Ⅰ.Iyo pfungwa inokosha yekurapa kupisa.

A.The basic concept of heat treatment.

Zvinhu zvakakosha uye mabasa ekupisa kurapwa:

1.Kupisa

Chinangwa ndechekuwana yunifomu uye yakanaka austenite chimiro.

2.Kubata

Chinangwa ndechekuona kuti workpiece yakanyatsodziya uye kudzivirira decarburization uye oxidation.

3.Kutonhorera

Chinangwa ndechekushandura austenite kuita akasiyana microstructures.

Microstructures mushure mekupisa Kurapa

Munguva yekutonhodza mushure mekudziya uye kubata, iyo austenite inoshandura kuita akasiyana mamicrostructures zvichienderana nekutonhora kwekutonhora. Yakasiyana microstructures inoratidza zvakasiyana zvivakwa.

B.Nheyo yekutanga yekurapa kwekupisa.

Classification Yakavakirwa paKupisa uye Kutonhodza Nzira, pamwe neiyo Microstructure uye Zvivakwa zveSimbi

1. Conventional Heat Kurapa (Kupisa Kwese Kurapa): Kupisa, Kupisa, Kugadzirisa, Kudzima

2.Surface Heat Treatment: Surface Quenching, Induction Heating Surface Kudzima, Kupisa Kwemoto Kupisa Kupisa, Kwemagetsi Kubata Kupisa Kwepamusoro Kudzima.

3.Chemical Heat Treatment:Carburizing,Nitriding,Carbonitriding.

4.Kumwe Kurapa Kupisa: Kunodzorwa Atmosphere Heat Treatment, Vacuum Heat Treatment, Deformation Heat Treatment.

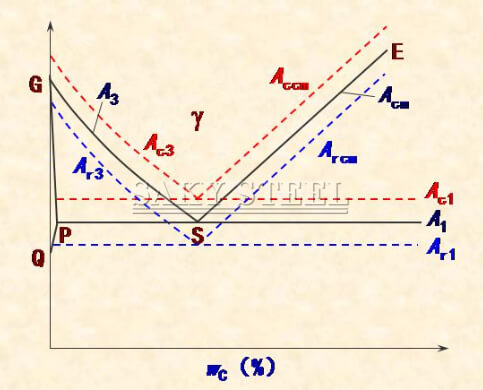

C.Critical Temperature yeSimbi

Iyo yakakosha shanduko tembiricha yesimbi ndiyo hwaro hwakakosha hwekuona kudziyisa, kubata, uye kutonhora maitiro panguva yekupisa kupisa. Inotaridzirwa nearon-carbon phase diagram.

Mhedziso Yakakosha:Iyo chaiyo yakakosha shanduko tembiricha yesimbi inogara yasara kumashure kweiyo theoretical yakakosha shanduko tembiricha. Izvi zvinoreva kuti kupisa kunodiwa panguva yekupisa, uye undercooling inofanirwa panguva yekutonhora.

Ⅱ.Annealing uye Normalizing yeSimbi

1. Tsanangudzo yeAnealing

Kuisa simbi kunosanganisira kudziyisa tembiricha pamusoro kana pazasi penzvimbo yakaoma Ac₁ kuibata patembiricha iyoyo, uye wozoitonhodza zvishoma nezvishoma, kazhinji mukati mechoto, kuti iwane chimiro chiri pedyo nekuenzana.

2. Chinangwa cheAnealing

① Gadzirisa Kuoma kweMachining: Kuwana machinable kuomarara muhuwandu hweHB170 ~ 230.

②Relieve Residual Stress: Inodzivirira deformation kana kuputika panguva dzinotevera maitiro.

③Natsa Chimiro cheGrain: Inovandudza iyo microstructure.

④Kugadzirira Kwekupedzisira Kupisa Kurapa: Inowana granular (spheroidized) pearlite yekutevera kudzima uye kupisa.

3.Spheroidizing Annealing

Maitiro Ekuita: Kupisa tembiricha iri padyo nenzvimbo yeAc₁.

Chinangwa: Kuita spheroidize simenti kana carbides musimbi, zvichikonzera granular (spheroidized) pearlite.

