OEM/ODM Factory High Tensile Spring Steel Wire - Stainless Steel Pipe Polished – Saky Steel

OEM/ODM Factory High Tensile Spring Steel Wire - Stainless Steel Pipe Polished – Saky Steel Detail:

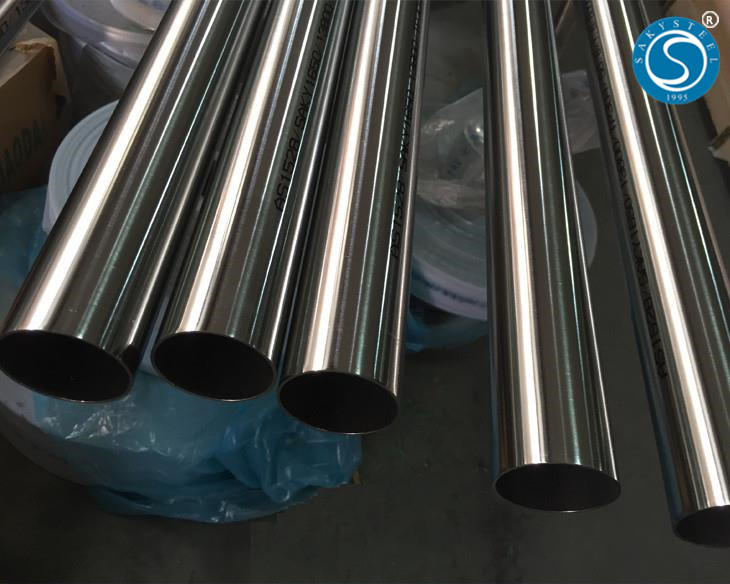

Specifications of stainless steel pipe polished

| 1. Product | Stainless Steel Welded Pipe |

| 2. Material | 201,202,301,302,304,309,310S,316L,321,347,410,430,409Letc. |

| 3. Standard | ASTM, ASME, DIN, EN, ISO,JIS, GOST, etc. |

| 4. Size range | OD: from 6mm to 1219mm (NPS from 1/8” to 40”) |

| WT: from 0.7mm to 38mm (Schedule from 5S to XXS) | |

| Length: fix length or un-fix length, Max 30meters | |

| 5. Produce process | welded,hot bending;resistance welding;Thermal expansion etc. |

| 6. Surface | 2B,Pickled,180G, 320G, Satin, Hairline,400G, 500G, 600G |

| ,800G, Mirror finish | |

| 7. Marking | SAKY, GRADE, Seamless, Standard, Size, Heat NO. |

| 8. Package | Bundles with waterproof cloth outside. |

| or plywood box. | |

| 9. Length | 5.8m,6m,12m or as required |

| Typical mechanical properties for 304 stainless steel alloys | |||||

| Grade | Tensile Strength (MPa) | Compression Strength (MPa) | Proof Stress 0.2% (MPa) | Elongation A5 (%) | Hardness Rockwell B |

| 304 | 520-720 | 210 | 210 | 45 Min | 92 |

| 304L | 500-670 | 200 | 45 Min | ||

| 304H | 520-720 | 210 | 45Min | ||

Grades of stainless steel pipe polished:

