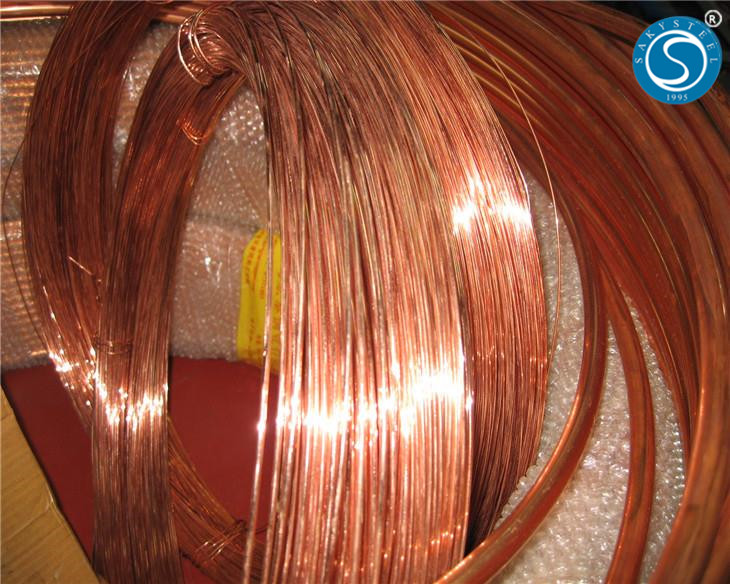

OEM/ODM Factory Stainless Steel Bar Hollow - Copper Brass Wire – Saky Steel

OEM/ODM Factory Stainless Steel Bar Hollow - Copper Brass Wire – Saky Steel Detail:

| The Chemical Composition of High Copper Alloys in ASTM | |||||||||

| Copper Alloy No | Cu(inclAg) | Fe | Sn | Ni | Co | Cr | Si | Be | Pb |

| C19024 | Rem. | .02 | .20-.8 | .10-.6 | – | – | – | – | .01 |

| C19025 | Rem. | .10 | .7-1.1 | .8-1.2 | – | – | – | – | – |

| C19027 | Rem. | .10 | 1.20-1.80 | .50-1.20 | – | – | – | – | – |

| C19030 | Rem. | .10 | 1.0-1.5 | 1.5-2.0 | – | – | – | – | .02 |

| C19040 | 96.1min | .06 | 1.0-2.0 | .7-.9 | – | – | .010 | – | .02 |

| C19050 | 95.1min | .05-.15 | .8-2.5 | .50-1.0 | – | – | – | – | .02 |

| C19100 | Rem. | .20 | – | .9-1.3 | – | – | – | – | .10 |

| C19140 | Rem. | .05 | .05 | .8-1.2 | – | – | – | – | .40-.8 |

| C19150 | Rem. | .05 | .05 | .8-1.2 | – | – | – | – | .50-1.0 |

| C19160 | Rem. | .05 | .05 | .8-1.2 | – | – | – | – | .8-1.2 |

| C19170 | 96.8min | .05-.15 | .8 | .50-1.0 | – | – | .010 | – | .02 |

| Material | Copper, Brass, Bronze and special copper alloy | |

| Grade | ASTM | C10100,C11000,C12200,C21000,C22000,C23000,C24000,C26000, C27000,C26800,C27200,C27400,C28000,C36500,C33000,C35300, C35600,C36000,C38500,C44300,C46400,C52100,C54400,C62300, C65500,C67500,C67600,C86300,C90700,C93200,C95400 etc. |

| G/B | TU1,T2,TP2,H96,H90,H85,H80,H70,H65,H63,H62,H59,HPb63-3,

HPb66-0.5,HPb62-2,HPb62-3,HPb59-3,HSn70-1,HSn62-1,QSn8-0.3, QSn4-4-4,QAl9-4,QSB-1 etc. |

|

| JIS | C 1011,C 1100,C 1220,C3604,C 2100,C 2200,C 2300,C 2400, C 2600,C 2700,C 2680,C 2720,C 2800,C 4430,C 4640,C 5210, C 5441, CAC304 etc | |

| BS | Cu-OFE,C 101,Cu-DHP,CZ 125,CZ 101,CZ 102,CZ 103,CZ 106,CZ 107, CZ 108,CZ 109,CZ 123,CZ 124,CZ 121,CZ 111,CZ 133, Pb 104,CS 101, CuSn10P etc. | |

| DIN/ISO | CuZn5,CuZn10,CuZn15,CuZn20,CuZn30,CuZn35,CuZn33,CuZn36,

CuZn37,CuZn40,CuZn40Pb,CuZn37Pb2,CuZn36Pb3,CuZn39Pb3, CuZn28Sn1,CuZn38Sn1,CuSn8,CuSn4Pb4Zn3,CuSi3Mn,CuZn25Al5, CuSn10, CuSn7Zn3Pb7 etc. |