Inoshanda Range: Inoshandiswa kune simbi ine eutectoid uye hypereutectoid nziyo.

4.Diffusing Annealing (Homogenizing Annealing)

Maitiro Ekuita: Kupisa tembiricha iri pazasi peiyo solvus mutsara pane chikamu dhizaini.

Chinangwa: Kubvisa kusarura.

① Zvepasi-carbon steeline kabhoni yemukati isingasviki 0.25%, normalizing inosarudzwa pane annealing segadziriro yekugadzirira kupisa.

②Kune yepakati-kabhoni simbi ine kabhoni yemukati iri pakati pe0.25% ne0.50%, ingave annealing kana normalizing inogona kushandiswa sekugadzirira kupisa kupisa.

③Pakati nepamusoro-kabhoni simbi ine kabhoni iri pakati pe0.50% ne0.75%, kuzara kuzere kunokurudzirwa.

④Yepamusoro-carbon steeline kabhoni inodarika 0.75%, normalizing inotanga kushandiswa kubvisa network Fe₃C, ichiteverwa ne spheroidizing annealing.

Ⅲ.Kudzima nekupisa kweSimbi

A.Kudzima

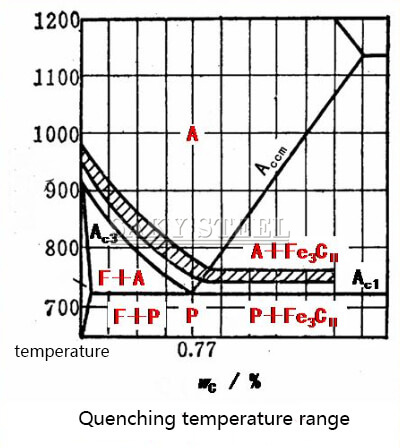

1. Tsanangudzo yeKudzima: Kudzima kunosanganisira kudziyisa simbi kusvika kune imwe tembiricha iri pamusoro peAc₃ kana Ac₁ point, kuibata patembiricha iyoyo, wozoitonhodza nemwero mukuru kupfuura mwero wakakomba wekutonhora kuti ugadzire martensite.

2. Chinangwa cheKudzima: Chinangwa chekutanga ndechekuwana martensite (kana dzimwe nguva yakaderera bainite) kuwedzera kuoma uye kupfeka kusagadzikana kwesimbi. Kudzima ndeimwe yeakanyanya kukosha ekupisa kupisa maitiro esimbi.

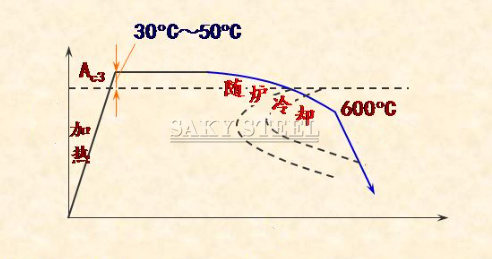

3.Kusarudza Kudzima Kupisa Kwemhando dzakasiyana dzeSimbi

Hypoeutectoid Simbi: Ac₃ + 30°C kusvika 50°C

Eutectoid uye Hypereutectoid Simbi: Ac₁ + 30°C kusvika 50°C

Alloy Steel: 50 ° C kusvika 100 ° C pamusoro pekupisa kwakanyanya

4.Kutonhodza Hunhu hweYakanaka Kudzima Medium:

Kutonhora Kunononoka Pamberi pe "Mhino" Tembiricha: Kudzikisa zvakakwana kushushikana kwekupisa.

Yakakwira Kutonhodza Capacity Pedyo ne "Nose" Tembiricha: Kudzivirira kuumbwa kweasiri-martensitic zvimiro.

Kutonhora Kunononoka Pedyo neM₅ Point: Kudzikisa kushushikana kunokonzerwa nemartensitic shanduko.