| Type | Grade | Grade | Chemical Component % | ||||

| Austenitic stainless steel | C | Cr | Ni | Mn | |||

| 201 | 1Cr17Mn6Ni5N | =0.15 | 16.00-18.00 | 3.50-5.50 | 5.50-7.50 | ||

| 201L | 03Cr17Mn6Ni5N | =0.030 | 16.00-18.00 | 3.50-5.50 | 5.50-7.50 | ||

| 202 | 1Cr18Mn8Ni5N | =0.15 | 17.00-19.00 | 4.00-6.00 | 7.50-10.00 | ||

| 204 | 03Cr16Mn8Ni2N | =0.030 | 15.00-17.00 | 1.50-3.50 | 7.00-9.00 | ||

| 1Cr18Mn10Ni5Mo3N | =0.10 | 17.00-19.00 | 4.00-6.00 | 8.50-12.00 | |||

| 2Cr13Mn9Ni4 | 0.15-0.25 | 12.00-14.00 | 3.70-5.00 | 8.00-10.00 | |||

| 2Cr15Mn15Ni2N | 0.15-0.25 | 14.00-16.00 | 1.50-3.00 | 14.00-16.00 | |||

| 1Cr18Mn10Ni5Mo3N | =0.15 | 17.00-19.00 | 4.00-6.00 | 8.50-12.00 | |||

| 301 | 1Cr17Ni7 | =0.15 | 16.00-18.00 | 6.00-8.00 | =2.00 | ||

| 302 | 1Cr18Ni9 | =0.15 | 17.00-19.00 | 8.00-10.00 | =2.00 | ||

| 303 | Y1Cr18Ni9 | =0.15 | 17.00-19.00 | 8.00-10.00 | =2.00 | ||

| 303se | Y1Cr18Ni9Se | =0.15 | 17.00-19.00 | 8.00-10.00 | =2.00 | ||

| 304 | 0Cr18Ni9 | =0.07 | 17.00-19.00 | 8.00-10.00 | =2.00 | ||

| 304L | 00Cr19Ni10 | =0.030 | 18.00-20.00 | 8.00-10.00 | =2.00 | ||

| 304N1 | 0Cr19Ni9N | =0.08 | 18.00-20.00 | 7.00-10.50 | =2.00 | ||

| 304N2 | 0Cr18Ni10NbN | =0.08 | 18.00-20.00 | 7.50-10.50 | =2.00 | ||

| 304LN | 00Cr18Ni10N | =0.030 | 17.00-19.00 | 8.50-11.50 | =2.00 | ||

| 305 | 1Cr18Ni12 | =0.12 | 17.00-19.00 | 10.50-13.00 | =2.00 | ||

| 309S | 0Cr23Ni13 | =0.08 | 22.00-24.00 | 12.00-15.00 | =2.00 | ||

| 310S | 0Cr25Ni20 | =0.08 | 24.00-26.00 | 19.00-22.00 | =2.00 | ||

| 316 | 0Cr17Ni12Mo2 | =0.08 | 16.00-18.50 | 10.00-14.00 | =2.00 | ||

| 1Cr18Ni12Mo2Ti6) | =0.12 | 16.00-19.00 | 11.00-14.00 | =2.00 | |||

| 0Cr18Ni12Mo2Ti | =0.08 | 16.00-19.00 | 11.00-14.00 | =2.00 | |||

| 316L | 00Cr17Ni14Mo2 | =0.030 | 16.00-18.00 | 12.00-15.00 | =2.00 | ||

| 316N | 0Cr17Ni12Mo2N | =0.08 | 16.00-18.00 | 10.00-14.00 | =2.00 | ||

| 316N | 00Cr17Ni13Mo2N | =0.030 | 16.00-18.50 | 10.50-14.50 | =2.00 | ||

| 316J1 | 0Cr18Ni12Mo2Cu2 | =0.08 | 17.00-19.00 | 10.00-14.50 | =2.00 | ||

| 316J1L | 00Cr18Ni14Mo2Cu2 | =0.030 | 17.00-19.00 | 12.00-16.00 | =2.00 | ||

| 317 | 0Cr19Ni13Mo3 | =0.12 | 18.00-20.00 | 11.00-15.00 | =2.00 | ||

| 317L | 00Cr19Ni13Mo3 | =0.08 | 18.00-20.00 | 11.00-15.00 | =2.00 | ||

| 1Cr18Ni12Mo3Ti6 | =0.12 | 16.00-19.00 | 11.00-14.00 | =2.00 | |||

| 0Cr18Ni12Mo3Ti | =0.08 | 16.00-19.00 | 11.00-14.00 | =2.00 | |||

| 317J1 | 0Cr18Ni16Mo5 | =0.040 | 16.00-19.00 | 15.00-17.00 | =2.00 | ||

| 321 | 1Cr18Ni9Ti6 | =0.12 | 17.00-19.00 | 8.00-11.00 | =2.00 | ||

| 0Cr18Ni10Ti | =0.08 | 17.00-19.00 | 9.00-12.00 | =2.00 | |||

| 347 | 0Cr18Ni11Nb | =0.08 | 17.00-19.00 | 9.00-13.00 | =2.00 | ||

| XM7 | 0Cr18Ni9Cu3 | =0.08 | 17.00-19.00 | 8.50-10.50 | =2.00 | ||

| XM15J1 | 0Cr18Ni13Si4 | =0.08 | 15.00-20.00 | 11.50-15.00 | =2.00 | ||

| Austenite Ferrite Stainless Steel |

329J1 | 0Cr26Ni5Mo2 | =0.08 | 23.00-28.00 | 3.00-6.00 | =1.50 | =0.035 | =0.030 | 1.00-3.00 | =1.00 | - | - | 2) |

