Chitsulo chosapanga dzimbiri HI Beam

Kufotokozera Kwachidule:

"H Beam" amatanthawuza zigawo zomangika ngati chilembo "H" zomwe zimagwiritsidwa ntchito pomanga ndi machitidwe osiyanasiyana.

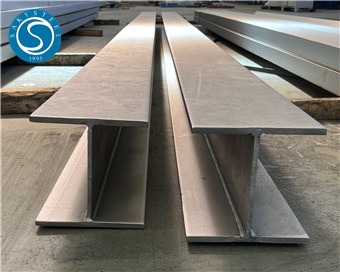

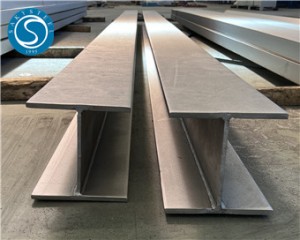

Beam yachitsulo chosapanga dzimbiri H:

Chitsulo chosapanga dzimbiri H Beam ndi zigawo zodziwika ndi gawo lawo lopangidwa ndi H. Makanemawa amapangidwa kuchokera ku chitsulo chosapanga dzimbiri, aloyi osachita dzimbiri omwe amadziwika ndi kulimba kwake, ukhondo, komanso kukongola kwake. Zipangizo zazitsulo zosapanga dzimbiri za H zimapeza ntchito m'mafakitale osiyanasiyana, kuphatikizapo zomangamanga, zomangamanga, ndi kupanga, kumene kukana kwa dzimbiri ndi mphamvu kumawapanga kukhala chisankho chokondedwa cha chithandizo cha zomangamanga ndi mapangidwe.

Zolemba za I Beam:

| Gulu | 302 304 304L 310 316 316L 321 2205 2507 etc. |

| Standard | GB T33814-2017,GBT11263-2017 |

| Pamwamba | Kupukuta mchenga, kupukuta, kuphulika kwa mfuti |

| Zamakono | Wotentha Wokulungidwa, Wowotchedwa |

| Utali | 1 mpaka 12 mamita |

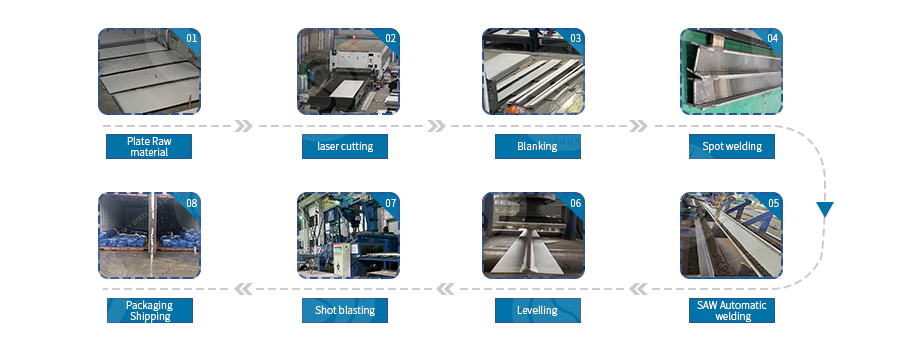

I-beam kupanga ma flow chart:

Webusaiti:

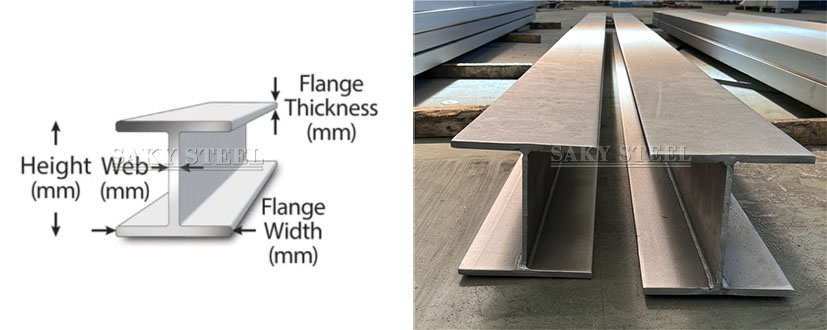

Ukonde umagwira ntchito ngati pakatikati pa mtengowo, womwe nthawi zambiri umayikidwa molingana ndi makulidwe ake. Imagwira ntchito ngati ulalo wamapangidwe, imagwira ntchito yofunika kwambiri pakusunga kukhulupirika kwa mtengowo polumikiza ndi kulumikiza ma flanges awiri, kugawa bwino ndikuwongolera kukakamizidwa.

