Quality Inspection for Stainless Steel Flat Bar Ss316 - A240 tp 316l stainless steel plate – Saky Steel

Quality Inspection for Stainless Steel Flat Bar Ss316 - A240 tp 316l stainless steel plate – Saky Steel Detail:

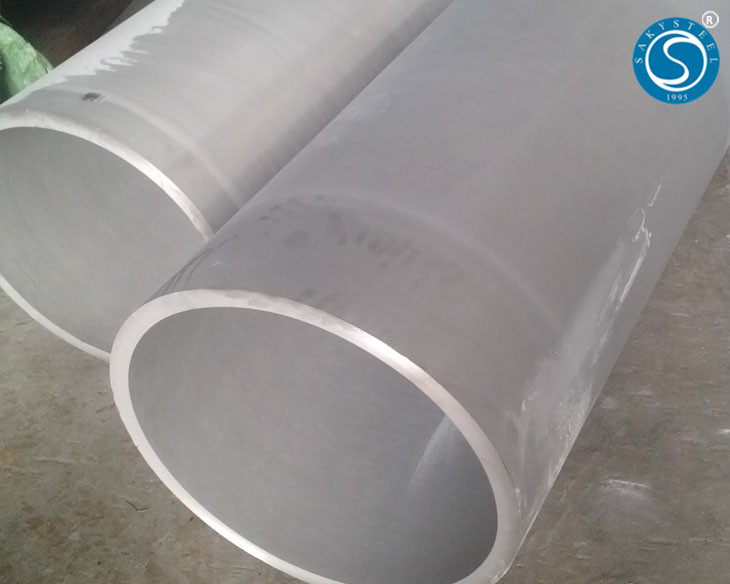

Sakysteel maintains an extensive inventory of stainless steel products, including stainless steel plate, diamond plate, 2B 2D

mirror stainless steel sheet, stainless steel polished sheet, stainless steel flat & expanded sheet, and perforated stainless steel sheet.

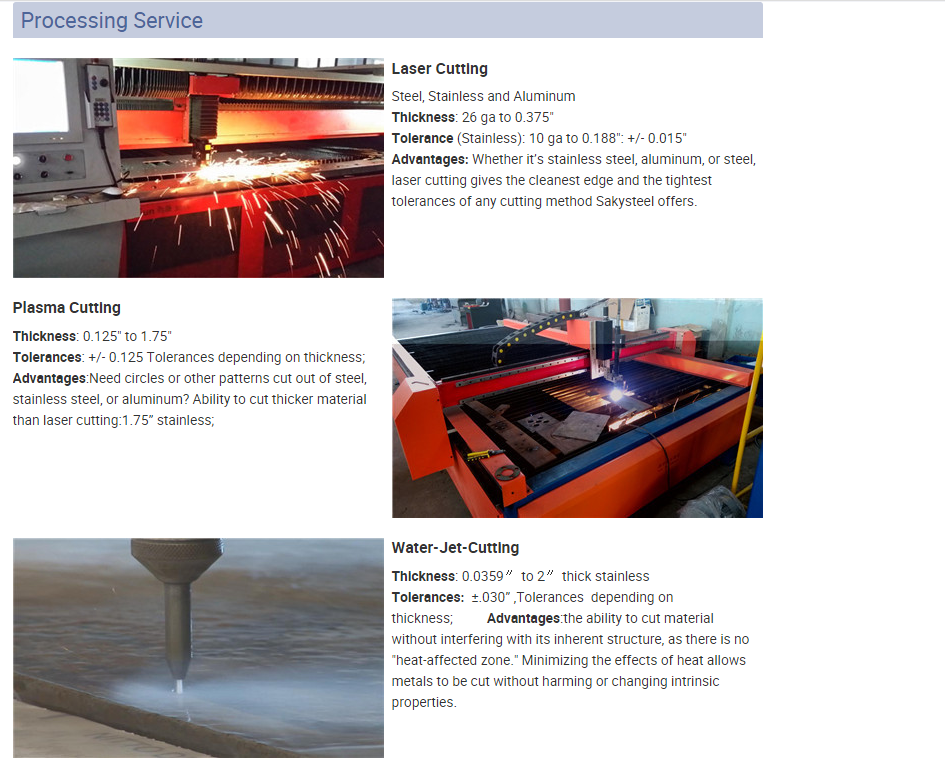

Sakysteel Stainless offers over 20 different grades in stainless steel products. With our mill partnerships, we can also source many hard to find or other non-standards sizes. All stainless steel sheet can be cut to size with our full range of processing services, including shear cutting, waterjet cutting or laser cutting capabilities.

|

Free Sample astm a240 tp 316l stainless steel plate price

|

|||

|

Thickness

|

0.3-3.0mm or Customer’s request

|

||

|

Size

|

1500*3000mm,1500*6000mm,1000*2000mm,1800*6000mm, or as request.