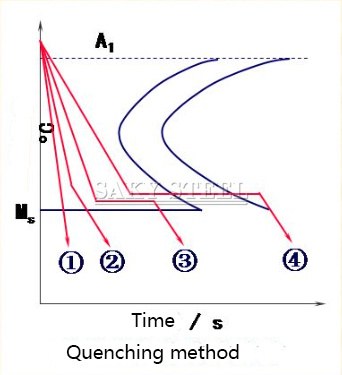

5.Kudzima Nzira uye Hunhu Hwadzo:

①Kudzima Kureruka: Zviri nyore kushandisa uye yakakodzera kune zvidiki, zvakapusa-maumbirwo emabasa. Iyo inoguma microstructure ndiyo martensite (M).

②Kudzima Kaviri: Zvakanyanya kuoma uye zvakaoma kudzora, zvinoshandiswa kune yakaoma-yakaumbwa yakakwira-kabhoni simbi uye yakakura alloy simbi yekushanda. Iyo inoguma microstructure ndiyo martensite (M).

③Kudzima Kwakaputsika: Iyo yakanyanya kuomarara maitiro, inoshandiswa kune hombe, yakaoma-yakaumbwa-yakaumbwa alloy simbi yekushanda. Iyo inoguma microstructure ndiyo martensite (M).

④Isothermal Kudzima: Inoshandiswa kune zvidiki, zvakaoma-maumbirwo emabasa ane zvakakwirira zvinodiwa. Iyo inoguma microstructure yakaderera bainite (B).

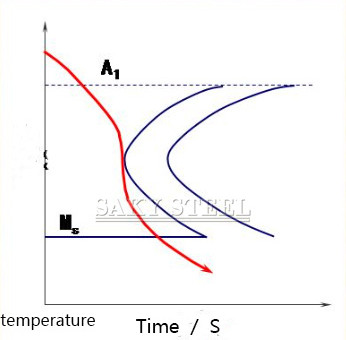

6.Factors Anobata Kuoma

Chiyero chekuoma chinoenderana nekugadzikana kwe supercooled austenite musimbi. Iyo yakakwirira kugadzikana kweiyo supercooled austenite, zviri nani kuomarara, uye zvinopesana.

Zvinhu Zvinokonzera Kugadzikana kweSupercooled Austenite:

Nzvimbo yeC-Curve: Kana iyo C-curve ikaenda kurudyi, iyo yakakosha kutonhora mwero wekudzima inoderera, ichivandudza kuoma.

Mhedziso Yakakosha:

Chero chinhu chinoshandura C-curve kurudyi chinowedzera kuoma kwesimbi.

Main Factor:

Kemikari Inoumbwa: Kunze kwecobalt (Co), ese alloying zvinhu zvakanyungudutswa mu austenite inowedzera kuoma.

Iyo padhuze iyo kabhoni yemukati ndeye eutectoid kuumbwa mucarbon simbi, ndiko kuwedzera kweC-curve kuchinjika kurudyi, uye kunowedzera kuoma.

7.Kutsunga uye Kumiririrwa kwekuoma

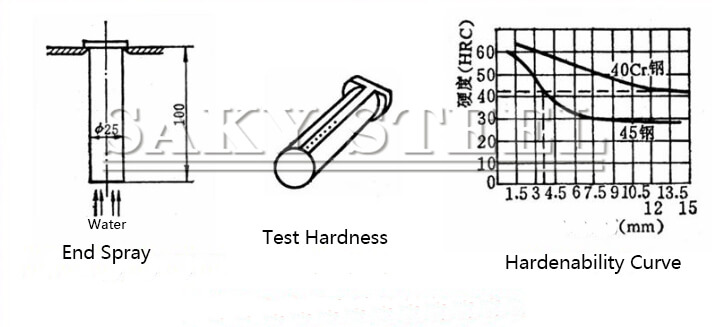

①End Quench Hardenability Test: Hurema hunoyerwa uchishandisa nzira yekupedza-yekudzima bvunzo.

②Critical Quench Diameter Method: Iyo yakakosha yekudzima dhayamita (D₀) inomiririra yakakura dhayamita yesimbi inogona kuomeswa zvizere mune chaiyo yekudzima svikiro.

B.Tempering

1. Tsanangudzo yeKupisa

Tempering inzira yekupisa kupisa uko simbi yakadzimwa inodziyiswa kusvika kune tembiricha iri pazasi peA₁ point, inobatwa patembiricha iyoyo, yobva yatonhodzwa kusvika mutembiricha yekamuri.