Flange:

Zigawo zam'mwamba ndi zosalala zam'munsi zazitsulo zimakhala ndi katundu woyamba. Kuti titsimikizire kugawa kwamphamvu kofanana, timapanga ma flanges. Zigawo ziwirizi zimayenda mofanana, ndipo pazigawo za I-matanda, zimakhala ndi zowonjezera ngati mapiko.

H Kuyeza makulidwe a Beam Welded Line:

Stainless Steel I Beam Beveling Njira:

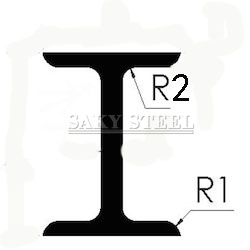

Ngongole ya R ya I-beam imapukutidwa kuti pamwamba ikhale yosalala komanso yopanda burr, yomwe ndi yabwino kuteteza chitetezo cha ogwira ntchito. Titha kukonza ngodya ya R ya 1.0, 2.0, 3.0. 304 316 316L 2205 Miyendo ya IH yachitsulo chosapanga dzimbiri. Ma angles a R a mizere 8 onse ndi opukutidwa.

Chitsulo chosapanga dzimbiri I Beam Wing/Flange kuwongola:

Mawonekedwe & Ubwino:

•Mapangidwe a "H" -oboola pakati achitsulo cha I-beam amapereka mphamvu zonyamula katundu zonyamula zoyima komanso zopingasa.

•Mapangidwe opangidwa ndi chitsulo cha I-beam amapereka kukhazikika kwapamwamba, kuteteza kusinthika kapena kupindika pansi pa kupsinjika.

•Chifukwa cha mawonekedwe ake apadera, chitsulo cha I-beam chimatha kugwiritsidwa ntchito kuzinthu zosiyanasiyana, kuphatikiza mizati, mizati, milatho, ndi zina zambiri.

•Chitsulo cha I-beam chimagwira ntchito bwino kwambiri popinda ndi kukanikiza, kuonetsetsa kuti pakhale bata pansi pazovuta zotsegula.

•Ndi mapangidwe ake ogwira ntchito komanso mphamvu zapamwamba, zitsulo za I-beam nthawi zambiri zimapereka ndalama zabwino.

•Chitsulo cha I-beam chimagwiritsidwa ntchito kwambiri pomanga, milatho, zida zamafakitale, ndi magawo ena osiyanasiyana, kuwonetsa kusinthasintha kwake pama projekiti osiyanasiyana omanga ndi zomangamanga.

•Mapangidwe a chitsulo cha I-beam amalola kuti agwirizane bwino ndi zofunikira pakumanga kokhazikika ndi kapangidwe kake, ndikupereka njira yabwino yopangira njira zomangira zachilengedwe komanso zobiriwira.

Mapangidwe a Chemical H Beam:

| Gulu | C | Mn | P | S | Si | Cr | Ni | Mo | Nayitrogeni |

| 302 | 0.15 | 2.0 | 0.045 | 0.030 | 1.0 | 17.0-19.0 | 8.0-10.0 | - | 0.10 |

| 304 | 0.08 | 2.0 | 0.045 | 0.030 | 1.0 | 18.0-20.0 | 8.0-11.0 | - | - |

| 309 | 0.20 | 2.0 | 0.045 | 0.030 | 1.0 | 22.0-24.0 | 12.0-15.0 | - | - |

| 310 | 0.25 | 2.0 | 0.045 | 0.030 | 1.5 | 24-26.0 | 19.0-22.0 | - | - |

| 314 | 0.25 | 2.0 | 0.045 | 0.030 | 1.5-3.0 | 23.0-26.0 | 19.0-22.0 | - | - |

| 316 | 0.08 | 2.0 | 0.045 | 0.030 | 1.0 | 16.0-18.0 | 10.0-14.0 | 2.0-3.0 | - |

| 321 | 0.08 | 2.0 | 0.045 | 0.030 | 1.0 | 17.0-19.0 | 9.0-12.0 | - | - |

Makina a I Beams:

