Ⅰ.Lingaliro loyambirira la chithandizo cha kutentha.

A. Lingaliro loyambirira la chithandizo cha kutentha.

Zofunikira ndi ntchito zakutentha mankhwala:

1.Kutentha

Cholinga chake ndikupeza mawonekedwe a yunifolomu komanso abwino austenite.

2.Kugwira

Cholinga ndikuwonetsetsa kuti chogwirira ntchito chatenthedwa bwino komanso kupewa decarburization ndi oxidation.

3.Kuziziritsa

Cholinga chake ndikusintha austenite kukhala ma microstructures osiyanasiyana.

Microstructures Pambuyo Kuchiza Kutentha

Panthawi yozizira pambuyo potentha ndi kugwira, austenite imasandulika kukhala ma microstructures osiyanasiyana malingana ndi kuzizira. Ma microstructures osiyanasiyana amawonetsa zinthu zosiyanasiyana.

B. Lingaliro loyambirira la chithandizo cha kutentha.

Gulu Lotengera Kutentha ndi Njira Zoziziritsira, komanso Microstructure ndi Properties of Steel

1.Kuchiza Kutentha Kwambiri (Kuchiza Kutentha Kwambiri): Kutentha, Kutentha, Kutentha, Normalizing, Kuzimitsa

2.Kuchiza Kutentha kwa Pamwamba: Kuzimitsa Kutentha Kwambiri, Kutentha Kutentha Kwambiri Pamwamba Kuzimitsidwa, Kutentha kwa Moto Pamwamba Kuzimitsidwa, Kutentha kwa Magetsi Kutentha Kwapamwamba.

3.Chemical Heat Chithandizo: Carburizing,Nitriding,Carbonitriding.

4.Zinthu Zina Zochizira Kutentha: Kuwongolera Kutentha kwa Atmosphere, Chithandizo cha Kutentha kwa Vacuum, Chithandizo cha Kutentha kwa Kusintha.

C. Kutentha Kwambiri kwa Zitsulo

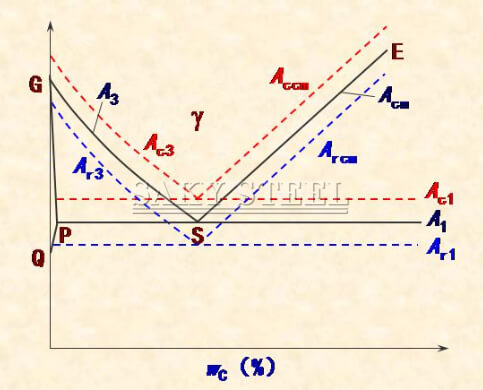

Kutentha kofunikira kosinthika kwachitsulo ndi maziko ofunikira pozindikira kutentha, kugwira, ndi kuziziritsa panthawi ya chithandizo cha kutentha. Zimatsimikiziridwa ndi chithunzi cha iron-carbon phase.

Mfungulo Yomaliza:Kutentha kwenikweni kofunikira kwachitsulo nthawi zonse kumatsalira kumbuyo kwa kutentha kwa chiphunzitso chovuta kwambiri. Izi zikutanthauza kuti kutentha kumafunika panthawi yotentha, ndipo kuzizira kumafunika panthawi yozizira.

Ⅱ.Annealing and Normalizing of Steel

1. Tanthauzo la Annealing

Kuwotcha kumaphatikizapo kutenthetsa zitsulo ku kutentha pamwamba kapena pansi pa malo ovuta kwambiri Ac₁ kuigwira pa kutentha komweko, ndiyeno kuziziritsa pang'onopang'ono, kawirikawiri mkati mwa ng'anjo, kuti akwaniritse dongosolo lomwe liri pafupi ndi kufanana.

2. Cholinga cha Annealing

①Sinthani Kuuma Kwa Machining: Kukwaniritsa kuuma kosinthika mumitundu ya HB170~230.

②Perekani Kupsinjika Kwambiri: Kumalepheretsa kusinthika kapena kusweka pakanthawi kotsatira.

③Yengerani Kapangidwe ka Mbewu: Kupititsa patsogolo mawonekedwe a microstructure.

