Stainless Simbi H Channels

Tsanangudzo Pfupi:

"H Zviteshi" zvinoreva zvikamu zvezvimiro zvakaumbwa sebhii "H" izvo zvinowanzoshandiswa mukuvaka uye zvakasiyana-siyana zvimiro zvekushandisa.

Stainless Simbi H Channels:

Simbi isina Stainless H chiteshi zvinhu zvezvimiro zvinoratidzwa neH-shaped cross-section yavo.Aya machani akagadzirwa kubva kusimbi isina tsvina, alloy inodzivirira corrosion inozivikanwa nekusimba kwayo, hutsanana, uye aesthetic kukwezva.Stainless simbi H machani anowana maapplication mumaindasitiri akasiyana siyana, anosanganisira kuvaka, zvivakwa, uye kugadzira, uko kushora kwavo kusimba uye kusimba kunoita kuti ive sarudzo inosarudzika yerutsigiro rwechimiro uye dhizaini.Zvikamu izvi zvinowanzoshandiswa pakuvaka mapuranga, zvinotsigira, nezvimwe. maumbirwo ezvinhu apo zvose simba uye chitarisiko chinopenya zvakakosha.

Zvinotsanangurwa zveH Channels:

| Giredhi | 302,304,314,310,316,321 zvichingodaro. |

| Standard | ASTM A276, GB/T 11263-2010,ANSI/AISC N690-2010,EN 10056-1:2017 |

| Surface | hot rolled pickled , polishshed |

| Vadivelu Comedy Technology | Inopisa Yakakungurutswa, Yakaputirwa |

| Urefu | 1 kusvika ku6 Mamita |

Features & Benefits:

•Iyo "H"-yakaumbwa muchinjika-chikamu dhizaini yeI-beam simbi inopa yakatanhamara-yekutakura mitoro yezvose zvakamira uye zvakachinjika mitoro.

•Chimiro chekugadzirwa kweI-beam simbi inopa kugadzikana kwepamusoro, kudzivirira deformation kana kukotama pasi pekunetseka.

•Nekuda kwechimiro chayo chakasiyana, I-beam simbi inogona kuchinjika kuiswa kune akasiyana zvimiro, kusanganisira matanda, makoramu, mabhiriji, nezvimwe.

•I-beam simbi inoita zvakanakisa mukukotama uye kudzvanya, kuve nechokwadi kugadzikana pasi pemamiriro ekutakura akaomarara.

•Nekugadzirwa kwayo kwakanaka uye simba repamusoro, I-beam simbi inowanzopa mari yakanaka-inoshanda.

•I-beam simbi inowana kushandiswa kwakakura mukuvaka, mabhiriji, zvishandiso zvemaindasitiri, uye zvimwe zvakasiyana siyana, ichiratidza kuchinjika kwayo mumapurojekiti akasiyana einjiniya uye zvimiro.

•Dhizaini yeI-beam simbi inobvumira kuti igadzirise zvirinani kune zvinodiwa zvekuvaka uye dhizaini, ichipa inogoneka yemaitiro mhinduro yezvakatipoteredza-inoshamwaridzika uye yakasvibira kuvaka maitiro.

Kemikari Inoumbwa H Channels:

| Giredhi | C | Mn | P | S | Si | Cr | Ni | Mo | Nitrogen |

| 302 | 0.15 | 2.0 | 0.045 | 0.030 | 1.0 | 17.0-19.0 | 8.0-10.0 | - | 0.10 |

| 304 | 0.08 | 2.0 | 0.045 | 0.030 | 1.0 | 18.0-20.0 | 8.0-11.0 | - | - |

| 309 | 0.20 | 2.0 | 0.045 | 0.030 | 1.0 | 22.0-24.0 | 12.0-15.0 | - | - |

| 310 | 0.25 | 2.0 | 0.045 | 0.030 | 1.5 | 24-26.0 | 19.0-22.0 | - | - |

| 314 | 0.25 | 2.0 | 0.045 | 0.030 | 1.5-3.0 | 23.0-26.0 | 19.0-22.0 | - | - |

| 316 | 0.08 | 2.0 | 0.045 | 0.030 | 1.0 | 16.0-18.0 | 10.0-14.0 | 2.0-3.0 | - |

| 321 | 0.08 | 2.0 | 0.045 | 0.030 | 1.0 | 17.0-19.0 | 9.0-12.0 | - | - |

Mechanical zvivakwa zveH Channels:

| Giredhi | Tensile Strength ksi[MPa] | Yiled Strengtu ksi[MPa] | Elongation % |

| 302 | 75[515] | 30[205] | 40 |

| 304 | 95[665] | 45[310] | 28 |

| 309 | 75[515] | 30[205] | 40 |

| 310 | 75[515] | 30[205] | 40 |

| 314 | 75[515] | 30[205] | 40 |

| 316 | 95[665] | 45[310] | 28 |

| 321 | 75[515] | 30[205] | 40 |

Sei Sarudza isu?

