Hunhu 254SMO zvinhu zvinogara zvine chiyero chakakwana muchimiro chayo chemakemikari, chimwe nechimwe chine basa racho:

Nickel (Ni): Nickel inogona kuwedzera simba re254SMO simbi ichichengetedza yakanaka plastiki uye kuoma. Nickel ine high corrosion resistance kune acids uye alkalis, uye ine ngura uye inodzivirira kupisa pakupisa kwakanyanya.

Molybdenum (Mo): Molybdenum inogona kunatsa zviyo zve254SMO simbi, kuvandudza kuoma uye simba rinopisa, uye kuchengetedza simba rakakwana uye kurwisana kunokambaira pakupisa kwepamusoro (kushungurudzika kwenguva refu pakupisa kwakanyanya, deformation, kuchinja kunokambaira).

Titanium (Ti): Titanium ideoxidizer yakasimba mu254SMO simbi. Inogona kuita chimiro chemukati chesimbi dense, kunatsa simba rezviyo; kuderedza kuchembera kunzwa uye kutonhora brittleness. Kuvandudza welding performance. Kuwedzerwa kwetitanium yakakodzera kune chromium 18 nickel 9 austenitic simbi isina tsvina inodzivirira intergranular corrosion.

Chromium (Cr): Chromium inogona kunatsiridza kusaora kwesimbi uye naizvozvo chinhu chakakosha chesimbi ye254SMO simbi isina kupisa uye isingadziviriri kupisa.

Mhangura (Cu): Mhangura inogona kuwedzera simba uye kuoma, kunyanya pakuora kwemuchadenga. Izvo zvisingabatsiri ndezvokuti brittleness inopisa inowanzoitika panguva yekushanda inopisa uye plastiki yemhangura inodarika 0.5%. Kana iyo mhangura yemukati iri pasi pe0.50%, hapana mhedzisiro pane solderability ye254SMO zvinhu.

Zvichienderana nemisiyano yezvikamu zvikuru zviri pamusoro, mhando dzinotevera dze254SMO nickel alloys dzinogona kushandiswa:

1. Nickel-copper (Ni-Cu) alloy, inozivikanwawo seMonel alloy (Monel alloy)

2. Nickel-chromium (Ni-Cr) alloy is nickel-based heat-resistant alloy.

3. Ni-Mo alloy inonyanya kureva Hastelloy B series

4. Ni-Cr-Mo alloy inonyanya kureva Hastelloy C series

254SMO inoshandiswa mumidziyo yakasiyana-siyana yemaindasitiri, kushandiswa kwayo kwemukati kwemashizha emashizha, zvitubu zvekoil, zvikamu zvekuisa chisimbiso, magetsi emagetsi emagetsi, catalytic converters, EGR coolers, turbocharges uye mamwe magasi asingadziviriri kupisa, ndege Austenitic stainless steel plates inoshandiswa pakubatana.

Kunyanya, chikamu chekushandiswa kwezvakasiyana siyana zvemaindasitiri emidziyo, mota inopedza gaskets, nezvimwewo inoshandiswa pasi pekushisa kwepamusoro inoshandisa NPF625 uye NCF718 inotsanangurwa muJIS G 4902 (isingadziviriri uye inodzivirira kupisa superalloy ndiro) kuti ive nehuwandu hwehuwandu. Iyo inopfuura 50% yezvinhu zvinodhura zveNi. Kune rumwe rutivi, kune zvinhu zvakadai semvura-yakasimudzirwa simbi isina tsvina yakadai seSUH660 inoshandisa intermetallic compounds yeTi neAl inotsanangurwa muJIS G 4312 (ndiro yesimbi inodzivirira kupisa), kuoma kwe254 SMO kunoderera zvikuru kana yakashandiswa kwenguva yakareba pakupisa, uye chete Kushandiswa kusvika kunodiwa kunoda 500 ° C hakugutse kupisa kwe500 ° C. yakasimudzirwa nekupisa kwakanyanya mumakore achangopfuura.

Mutengo: 254SMO

Zviyero zvenyika: 254SMO/F44 (UNS S31254/W.Nr.1.4547)

Vadyidzani: Outokumpu, AVESTA, Hastelloy, SMC, ATI, Germany, ThyssenKrupp VDM, Mannex, Nickel, Sandvik, Sweden Japan Metallurgical, Nippon Steel nemamwe mabhureki ane mukurumbira.

Chiratidzo cheAmerica: UNS S31254

Mhedziso ye254SMo (S31254): Iyo yepamusoro austenitic simbi isina tsvina. Nekuda kweiyo yakakwira molybdenum yemukati, ine yakanyanyisa kupikisa kugomba uye crevice corrosion. 254SMo simbi isina tsvina yakagadziridzwa uye yakagadziridzwa kuti ishandiswe munzvimbo dzine halide dzakaita semvura yegungwa.

