17-4PH 630 Stainless Steel Bar

Tsanangudzo Pfupi:

SAKYSTEEL inopa 17-4PH (630) simbi isina simbi ine simba rakanyanya uye inodzivirira corrosion yeaerospace, yegungwa, uye kushandiswa kwemaindasitiri.

Saky Steel's 17-4PH / 630 / 1.4542 ndeimwe yeanonyanya kufarirwa uye anonyanya kushandiswa simbi isina chromium-nickel alloy simbi ine mhangura yekuwedzera, kunaya kwakaomeswa nemartensitic chimiro. Iyo inoratidzirwa neyakakura corrosion resistance apo ichichengetedza yakakwirira simba zvivakwa, kusanganisira kuoma. Simbi inogona kushanda mutembiricha kubva -29 ℃ kusvika 343 ℃, ichichengeta yakanaka paramita. Uye zvakare, zvinhu zviri mugiredhi iri zvinoratidzwa nekunaka ductility uye kushora kwavo kusimba kunofananidzwa ne1.4301 / X5CrNi18-10.

17-4PH, inozivikanwawo seUNS S17400, ndeye martensitic precipitation-inoomesa simbi isina tsvina. Icho chinhu chinogoneka uye chinoshandiswa zvakanyanya mumaindasitiri akasiyana siyana, senge aerospace, nyukireya, petrochemical, uye kugadzira chikafu.

17-4PH ine simba rakakwirira, kunaka kwekusagadzikana, uye kuoma kwakanaka kuenzaniswa nemamwe masimbi asina tsvina. Musanganiswa we17% chromium, 4% nickel, 4% mhangura, uye shoma shoma ye molybdenum uye niobium. Iko kusanganiswa kwezvinhu izvi kunopa simbi midziyo yayo yakasiyana.

Pakazere, 17-4PH chinhu chakasiyana-siyana uye chinobatsira chinopa chiyero chakanaka chezvivakwa kune akasiyana siyana ekushandisa.

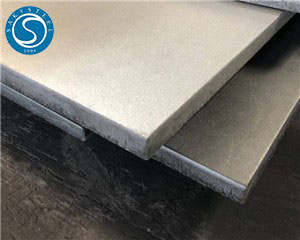

| Stainless Steel Round Bar Bright Products Show: |

| Zvinyorwa zve630Stainless simbi bar: |

Specifications :ASTM A564/ASME SA564

Giredhi:AISI 630 SUS630 17-4PH 1.4542 PH

Urefu :5.8M, 6M & Inodiwa Urefu

Round Bar Diameter :4.00 mm kusvika 400 mm

Bright Bar :4mm - 100mm,

Tolerance :H8, H9, H10, H11, H12, H13, K9, K10, K11, K12 kana sezvinodiwa nevatengi.

Condition :Cold Drawn & polished Cold Drawn, Peeled & Forged

Surface FinishDema, Kupenya, Kupenya, Yakakasharara Yakatendeuka, NO.4 Pedzisa, Matt Pedzisa

Fomu :Round, Square, Hex (A/F), Rectangle, Billet, Ingot, Forged Etc.

End :Plain End, Beveled End

| Stainless Steel Bar Magiredhi Kemikari Kuumbwa: |

| UNS Designation | Type | C | Mn | P | S | Si | Cr | Ni | Al | Mo | Ti | Cu | Zvimwe Zvinhu |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| S17400 | 630 | 0.07 | 1.00 | 0.040 | 0.030 | 1.00 | 15.00–17.50 | 3.00–5.00 | - | - | - | 3.00–5.00 | C |

