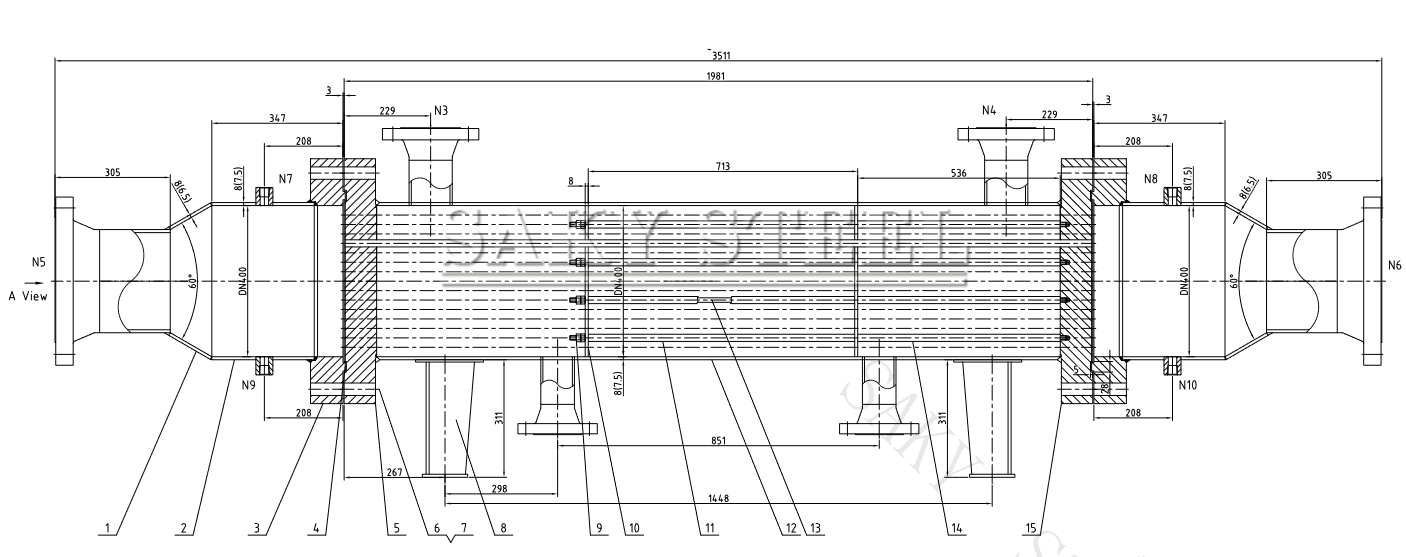

Shell Tube Heat Exchanger

Short Description:

A Shell Tube Heat Exchanger is an efficient industrial device used to transfer heat between two fluids, typically in chemical, power, and HVAC systems.

Heat Exchanger:

A heat exchanger is a device designed to efficiently transfer heat between two or more fluids (liquid, gas, or both) without them mixing. It is commonly used in heating, cooling, or energy recovery processes across industries such as power generation, chemical processing, and HVAC systems. Heat exchangers come in various designs, such as shell and tube, plate, and air-cooled, each optimized for different applications to maximize energy transfer and improve efficiency.

Specifications Of Tubular Heat Exchanger:

| Grade | 304,316,321 etc. |

| Specifications | ASTM A 213,ASTM A249/ ASME SA 249 |

| Condition | Annealed and Pickled, Bright Annealed, Polished, Cold Drawn, MF |

| Length | Customized |

| Technique | Hot rolled, Cold rolled, Cold drawn, Extrusion Tube |

| Mill Test Certificate | EN 10204 3.1 or EN 10204 3.2 |

Shell and Tube Heat Exchanger Test

Penetration Testing.

What are Heat Exchangers?

In fixed-type heat exchangers, the tube sheets are fully welded to the shell and function as shell flanges, making them suitable for applications where preventing the mixing of the two fluids is essential. In contrast, floating-type heat exchangers feature a removable tube bundle, allowing for easy cleaning of both the outer and inner surfaces of the tubes and shell. In ‘U’-shaped shell and tube heat exchangers, the tubes are bent into a ‘U’ shape and attached to a single tube sheet through mechanical rolling. These designs have removable shells and tubes to facilitate maintenance. Corrugated heat exchangers, on the other hand, use corrugated tubes to enhance heat transfer efficiency compared to smooth-tube exchangers.

Heat Exchanger Sealing and Testing Methods

The sealing integrity of heat exchangers is crucial, as it directly affects the efficiency, safety, and reliability of the equipment. Good sealing prevents fluid leakage, ensures proper operation of the heat exchanger, and enhances heat transfer efficiency.

1.Pressure Testing: Before commissioning or during regular maintenance, apply pressure to check sealing performance. If pressure drops during testing, it may indicate leakage.

2.Gas Leak Detection: Use gas leak detectors (such as helium or nitrogen) to inspect the heat exchanger for any signs of gas leakage.

3.Visual Inspection: Regularly check the condition of sealing components for signs of wear, such as cracks or aging, and replace them promptly if necessary.

4.Temperature Variation Monitoring: Monitor the temperature changes in the heat exchanger; abnormal temperature fluctuations may indicate leakage or sealing failure.

Common Types of Heat Exchangers

1.Shell and Tube Heat Exchangers: Widely used in commercial HVAC systems, these heat exchangers consist of a series of tubes housed within a shell. The hot fluid flows through the tubes, while the cold fluid circulates around them within the shell, enabling effective heat transfer.

2.Plate Heat Exchangers: This type employs a stack of metal plates with alternating raised and recessed sections. The hot and cold fluids pass through separate channels formed by the gaps between the plates, which enhances heat transfer efficiency due to the increased surface area.

3.Air-to-Air Heat Exchangers: Also referred to as heat recovery ventilation units, these exchangers facilitate heat transfer between exhaust and supply airstreams. They extract heat from stale air and transfer it to incoming fresh air, which helps lower energy consumption by pre-conditioning the incoming air.

Why Choose us ?

• You can get the perfect material according to your requirement at the least possible price.

• We also offer Reworks, FOB, CFR, CIF, and door to door delivery prices. We suggest you to do deal for shipping which will be quite economical.

• The materials we provide are completely verifiable, right from raw material test certificate to the final dimensional statement.(Reports will show on requirement)

• We guarantee to give a response within 24hours(usually in the same hour)

• Provide SGS TUV report.

• We are fully dedicated to our customers. If it will not possible to meet your requirements after examining all options, we will not mislead you by making false promises which will create good customer relations.

• Provide one-stop service.

Fixed Tube Sheet Heat Exchanger Packing:

1. Packing is quite important especially in a case of international shipments in which consignment pass through various channels to reach the ultimate destination, so we put special concern regarding packaging.

2. Saky Steel's pack our goods in numerous ways based on the products. We pack our products in multiple ways, such as,