| Gulu | Tensile Strength ksi[MPa] | Yiled Strengtu ksi[MPa] | Elongation % |

| 302 | 75[515] | 30[205] | 40 |

| 304 | 95[665] | 45[310] | 28 |

| 309 | 75[515] | 30[205] | 40 |

| 310 | 75[515] | 30[205] | 40 |

| 314 | 75[515] | 30[205] | 40 |

| 316 | 95[665] | 45[310] | 28 |

| 321 | 75[515] | 30[205] | 40 |

Chifukwa Chiyani Mutisankhe?

•Mutha kupeza zinthu zabwino kwambiri malinga ndi zomwe mukufuna pamtengo wotsika kwambiri.

•Timaperekanso Reworks, FOB, CFR, CIF, ndi mitengo yoperekera khomo ndi khomo. Tikukulangizani kuti mugwiritse ntchito zotumiza zomwe zingakhale zotsika mtengo.

•Zipangizo zomwe timapereka ndizotsimikizika kotheratu, kuyambira pa satifiketi yoyeserera ya zinthu zosaphika mpaka pachiwonetsero chomaliza. (Malipoti awonetsedwa pakufunika)

•Timatsimikizira kuti tipereka yankho mkati mwa 24hours (nthawi zambiri mu ola lomwelo)

