OEM Factory for Cold Rolled Stainless Steel Bar - Ss 310 Seamless Pipe – Saky Steel

OEM Factory for Cold Rolled Stainless Steel Bar - Ss 310 Seamless Pipe – Saky Steel Detail:

Grade 310S austentic stainless steel bar,SUS310S,EN 1.4841,EN 1.4845

| C% | Si% | Mn% | P% | S% | Cr% | Ni% | N% | Mo% | Ti% |

| =0.08 | =1.50 | =2.0 | =0.045 | =0.030 | 24.0-26.0 | 19.0-22.0 | – | - | – |

| T*S | Y*S | Hardness | Elongation | |

| (Mpa) | (Mpa) | HRB | HB | (%) |

| =520 | =205 | – | – | =40 |

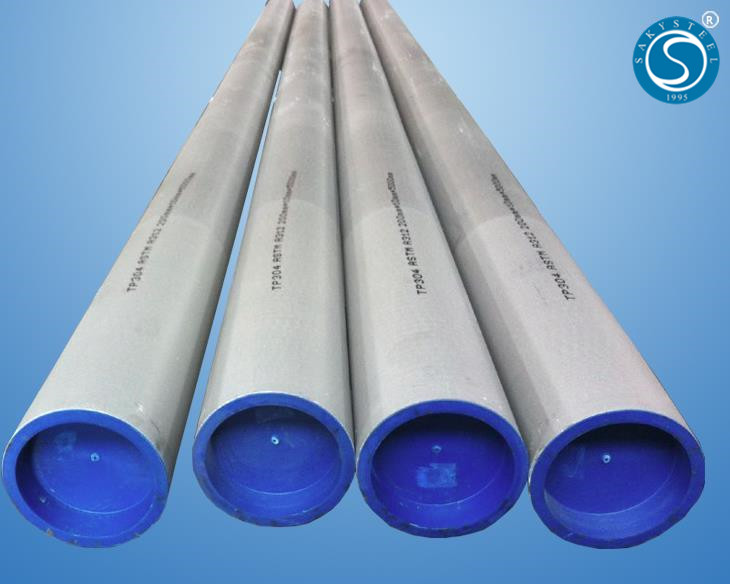

Stainless Steel Seamless Pipe products from Sakysteel:

ss 310 seamless pipe manufacturers ss 310 seamless pipe manufacturers |

ss 310 seamless pipe suppliers ss 310 seamless pipe suppliers |

ss 310 seamless pipe for sale ss 310 seamless pipe for sale |

ss 310 seamless pipe price ss 310 seamless pipe price |

Specifications of ss 310 seamless pipe:

| Production | ss 310 seamless pipe,310 ss pipe,stainless steel pipes,stainless steel tubes,tube ss,ss tube,tube inox,ss pipe |

| Technique | Seamless (Cold Drawn/Cold Rolling) |

| Standard | GB/T 14975-2002,GB/T 14976-2002,GB 13296-2007,GB 9948-2006,GB 5310-95 |

| ASTM A312, ASTM A213, ASTM A269 and ASTM A511, ASTM A789 and ASTM A790 | |

| JIS 3463 and JIS 3459 | |

| DIN 2462, DIN 17458 and DIN 17456 | |

| GOST 9941 | |

| Out Diameter | 9.53mm–1219mm |

| Wall Thickness | SCH10S,SCH40S,SCH80S,SCH160S,1mm~60mm |

| Material | TP304,TP304L,TP304H,TP316,TP316L,TP316Ti,TP309,TP310S,TP314, |

| TP317L,TP321,TP347H,904L,S31803,S32205,S32750 etc. | |

| Length | 1-12m or as customers required |

| Surface treatment |

polishing,annealing,bright annealing and acid pickling |

| Package | 1. Bundle packing. |

| 2. Bevelled end or plain end as buyer’s required. | |

| 3. Marking: as per customer’s requests. | |

| 4. Plastic bag wrapped outside the pipe. | |

| 5. Pack into plywood case. | |

| 6. Plastic caps at ends. |

Chemical composition of ss 310 seamless pipe :