2. Chinangwa Kudzikamisa

Deredza kana Kubvisa Residual Stress: Inodzivirira deformation kana kuputika kweiyo workpiece.

Deredza kana Kubvisa Residual Austenite: Inodzikamisa zviyero zveiyo workpiece.

Bvisa Brittleness yeSimbi Yakadzimwa: Inogadzirisa iyo microstructure uye zvivakwa kuti isangane nezvinodiwa zveworkpiece.

Chirevo Chakakosha: Simbi inofanirwa kudzikiswa nekukurumidza mushure mekudzima.

3.Tempering Maitiro

1.Low Tempering

Chinangwa: Kuderedza kudzima kushushikana, kunatsiridza kuoma kweiyo workpiece, uye kuwana yakanyanya kuoma uye kupfeka kuramba.

Tembiricha: 150°C ~ 250°C.

Kuita: Kuoma: HRC 58 ~ 64. Kuoma kwepamusoro uye kupfeka kusagadzikana.

Zvishandiso: Zvishandiso, mold, mabearings, carburized parts, uye pamusoro-akaomeswa zvikamu.

2.High Tempering

Chinangwa: Kuwana kuomarara kwepamusoro pamwe nesimba rakakwana uye kuoma.

Tembiricha: 500°C ~ 600°C.

Performance: Kuoma: HRC 25 ~ 35. Yakanaka yakazara mechanical properties.

Zvishandiso: Shafts, magiya, tsvimbo dzekubatanidza, nezvimwe.

Thermal Refining

Tsanangudzo: Kudzima kunoteverwa nekupisa kwakanyanya kunonzi kucheneswa kwemafuta, kana kuti kungopisa. Simbi inobatwa neiyi maitiro ine yakanakisa kuita kwese uye inoshandiswa zvakanyanya.

Ⅳ.Surface Heat Treatment yeSimbi

A.Pamusoro Kudzima Simbi

1. Tsanangudzo yeSurface Hardening

Kuomeswa kwepamusoro inzira yekurapa yekupisa yakagadzirirwa kusimbisa nzvimbo yebasa nekukasira kuipisa kuti ishandure chikamu chepamusoro kuita austenite uye nekukasira kuchitonhodza. Iyi nzira inoitwa pasina kushandura kemikari yesimbi kana chimiro chepakati chechinhu.

2. Zvishandiso Zvinoshandiswa Pakuomeswa Kwepamusoro uye Kuomeswa Kwemashure

Zvishandiso Zvinoshandiswa Kuomesa Musoro

Zvakajairwa Zvishandiso: Medium kabhoni simbi uye yepakati kabhoni alloy simbi.

Pre-Kurapwa:Yakajairika Maitiro: Tempering. Kana iyo yakakosha zvivakwa isiri yakakosha, normalizing inogona kushandiswa pachinzvimbo.

Post-Kuoma Maumbirwo

Surface Structure: Iyo yekumusoro dhizaini inowanzo gadzira yakaomeswa chimiro semartensite kana bainite, iyo inopa kuoma kwakanyanya uye kupfeka kuramba.

Core Structure: Nheyo yesimbi inowanzo chengetedza chimiro chayo chepakutanga, senge pearlite kana mamiriro ane hasha, zvichienderana nekutanga kurapwa maitiro uye zvimiro zvehwaro zvinhu. Izvi zvinovimbisa kuti musimboti unochengetedza kusimba kwakanaka uye kusimba.

B. Hunhu hwe induction surface kuomesa

1.High Heating Temperature uye Rapid Temperature Rise: Induction surface kuomeswa kunowanzobatanidza kupisa kwekushisa kwakanyanya uye kukurumidza kupisa kwemazinga, zvichibvumira kukurumidza kupisa mukati menguva pfupi.

2.Fine Austenite Grain Structure muSurface Layer: Munguva yekukurumidza kupisa uye kunotevera kudzima nzira, iyo yepamusoro pedenga inoumba yakanaka austenite tsanga. Mushure mekudzima, iyo nzvimbo inonyanya kuve ine yakanaka martensite, nekuoma kwakajairika 2-3 HRC yakakwirira kupfuura yakajairwa kudzimwa.

