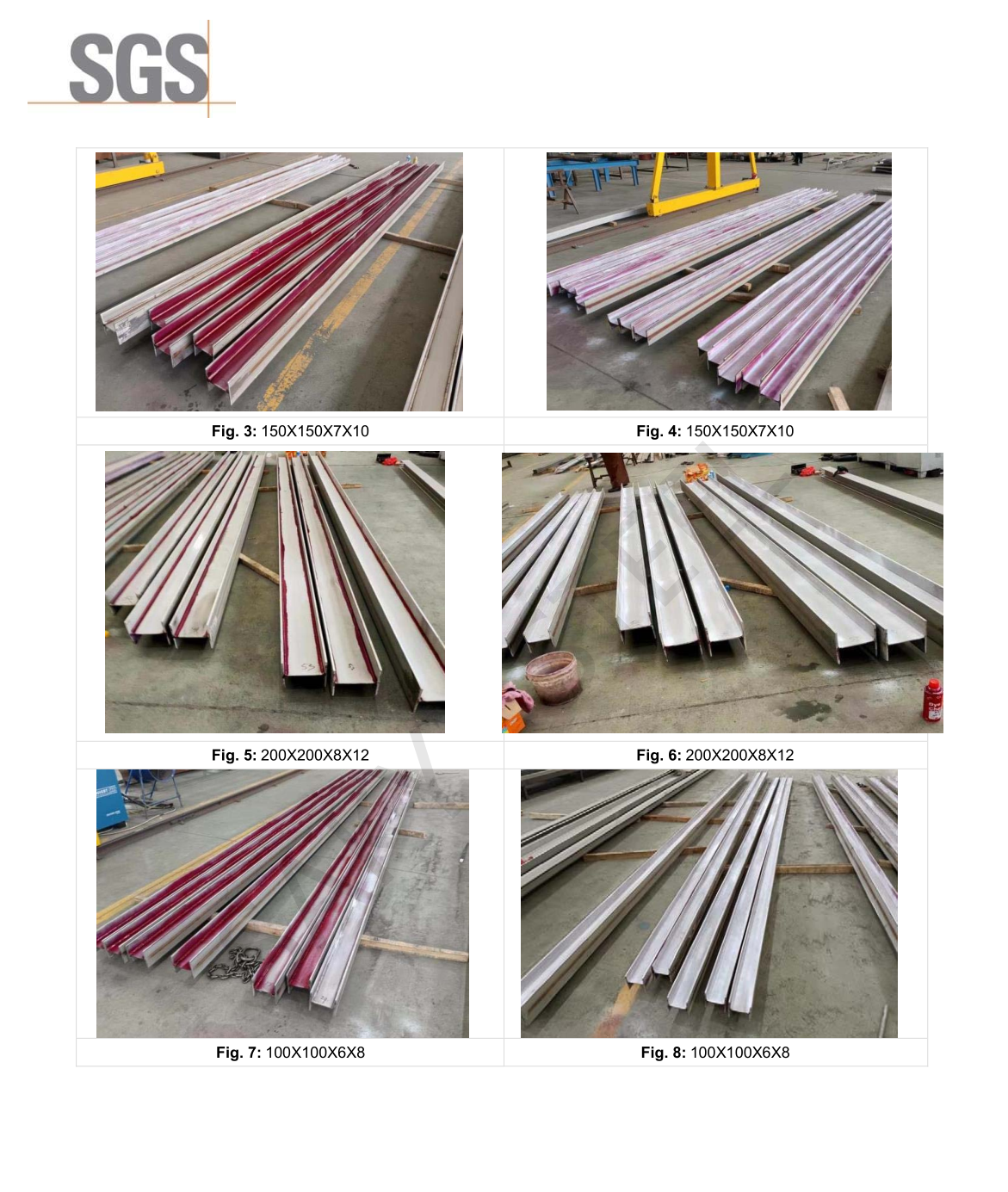

•Ipa SGS TUV chirevo.