| S17700 | 631 | 0.09 | 1.00 | 0.040 | 0.030 | 1.00 | 16.00–18.00 | 6.50–7.75 | - | - | - | - | - |

| S15700 | 632 | 0.09 | 1.00 | 0.040 | 0.030 | 1.00 | 14.00–16.00 | 6.50–7.75 | - | 2.00–3.00 | - | - | - |

| S35500 | 634 | 0.10–0.15 | 0.50–1.25 | 0.040 | 0.030 | 0.50 | 15.00–16.00 | 4.00–5.00 | - | 2.50–3.25 | - | - | D |

| S17600 | 635 | 0.08 | 1.00 | 0.040 | 0.030 | 1.00 | 16.00–17.50 | 6.00–7.50 | 0.40 | - | - | - | - |

| S15500 | XM-12 | 0.07 | 1.00 | 0.040 | 0.030 | 1.00 | 14.00–15.50 | 3.50–5.50 | - | - | - | 2.50–4.50 | C |

| S13800 | XM-13 | 0.05 | 0.20 | 0.040 | 0.008 | 1.00 | 12.25–13.25 | 7.50–8.50 | 0.90–1.35 | 2.00–2.50 | - | - | E |

| S45500 | XM-16 | 0.03 | 0.50 | 0.015 | 0.015 | 0.50 | 11.00–12.50 | 7.50–9.50 | - | 0.50 | 0.90–1.40 | 1.50–2.50 | F |

| S45503 | - | 0.010 | 0.50 | 0.010 | 0.010 | 0.50 | 11.00–12.50 | 7.50–9.50 | - | 0.50 | 1.00–1.35 | 1.50–2.50 | F |

| S45000 | XM-25 | 0.05 | 1.00 | 0.030 | 0.030 | 0.50 | 14.00–16.00 | 5.00–7.00 | - | - | - | 1.25–1.75 | G |

| S46500 | - | 0.02 | 0.25 | 0.040 | 0.030 | 1.00 | 11.00–13.0 | 10.75–11.25 | 0.15–0.50 | 0.75–1.25 | - | - | E |

| S46910 | - | 0.030 | 1.00 | 0.040 | 0.020 | 1.00 | 11.00–12.50 | 8.00–10.00 | 0.50–1.20 | 3.0–5.0 | - | 1.5–3.5 | - |

| S10120 | - | 0.02 | 1.00 | 0.040 | 0.015 | 0.25 | 11.00–12.50 | 9.00–11.00 | 1.10 | 1.75–2.25 | 0.20–0.50 | - | E |

| S11100 | - | 0.02 | 0.25 | 0.040 | 0.010 | 0.25 | 11.00–12.50 | 10.25–11.25 | 1.35–1.75 | 1.75–2.25 | 0.20–0.50 | - | E |

| 17-4PH Stainless Steel Bar Yakaenzana Magiredhi: |

| STANDARD | UNS | WERKSTOFF NR. | AFNOR | JIS | EN | BS | GOST |

| 17-4PH | S17400 | 1.4542 |

| 17-4PH Stainless Bar Solution Kurapa: |

| Giredhi | Tensile Simba (MPa) min | Elongation (% mu50mm) min | Goho Simba 0.2% Uchapupu (MPa) min | Kuoma | |

| Rockwell C max | Brinell (HB) max | ||||

| 630 | - | - | - | 38 | 363 |

Reamark: Chimiro A 1900±25°F[1040±15°C](inotonhorera sezvinodiwa pasi pe90°F(30°C))

1.4542 Mechanical Test Zvinodiwa Mushure meZera Kuomesa Kupisa Kurapwa:

Tensile Strength:Chikwata – ksi (MPa) , Chidiki

Yeild Strength:0.2 % Offset , Unit – ksi (MPa) , Minimum

Elongation :mu2″, Chikwata: % , Zvishoma

Kuoma :Rockwell, Maximum

17-4PH Stainless Simbi Mechanical Properties neKupisa Kurapa Mamiriro:

| H900 | H 925 | H 1025 | H 1075 | H 1100 | H 1150 | H 1150-M | |

| Ultimate Tensile Strength, ksi | 190 | 170 | 155 | 145 | 140 | 135 | 115 |

| 0.2% Goho Simba, ksi | 170 | 155 | 145 | 125 | 115 | 105 | 75 |

| Elongation % mu2″ kana 4XD | 10 | 10 | 12 | 13 | 14 | 16 | 16 |

| Kuderedzwa kweNzvimbo,% | 40 | 54 | 56 | 58 | 58 | 60 | 68 |

| Kuoma, Brinell (Rockwell) | 388 (C 40) | 375 (C 38) | 331 (C 35) | 311 (C 32) | 302 (C 31) | 277 (C 28) | 255 (C 24) |

| Impact Charpy V-Notch, ft - lbs | | 6.8 | 20 | 27 | 34 | 41 | 75 |

| Smelting Option: |

1 EAF: Electric Arc Furnace

2 EAF + LF + VD: Yakanatswa-kunyungudutsa uye vacuum degassing

3 EAF + ESR: Electro Slag Remelting

4 EAF + PESR: inodzivirira mamiriro Electro Slag Remelting

5 VIM + PESR: Vacuum induction kunyunguduka

| Sarudzo yekurapa kupisa: |

1 +A: Yakanamirwa (yakazara / yakapfava / spheroidizing)