3.Good Surface Quality: Pamusana penguva pfupi yekupisa, iyo workpiece yepamusoro haina kutarisana neoxidation uye decarburization, uye quenching-induced deformation inoderedzwa, inovimbisa kunaka kwepamusoro.

4.Kusimba Kwekuneta Kwepamusoro: Kuchinja kwemartensitic muchikamu chepamusoro kunokonzera kushungurudzika, izvo zvinowedzera kuneta kwesimba rekushanda.

5.Kubudirira Kwekugadzirwa Kwepamusoro: Induction surface kuomeswa kwakakodzera kugadzirwa kwemazhinji, kupa hukuru hwekushanda.

C.Kuronga kwemakemikari kupisa kurapwa

Carburizing,Carburizing,Carburizing,Chromizing,Siliconizing,Siliconizing,Siliconizing,Carbonitriding,Borocarburizing

D.Gas Carburizing

Gasi Carburizing inzira inoiswa mugasi rakavharidzirwa carburizing muchoto uye inopisa kune tembiricha inoshandura simbi kuita austenite. Zvadaro, carburizing agent inodonhedzwa muchoto, kana kuti carburizing mhepo inounzwa zvakananga, ichibvumira maatomu ecarbon kuti apararire muchikamu chepamusoro chebasa. Iyi nzira inowedzera kabhoni yemukati (wc%) pane workpiece pamusoro.

√Carburizing Agents:

•Magasi ane Carbon-rich: Semarasha gasi, liquefied petroleum gas (LPG), nezvimwewo.

•Organic Liquids: Separafini, methanol, benzene, nezvimwe.

√Carburizing Process Parameters:

•Carburizing Tembiricha: 920~950°C.

•Nguva yeCarburizing: Zvinoenderana nekudzika kwaunoda kweiyo carburized layer uye tembiricha yecarburizing.

E.Kupisa Kurapa Mushure meCarburizing

Simbi inofanirwa kurapwa kupisa mushure mekuvhiyiwa.

Kupisa Kurapa Maitiro Mushure meCarburizing:

√Kudzima + Kudzika-Kupisa Kupisa

1.Kudzima kwakananga Mushure mePre-Kutonhodza + Kudzika-Kupisa Kupisa: Iyo workpiece isati yatonhodzwa kubva kune carburizing tembiricha kusvika pamusoro peiyo core's Ar₁ tembiricha uye yobva yadzima, ichiteverwa nekudzika-tembiricha pa160 ~ 180 ° C.

2.Single Quenching Mushure mePre-Kutonhora + Yakaderera-Temperature Tempering: Mushure me carburizing, workpiece inotonhodzwa zvishoma nezvishoma kusvika kune tembiricha yekamuri, yozodziiswazve kuti idzime uye yakaderera-kupisa.

3.Kudzima Kaviri Mushure mePre-Kutonhora + Kudzika-Kupisa Kupisa: Mushure mekuputira uye kunonoka kutonhora, iyo workpiece inopinda matanho maviri ekupisa uye kudzima, inoteverwa nekudzika-kupisa.

Ⅴ.Chemical Heat Treatment yeSimbi

1.Tsanangudzo yeChemical Heat Treatment

Kemikari kupisa kurapwa inzira yekupisa kupisa umo simbi yekushanda inoiswa mune chaiyo inoshanda svikiro, inopisa, uye inobatwa patembiricha, ichibvumira maatomu anoshanda ari pakati kuti apararire mukati meiyo workpiece. Izvi zvinoshandura kuumbwa kwemakemikari uye microstructure yebasa rekushanda, nokudaro kuchinja maitiro ayo.

2.Basic Process yeChemical Heat Treatment

Kuora: Panguva yekupisa, iyo inoshanda yepakati inoora, ichiburitsa maatomu anoshanda.

Absorption: Maatomu anoshanda anoiswa nepamusoro pesimbi uye anonyungudika mumhinduro yakasimba yesimbi.