•Isu takazvipira zvizere kune vatengi vedu. Kana zvisingabviri kuzadzisa zvaunoda mushure mekuongorora zvese zvingasarudzwa, isu hatizokunyengedzi nekuita zvipikirwa zvenhema izvo zvinogadzira hukama hwakanaka hwevatengi.

•Ipa imwe-stop service.

316L simbi isina tsvina yakashongedzwa H Beam Penetration bvunzo (PT)

Yakavakirwa paJBT 6062-2007 Kuyedza kusingaparadzi - kupindira kwekuyedza welds ye304L 316L simbi isina tsvina yakashongedzwa H Beam.

Ndedzipi nzira dzewelding?

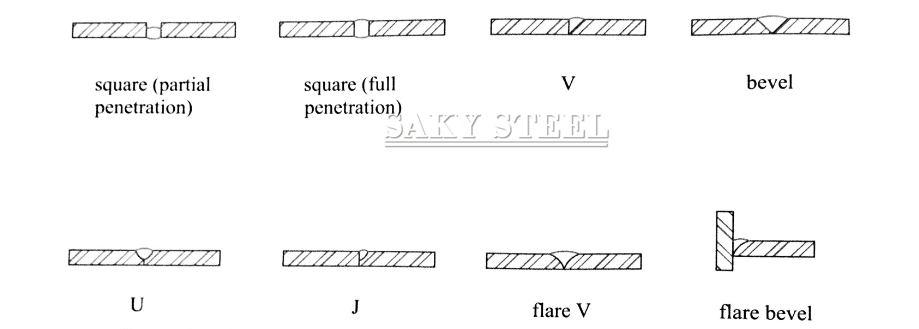

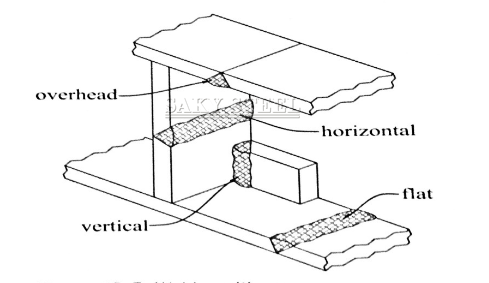

Welding nzira dzinosanganisira arc welding, gasi shielded welding (MIG/MAG welding), resistance welding, laser welding, plasma arc welding, friction stir welding, pressure welding, electron beam welding, nezvimwewo. Kazhinji arc welding nzira dzinosanganisira manual arc welding, argon arc welding, submerged arc welding, etc.Kupisa kunogadzirwa nekupikiswa kunoshandiswa kunyungudutsa simbi pamusoro pebasa rekushanda kuti rigadzire kubatana. Resistance welding inosanganisira spot welding, seam welding uye bolt welding.

Pese pazvinogoneka, mawelds anofanirwa kuitwa muchitoro umo mhando yeweld inowanzova nani, Shop welds haina kuisirwa mamiriro ekunze uye kuwana iyojoint yakavhurika zvakaringana. Welds inogona kuverengerwa seyakatsetseka, yakachinjika, yakatwasuka, uye pamusoro. Zvinogona kuonekwa kuti flat welds ndiyo iri nyore kuita; ndiyo nzira inodiwa. Mawedhi epamusoro, ayo anowanzoitwa mumunda, anofanirawo kudziviswa pazvinobvira nokuti akaoma uye anotora nguva yakawanda, uye naizvozvo.