|

||

|

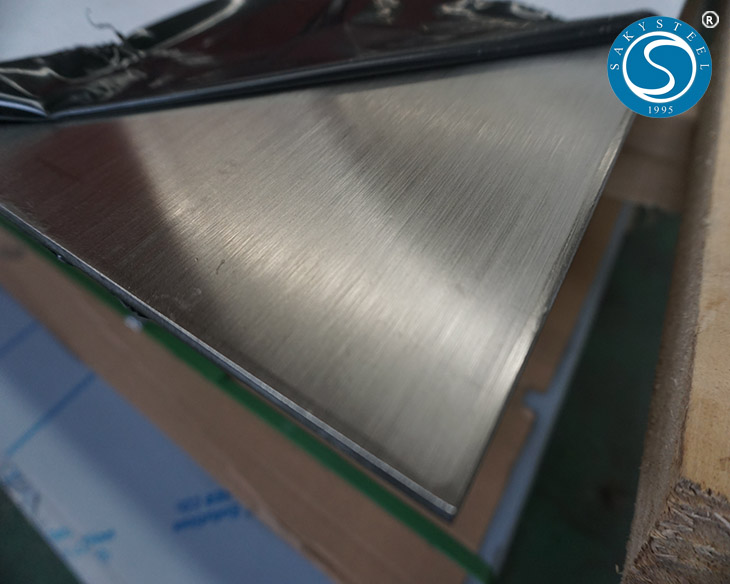

Surface

|

2B,BA,HL,BK,NO.1,No.4, Hairline, Mirror, Etching, PVD Color, Embossed etc

|

||

|

Grade

|

201/201/304/304L/316/316L/420/309S/310S/904L

|

||

|

Origin

|

POSCO,JISCO,TISCO,LISCO,BAOSTEEL etc.

|

||

|

MOQ

|

1 Ton

|

||

|

Application

|

Decoration , construction etc

|

||

|

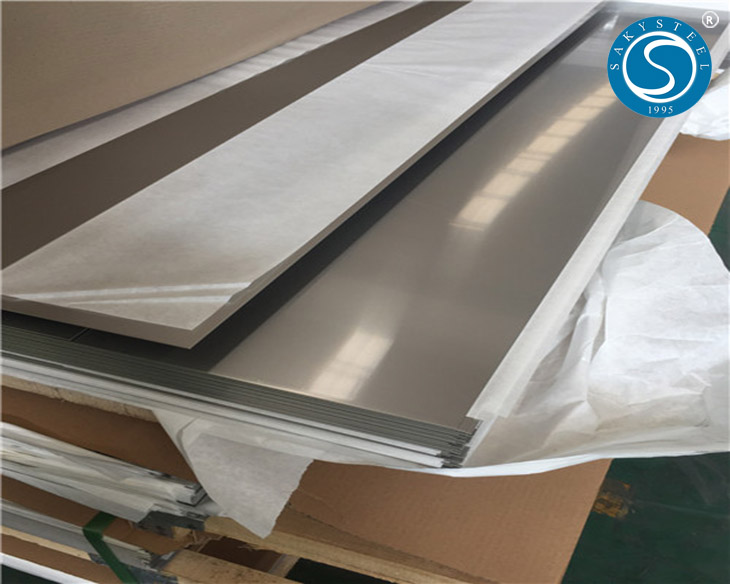

Packing way

|

PVC+ waterproof paper + strong sea-worthy wooden package

|

||

|

Chemical Component

|

|||

|

Grade

|

STS304

|

STS316

|

STS430

|

|

Elong

|

Above 40

|

30MIN

|

Above 22

|

|

Hardness

|

≤200HV

|

≤200HV

|

Below 200

|

|

Cr(%)

|

18-20

|

16-18

|

16-18

|

|

Ni(%)

|

8-10

|

10-14

|

≤0.6

|

|

C(%)

|

≤0.08

|

≤0.07

|

≤0.12

|

Sakysteel Stainless steel Sheet Finish (According to ASTM 480)

No. 2D - A smooth, non-reflective cold-rolled annealed and pickled or descaled finish.

No. 2B - A smooth, moderately reflective cold-rolled annealed and pickled or descaled finish typically produced by imparting a final light cold-rolled pass using [large diameter] polished rolls.

Bright Annealed [BA] Finish- A smooth, bright, reflective finish typically produced by cold rolling followed by annealing in a protective atmosphere so as to prevent oxidation and scaling during annealing.

No. 3 Finish is characterized by short, coarse, parallel polishing lines, which extend uniformly along the length of the coil.

No.4 Finish is characterized by short, parallel polishing lines, which extend uniformly along the length of the coil. It is obtained by mechanically polishing a No. 3 finish with gradually finer abrasives.

No.7 Finish has a high degree of reflectivity and a mirror-like appearance. A No. 4 finish that has been polished to 320-grit is buffed for up to 10 minutes but existing grit lines are not removed. The remnants of fine polishing lines can generally seen by an observer standing several feet from a panel.

No.8 Finish It is produced in the same manner as the No. 7 finish except that the buffing is continued for an additional five to ten minutes. In comparison to a No. 7 finish, the grit lines are much less visible, but they can be seen if the finish is examined closely. The resulting finish is mirror-like but not a perfect mirror.

PE FILM DETAILS

- Laser PVC: Poli-film, Novancel

- 70 /100 Micron Laser PVC

- Single/Double 70 Micron Black&white PVC.

Product detail pictures:

Related Product Guide:

Stainless Steel Bars – Production, Importance, and Uses

Stainless Steel Bar Tops In the Great British Pub

We rely upon strategic thinking, constant modernisation in all segments, technological advances and of course upon our employees that directly participate in our success for Quality Inspection for Stainless Steel Flat Bar Ss316 - A240 tp 316l stainless steel plate – Saky Steel, The product will supply to all over the world, such as: Auckland , Finland , Nepal , We warmly welcome domestic and overseas customers to visit our company and have business talk. Our company always insists on the principle of "good quality, reasonable price, the first-class service". We have been willing to build long-term, friendly and mutually beneficial cooperation with you.

This company has the idea of "better quality, lower processing costs, prices are more reasonable", so they have competitive product quality and price, that's the main reason we chose to cooperate.