2 +N: Yakagadziridzwa

3 +NT: Yakajairwa uye yakapfava

4 + QT: Yakadzimwa uye yakadzikama (mvura / mafuta)

5 +AT: Mhinduro yakavharwa

6 +P: Kunaya kwakaoma

| Kurapa Kupisa: |

Solution kurapwa (Chimiro A) — Grade 630 Stainless steels anodziiswa pa1040°C kwe0.5 h, ozotonhodzwa nemhepo kusvika pa30°C. Zvikamu zvidiki zvemagiredhi aya zvinogona kudzimwa mafuta.

Kuomesa - Giredhi 630 masimbi asina simbi anoomeswa nezera pane yakaderera tembiricha kuti awane zvinodikanwa zvemuchina. Munguva yekushanda, kusvibiswa kwepamusoro kunoitika kunoteverwa nekuderera pa 0.10% yehutano H1150, uye 0.05% yehutano H900.

| Zviyero zve17-4PH Stainless Simbi |

17-4PH simbi isina tsvina inoenderana neyakasiyana siyana zviyero zvepasirese uye zvakatemwa, kuve nechokwadi chekuvimbika kwemhando uye kushanda mumaindasitiri akadai seaerospace, simba, uye kugadzirisa makemikari.

| Standard Organisation | Tsanangudzo | Tsanangudzo |

|---|---|---|

| ASTM | ASTM A564 / A564M | Chiyero chekupisa-kukungurutswa uye kutonhora-kupedzwa-kuomesa zera-kuomesa simbi isina simbi nemaumbirwo |

| ASTM A693 | Tsanangudzo yekunaya-kuomesa simbi isina simbi ndiro, sheet, uye strip | |

| ASTM A705 / A705M | Tsanangudzo yekugadzira kunaya kwemvura-kuomesa simbi uye inodzivirira kupisa simbi | |

| ASME | ASME SA564 / SA693 / SA705 | Yakaenzana kumanikidza mudziyo kodhi zvirevo |

| AMS (Muchadenga) | AMS 5643 | Aerospace spec yebha, waya, forgings, uye mhete mu17-4PH mhinduro-yakarapwa uye yakwegura. |

| AMS 5622 | Ndiro, pepa, uye mitsetse | |

| EN / DIN | EN 1.4542 / DIN X5CrNiCuNb16-4 | Kudanwa kweEuropean kwe17-4PH ine yakafanana kuumbwa uye zvivakwa |

| UNS | UNS S17400 | Unified Numbering System kudanwa |

| ISO | ISO 15156-3 | Kukodzera kushandiswa mumidziyo yemafuta munzvimbo dzakaoma gasi |

| NACE | MR0175 | Zvinhu zvinodikanwa zvekuramba sulfide kushushikana kutsemuka |

| Sei Tisarudze: |

1. Unogona kuwana zvinhu zvakakwana maererano nezvinodiwa zvako pamutengo wakaderera.

2. Isu tinopawo Reworks, FOB, CFR, CIF, uye mitengo yekutumira pamusuwo kumasuo. Tinokupa zano kuti uite dhiri yekutumira iyo inove ine mari shoma.