•Iwe unogona kuwana iyo yakakwana zvinhu zvinoenderana nezvinodiwa zvako pamutengo unogoneka.

•Isu tinopawo Reworks, FOB, CFR, CIF, uye mitengo yekuendesa gonhi kumusuwo.Tinokupa zano kuti uite dhiri yekutumira iyo inove ine mari shoma.

•Zvishandiso zvatinopa zvinonyatso zivikanwa, kubva pachitupa chebvunzo kusvika kune yekupedzisira dimensional statement. (Mishumo icharatidza pane zvinodiwa)

•Isu tinovimbisa kupa mhinduro mukati me24hours (kazhinji muawa imwe chete)

•Ipa SGS TUV chirevo.

•Isu takazvipira zvizere kune vatengi vedu.Kana zvisingabviri kuzadzisa zvaunoda mushure mekuongorora zvese zvingasarudzwa, isu hatizokunyengedzi nekuita zvipikirwa zvenhema izvo zvinogadzira hukama hwakanaka hwevatengi.

•Ipa imwe-stop service.

Ndedzipi nzira dzewelding?

Welding nzira dzinosanganisira arc welding, gas shielded welding (MIG/MAG welding), resistance welding, laser welding, plasma arc welding, friction stir welding, pressure welding, electron beam welding, etc. Nzira imwe neimwe ine mashandisirwo akasiyana uye maitiro, akakodzera zvakasiyana-siyana. mhando dzezvishandiso uye zvinodiwa zvekugadzira.A arc inoshandiswa kugadzira kupisa kwakanyanya, kunyungudutsa simbi pamusoro peiyo workpiece kuti iite kubatana.Kazhinji arc welding nzira dzinosanganisira manual arc welding, argon arc welding, submerged arc welding, etc.Kupisa kunogadzirwa nekupikiswa kunoshandiswa kunyungudutsa simbi pamusoro pebasa rekushanda kuti rigadzire kubatana.Resistance welding inosanganisira spot welding, seam welding uye bolt welding.

Ndezvipi zvakanakira zve submerged arc welding?

Submerged arc welding inokodzera otomatiki uye yakakwirira-vhoriyamu nharaunda.Inogona kupedzisa huwandu hukuru hwebasa rewelding munguva pfupi yenguva uye kuvandudza kugadzirwa kwehunyanzvi.Submerged arc welding inokodzera otomatiki uye yakakwirira-vhoriyamu nharaunda.Inogona kupedzisa huwandu hukuru hwebasa rewelding munguva pfupi yenguva uye kuvandudza kugadzirwa kwehunyanzvi.Submerged arc welding inowanzo shandiswa kupinza simbi dzakakora masheets nekuti kukwira kwayo kwazvino uye kupinza kwepamusoro kunoita kuti inyatsoshanda mumashandisirwo aya.Sezvo weld yakafukidzwa nekuyerera, okisijeni inogona kunyatsodzivirirwa kuti isapinda munzvimbo yeweld, nekudaro ichideredza mukana weiyo oxidation uye spatter.Kuenzaniswa nedzimwe nzira dzemanyorero ekugadzira, kunyudza kwearc welding kunowanzo kuve otomatiki nyore, kuderedza izvo zvakakwirira zvinoda unyanzvi hwevashandi.Mune yakanyura arc welding, akawanda welding waya uye ma arcs anogona kushandiswa panguva imwe chete kuwana akawanda-channel (multi-layer) welding uye kuvandudza kushanda zvakanaka.

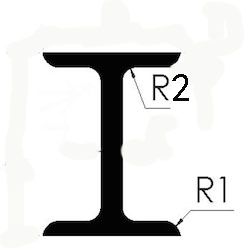

Nhanganyaya kune chimiro cheH beam ?

Muchinjikwa-chikamu chimiro cheI-beam simbi, inowanzozivikanwa se "工字钢" (gōngzìgāng) muchiChinese, yakafanana nebhii rekuti "H" kana yakavhurwa.Kunyanya, muchinjiko-chikamu chinowanzo kuve nemabhawa maviri akachinjika (flanges) kumusoro uye pasi uye yakatwasuka yepakati bar (web).Ichi "H" chimiro chinopa simba repamusoro uye kugadzikana kune I-beam simbi, zvichiita kuti ive chinhu chinowanzo kugadzirwa mukuvaka uye engineering.Iyo yakagadzirwa chimiro cheI-beam simbi inobvumira kuti ive yakakodzera kune zvakasiyana-siyana zvinotakura uye zvinotsigira zvikumbiro, zvakadai. sematanda, makoramu, uye zvivakwa zvebhiriji.Uku kurongeka kwemaitiro kunoita kuti I-beam simbi inyatso kugovera mitoro kana ichiiswa pasi pemasimba, ichipa rutsigiro rwakasimba.Nekuda kwechimiro chayo chakasiyana uye chimiro chechimiro, I-beam simbi inowana kushandiswa kwakapararira muminda yekuvaka neinjiniya.