| 1Cr18Ni11Si4AlTi | 0.10-0.18 | 17.50-19.50 | 10.–120.. | =0.80 | =0.035 | =0.030 | - | 3.40-4.00 | - | - | Al 0.10-0.30; Ti 0.40-0.70 | ||

| 00Cr18Ni5MoSi2 | =0.030 | 18.00-19.50 | 4.50-5.50 | 1.00-2.00 | =0.035 | =0.030 | 2.50-3.00 | 1.30-2.00 | - | - | - | ||

| Ferrite Stainless Steel | 405 | 0Cr13Al | =0.08 | 11.50-14.50 | 3) | =1.00 | =0.035 | =0.030 | - | =1.00 | - | - | Al 0.10-0.30 |

| 410L | 00Cr12 | =0.030 | 11.00-13.00 | 3) | =1.00 | =0.035 | =0.030 | - | =1.00 | - | - | - | |

| 430 | 1Cr17 | =0.12 | 16.00-18.00 | 3) | =1.25 | =0.035 | =0.030 | - | =0.75 | - | - | - | |

| 430F | Y1Cr17 | =0.12 | 16.00-18.00 | 3) | =1.00 | =0.035 | =0.15 | 1) | =1.00 | - | - | - | |

| 434 | 1Cr17Mo | =0.12 | 16.00-18.00 | 3) | =1.00 | =0.035 | =0.030 | 0.75-1.25 | =1.00 | - | - | - | |

| 447J1 | 00Cr30Mo2 | =0.010 | 28.50-32.00 | - | =0.40 | =0.035 | =0.030 | 1.50-2.50 | =0.40 | - | =0.015 | - | |

| XM27 | 00Cr27Mo | =0.010 | 25.00-27.50 | - | =0.40 | =0.035 | =0.030 | 0.75-1.50 | =0.40 | - | =0.015 | - |

| Martensite stainless steel | 403 | 1Cr12 | =0.15 | 11.50-13.00 | 3) | =1.00 | =0.035 | =0.030 | - | =0.50 | - | - | - |

| 410 | 1Cr13 | =0.15 | 11.50-13.50 | 3) | =1.00 | =0.035 | =0.030 | - | =1.00 | - | - | - | |

| 405 | 0Cr13 | =0.08 | 11.50-13.50 | 3) | =1.00 | =0.035 | =0.030 | - | =1.00 | - | - | - | |

| 416 | Y1Cr13 | =0.15 | 12.00-14.00 | 3) | =1.25 | =0.035 | =0.15 | 1) | =1.00 | - | - | - | |

| 410J1 | 1Cr13Mo | =0.08-0.18 | 11.50-14.00 | 3) | =1.00 | =0.035 | =0.030 | 0.30-0.60 | =0.60 | - | - | - | |

| 420J1 | 2Cr13 | 0.16-0.25 | 12.00-14.00 | 3) | =1.00 | =0.035 | =0.030 | - | =1.00 | - | - | - | |

| 420J2 | 3Cr13 | 0.26-0.35 | 12.00-14.00 | 3) | =1.00 | =0.035 | =0.030 | - | =1.00 | - | - | - | |

| 420F | Y3Cr13 | 0.26-0.40 | 12.00-14.00 | 3) | =1.25 | =0.035 | =0.15 | 1) | =1.00 | - | - | - | |

| 3Cr13Mo | 0.28-0.35 | 12.00-14.00 | 3) | =1.00 | =0.035 | =0.030 | 0.50-1.00 | =0.80 | - | - | - | ||

| 4Cr13 | 0.36-0.45 | 12.00-14.00 | 3) | =0.80 | =0.035 | =0.030 | - | =0.60 | - | - | - | ||

| 431 | 1Cr17Ni2 | 0.11-0.17 | 16.00-18.00 | 1.50-2.50 | =0.80 | =0.035 | =0.030 | - | =0.80 | - | - | - | |