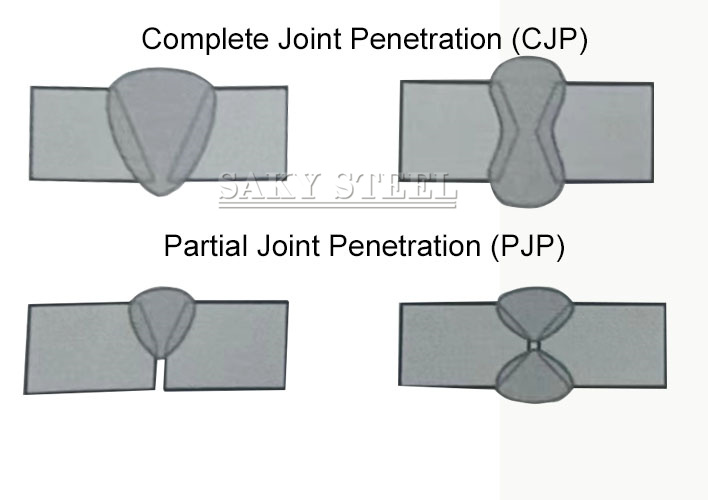

Groove welds inogona kupinda munhengo yakabatana kune chikamu chemutezo wehukobvu, kana kuti inogona kupinda mukati mehupamhi hwakazara hwenhengo yakabatana. Izvi zvinodaidzwa kuti partialjoint penetration (PJP) uye kukwana-joint kupinza (CJP), zvichiteerana . Complete-penetration welds (inonziwo full.penetration kana "'full-pen" welds) fuse hudzamu hwese hwemigumo yenhengo dzakabatanaPartial penetration welds inodhura zvakanyanya uye inoshandiswa kana mitoro yakaiswa iri zvekuti haidiwi. Iwo anogona zvakare kushandiswa uko kuwana kune grooveis kunogumira kune rimwe divi rekubatanidza.

Cherechedza: Index STRUCTURAL STEEL DESIGN

Ndezvipi zvakanakira zve submerged arc welding?

Submerged arc welding inokodzera otomatiki uye yakakwirira-vhoriyamu nharaunda. Inogona kupedzisa huwandu hukuru hwebasa rewelding munguva pfupi yenguva uye kuvandudza kugadzirwa kwehunyanzvi. Submerged arc welding inokodzera otomatiki uye yakakwirira-vhoriyamu nharaunda. Inogona kupedzisa huwandu hukuru hwebasa rewelding munguva pfupi yenguva uye kuvandudza kugadzirwa kwehunyanzvi. Submerged arc welding inowanzo shandiswa kupinza simbi dzakakora masheets nekuti kukwira kwayo kwazvino uye kupinza kwepamusoro kunoita kuti inyatsoshanda mumashandisirwo aya. Sezvo weld yakafukidzwa nekuyerera, okisijeni inogona kunyatsodzivirirwa kupinda munzvimbo yeweld, nekudaro ichideredza mukana weiyo oxidation uye spatter.Kuenzaniswa nedzimwe nzira dzekugadzira welding, kunyudzwa kwearc welding kunowanzo kuve otomatiki nyore, kuderedza kudiwa kwepamusoro paunyanzvi hwevashandi. Mune yakanyura arc welding, akawanda welding waya uye ma arcs anogona kushandiswa panguva imwe chete kuwana akawanda-channel (multi-layer) welding uye kuvandudza kushanda zvakanaka.

Ndeapi mashandisirwo eStainless Steel H matanda?

Simbi isina Stainless H matanda anoshandiswa zvakanyanya mukuvaka, injiniya yemugungwa, midziyo yemumaindasitiri, mota, mapurojekiti emagetsi, uye mamwe minda nekuda kwekuramba kwecorrosion uye kugara kwenguva refu. Ivo vanopa rutsigiro rwechimiro mumapurojekiti ekuvaka uye vanoita basa rakakosha munzvimbo dzinoda corrosion resistance, zvakaita semugungwa kana maindasitiri. Pamusoro pezvo, chitarisiko chavo chemazuva ano uye chekunakisa chinoita kuti ive yakakodzera yekuvaka uye yemukati dhizaini dhizaini.

Stainless Steel HI danda yakatwasuka sei?