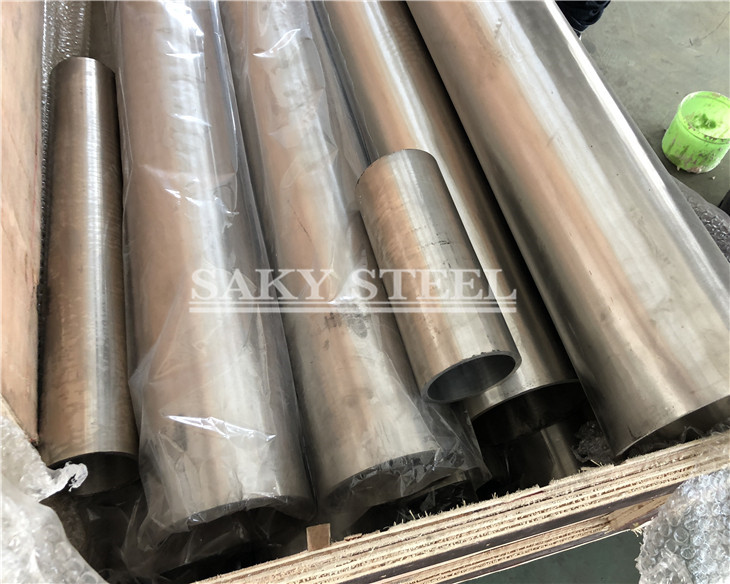

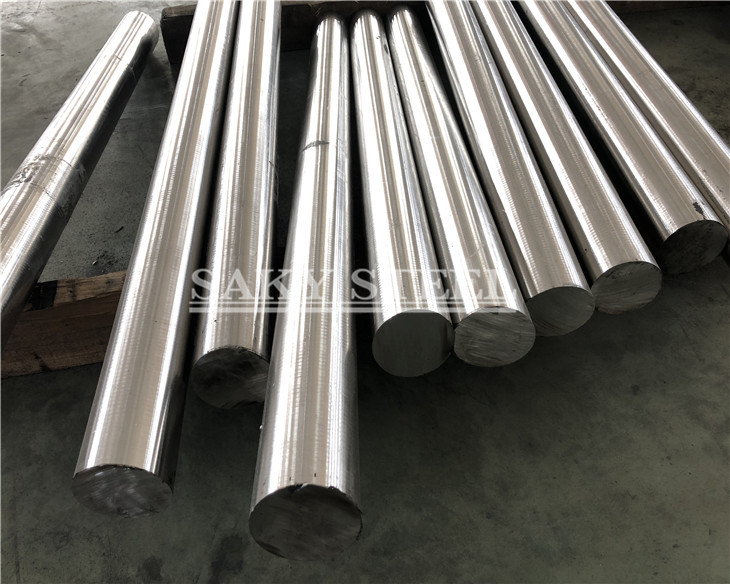

254SMo (S31254) Super Stainless Steel imhando yakakosha yesimbi isina tsvina. Yakasiyana kubva kune yakajairwa Stainless simbi maererano nekuumbwa kwemakemikari. Inoreva simbi yesimbi isina tsvina ine yakakwirira nickel, high chromium, uye high molybdenum. Super Stainless simbi, nickel-based alloy imhando yakakosha yesimbi isina tsvina, yekutanga kemikari kuumbwa kwakasiyana neyakajairwa simbi isina tsvina, inoreva alloy yakakwira ine nickel yakakwirira, yakakwirira chromium, yakakwira-molybdenum simbi isina tsvina. Iyo iri nani ndeye 254Mo, iyo ine 6% Mo. Rudzi urwu rwesimbi rune kupikisa kwakanaka kwazvo kune corrosion yenzvimbo. Iine kupikisa kwakanaka kwegomba pasi pemvura yegungwa, aeration, gap, uye low-velocity erosion mamiriro (PI ≥ 40) uye zviri nani kusagadzikana kwekuora kwekudzivirira, zvimwe zvinhu zveNi-based alloys uye titanium alloys. Chechipiri, mune yakanyanya tembiricha kana corrosion kuramba kuita, ine kuramba iri nani kune yakanyanya tembiricha kana corrosion kuramba, ndeye 304 simbi isina tsvina haigone kutsiviwa. Pamusoro pezvo, kubva pakurongeka kwesimbi isina tsvina, iyo yakakosha simbi yesimbi metallographic chimiro yakagadzikana austenite metallographic chimiro. Nekuti iyi yakakosha simbi imhando yemhando yepamusoro-alloy zvinhu, zvakaomesesa mukugadzira maitiro. Kazhinji, vanhu vanogona kungovimba nemaitiro echinyakare kugadzira iyi yakakosha simbi isina tsvina, sekudira, kuforoma, kukunguruka uye zvichingodaro.

Panguva imwecheteyo ine hunhu hwekupikiswa kwekushisa kwakanyanya sezvinotevera:

1. Nhamba huru yezvidzidzo zvemumunda uye ruzivo rwakakura runoratidza kuti kunyange kune tembiricha yakakwira zvishoma, iyo 254SMO ine yakakwira crevice corrosion resistance mumvura yegungwa, uye mhando shoma dzesimbi isina tsvina dzine pfuma iyi.

2. Kudzivirirwa kwekuora kwe254SMO mumhinduro dzine acidic uye oxidizing halide solutions sezviya zvinodiwa pakugadzirwa kwebleach-based bleach zvinogona kuenzaniswa ne nickel-base alloys uye titanium alloys iyo inopesana zvikuru nekuora.

Nguva yekutumira: Kubvumbi-24-2018