| NO. | STAN DARD |

GRAND | C | Si | Mn | P | S | Cr | Ni | Mo | N | Cu | Ti | Nb |

| 1 | ASTM A312 |

TP304 | =0.08 | =1.0 | =2.0 | =0.045 | = 0.030 |

18.0 -20.0 | 8.0 -11.0 | |||||

| 2 | ASTM A312 | TP304H | 0.04 -0.10 |

=1.0 | =2.0 | =0.045 | = 0.030 | 18.0 -20.0 | 8.0 -11.0 |

|||||

| 3 | ASTM A312 | TPP304L | =0.035 | =1.0 | =2.0 | =0.045 | = 0.030 |

18.0 -20.0 | 8.0 -12.0 |

|||||

| 4 | ASTM A312 |

TP316L | =0.035 | =1.0 | =2.0 | =0.045 | = 0.030 |

16.0 -18.0 | 10.0 -14.0 |

2.00 -3.00 |

||||

| 5 | ASTM A312 | TP316 | =0.08 | =1.0 | =2.0 | =0.045 | = 0.030 | 16.0 -18.0 | 11.0 -14.0 |

2.00 -3.00 | ||||

| 6 | ASTM A312 |

TP317 | =0.08 | =1.0 | =2.0 | =0.045 | = 0.030 | 18.0 -20.0 | 11.0 -14.0 |

3.00 -4.00 | ||||

| 7 | ASTM A312 |

TP317L | =0.035 | =1.0 | =2.0 | =0.045 | = 0.030 | 18.0 -20.0 | 11.0 -15.0 |

3.00 -4.00 | ||||

| 8 | ASTM A312 |

TP321 | =0.03 | =1.0 | =2.0 | =0.045 | = 0.030 |

17.0 -19.0 | 9.0 -12.0 | 5* C+N) ~0.7 |

||||

| 9 | ASTM A312 |

TP347H | 0.04 -0.10 |

=1.0 | =2.0 | =0.045 | = 0.030 |

17.0 -19.0 |

9.0 -12.0 |

8*C ~1.10 |

||||

| 10 | ASTM A789 |

S31803 | =0.03 | =1.0 | =2.0 | =0.030 | = 0.020 | 21.0 -23.0 | 4.50 -6.50 | 2.50 -3.50 |

0.08 -0.20 |

|||

| 11 | ASTM A789 |

904L | =0.02 | =1.0 | =2.0 | =0.045 | = 0.035 |

19.0 -23.0 | 23.0 -28.0 | 4.00 -5.00 | 1.0 -2.0 |

|||

| 12 | ASTM A312 |

TP310S | =0.08 | =1.0 | =2.0 | =0.045 | = 0.030 |

24.0 -26.0 |

19.0 -22.0 |

|||||

| 13 | ASTM A312 |

TP314 | =0.025 | 1.5 -3.0 |

=2.0 | =0.045 | = 0.030 | 23.0 -26.0 | 19.0 -22.0 |

|||||

| 14 | DIN17 458-85 |

1.4301 (304) |

=0.07 | =1.0 | =2.0 | =0.045 | = 0.015 | 17.0 -19.5 |

8.5 -10.5 |

=0.11 | ||||

| 15 | DIN174 58-85 |

1.4306 (304L) |

=0.03 | =1.0 | =2.0 | =0.045 | = 0.015 | 18.0 -20.0 |

10.0 -12.5 |

=0.11 | ||||

| 16 | DIN174 58-85 |

1.4404 (316L) |

=0.03 | =1.0 | =2.0 | =0.045 | = 0.015 | 16.5 -18.5 |

11.0 -14.0 |

2.00 -2.50 |

=0.11 | |||

| 17 | DIN17 458-85 |

1.4401 (316) |

=0.07 | =1.0 | =2.0 | =0.045 | = 0.015 |

16.5 -18.5 |

10.5 -13.5 |

2.00 -2.50 |

=0.11 | |||

| 18 | DIN17 458-85 |

1.4541 (321) |

=0.08 | =1.0 | =2.0 | =0.045 | = 0.015 |

17.0 -19.0 |

9.0 -12.0 |

5*C -0.70 |

||||

| 19 | DIN17 458-85 |

1.4550 (347H) | =0.08 | =1.0 | =2.0 | =0.045 | = 0.015 |

17.0 -19.0 |

9.0 -12.0 |

10*C ~1.00 |

||||

| 20 | DIN17 458-85 |

1.4462 (2205) | =0.03 | =1.0 | =2.0 | =0.035 | = 0.015 |

21.0 -23.0 |

4.5 -6.5 |

2.50 -3.50 |

0.10 -0.22 |

|||

| 21 | DIN17 458-85 |

1.4539 (904L) | =0.02 | =0.70 | =2.0 | =0.035 | = 0.015 |

19.0 -21.0 |

24.0 -26.0 |

4.00 -5.00 |

=0.15 | 1.20 -2.00 |

||

| 22 | DIN17 458-85 |

1.4841 (314) | =0.20 | 1.50 -2.50 |

=2.0 | =0.045 | = 0.030 |

24.0 -26.0 |

19.0 -22.0 |

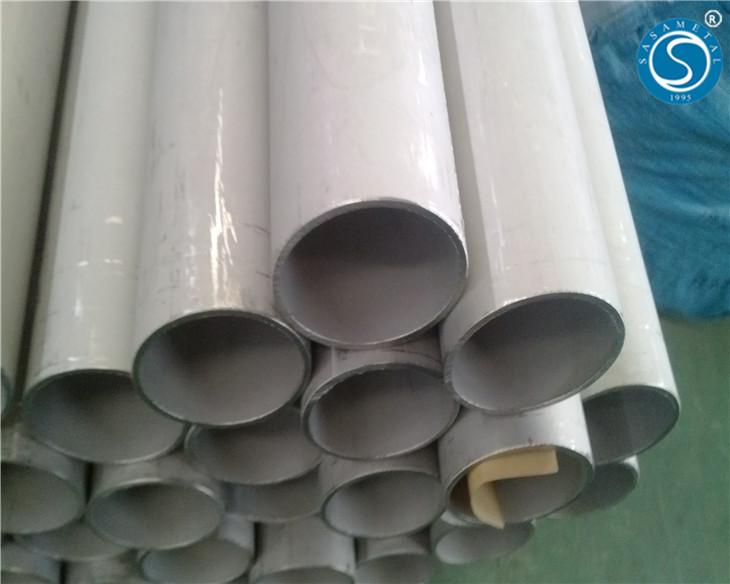

ss 310 seamless pipe Packaging:

Sakysteel ss 310 seamless pipe are packed and labeled according to the regulations and customer’s requests. Great care is taken to avoid any damage which might otherwise be caused during storage or transportation.