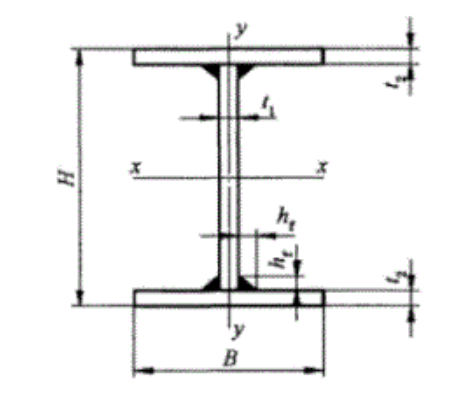

Nzira yekutaura sei ukuru uye kutaura kweI-beam?

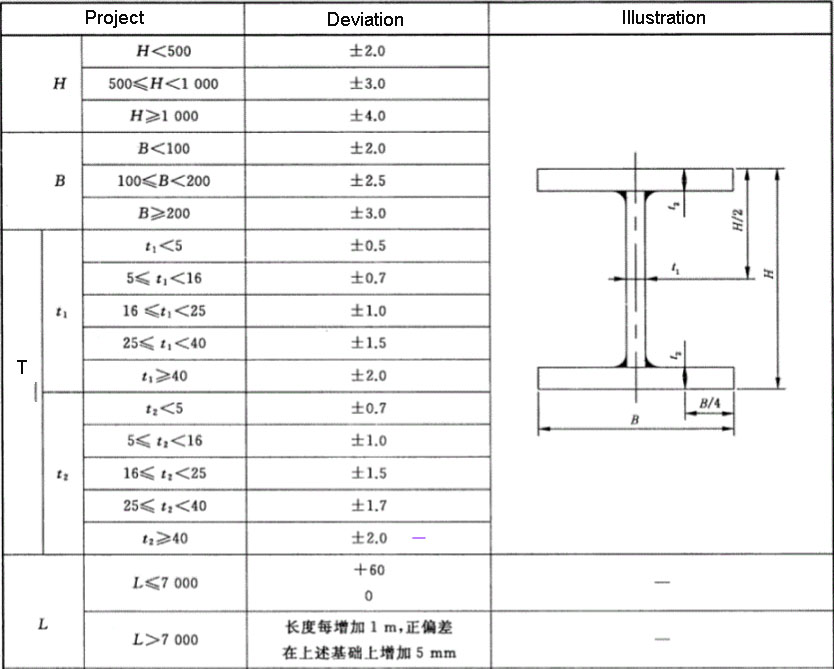

H——Pamusoro

B——Upamhi

t1——Webhu ukobvu

t2——Flange plate ukobvu

h £—— Saizi yeWelding (kana uchishandisa musanganiswa webutt uye fillet welds, inofanirwa kunge iri yakasimbiswa welding yegumbo saizi hk)