| 440A | 7Cr17 | 0.60-0.75 | 16.00-18.00 | 3) | =1.00 | =0.035 |

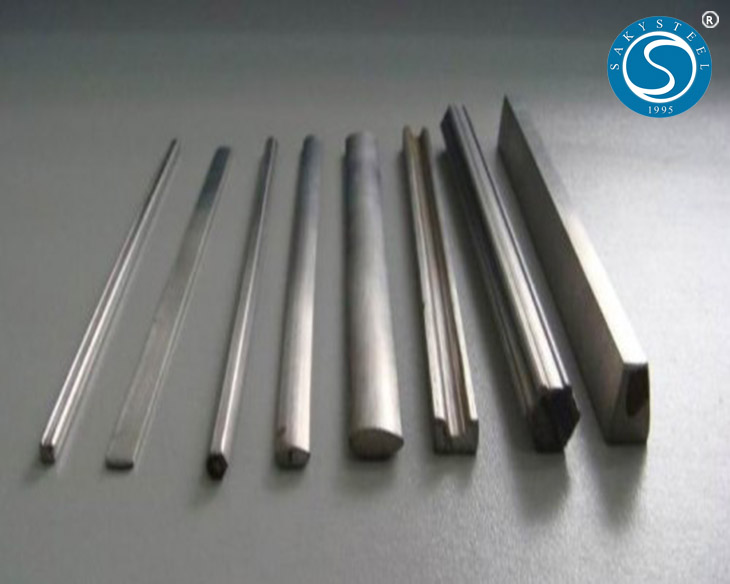

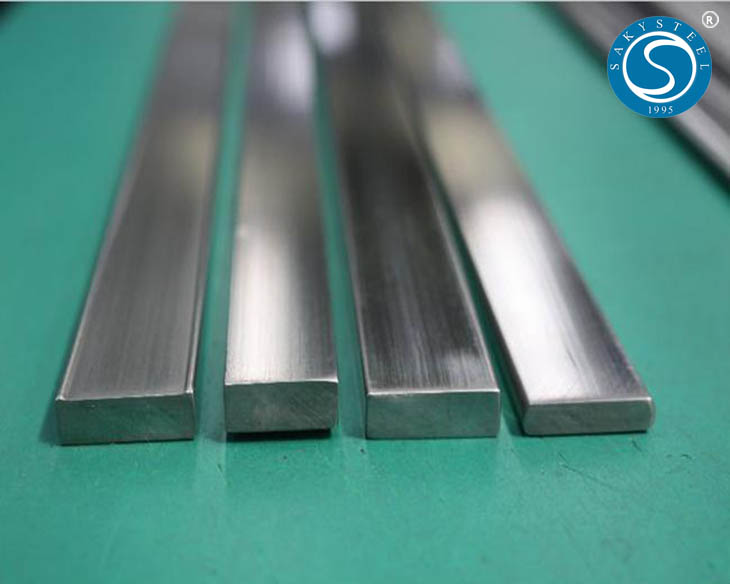

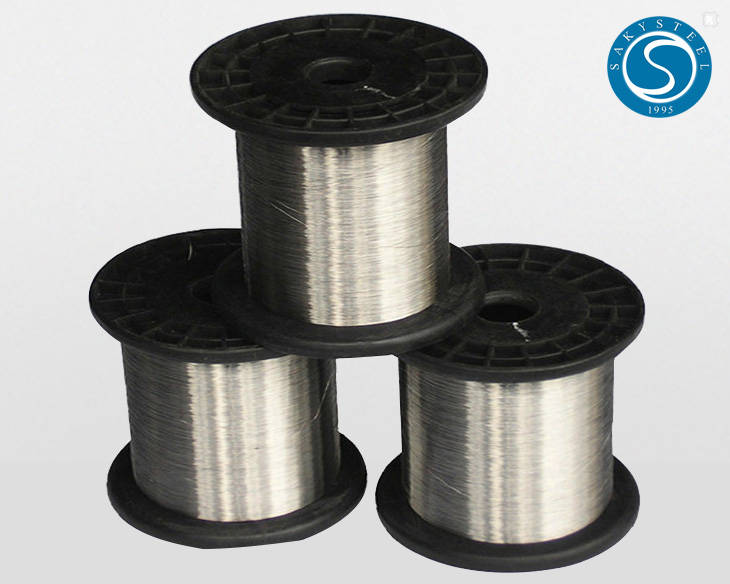

Product detail pictures:

Related Product Guide:

What is Stainless Steel Bar?

How to Save Time and Cost With a 316 Stainless Steel Bar

To meet the customers' over-expected pleasure , now we have our potent staff to offer our greatest general service which includes internet marketing, sales, planning, output, quality controlling, packing, warehousing and logistics for OEM/ODM Factory High Tensile Spring Steel Wire - Stainless Steel Pipe Polished – Saky Steel, The product will supply to all over the world, such as: Plymouth , Turkmenistan , Riyadh , Abiding by our motto of "Hold well the quality and services, Customers Satisfaction", So we give our clients with high quality products and solutions and excellent service. Be sure to feel free to contact us for further information.

This is a very professional wholesaler, we always come to their company for procurement, good quality and cheap.