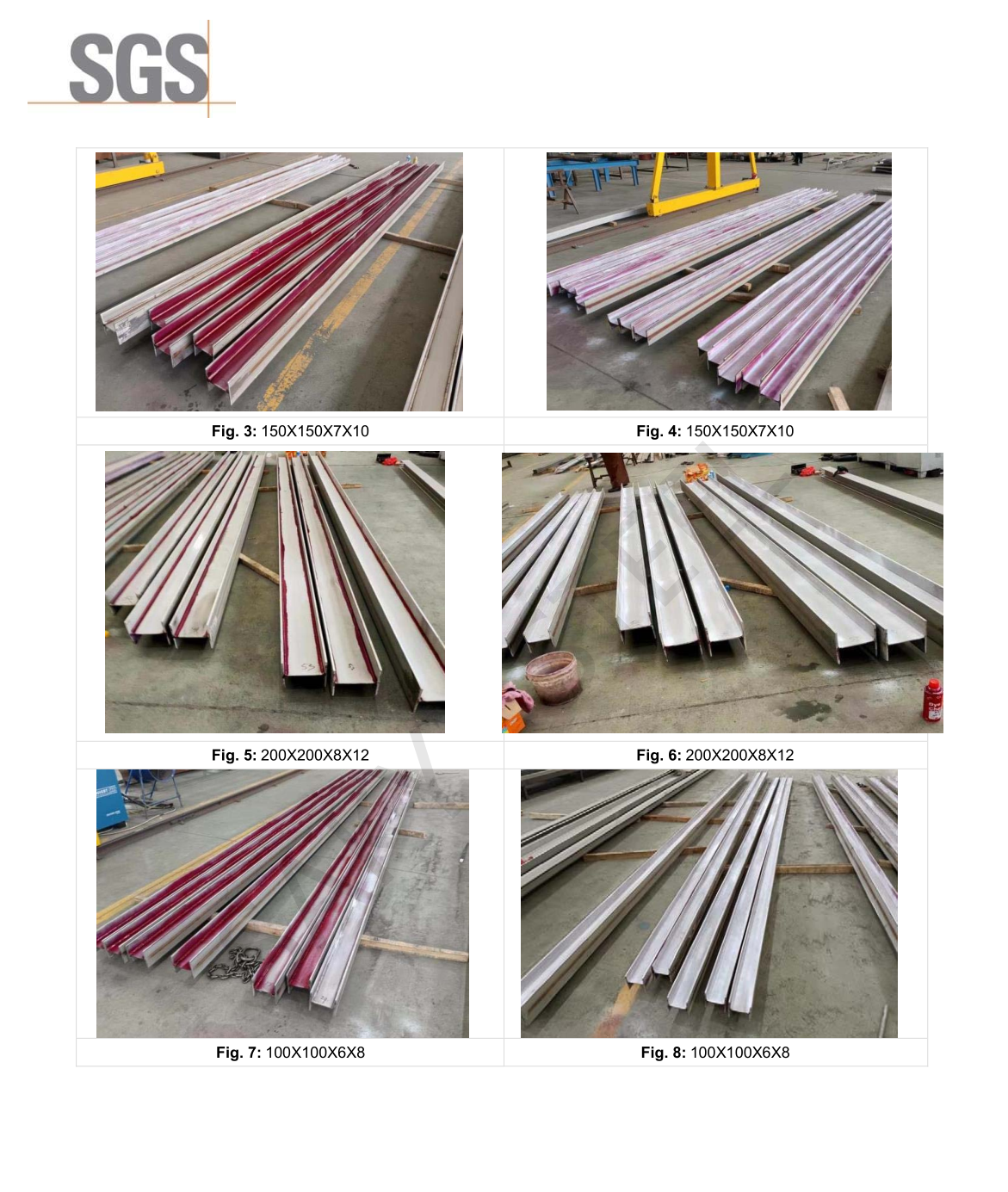

•Perekani lipoti la SGS TUV.

•Ndife odzipereka kwathunthu kwa makasitomala athu. Ngati sizingatheke kukwaniritsa zomwe mukufuna mutapenda zonse zomwe mungasankhe, sitidzakusocheretsani popanga malonjezo abodza omwe angapangitse ubale wabwino ndi makasitomala.

•Perekani ntchito yoyimitsa kamodzi.

316L chitsulo chosapanga dzimbiri choyezera H Beam Penetration test (PT)

Zoyambira pa JBT 6062-2007 Kuyesa kosawononga - kuyesa kolowera kwa ma welds kwa 304L 316L chitsulo chosapanga dzimbiri chopangidwa ndi H Beam.

Kodi njira zowotcherera ndi ziti?

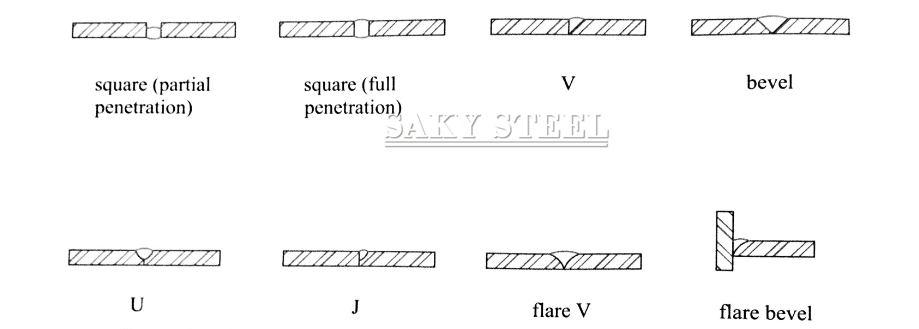

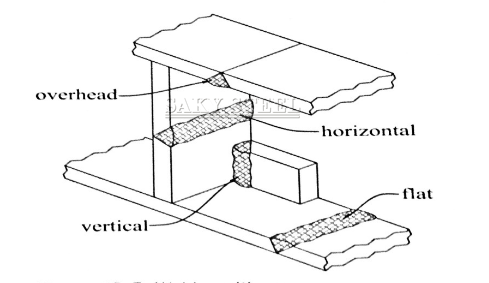

Njira zowotcherera zikuphatikizapo kuwotcherera kwa arc, kuwotcherera kwa gasi (MIG / MAG), kuwotcherera kukana, kuwotcherera kwa laser, kuwotcherera kwa plasma arc, kuwotcherera kwa mikangano, kuwotcherera, kuwotcherera kwa ma elekitironi, etc. Njira zowotcherera za arc zimaphatikizira kuwotcherera kwa arc, kuwotcherera kwa argon, kuwotcherera kwa arc pansi pamadzi, etc.Kutentha kopangidwa ndi kukana kumagwiritsidwa ntchito kusungunula chitsulo pamwamba pa workpiece kuti apange kulumikizana. Kuwotcherera Resistance kumaphatikizapo kuwotcherera malo, kuwotcherera msoko ndi kuwotcherera bawuti.