|

| Shape | Round, Square, Flat, Hexagon, Oval, Half-round or Customized | |

| Dimension | Bar/Rod | Standard(Diameter 5-160 mm) or Customized |

| Wire | Standard(Diameter 0.02-6 mm) or Customized | |

| Plate/Sheet | Standard(T 0.2-50 mm/W 200-3000 mm/L 6000 mm) or Customized | |

| Strip | Standard(T 0.05-1.5 mm/W 20-600 mm/L 20000 mm) or Customized | |

| Tube/Pipe | Standard(OD 3-360mm/Wall thickness 0.5-50 mm) or Customized | |

| Standard | GB/T,JIS,ASTM, ISO, DIN, BS, NF etc. | |

| Hardness | 1/16 hard,1/8 hard,3/8 hard,1/4 hard,1/2hard,full hard. | |

| Place of origin | Zhejiang Province, China | |

| Package | Plastic film + Wooden case or as per customer requirement | |

| Surface | Polished,bright,oiled,hair line,brush,mirror,or as required | |

| MOQ | Negotiable | |

| Deliver time | According to order’s quantity. | |

| Shipment | By sea, by air, DHL, UPS, FedEx etc. or as required | |

| Application | Electric light industry, machinery manufacturing, Building industry ,defense industry, and other fields Manufacturing industrial | |

| Bronze Material, phosphor bronze material ,Cast Bronze Materials, Tin bronze Materials | |||||

| Grade standard | PERFORMANCE | APPLICATION | |||

| ASTM | ISO | BS | GB/QB | ||

| C54400 | CuSn4Zn4Pb4 | QSn4-4-4 | Good cutting drilling performance, high strength,Free cut, | For the aerospace, automotive, heavy machinery and other industrial precision parts and components in such as bushings, disc, sleeve liner, such as automatic lathes, CNC lathe processing products. | |

| C51100 | CuSn4 | PB101 | QSn4-0.3 | 1,Excellent cold working performance | Connectors for aerospace, computer accessories, instrument springs, arc brazing material, fastener, elastic component. |

| C51000 | CuSn5 | PB102 | 2,High strength high elasticity | ||

| C51900 | CuSn6 | PB103 | QSn6.5-0.1 | 3,Good electrical conductivity | |

| C52100 | CuSn8 | PB104 | QSn8-0.3 | 4,Excellent wear resistance | |

| C62300 | CuAl10Fe3 | CA103 | QAl9-4 | High strength, good anti-friction quality, | Widely used in machinery, ships, aviation and manufacturing sectors such as bearings, bushings, pump parts, gear turbo, seat, bolts, nuts, structural parts. |

| C63200 | CuAl10Fe3Mn2 | CA105 | QAl10-3-1.5 | good corrosion resistance in the atmosphere, fresh water, seawater, | |

| C63000 | CuAl10Ni5Fe4 | CA104 | QAl10-4-4 | hot processing, can be welding, brazing is not easy. | |

| C83600 | GCuPb5Sn5Zn5 | LG2 | ZQSnD5-5-5 | Good wear resistance and corrosion resistance, easy to process, casting performance and good air tightness. | Construction machinery industry:hydraulic pump/motor,synchronizer loop,bearing,bushing,gear,mold standard parts,engine wear resisting precision components,turbine. |

| C90700 | GCuSn10P | PB1 – PB4 | ZQSnD10-1 | High hardness, excellent wear resistance, good casting | |

| C93200 | CuSn7Zn4Pb7 | QSn7-7-3 | Performance and machinability, | ||

| C95200 | GCuAl10Fe3 | ZQAlD9-4 | |||

| C65500 | CuSi3Mn1 | ||||

Hot Tags: copper brass wire manufacturers, suppliers, price, for sale

Product detail pictures:

Related Product Guide:

How to Save Time and Cost With a 316 Stainless Steel Bar

Stainless Steel Bar Tops In the Great British Pub

We always think and practice corresponding to the change of circumstance, and grow up. We aim at the achievement of a richer mind and body and the living for OEM/ODM Factory Stainless Steel Bar Hollow - Copper Brass Wire – Saky Steel, The product will supply to all over the world, such as: Seychelles , Slovenia , Swaziland , Our products have won an excellent reputation at each of the related nations. Because the establishment of our firm. we have insisted on our production procedure innovation together with the most recent modern day managing method, attracting a sizable quantity of talents within this industry. We regard the solution good quality as our most vital essence character.

Staff is skilled, well-equipped, process is specification, products meet the requirements and delivery is guaranteed, a best partner!

Write your message here and send it to us