Rolled Ring Forging

Short Description:

Rolled ring forging is a metalworking process that produces strong, durable rings with various applications across multiple industries.

Rolled Ring Forging:

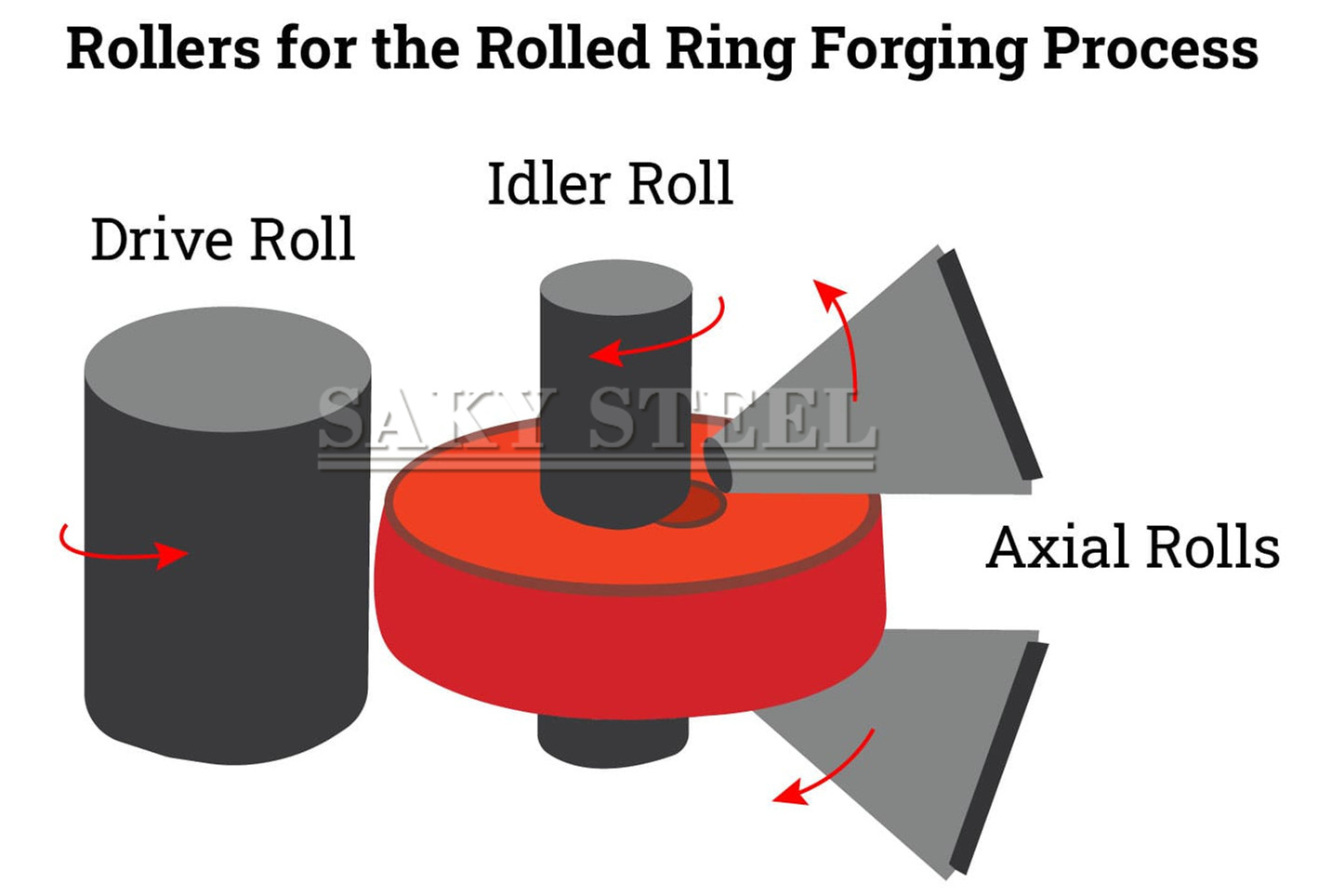

Seamless forged rings are created through a process known as ring rolling. This process starts with a circular metal preform, which is pierced using open die forging to create a "ring blocker." The ring blocker is then reheated to the appropriate temperature for its material grade. Once heated, it is positioned over a mandrel. The mandrel is then moved to a drive roll, also called a king roll, which rotates under pressure. This pressure reduces the wall thickness of the ring, while simultaneously increasing its inner and outer diameters.

Specifications Of Seamless Rolled Ring Forging:

| Grade | 304,316,321 etc. |

| Size | Customized |

| Surface | Polishing, sandblasting, electroplating, etc |

| Raw Materail | POSCO, Baosteel, TISCO, Saky Steel, Outokumpu |

What is Rolled Ring Forging?

Rolled ring forging is a metalworking technique that starts with a circular, preformed metal piece, which is upset and pierced to create a doughnut-like shape. This torus-shaped piece is then heated to a temperature above its recrystallization point and placed onto a mandrel or idler.The idler directs the pierced torus towards a drive roller, which uniformly rotates and applies pressure to reduce the wall thickness while expanding the inner and outer diameters. This process results in the formation of a seamless rolled ring.Seamless metal rings produced through rolled ring forging can vary in size and are commonly used in machine tools, turbines, pipes, and pressure vessels. This forging method significantly enhances the mechanical properties of the metal, preserving its grain structure while shaping it.

Why Choose us ?

• You can get the perfect material according to your requirement at the least possible price.

• We also offer Reworks, FOB, CFR, CIF, and door to door delivery prices. We suggest you to do deal for shipping which will be quite economical.

• The materials we provide are completely verifiable, right from raw material test certificate to the final dimensional statement.(Reports will show on requirement)

• We guarantee to give a response within 24hours(usually in the same hour)

• Provide SGS TUV report.

• We are fully dedicated to our customers. If it will not possible to meet your requirements after examining all options, we will not mislead you by making false promises which will create good customer relations.

• Provide one-stop service.

Our Services

1.Quenching and tempering

2.Vacuum heat treating

3.Mirror-polished surface

4.Precision-milled finish

4.CNC machining

5.Precision drilling

6.Cut into smaller sections

7.Achieve mold-like precision

Packing:

1. Packing is quite important especially in a case of international shipments in which consignment pass through various channels to reach the ultimate destination, so we put special concern regarding packaging.

2. Saky Steel's pack our goods in numerous ways based on the products. We pack our products in multiple ways, such as,