Ngati n'kotheka, zowotcherera ziyenera kuchitidwa m'sitolo momwe mawonekedwe a weld nthawi zambiri amakhala abwinoko, zowotcherera zogulira sizimayenderana ndi nyengo ndipo mwayi wolumikizana ndi wotseguka. Ma welds amatha kugawidwa kukhala athyathyathya, opingasa, ofukula, ndi pamwamba. Zitha kuwoneka kuti zowotcherera zosalala ndizosavuta kuchita; iwo ndi njira yosankhidwa. Zowotcherera pamutu, zomwe nthawi zambiri zimachitikira m'munda, ziyeneranso kupeŵedwa ngati zingatheke chifukwa zimakhala zovuta komanso zimatenga nthawi, ndipo chifukwa chake zimakhala zokwera mtengo.

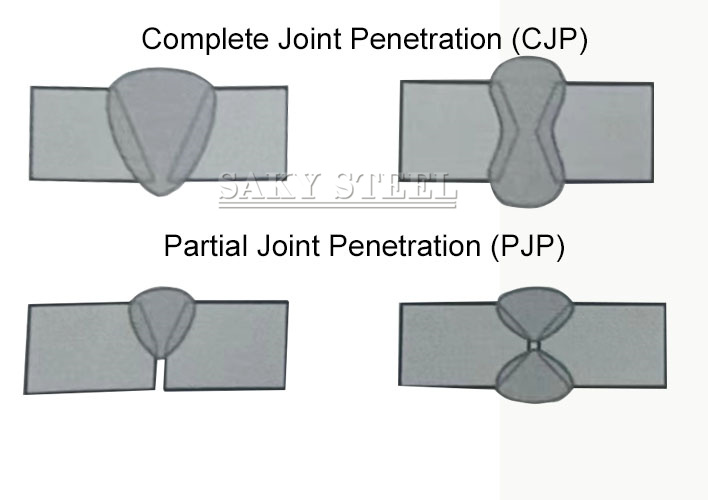

Groove welds amatha kulowa membala wolumikizidwa ndi gawo la makulidwe a membala, kapena amatha kulowa mu makulidwe athunthu a membala wolumikizidwa. Izi zimatchedwa kulowetsa kwapang'ono (PJP) ndi kulowa molumikizana kwathunthu (CJP), motsatana . Ma welds olowa kwathunthu (omwe amatchedwanso full.penetration kapena "'full-pen" welds) amaphatikiza kuya konse kwa malekezero a mamembala olumikizidwa Mawotchi olowera pang'onopang'ono amakhala otsika mtengo ndipo amagwiritsidwa ntchito ngati zowotcherera zomwe zimagwiritsidwa ntchito kuti zowotcherera zonse sizikufunika. Zitha kugwiritsidwanso ntchito pomwe mwayi wopita ku grooveis umangokhala mbali imodzi ya kulumikizana.

Chidziwitso: Index STRUCTURAL STEEL DESIGN

Ubwino wa kuwotcherera arc pansi pamadzi ndi chiyani?

Kuwotcherera kwa arc ndi koyenera kuti azingodzipangira okha komanso malo okwera kwambiri. Ikhoza kumaliza ntchito yowotcherera yambiri mu nthawi yochepa ndikuwongolera kupanga bwino. Kuwotcherera kwa arc ndi koyenera kuti azingodzipangira okha komanso malo okwera kwambiri. Ikhoza kumaliza ntchito yowotcherera yambiri mu nthawi yochepa ndikuwongolera kupanga bwino. Kuwotcherera kwa arc pansi pamadzi kumagwiritsidwa ntchito powotcherera zitsulo zokhuthala chifukwa kulowera kwake komweko komanso kulowera kwambiri kumapangitsa kuti izi zitheke. Popeza kuwotcherera kumaphimbidwa ndi flux, mpweya ukhoza kupewedwa bwino kuti usalowe m'dera la weld, motero kuchepetsa kuthekera kwa okosijeni ndi spatter.Poyerekeza ndi njira zowotcherera zamanja, kuwotcherera kwa arc pansi pamadzi nthawi zambiri kumakhala kosavuta, kuchepetsa zofuna zapamwamba pa luso la ogwira ntchito. Mu kuwotcherera kwa arc pansi pamadzi, mawaya owotcherera angapo ndi ma arcs atha kugwiritsidwa ntchito nthawi imodzi kuti akwaniritse kuwotcherera kwamitundu yambiri (mipikisano wosanjikiza) ndikuwongolera bwino.

