DIN 1.2714 L6 Mold Steel

Tsanangudzo Pfupi

1.2714 imhando yealloy tool simbi, inozivikanwawo seL6 simbi. Iyo inoratidzirwa nekusimba kwayo kwakanyanya, kuomarara kwepamusoro, uye kwakanaka kupfeka kuramba, ichiita kuti ive yakakodzera kune akasiyana maapplication mukugadzira yefogi inofa, kufa-kukanda kufa, uye zvimwe zvishandiso zvinoiswa mukurema uye kupfeka.

DIN 1.2714 L6 Mold Simbi:

Simbi dzesimbi dzakagadzirwa kubva ku1.2714 alloy dzinowanzo kupihwa mune annealed mamiriro, ayo anobvumira nyore machining uye kunotevera kupisa kurapwa. Vanogona kupisa-kugadziriswa kuti vabudirire kuomarara kunodiwa uye kuomarara kwemazinga akakodzera kune chinangwa chekushandisa.Kufanana nemamwe masimbi emidziyo, 1.2714 simbi inoda kurapwa kwakakodzera kwekupisa kuti iwedzere kushanda kwayo. Izvi zvinogona kusanganisira nzira dzakaita sekuvhara, kudzima, uye kupisa, zvichienderana nemhando yaunoda.Simbi iyi inowanzove ine zvinhu zvakaita sechromium, nickel, uye molybdenum, izvo zvinobatsira pakugadzirisa kwayo. Iyo "1.2714" dhizaini ikodhi yenhamba inoshandiswa kuratidza chaiyo kuumbwa uye zvimiro zvesimbi.

Zvinotsanangurwa zveDIN 1.2714 Mold Steel:

| Giredhi | 5CrNiMo (T20103), L6 (T61206),SKT4,55NiCrMoV7 (1.2714),55NiCrMoV7 |

| Standard | GB/T 1299-2000,ASTM A681-08,JIS G4404-2006,EN ISO 4957-1999 |

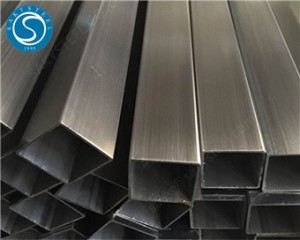

| Surface | Dema, Yakakasharara Yakagadzirwa, Yakatendeuka |

| Urefu | 1 kusvika ku6 Mamita |

| Processing | Cold Drawn & polished Cold Drawn, Centreless Ground & Polished |

| Raw Materail | POSCO, Baosteel, TISCO, Saky Steel, Outokumpu |

L6 Mold Steel yakaenzana:

| Standard | GB/T 1299-2000 | ASTM A681-08 | JIS G4404-2006 | EN ISO 4957-1999 | ISO 4957:1999 |

| Giredhi | 5CrNiMo (T20103) | L6 (T61206) | SKT4 | 55NiCrMoV7 (1.2714) | 55NiCrMoV7 |

Kemikari Kuumbwa KweL6 Zvishandiso simbi mabara:

| STAND | Giredhi | C | Mn | P | S | Cr | Mo | Ni | V | Si |

| GB/T 1299-2000 | 5CrNiMo (T20103) | 0.50-0.60 | 0.50-0.80 | 0.030 | 0.030 | 0.50-0.80 | 0.15-0.30 | 1.40-1.80 | 0.40 | |

| ASTM A681-08 | L6 (T61206) | 0.65-0.75 | 0.25-0.80 | 0.030 | 0.030 | 0.60-1.20 | 0.50 | 1.25-2.00 | 0.10-0.50 | |

| JIS G4404-2006 | SKT4 | 0.50-0.60 | 0.60-0.90 | 0.030 | 0.020 | 0.80-1.20 | 0.35-0.55 | 1.50-1.80 | 0.05-0.15 | 0.10-0.40 |

| EN ISO 4957-1999 | 55NiCrMoV7 (1.2714) | 0.50-0.60 | 0.60-0.90 | 0.030 | 0.030 | 0.80-1.20 | 0.35-0.55 | 1.50-1.80 | 0.05-0.15 | 0.10-0.40 |

| ISO 4957:1999 | 55NiCrMoV7 | 0.50-0.60 | 0.60-0.90 | 0.030 | 0.030 | 0.80-1.20 | 0.35-0.55 | 1.50-1.80 | 0.05-0.15 | 0.10-0.40 |

1.2714 Simbi Yepanyama Zvivakwa:

| Zvinhu Zvenyama | Metric | Imperial |

| Density | 7.86 g/cm³ | 0.284 lb/in³ |

| Melting point | 2590°F | 1421°C |

Sei Sarudza isu?

•Iwe unogona kuwana iyo yakakwana zvinhu zvinoenderana nezvinodiwa zvako pamutengo unogoneka.

•Isu tinopawo Reworks, FOB, CFR, CIF, uye mitengo yekuendesa gonhi kumusuwo. Tinokupa zano kuti uite dhiri yekutumira iyo inove ine mari shoma.

•Zvishandiso zvatinopa zvinonyatso zivikanwa, kubva pachitupa chebvunzo kusvika kune yekupedzisira dimensional statement. (Mishumo icharatidza pane zvinodiwa)

•Isu tinovimbisa kupa mhinduro mukati me24hours (kazhinji muawa imwe chete)

•Ipa SGS TUV chirevo.

•Isu takazvipira zvizere kune vatengi vedu. Kana zvisingabviri kuzadzisa zvaunoda mushure mekuongorora zvese zvingasarudzwa, isu hatizokunyengedzi nekuita zvipikirwa zvenhema izvo zvinogadzira hukama hwakanaka hwevatengi.

•Ipa imwe-stop service.

Packing:

1. Kurongedza kwakakosha zvakanyanya muchiitiko chekutumira kune dzimwe nyika uko kutakurwa kunopfuura nemumatanho akasiyana-siyana kuti usvike kwaunoenda, saka tinoisa hanya zvakanyanya maererano nekurongedza.

2. Saky Steel inorongedza zvinhu zvedu nenzira dzakawanda zvichienderana nezvigadzirwa. Isu tinorongedza zvigadzirwa zvedu nenzira dzakawanda, senge,