Diffusion: Maatomu anoshanda anotorwa nekunyungudika pamusoro pesimbi anoenda mukati.

Mhando dzeInduction Surface Kuomesa

a.High-Frequency Induction Heating

Ikozvino Frequency: 250 ~ 300 kHz.

Yakaomeswa Layer Kudzika: 0.5 ~ 2.0 mm.

Zvishandiso: Epakati uye madiki module magiya uye madiki kusvika epakati-saizi shafts.

b.Medium-Frequency Induction Heating

Yazvino Frequency: 2500 ~ 8000 kHz.

Yakaomeswa Layer Kudzika: 2 ~ 10 mm.

Zvishandiso: Mahombe shafts uye makuru kusvika epakati module magiya.

c.Simba-Frequency Induction Heating

Yazvino Frequency: 50 Hz.

Yakaomeswa Layer Kudzika: 10 ~ 15 mm.

Zvishandiso: Zvishandiso zvinoda yakadzika yakaomeswa layer.

3. Induction Surface Kuomesa

Basic Nheyo yeInduction Surface Kuomesa

Skin Effect:

Kana kuchinjanisa ikozvino mu induction coil kunokonzera ikozvino pamusoro pebasa rekushanda, iyo yakawanda yakakonzerwa ikozvino inonamirwa pedyo nechepamusoro, nepo pasina ikozvino inopfuura nepakati pebasa rekushanda. Chiitiko ichi chinozivikanwa seganda maitiro.

Nheyo yeInduction Surface Kuomesa:

Zvichienderana nemhedzisiro yeganda, pamusoro peiyo workpiece inokurumidza kupisa kusvika kune austenitizing tembiricha (inokwira kusvika 800 ~ 1000 ° C mumasekondi mashoma), nepo mukati meiyo workpiece inoramba isingaite. Iyo workpiece inozotonhodzwa nekupfapfaidza mvura, ichiita kuoma kwepamusoro.

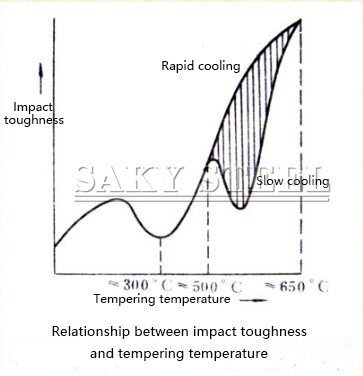

4.Temper Brittleness

Kudzikamisa Brittleness muSimbi Yakadzima

Tempering brittleness zvinoreva chiitiko apo kusimba kwesimbi yakadzimwa kunodzikira zvakanyanya kana yakadzimwa pane imwe tembiricha.

Rudzi Rwokutanga rweKudziya Brittleness

Tembiricha Range: 250°C kusvika 350°C.

Hunhu: Kana simbi yakadzimwa ichidzikatidzwa mukati meiyi tembiricha renji, ine mukana mukuru wekugadzira iyi mhando yekushatisa brittleness, iyo isingagone kubviswa.

Solution: Dzivisa kupisa simbi yakadzima mukati meiyi tembiricha renji.

Rudzi rwekutanga rwekupisa brittleness inozivikanwawo seyakadzika-tembiricha inodziya brittleness kana isingachinjiki kushatirwa brittleness.

Ⅵ.Tempering

1.Tempering ndeyekupedzisira kupisa kupisa nzira inotevera quenching.

Sei Simbi dzakadzimwa dzichida Kudziya?

Microstructure Mushure mekudzima: Mushure mekudzima, iyo microstructure yesimbi inowanzo sanganisira martensite uye yakasara austenite. Ose ari maviri mametastable phases uye anochinja mune mamwe mamiriro.

Zvivakwa zveMartensite:Martensite inoratidzwa nekuomarara kwakanyanya asiwo yakanyanya brittleness (kunyanya mune yakakwira-kabhoni tsono-senge martensite), iyo isingaenderane nekuita zvinodiwa kune akawanda maapplication.

Hunhu hweMartensitic Shanduko: Shanduko yemartensite inoitika nekukurumidza. Mushure mekudzima, iyo workpiece ine zvakasara zvemukati zvinonetsa izvo zvinogona kutungamirira ku deformation kana kuputika.