Kodi matabwa a Stainless Steel H amagwiritsidwa ntchito bwanji?

Miyendo yachitsulo chosapanga dzimbiri H imagwiritsidwa ntchito kwambiri pomanga, uinjiniya wam'madzi, zida zamafakitale, magalimoto, mapulojekiti amagetsi, ndi zina zambiri chifukwa cha kukana kwa dzimbiri komanso kulimba. Amapereka chithandizo chomangika pantchito yomanga ndipo amagwira ntchito yofunika kwambiri m'malo omwe amafunikira kuti zisawonongeke, monga zam'madzi kapena mafakitale. Kuphatikiza apo, mawonekedwe awo amakono komanso okongola amawapangitsa kukhala oyenera kugwiritsa ntchito zomangamanga komanso zamkati.

Kodi mtengo wa Stainless Steel HI ndi wowongoka bwanji?

Kuwongoka kwachitsulo chosapanga dzimbiri cha H-mtengo, monga gawo lililonse lachimangidwe, ndizofunikira kwambiri pakugwira ntchito ndi kukhazikitsa kwake. Kawirikawiri, opanga amapanga zitsulo zosapanga dzimbiri za H-zitsulo zokhala ndi mlingo wina wowongoka kuti akwaniritse miyezo yamakampani ndi ndondomeko.

Muyezo wovomerezeka wamakampani wowongoka muzitsulo zomangika, kuphatikiza zitsulo zosapanga dzimbiri za H, nthawi zambiri zimatanthauzidwa molingana ndi zololeka zopatuka kuchokera pamzere wowongoka pautali wodziwika. Kupatuka uku kumawonetsedwa motengera mamilimita kapena mainchesi akusesa kapena kusamuka kotsatira.

Chiyambi cha mawonekedwe a H beam ?

Mawonekedwe amtundu wa I-beam steel, omwe amadziwika kuti "工字钢" (gōngzìgāng) m'Chitchaina, amafanana ndi chilembo "H" akatsegulidwa. Makamaka, magawo odutsa amakhala ndi mipiringidzo iwiri yopingasa (ma flanges) pamwamba ndi pansi ndi mipiringidzo yapakati (webu). Mawonekedwe a "H"wa amapereka mphamvu zapamwamba komanso kukhazikika kwazitsulo za I-beam, zomwe zimapangitsa kukhala chinthu chodziwika bwino cha zomangamanga pa zomangamanga ndi zomangamanga.Mawonekedwe opangidwa ndi chitsulo cha I-beam amalola kuti akhale oyenera kunyamula katundu ndi ntchito zosiyanasiyana, monga matabwa, mizati, ndi mapangidwe a mlatho. Kukonzekera kwapangidwe kumeneku kumathandizira chitsulo cha I-beam kuti chigawitse bwino katundu pamene chikugwiritsidwa ntchito, kupereka chithandizo champhamvu. Chifukwa cha mawonekedwe ake apadera komanso mawonekedwe ake, chitsulo cha I-beam chimagwiritsidwa ntchito kwambiri pantchito zomanga ndi zomangamanga.

Momwe mungafotokozere kukula ndi mawu a I-mtengo?

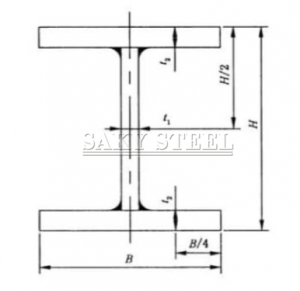

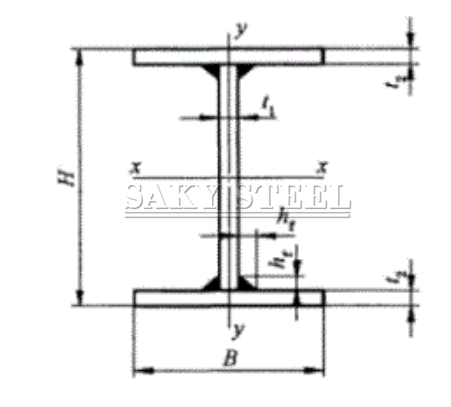

Ⅰ. Chithunzi chodutsa ndi zizindikiro za 316L chitsulo chosapanga dzimbiri chowotcherera chooneka ngati H:

