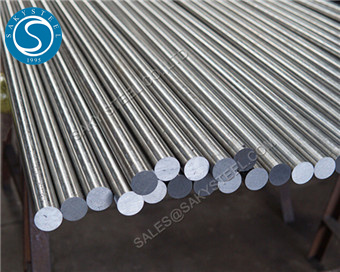

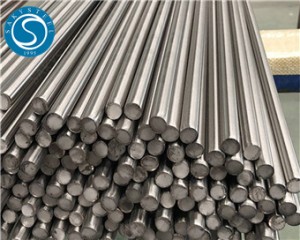

S31254 Steel Bar

Short Description:

S31254 offers outstanding corrosion resistance in various corrosive media, including those with high chloride content.

UT Inspection Automatic S31254 bar:

S31254, also known as 254 SMO or 6MO, is a high-alloy austenitic stainless steel with exceptional corrosion resistance, especially in aggressive and corrosive environments.S31254 offers outstanding corrosion resistance in various corrosive media, including those with high chloride content.Despite its high alloy content, S31254 maintains good ductility and formability.S31254 is well-suited for use in seawater desalination plants.Typically supplied in the solution-annealed condition. Heat treatment is generally not required for S31254 stainless steel.S31254 exhibits good weldability. Common welding methods such as shielded metal arc welding (SMAW), gas tungsten arc welding (GTAW/TIG), and gas metal arc welding (GMAW/MIG) can be used.

Specifications of S31254 steel bar:

| Grade | S32760 S31254 S20910 |

| Specifications | ASTM A276 |

| Length | 2.5M,3M,6M & Required Length |

| Diameter | 4.00 mm to 500 mm |

| Size | 6 mm to 120 mm |

| Thickness | 100 to 6000 mm |

| surface | Bright, Black, Polish |

| Type | Round, Square, Hex (A/F), Rectangle, Billet, Ingot, Forging Etc. |

| Raw Materail | POSCO, Baosteel, TISCO, Saky Steel, Outokumpu |

S31254 Bar Equivalent grades:

| Grade | UNS | Werkstoff Nr. |

| S31254 | S31254 | 1.4547 |

S31254 Bar Chemical Composition:

| Grade | C | Si | Mn | S | P | Cr | Mo | Ni | Cu |

| S31254 | 0.02 | 0.08 | ≤1.0 | ≤0.01 | ≤0.03 | 19.5~20.50 | 6.0-6.5 | 17.5-18.5 | 0.50-1.0 |

S31254 Bar Mechanical & Physical Properties:

| Density | Melting Point | Yield Strength (0.2%Offset) | Tensile Strength | Elongation |

| 8.0 g/cm3 | 1320-1390 ℃ | 300 | 650 | 35% |

Why Choose Us:

1. You can get the perfect material according to your requirement at the least possible price.

2. We also offer Reworks, FOB, CFR, CIF, and door to door delivery prices. We suggest you to do deal for shipping which will be quite economical.

3. The materials we provide are completely verifiable, right from raw material test certificate to the final dimensional statement.(Reports will show on requirement)

4. We guarantee to give a response within 24hours(usually in the same hour)

5. Provide SGS TUV report.

6. We are fully dedicated to our customers. If it will not possible to meet your requirements after examining all options, we will not mislead you by making false promises which will create good customer relations.

7.Provide one-stop service.

8.Our products come directly from the manufacturing factory, ensuring original quality and eliminating additional costs associated with intermediaries.

9.We commit to providing prices that are highly competitive, allowing you to enjoy significant cost advantages without compromising on quality.

10.To meet your needs promptly, we maintain ample stock, ensuring you can access the products you require at any time without delays.

SAKY STEEL'S Quality Assurance

1. Visual Dimension Test

2. Mechanical examining like tensile, Elongation and reduction of area.

3. Impact analysis

4. Chemical examination analysis

5. Hardness test

6. Pitting protection test

7. Penetrant Test

8. Intergranular Corrosion Testing

9. Roughness Testing

10. Metallography Experimental Test

SAKY STEEL'S Packaging:

1. Packing is quite important especially in a case of international shipments in which consignment pass through various channels to reach the ultimate destination, so we put special concern regarding packaging.

2. Saky Steel's pack our goods in numerous ways based on the products. We pack our products in multiple ways, such as,