Mhedziso:Iyo workpiece haigone kushandiswa zvakananga mushure mekudzima! Kupisa kunodiwa kuderedza kushushikana kwemukati uye kuvandudza kuoma kweiyo workpiece, ichiita kuti ive yakakodzera kushandiswa.

2.Musiyano pakati peKuomeswa uye Kuomesesa Capacity:

Hardenability :

Kuomarara (Hardenability) zvinoreva kugona kwesimbi kuwana humwe hudzamu hwekuomesa (hudzamu hweiyo yakaoma layer) mushure mekudzima. Izvo zvinoenderana nekuumbwa kwesimbi uye chimiro, kunyanya ayo alloying zvinhu uye rudzi rwesimbi. Hardenability chiyero chekuti simbi inogona kuomesa sei mukati meukobvu hwayo panguva yekudzima.

Kuoma (Kuomesa Kugona):

Kuomarara, kana kuomarara kwesimba, zvinoreva kuomarara kwakanyanya kunogona kuwanikwa musimbi mushure mekudzima. Iyo inonyanya kukonzerwa nekabhoni yemukati yesimbi. Yepamusoro kabhoni yemukati kazhinji inotungamira kune yakanyanya kuoma kuoma, asi izvi zvinogona kudzikiswa nesimbi yealloying zvinhu uye kushanda kwekuita kwekudzima.

3.Kuoma kweSimbi

√Concept of Hardenability

Kuoma (Hardenability) zvinoreva kugona kwesimbi kuwana humwe hudzamu hwekuomesa martensitic mushure mekudzima kubva pakudziya kwe austenitizing. Mumashoko akareruka, iko kugona kwesimbi kuumba martensite panguva yekudzima.

Kuyera Kuoma

Kukura kwekuoma kunoratidzwa nekudzika kwechigadziko chakaomeswa chinowanikwa pasi pemamiriro akatsanangurwa mushure mekudzima.

Yakaomeswa Layer Depth: Uku ndiko kudzika kubva pamusoro peiyo workpiece kusvika kunharaunda iyo chimiro chiri hafu martensite.

Common Quenching Media:

•Mvura

Hunhu: Zveupfumi zvine simba rekutonhodza kwakasimba, asi zvine mwero wekutonhodza wakanyanya pedyo nepairi kufashaira, izvo zvinogona kukonzera kutonhora zvakanyanya.

Chishandiso: Inowanzo shandiswa kune kabhoni simbi.

Mvura yeMunyu: Mushonga wemunyu kana alkali mumvura, une kutonhora kwepamusoro pakupisa kwepamusoro kana uchienzaniswa nemvura, zvichiita kuti ive yakakodzera kune carbon steels.

•Mafuta

Hunhu: Inopa kutonhora kunononoka pakudziya kwakadzikira (padyo nenzvimbo yekubikira), izvo zvinonyatso dzikisa maitiro e deformation uye kutsemuka, asi ine yakaderera yekutonhodza pakupisa kwepamusoro.

Kushandisa: Inokodzera masimbi alloy.

Mhando: Inosanganisira kudzima mafuta, muchina mafuta, uye mafuta edhiziri.

Kupisa Nguva

Nguva yekupisa ine zvese zviri zviviri mwero wekudziya (nguva inotorwa kusvika kune yaunoda tembiricha) uye nguva yekubata (nguva inochengetedzwa pane yakatarwa tembiricha).

Nheyo dzeKuona Nguva Yekupisa: Ita shuwa kugovera tembiricha yakafanana mukati mese workpiece, mukati nekunze.

Ita shuwa kuti austenitization yakakwana uye kuti iyo austenite yakaumbwa yakafanana uye yakanaka.

Nheyo yeKuona Nguva Yekupisa:Inowanzo fungirwa uchishandisa empirical mafomula kana kutsanangurwa kuburikidza nekuyedza.

Kudzima Media

Zvinhu Zviviri Akakosha:

a.Cooling Rate: Kutonhora kwakanyanya kunosimudzira kuumbwa kwemartensite.

b.Residual Stress: Chiyero chepamusoro chekutonhora chinowedzera kusara kunetseka, izvo zvinogona kutungamirira kune hukuru hwekuita deformation uye kuputika mubasa rekushanda.