Kururama kwesimbi isina tsvina H-beam, sechinhu chipi nechipi chekugadzirisa, chinhu chinokosha mukushanda kwayo uye kuiswa. Kazhinji, vagadziri vanogadzira simbi isina Stainless H-matanda ane imwe dhigirii yekutwasuka kuti isangane neindasitiri zviyero uye zvakatemwa.

Muyero weindasitiri unogamuchirwa wekutwasanuka musimbi yezvimiro, kusanganisira simbi isina tsvina H-matanda, inowanzotsanangurwa maererano nekutsauka kunobvumidzwa kubva mumutsara wakatwasuka pamusoro pehurefu hwakatarwa. Kutsauka uku kunowanzo kuratidzwa maererano nemamilimita kana masendimita ekutsvaira kana lateral displacement.

Nhanganyaya kune chimiro cheH beam ?

Muchinjikwa-chikamu chimiro cheI-beam simbi, inowanzozivikanwa se "工字钢" (gōngzìgāng) muchiChinese, yakafanana nebhii rekuti "H" kana yakavhurwa. Kunyanya, muchinjiko-chikamu chinowanzo kuve nemabhawa maviri akachinjika (flanges) kumusoro uye pasi uye yakatwasuka yepakati bar (web). Ichi "H" chimiro chinopa simba repamusoro uye kugadzikana kune I-beam simbi, ichiita kuti ive chinhu chakajairika chekugadzirisa zvinhu mukuvaka uye engineering.Iyo yakagadzirwa chimiro cheI-beam simbi inobvumira kuti ive yakakodzera kune zvakasiyana-siyana zvinotakura uye zvinotsigira zvikumbiro, zvakadai sematanda, mbiru, uye zvivakwa zvebhiriji. Uku kurongeka kwemaitiro kunoita kuti I-beam simbi inyatso kugovera mitoro kana ichiiswa pasi pemasimba, ichipa rutsigiro rwakasimba. Nekuda kwechimiro chayo chakasiyana uye chimiro chechimiro, I-beam simbi inowana kushandiswa kwakapararira muminda yekuvaka neinjiniya.

Nzira yekutaura sei ukuru uye kutaura kweI-beam?

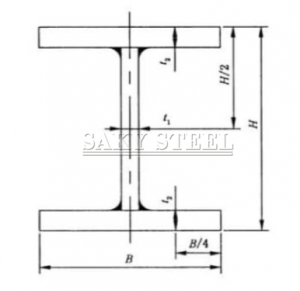

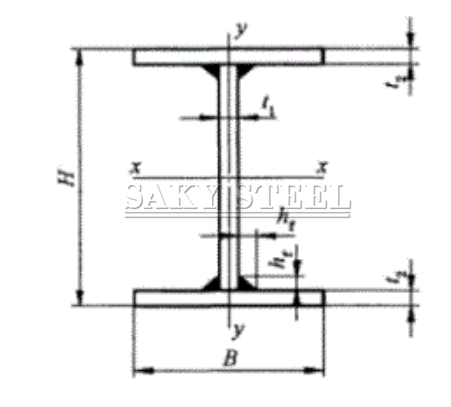

Ⅰ.Cross-sectional mufananidzo uye zviratidzo zvekumaka zve 316L simbi isina tsvina yakakandwa H-yakaita sesimbi:

H——Kureba

B——Width

t1——Webhu ukobvu

t2——Flange plate ukobvu

h£-- Welding size(kana uchishandisa musanganiswa webutt uye fillet welds, inofanirwa kunge iri yakasimbiswa welding yegumbo saizi hk)

