DIN 1.2311 P20 Mold Steel

Tsanangudzo Pfupi

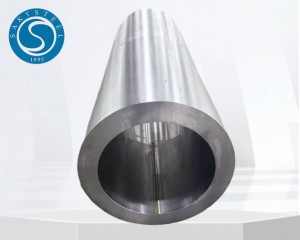

DIN 1.2311 ″ imhando yakajairika yesimbi yekuumbwa, inowanzonzi P20 simbi. P20 isimbi yakaderera-alloy mold inozivikanwa nekunaka kwayo machina uye kupfeka kuramba, inowanzoshandiswa mukugadzira molds epurasitiki uye kufa-casting molds.

DIN 1.2311 P20 Mold Simbi:

DIN 1.2311 P20 Mold Steel isimbi inowanzoshandiswa mukugadzira molds, inoshandiswa zvakanyanya mukugadzirwa kwemapuranga epurasitiki uye kufa-casting molds.DIN 1.2311 P20 Mold Steel ine maitiro akanaka ekucheka uye machinability, zvichiita kuti zvive nyore kugadzirisa mumhando dzakasiyana-siyana dzehuni.Mushure mekugadzirisa kupisa kwakakodzera, DIN 11620 Mold resistance, DIN 120 1. yakakodzera kugadzira molds ine zvinodiwa zvakanyanya.DIN 1.2311 P20 Mold Steel inowanzoshandiswa mumhando dzakasiyana-siyana dzakadai semajekiseni ejekiseni, extrusion molds, die-casting molds, uye mold bases.

Zvinotsanangurwa zve 1.2311 TOOL STELS:

| Giredhi | 1.2311, P20 |

| Standard | ASTM A681 |

| Surface | Nhema; Peeled; Polished; Machined; Grinded; Turned; Milled |

| Raw Materail | POSCO, Baosteel, TISCO, Saky Steel, Outokumpu |

1.2311 Equivalent Simbi Magiredhi:

| Nyika | USA | ChiJerimani | GB/T |

| Standard | ASTM A681 | DIN EN ISO 4957 | GB/T 1299 |

| MaGrades | P20 | 1.2311 | 3Cr2Mo |

P20 TOOL STEELS Chemical Kuumbwa:

| Standard | Giredhi | C | Si | Mn | P | S | Cr | Mo |

| ASTM A681 | P20 | 0.28 ~ 0.40 | 0.2~0.8 | 0.60~1.0 | ≤0.030 | ≤0.030 | 1.4~2.0 | 0.3 ~ 0.55 |

| GB/T 9943 | 3Cr2Mo | 0.28 ~ 0.40 | 0.2~0.8 | 0.60~1.0 | ≤0.030 | ≤0.030 | 1.4~2.0 | 0.3 ~ 0.55 |

| DIN ISO4957 | 1.2311 | 0.35~0.45 | 0.2~0.4 | 1.3~1.6 | ≤0.030 | ≤0.030 | 1.8~2.1 | 0.15~0.25 |

1.2311 Tool Steels Mechanical Properties:

| Properties | Metric |

| Kuoma, Brinell (Yakajairika) | 300 |

| Kuoma, Rockwell C (Yakajairika) | 30 |

| Kusimba Simba, Pakupedzisira | 965-1030 MPa |

| Kusimba Simba, Kubereka | 827-862 MPa |

| Elongation Panguva Yekuzorora (Mu50 Mm (2″) | 20.00% |

| Compressive Strength | 862 MPa |

| Charpy Impact (V-Notch) | 27.1-33.9 J |

| Poisson's Ratio | 0.27-0.30 |

| Elastic Modulus | 190-210 GPA |

Sei Sarudza isu?

•Iwe unogona kuwana iyo yakakwana zvinhu zvinoenderana nezvinodiwa zvako pamutengo unogoneka.

•Isu tinopawo Reworks, FOB, CFR, CIF, uye mitengo yekuendesa gonhi kumusuwo. Tinokupa zano kuti uite dhiri yekutumira iyo inove ine mari shoma.

•Zvishandiso zvatinopa zvinonyatso zivikanwa, kubva pachitupa chebvunzo kusvika kune yekupedzisira dimensional statement. (Mishumo icharatidza pane zvinodiwa)

•Isu tinovimbisa kupa mhinduro mukati me24hours (kazhinji muawa imwe chete)

•Ipa SGS TUV chirevo.

•Isu takazvipira zvizere kune vatengi vedu. Kana zvisingabviri kuzadzisa zvaunoda mushure mekuongorora zvese zvingasarudzwa, isu hatizokunyengedzi nekuita zvipikirwa zvenhema izvo zvinogadzira hukama hwakanaka hwevatengi.

•Ipa imwe-stop service.

Masevhisi Edu

1.Kudzima uye kupisa

2.Vacuum kupisa kurapa

3.Mirror-polished surface

4.Precision-milled finish

4.CNC machining

5.Precision drilling

6.Cheka muzvikamu zviduku

7.Achieve mold-kufanana nemazvo

Packing:

1. Kurongedza kwakakosha zvakanyanya muchiitiko chekutumira kune dzimwe nyika uko kutakurwa kunopfuura nemumatanho akasiyana-siyana kuti usvike kwaunoenda, saka tinoisa hanya zvakanyanya maererano nekurongedza.

2. Saky Steel inorongedza zvinhu zvedu nenzira dzakawanda zvichienderana nezvigadzirwa. Isu tinorongedza zvigadzirwa zvedu nenzira dzakawanda, senge,