310 ss pipe manufacturers 310 ss pipe manufacturers |

310 ss pipe suppliers 310 ss pipe suppliers |

310 ss pipe for sale 310 ss pipe for sale |

310 ss pipe for price 310 ss pipe for price |

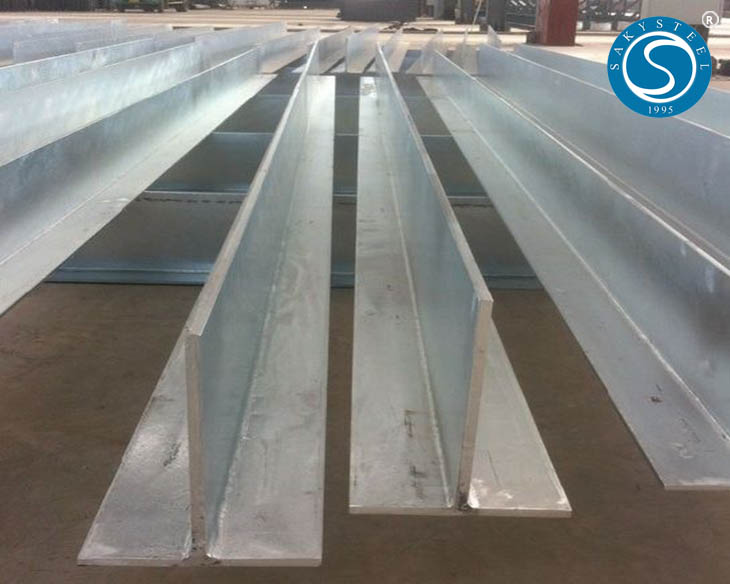

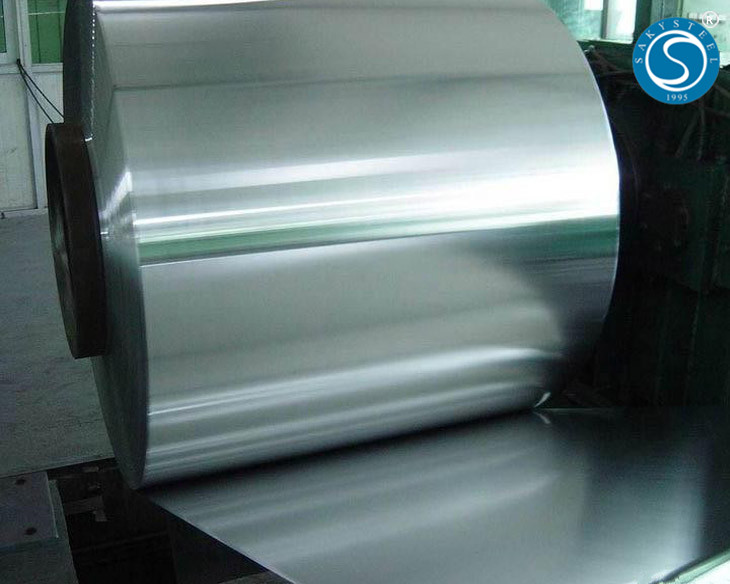

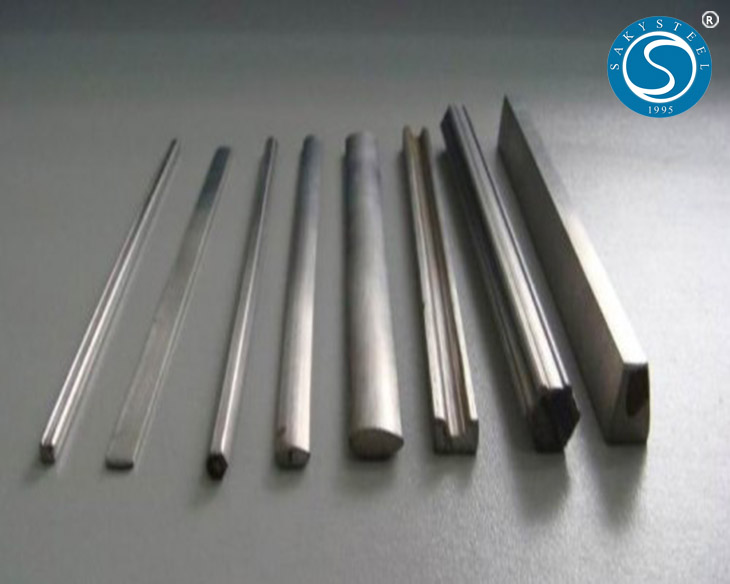

Product detail pictures:

Related Product Guide:

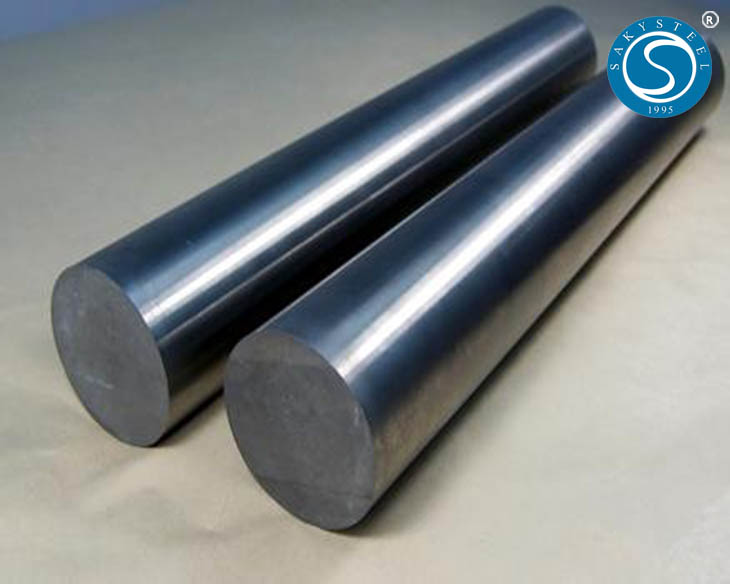

Stainless Steel Bar Tops In the Great British Pub

Stainless Steel Bars – Production, Importance, and Uses

We keep on with the basic principle of "quality to start with, support very first, continuous improvement and innovation to meet the customers" for your management and "zero defect, zero complaints" as the quality objective. To great our service, we offer the items with all the superior top quality at the reasonable selling price for OEM Factory for Cold Rolled Stainless Steel Bar - Ss 310 Seamless Pipe – Saky Steel, The product will supply to all over the world, such as: Israel , Saudi Arabia , New York , Our company is an international supplier on this kind of merchandise. We offer an amazing selection of high-quality products. Our goal is to delight you with our distinctive collection of mindful products while providing value and excellent service. Our mission is simple: To provide the best products and service to our customers at the lowest prices possible.

The enterprise has a strong capital and competitive power, product is sufficient, reliable, so we have no worries on cooperating with them.