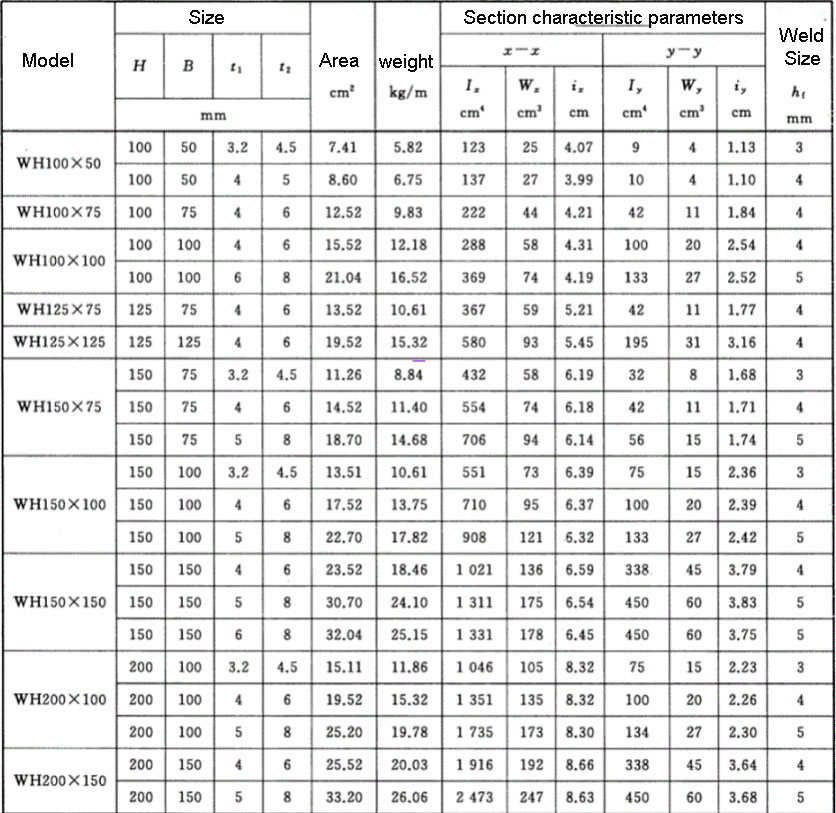

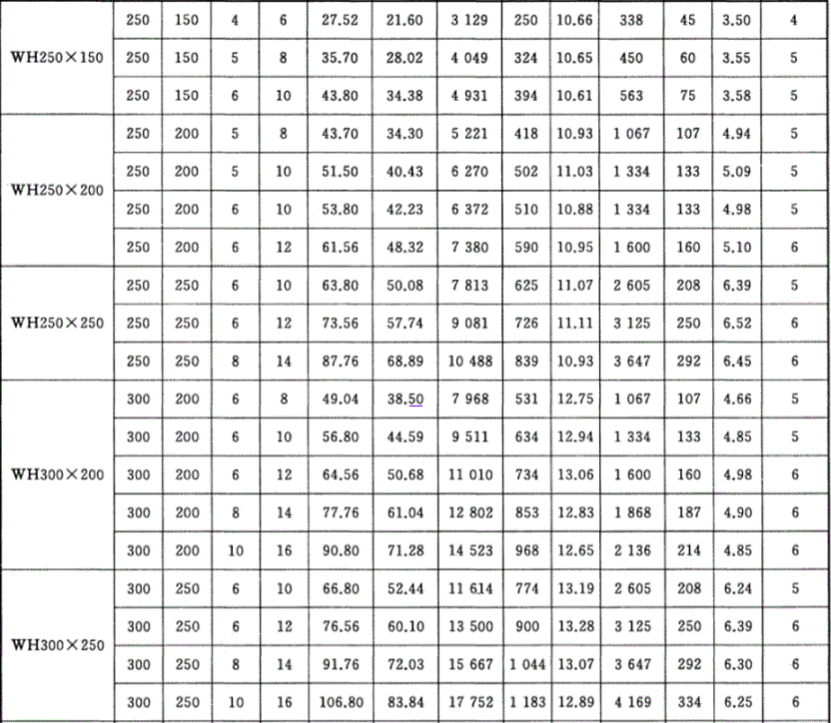

Zviyero, maumbirwo uye zvinotenderwa kutsauka kwewelded H-yakaita simbi

Muchinjikwa-sectional dimensions, cross-sectional nharaunda, theoretical huremu uye muchinjika-sectional hunhu paramita ye welded H-yakaita simbi.

Vatengi vedu

Mhinduro kubva kuvatengi vedu

Stainless Simbi H Channels zvinhu zvakasiyana-siyana zvezvimiro zvakagadzirirwa kubva kumhando yepamusoro simbi isina tsvina.Iyi migero ine chimiro che "H" chakasiyana, ichipa simba rinowedzera uye kugadzikana kune zvakasiyana-siyana zvekuvaka uye zvigadziridzo zvekugadzira.Kupera uye kupenya kwesimbi isina tsvina kunowedzera kugunzva, zvichiita kuti H Channels idzi dzive dzakakodzera kune zvose zvinoshanda uye zvinotaridzika zvinogadzirisa zvinhu zvekugadzira. Iyo H-yakaita dhizaini inowedzera simba rekutakura mutoro, ichiita kuti migero iyi ive yakanaka yekutsigira mitoro inorema mukuvaka uye maindasitiri ekugadzirisa.Stainless Steel H Channels inowana zvikumbiro muindasitiri dzakasiyana siyana, kusanganisira kuvaka, zvivakwa, uye kugadzira, uko kwakasimba kutsigirwa kwemaitiro kunokosha.

Packing:

1. Kurongedza kwakakosha zvakanyanya muchiitiko chekutumira kune dzimwe nyika uko kutakurwa kunopfuura nemumatanho akasiyana-siyana kuti usvike kwaunoenda, saka tinoisa hanya zvakanyanya maererano nekurongedza.

2. Saky Steel inorongedza zvinhu zvedu nenzira dzakawanda zvichienderana nezvigadzirwa.Isu tinorongedza zvigadzirwa zvedu nenzira dzakawanda, senge,