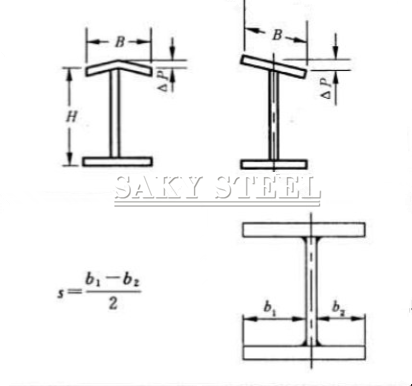

Ⅱ. Zviyero, zvimiro uye zvinotenderwa kutsauka kwe2205 duplex simbi yakakandwa H-yakaita sesimbi:

| H Beam | Kushivirira |

| Thlckness (H) | Helight 300 kana pasi: 2.0 mmKupfuura 300:3.0mm |

| Upamhi (B) | 士2.0mm |

| Perpendicularlty (T) | 1.2% kana pasi pe wldth (B) Ziva kuti minlmum toleranceis 2.0 mm |

| Offset yepakati (C) | 士2.0mm |

| Bending | 0.2096 kana pasi pehurefu |

| Kureba kwegumbo (S) | [web plate thlckness (t1) x0.7]kana kupfuura |

| Urefu | 3~12m |

| Kureba kushivirira | + 40mm, 一0mm |

Ⅲ. Zviyero, maumbirwo uye zvinotenderwa kutsauka kwewelded H-yakaita simbi

Ⅳ. Muchinjikwa-sectional dimensions, cross-sectional nharaunda, theoretical huremu uye muchinjika-sectional hunhu paramita ye welded H-yakaita simbi.

| Stainless simbi Miti | Size | Sectional Area (cm²) | Kurema (kg/m) | Characteristic Parameters | Weld fillet size h(mm) | ||||||||

| H | B | t1 | t2 | xx | yy | ||||||||

| mm | I | W | i | I | W | i | |||||||

| WH100X50 | 100 | 50 | 3.2 | 4.5 | 7.41 | 5.2 | 123 | 25 | 4.07 | 9 | 4 | 1.13 | 3 |

| 100 | 50 | 4 | 5 | 8.60 | 6.75 | 137 | 27 | 3.99 | 10 | 4 | 1.10 | 4 | |

| WH100X100 | 100 | 100 | 4 | 6 | 15.52 | 12.18 | 288 | 58 | 4.31 | 100 | 20 | 2.54 | 4 |

| 100 | 100 | 6 | 8 | 21.04 | 16.52 | 369 | 74 | 4.19 | 133 | 27 | 2.52 | 5 | |

| WH100X75 | 100 | 75 | 4 | 6 | 12.52 | 9.83 | 222 | 44 | 4.21 | 42 | 11 | 1.84 | 4 |

| WH125X75 | 125 | 75 | 4 | 6 | 13.52 | 10.61 | 367 | 59 | 5.21 | 42 | 11 | 1.77 | 4 |

| WH125X125 | 125 | 75 | 4 | 6 | 19.52 | 15.32 | 580 | 93 | 5.45 | 195 | 31 | 3.16 | 4 |

| WH150X75 | 150 | 125 | 3.2 | 4.5 | 11.26 | 8.84 | 432 | 58 | 6.19 | 32 | 8 | 1.68 | 3 |

| 150 | 75 | 4 | 6 | 14.52 | 11.4 | 554 | 74 | 6.18 | 42 | 11 | 1.71 | 4 | |

| 150 | 75 | 5 | 8 | 18.70 | 14.68 | 706 | 94 | 6.14 | 56 | 15 | 1.74 | 5 | |

| WH150X100 | 150 | 100 | 3.2 | 4.5 | 13.51 | 10.61 | 551 | 73 | 6.39 | 75 | 15 | 2.36 | 3 |

| 150 | 100 | 4 | 6 | 17.52 | 13.75 | 710 | 95 | 6.37 | 100 | 20 | 2.39 | 4 | |

| 150 | 100 | 5 | 8 | 22.70 | 17,82 | 908 | 121 | 6.32 | 133 | 27 | 2.42 | 5 | |

| WH150X150 | 150 | 150 | 4 | 6 | 23.52 | 18.46 | 1 021 | 136 | 6,59 | 338 | 45 | 3.79 | 4 |

| 150 | 150 | 5 | 8 | 30.70 | 24.10 | 1 311 | 175 | 6.54 | 450 | 60 | 3.83 | 5 | |