3. Zvishandiso zvatinopa zvinonyatso zivikanwa, kubva pazvitupa zvekuongorora zvinhu kusvika kune yekupedzisira dimensional statement.(Mishumo icharatidza pane zvinodiwa)

4. inovimbisa kupa mhinduro mukati memaawa makumi maviri nemana (kazhinji muawa imwe chete)

5. Unogona kuwana dzimwe nzira dzemasheya, kutakura zvigayo nekuderedza nguva yekugadzira.

6. Isu takazvipira zvizere kune vatengi vedu. Kana zvisingabviri kuzadzisa zvaunoda mushure mekuongorora zvese zvingasarudzwa, isu hatizokutsause nekuita zvipikirwa zvenhema izvo zvinogadzira hukama hwakanaka hwevatengi.

| SAKY STEEL'S Hunhu Simbiso (inosanganisira zvose Zvinoparadza uye Zvisingaparadzi) |

1. Visual Dimension Test

2. Mechanical bvunzo senge tensile, Elongation uye kuderedzwa kwenzvimbo.

3. Ultrasonic test

4. Kemikari yekuongorora kuongorora

5. Kuoma bvunzo

6. Pitting kudzivirira bvunzo

7. Penetrant Test

8. Intergranular Corrosion Testing

9. Kuongorora kwemigumisiro

10. Metallography Experimental Test

| Packaging |

1. Kurongedza kwakakosha zvakanyanya muchiitiko chekutumira kune dzimwe nyika uko kutakurwa kunopfuura nemumatanho akasiyana-siyana kuti usvike kwaunoenda, saka tinoisa hanya zvakanyanya maererano nekurongedza.

2. Saky Steel inorongedza zvinhu zvedu nenzira dzakawanda zvichienderana nezvigadzirwa. Isu tinorongedza zvigadzirwa zvedu nenzira dzakawanda, senge,

17-4PH, 630 uye X5CrNiCuNb16-4 / 1.4542 inopiwa nenzira yemapuranga akatenderera, mapepa, mbariro dzakapfava uye tambo inotonhora. Nyaya yacho inoshandiswa zvakanyanya muaerospace, marine, bepa, simba, kumahombekombe uye maindasitiri ezvekudya kune inorema-basa muchina zvikamu, bushings, turbine blades, couplings, screws, drive shafts, nzungu, yekuyeresa michina.

1. Aerospace Industry

-

Turbine injini zvikamu (impellers, shafts, housings)

-

Kumhara giya zvikamu

-

Fasteners (mabhaudhi, nzungu) uye zvimiro zvekubatanidza

-

Hydraulic system components

2. Indasitiri yeOiri neGasi

-

Zvishandiso zveDownhole (zvibooreso, zvigaro zvevharuvhu, pombi fittings)

-

Zvikamu zvevharuvhu isingadziviriri

-

Oilfield midziyo yemidziyo (pombi shafts, dzimba, zvindori zvekuisa chisimbiso)

3. Chemical Processing Indasitiri

-

Mapombi nemavharuvhu anoshandiswa munzvimbo dzine acidic

-

Zvinopisa kupisa uye midziyo yekumanikidza

-

Reactors uye agitator shafts

-

Fittings for storage tanks

4. Kugadziriswa Kwekudya & Zvishandiso Zvekurapa

-

Chikafu-giredhi molds uye dhiraivha zvikamu

-

Zvikamu zve-high-pressure sterilizers

-

Zvishandiso zvekuvhiya uye zviridzwa zvekurapa (certification inodiwa)

-

Zvikamu zvekurapa kudzvinyirira kudzora masisitimu

5. Marine uye Offshore Engineering

-

Propeller shafts uye propulsion magungano

-

Mvura yegungwa pombi shafts uye yekuisa chisimbiso zvikamu

-

Fasteners uye zvigadziriso zvinongedzo muzvikepe zvengarava

-

Zvinhu zvinodzivirira Corrosion kumapuratifomu ekumahombekombe

6. Nuclear uye Power Generation

-

Fasteners for nuclear reactor structures

-

Tube bundle inotsigira zvekutsinhanisa kupisa

-

Hydraulic valve rods uye miviri yepombi

-

High-tembiricha valve zvikamu

7. Mold uye Tooling Indasitiri

-

Injection mold frames

-

High-simba kugadzira shafts uye zvinotsigira

-

Tungamira zvigaro uye mabhushi ekudhinda molds

8. General Machinery & Automation

-

Zvekufambisa zvinhu zvakaita segiya shafts, couplings, uye spindles

-

Mechanical njanji uye yekumisa tsvimbo mune otomatiki masisitimu

-

Industrial hydraulic piston rods