Ⅶ.Normalizing

1. Tsanangudzo yeNormalizing

Normalizing inzira yekurapa kupisa umo simbi inopisa kusvika kune tembiricha 30 ° C kusvika 50 ° C pamusoro peiyo Ac3 tembiricha, inobatwa pane iyo tembiricha, uye ipapo mhepo-yakatonhorera kuti iwane microstructure iri pedyo neiyo equilibrium state. Kuenzaniswa neannealing, normalizing ine kukurumidza kutonhora mwero, zvichikonzera yakatsetseka pearlite chimiro (P) uye yakakwirira simba nekuoma.

2. Chinangwa Chekuita Normalizing

Chinangwa che normalizing chakafanana nechekuita annealing.

3. Zvikumbiro zveNormalizing

•Bvisa networked secondary cementite.

• Shumira seyekupedzisira kupisa kurapwa kwezvikamu zvine yakaderera zvinodiwa.

• Ita segadziriro yekugadzirira kupisa kwepasi uye yepakati kabhoni structural simbi yekuvandudza machinability.

4.Types of Annealing

Mhando yekutanga yeAnealing:

Chinangwa uye Basa: Chinangwa hachisi chekukurudzira shanduko yechikamu asi kushandura simbi kubva kune isina kuenzana nyika kuenda kune yakaenzana.

Mhando:

• Diffusion Annealing: Inovavarira kuita homogenize kuumbwa nekubvisa kupatsanurwa.

• Recrystallization Annealing: Inodzorera ductility nekubvisa migumisiro yekuoma kwebasa.

• Stress Relief Annealing: Inoderedza kushushikana kwemukati pasina kushandura microstructure.

Rudzi rwechipiri rweAnealing:

Chinangwa uye Basa: Chinangwa chekushandura microstructure uye zvivakwa, kuwana pearlite-inodzorwa microstructure. Rudzi urwu runovimbisawo kuti kugovera uye morphology ye pearlite, ferrite, uye carbides zvinosangana nezvinodiwa.

Mhando:

• Full Annealing: Inopisa simbi pamusoro petembiricha yeAc3 uye yozoitonhodza zvishoma nezvishoma kuti ibudise chimiro cheunifomu pearlite.

•Anealing isina kukwana: Inopisa simbi pakati peAc1 neAc3 tembiricha kuti isandure chimiro.

•Isothermal Annealing: Inopisa simbi kusvika pamusoro peAc3, inoteverwa nekukurumidza kutonhora kusvika kune isothermal tembiricha uye kubata kuti uwane iyo yaunoda chimiro.

•Spheroidizing Annealing: Inobudisa spheroidal carbide structure, inovandudza machinability uye kuoma.

Ⅷ.1.Tsanangudzo yeKupisa Kurapa

Kupisa kupisa kunoreva nzira yekudziisa simbi, inobatwa pane imwe tembiricha, yozotonhodzwa ichiri yakasimba kuti ishandure chimiro chayo chemukati uye microstructure, nekudaro kuwana hunhu hwainoda.

2.Unhu hweKupisa Kurapa

Kupisa kurapwa hakuchinje chimiro cheworkpiece; pane kudaro, inoshandura chimiro chemukati uye microstructure yesimbi, iyo inoshandura zvinhu zvesimbi.

3.Chinangwa cheKupisa Kurapa

Chinangwa chekurapa kupisa ndechekuvandudza michina kana kugadzirisa zvivakwa zvesimbi (kana workpieces), kushandisa zvizere kugona kwesimbi, kuwedzera kunaka kweiyo workpiece, uye kuwedzera hupenyu hwayo hwebasa.

4.Kiyi Mhedziso

Kunyangwe zvivakwa zvechinhu zvinogona kuvandudzwa kuburikidza nekupisa kurapwa zvinoenderana zvakanyanya nekuti pane shanduko mune yayo microstructure uye chimiro panguva yekudziya uye kutonhora maitiro.

Nguva yekutumira: Aug-19-2024