| 150 | 150 | 6 | 8 | 32.04 | 25, 15 | 1 331 | 178 | 6.45 | 450 | 60 | 3.75 | 5 | |

| WH200X100 | 200 | 100 | 3.2 | 4.5 | 15.11 | 11.86 | 1046 | 105 | 8.32 | 75 | 15 | 2.23 | 3 |

| 200 | 100 | 4 | 6 | 19.52 | 15.32 | 1 351 | 135 | 8.32 | 100 | 20 | 2.26 | 4 | |

| 200 | 100 | 5 | 8 | 25.20 | 19.78 | 1 735 | 173 | 8.30 | 134 | 27 | 2.30 | 5 | |

| WH200X150 | 200 | 150 | 4 | 6 | 25.52 | 20.03 | 1 916 | 192 | 8.66 | 338 | 45 | 3.64 | 4 |

| 200 | 150 | 5 | 8 | 33.20 | 26.06 | 2 473 | 247 | 8.63 | 450 | 60 | 3.68 | 5 | |

| WH200X200 | 200 | 200 | 5 | 8 | 41.20 | 32.34 | 3 210 | 321 | 8.83 | 1067 | 107 | 5.09 | 5 |

| 200 | 200 | 6 | 10 | 50.80 | 39.88 | 3 905 | 390 | 8.77 | 1 334 | 133 | 5, 12 | 5 | |

| WH250X125 | 250 | 125 | 4 | 6 | 24.52 | 19.25 | 2 682 | 215 | 10.46 | 195 | 31 | 2.82 | 4 |

| 250 | 125 | 5 | 8 | 31.70 | 24.88 | 3 463 | 277 | 10.45 | 261 | 42 | 2.87 | 5 | |

| 250 | 125 | 6 | 10 | 38.80 | 30.46 | 4210 | 337 | 10.42 | 326 | 52 | 2.90 | 5 | |

Vatengi vedu

Mhinduro kubva kuvatengi vedu

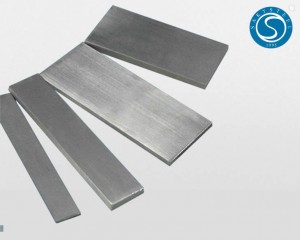

Stainless Simbi H Beams zvinhu zvakasiyana-siyana zvezvimiro zvakagadzirirwa kubva kumhando yepamusoro simbi isina tsvina. Machaneti aya ane chimiro che "H" chakasiyana, chinopa simba rakawedzerwa uye kugadzikana kune zvakasiyana-siyana zvekuvaka uye zvivakwa zvekugadzira. Iyo yakatsetseka uye yakakwenenzverwa kupera kwesimbi isina tsvina kunowedzera kubata kwehungwaru, zvichiita kuti H Beam idzi dzikwane kune ese ari maviri anoshanda uye anoyevedza magadzirirwo magadzirirwo. Iyo H-yakaita seH inokwidziridza mitoro inotakura zvinhu, ichiita kuti mitoro inorema iwane hunyanzvi hwekugadzira maindasitiri HS inowana inorema inotsigira maindasitiri. mashandisirwo mumaindasitiri akasiyana siyana, anosanganisira kuvaka, zvivakwa, uye kugadzira, uko kwakasimba tsigiro yezvimiro yakakosha.

Stainless Simbi I Beams Packing:

1. Kurongedza kwakakosha zvakanyanya muchiitiko chekutumira kune dzimwe nyika uko kutakurwa kunopfuura nemumatanho akasiyana-siyana kuti usvike kwaunoenda, saka tinoisa hanya zvakanyanya maererano nekurongedza.

2. Saky Steel inorongedza zvinhu zvedu nenzira dzakawanda zvichienderana nezvigadzirwa. Isu tinorongedza zvigadzirwa zvedu nenzira dzakawanda, senge,