317 simbi isina musono pombi

Tsanangudzo Pfupi

| Zvinotsanangurwa zvesimbi isina musono pombi: |

Seamless Pipes & Tubes Size:1 / 8″ NB – 24″ NB

Specifications :ASTM A/ASME SA213, A249, A269, A312, A358, A790

Standard :ASTM, ASME

Giredhi:304, 316,317,317L, 321, 321Ti, 420, 430, 446, 904L, 2205, 2507

MatekinikiKupisa-kwakakungurutswa, kunotonhorera

Urefu :5.8M, 6M & Inodiwa Urefu

Outer Diameter6.00 mm OD kusvika 914.4 mm OD, Saizi inosvika 24” NB

Ukobvu :0.3mm – 50 mm, SCH 5, SCH10, SCH 40, SCH 80, SCH 80S, SCH 160, SCH XXS, SCH XS

Chirongwa :SCH20, SCH30, SCH40, STD, SCH80, XS, SCH60, SCH80, SCH120, SCH140, SCH160, XXS

Types :Seamless Pipes

Fomu :Round, Square, Rectangle, Hydraulic, Honed Tubes

End :Magumo Akachena, Magumo Akanaka, Akatsikwa

| Stainless Simbi 317/317L Seamless Mapaipi Akaenzana Magiredhi: |

| STANDARD | WERKSTOFF NR. | UNS | JIS | EN |

| SS 317 | 1.4449 | S31700 | SUS 317 | - |

| SS 317L | 1.4438 | S31703 | SUS 317L | X2CrNiMo18-15-4 |

| SS 321 / 321H Seamless Pipes Kemikari Kuumbwa uye Mechanical zvivakwa: |

| MaGrades | C | Mn | Si | P | S | Cr | Mo | Ni | Fe |

| SS 317 | 0.08 max | 2.0 max | 1.0 max | 0.045 max | 0.030 max | 18.00 - 20.00 | 3.00 - 4.00 | 11.00 - 15.00 | 57.845 min |

| SS 317L | 0.035 max | 2.0 max | 1.0 max | 0.045 max | 0.030 max | 18.00 - 20.00 | 3.00 - 4.00 | 11.00 - 15.00 | 57.89 min |

| Density | Melting Point | Tensile Simba | Goho Simba (0.2% Offset) | Elongation |

| 7.9 g/cm3 | 1400 °C (2550 °F) | Psi - 75000 , MPa - 515 | Psi - 30000, MPa - 205 | 35 % |

| Sei Tisarudze: |

1. Unogona kuwana zvinhu zvakakwana maererano nezvinodiwa zvako pamutengo wakaderera.

2. Isu tinopawo Reworks, FOB, CFR, CIF, uye mitengo yekutumira pamusuwo kumasuo. Tinokupa zano kuti uite dhiri yekutumira iyo inove ine mari shoma.

3. Zvishandiso zvatinopa zvinonyatso zivikanwa, kubva pazvitupa zvekuedza kusvika kune yekupedzisira dimensional statement.(Mishumo icharatidza pane zvinodiwa)

4. inovimbisa kupa mhinduro mukati memaawa makumi maviri nemana (kazhinji muawa imwe chete)

5. Unogona kuwana dzimwe nzira dzemasheya, kutakura zvigayo nekuderedza nguva yekugadzira.

6. Isu takazvipira zvizere kune vatengi vedu. Kana zvisingabviri kuzadzisa zvaunoda mushure mekuongorora zvese zvingasarudzwa, isu hatizokunyengedzi nekuita zvipikirwa zvenhema izvo zvinogadzira hukama hwakanaka hwevatengi.

| SAKY STEEL'S Hunhu Simbiso (inosanganisira zvose Zvinoparadza uye Zvisingaparadzi) : |

1. Visual Dimension Test

2. Mechanical bvunzo senge tensile, Elongation uye kuderedzwa kwenzvimbo.

3. Muedzo mukuru

4. Kemikari yekuongorora kuongorora

5. Kuoma bvunzo

6. Pitting kudzivirira bvunzo

7. Flaring Testing

8. Mvura-Jet Test

9. Penetrant Test

10. X-ray test

11. Intergranular Corrosion Testing

12. Kuongorora kwemigumisiro

13. Eddy anoongorora

14. Hydrostatic analysis

15. Metallography Experimental Test

| Zvinotsanangurwa zveIncoloy A286 Wire: |

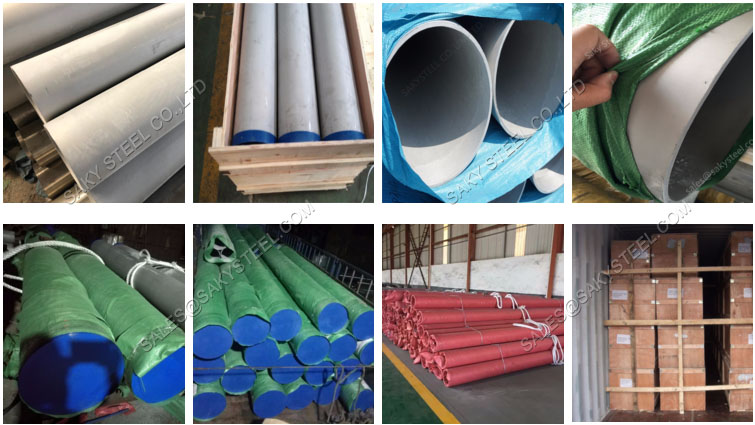

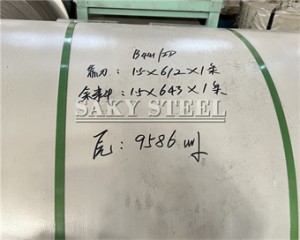

1. Kurongedza kwakakosha zvakanyanya muchiitiko chekutumira kune dzimwe nyika uko chinotakurwa chinopfuura nemumatanho akasiyana-siyana kuti chisvike kwaunoenda, saka tinoisa hanya zvakanyanya maererano nekurongedza.

2. Saky Steel inorongedza zvinhu zvedu nenzira dzakawanda zvichienderana nezvigadzirwa. Isu tinorongedza zvigadzirwa zvedu nenzira dzakawanda, senge,

Applications:

1. Pepa & Pulp Makambani

2. High Pressure Applications

3. Indasitiri yeOiri neGasi

4. Chemical Refinery

5. Pipeline

6. High Temperature Application

7. Mvura Pipe Lin

8. Zvigadzirwa zveNuclear Power Plants

9. Food Processing uye Dairy Industries

10. Boiler & Heat Exchangers