H——Utali

B——Ufupi

t1——Kuchuluka kwa intaneti

t2——Kukhuthala kwa mbale

h £ ndi——Kukula kwa kuwotcherera (pogwiritsa ntchito kuphatikizika kwa matako ndi fillet, kuyenera kukhala kukula kwa mwendo wowotcherera hk)

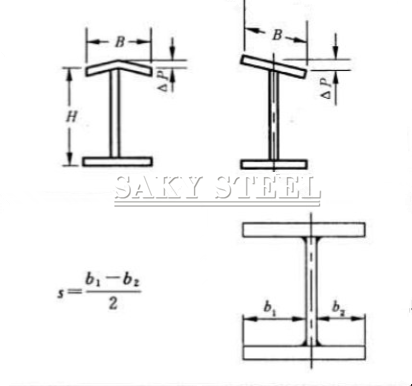

Ⅱ. Makulidwe, mawonekedwe ndi kupatuka kovomerezeka kwa chitsulo cha 2205 duplex welded H woboola pakati:

| H Beam | Kulekerera |

| Mphamvu (H) | Kutalika 300 kapena kuchepera: 2.0 mmKuposa 300:3.0mm |

| M'lifupi (B) | 2.0 mm |

| Perpendicularlty (T) | 1.2% kapena kuchepera kwa wldth (B)Dziwani kuti kulolerana kwa minlmum ndi 2.0 mm |

| Pakatikati (C) | 2.0 mm |

| Kupinda | 0.2096 kapena kuchepera kutalika kwake |

| Kutalika kwa mwendo (S) | [web plate thlckness (t1) x0.7] kapena zambiri |

| Utali | 3-12m |

| Kulekerera kwautali | + 40mm, 一0mm |

Ⅲ. Makulidwe, mawonekedwe ndi zololeka zopatuka za welded H woboola pakati chitsulo

Ⅳ. Miyezo yopingasa, gawo la magawo osiyanasiyana, kulemera kwamalingaliro ndi magawo osiyanasiyana azitsulo zowotcherera zooneka ngati H

| Mitengo yachitsulo chosapanga dzimbiri | Kukula | Chigawo Chachigawo (cm²) | Kulemera (kg/m) | Makhalidwe a Parameters | Weld fillet kukula h(mm) | ||||||||

| H | B | t1 | t2 | xx | yy | ||||||||

| mm | I | W | i | I | W | i | |||||||

| WH100X50 | 100 | 50 | 3.2 | 4.5 | 7.41 | 5.2 | 123 | 25 | 4.07 | 9 | 4 | 1.13 | 3 |

| 100 | 50 | 4 | 5 | 8.60 | 6.75 | 137 | 27 | 3.99 | 10 | 4 | 1.10 | 4 | |

| WH100X100 | 100 | 100 | 4 | 6 | 15.52 | 12.18 | 288 | 58 | 4.31 | 100 | 20 | 2.54 | 4 |

| 100 | 100 | 6 | 8 | 21.04 | 16.52 | 369 | 74 | 4.19 | 133 | 27 | 2.52 | 5 | |

| WH100X75 | 100 | 75 | 4 | 6 | 12.52 | 9.83 | 222 | 44 | 4.21 | 42 | 11 | 1.84 | 4 |

| WH125X75 | 125 | 75 | 4 | 6 | 13.52 | 10.61 | 367 | 59 | 5.21 | 42 | 11 | 1.77 | 4 |

| WH125X125 | 125 | 75 | 4 | 6 | 19.52 | 15.32 | 580 | 93 | 5.45 | 195 | 31 | 3.16 | 4 |

| WH150X75 | 150 | 125 | 3.2 | 4.5 | 11.26 | 8.84 | 432 | 58 | 6.19 | 32 | 8 | 1.68 | 3 |

| 150 | 75 | 4 | 6 | 14.52 | 11.4 | 554 | 74 | 6.18 | 42 | 11 | 1.71 | 4 | |

| 150 | 75 | 5 | 8 | 18.70 | 14.68 | 706 | 94 | 6.14 | 56 | 15 | 1.74 | 5 | |

| WH150X100 | 150 | 100 | 3.2 | 4.5 | 13.51 | 10.61 | 551 | 73 | 6.39 | 75 | 15 | 2.36 | 3 |

| 150 | 100 | 4 | 6 | 17.52 | 13.75 | 710 | 95 | 6.37 | 100 | 20 | 2.39 | 4 | |

| 150 | 100 | 5 | 8 | 22.70 | 17,82 | 908 | 121 | 6.32 | 133 | 27 | 2.42 | 5 | |

| WH150X150 | 150 | 150 | 4 | 6 | 23.52 | 18.46 | 1 021 | 136 | 6,59 | 338 | 45 | 3.79 | 4 |

| 150 | 150 | 5 | 8 | 30.70 | 24.10 | 1 311 | 175 | 6.54 | 450 | 60 | 3.83 | 5 | |

| 150 | 150 | 6 | 8 | 32.04 | 25, 15 | 1 331 | 178 | 6.45 | 450 | 60 | 3.75 | 5 | |

| WH200X100 | 200 | 100 | 3.2 | 4.5 | 15.11 | 11.86 | 1 046 | 105 | 8.32 | 75 | 15 | 2.23 | 3 |

| 200 | 100 | 4 | 6 | 19.52 | 15.32 | 1 351 | 135 | 8.32 | 100 | 20 | 2.26 | 4 | |

| 200 | 100 | 5 | 8 | 25.20 | 19.78 | 1 735 | 173 | 8.30 | 134 | 27 | 2.30 | 5 | |

| WH200X150 | 200 | 150 | 4 | 6 | 25.52 | 20.03 | 1 916 | 192 | 8.66 | 338 | 45 | 3.64 | 4 |

| 200 | 150 | 5 | 8 | 33.20 | 26.06 | 2 473 | 247 | 8.63 | 450 | 60 | 3.68 | 5 | |

| WH200X200 | 200 | 200 | 5 | 8 | 41.20 | 32.34 | 3 210 | 321 | 8.83 | 1067 | 107 | 5.09 | 5 |

| 200 | 200 | 6 | 10 | 50.80 | 39.88 | 3 905 ndi | 390 | 8.77 | 1 334 | 133 | 5, 12 | 5 | |

| WH250X125 | 250 | 125 | 4 | 6 | 24.52 | 19.25 | 2 682 | 215 | 10.46 | 195 | 31 | 2.82 | 4 |

| 250 | 125 | 5 | 8 | 31.70 | 24.88 | 3 463 | 277 | 10.45 | 261 | 42 | 2.87 | 5 | |

| 250 | 125 | 6 | 10 | 38.80 | 30.46 | 4210 | 337 | 10.42 | 326 | 52 | 2.90 | 5 | |

Makasitomala Athu

Ndemanga Zochokera kwa Makasitomala Athu

Miyezo ya Chitsulo chosapanga dzimbiri H ndi zida zosunthika zopangidwa kuchokera ku chitsulo chosapanga dzimbiri chapamwamba kwambiri. Makanemawa amakhala ndi mawonekedwe a "H" apadera, omwe amapereka mphamvu zowonjezera komanso kukhazikika pamamangidwe osiyanasiyana ndi zomangamanga. Kutha kwachitsulo chosapanga dzimbiri kumawonjezera kukhudza kwaukadaulo, kupangitsa H Beam iyi kukhala yoyenera pamapangidwe owoneka bwino komanso owoneka bwino. ntchito m'mafakitale osiyanasiyana, kuphatikiza zomangamanga, zomangamanga, ndi kupanga, komwe chithandizo champhamvu chimafunikira.

Stainless Steel I Beams Packing:

1. Kulongedza ndi kofunika kwambiri makamaka ngati katundu wapadziko lonse lapansi amadutsa munjira zosiyanasiyana kuti akafike komwe akupita, chifukwa chake timayika chidwi chapadera pakuyika.

2. Saky Steel's amanyamula katundu wathu m'njira zambiri kutengera zomwe timapanga. Timanyamula katundu wathu m'njira zingapo, monga,