④Kukonzekera Kwachidziwitso Chomaliza Chakutentha: Imapeza pearlite ya granular (spheroidized) pofuna kuzimitsa ndi kutentha.

3.Spheroidizing Annealing

Zofotokozera Ndondomeko: Kutentha kwa kutentha kuli pafupi ndi Ac₁ point.

Cholinga: Kuti spheroidize simenti kapena carbides mu chitsulo, kuchititsa granular (spheroidized) pearlite.

Range Yogwiritsidwa Ntchito: Amagwiritsidwa ntchito pazitsulo zokhala ndi nyimbo za eutectoid ndi hypereutectoid.

4. Diffusing Annealing (Homogenizing Annealing)

Zofotokozera Njira: Kutentha kwa kutentha kumakhala pansi pang'ono pa mzere wa solvus pa chithunzi cha gawo.

Cholinga: Kuthetsa tsankho.

①Kwa otsika-carbon steelndi mpweya wochepera 0.25%, normalizing ndi yabwino kuposa annealing monga kukonzekera kutentha mankhwala.

②Kwa chitsulo chapakati cha kaboni chokhala ndi mpweya wapakati pa 0.25% ndi 0.50%, kutsekereza kapena normalizing kungagwiritsidwe ntchito ngati mankhwala okonzekera kutentha.

③Pa chitsulo chapakati mpaka chapamwamba cha kaboni chokhala ndi kaboni pakati pa 0.50% ndi 0.75%, kutseketsa kwathunthu kumalimbikitsidwa.

④Zapamwamba-carbon steelyokhala ndi mpweya woposa 0.75%, normalizing imagwiritsidwa ntchito pochotsa netiweki Fe₃C, ndikutsatiridwa ndi spheroidizing annealing.

Ⅲ.Kuzimitsa ndi Kutentha kwa Zitsulo

A.Kuzimitsa

1. Tanthauzo la Kuzimitsa: Kuzimitsa kumaphatikizapo kutenthetsa zitsulo ku kutentha kwina pamwamba pa Ac₃ kapena Ac₁ point, kuzigwira pa kutentha kumeneko, ndiyeno kuziziziritsa pa mlingo waukulu kuposa mlingo wozizira kwambiri kuti upange martensite.

2. Cholinga cha Kuzimitsa: Cholinga chachikulu ndicho kupeza martensite (kapena nthawi zina kutsika bainite) kuonjezera kuuma ndi kuvala kukana kwachitsulo. Kuzimitsa ndi imodzi mwazinthu zofunika kwambiri zochizira kutentha kwachitsulo.

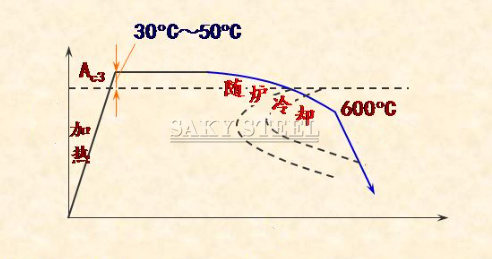

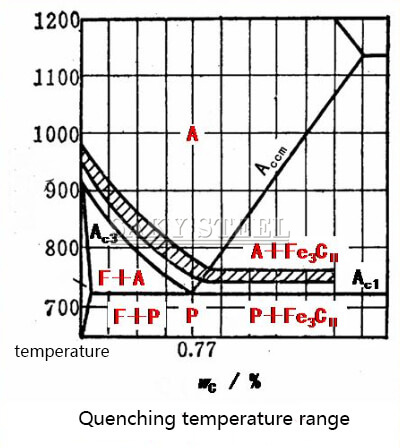

3.Kudziwa Kutentha Kozimitsa Mitundu Yosiyanasiyana ya Zitsulo

Chitsulo cha Hypoeutectoid: Ac₃ + 30°C mpaka 50°C

Chitsulo cha Eutectoid ndi Hypereutectoid: Ac₁ + 30°C mpaka 50°C

Chitsulo cha Aloyi: 50 ° C mpaka 100 ° C pamwamba pa kutentha kwakukulu

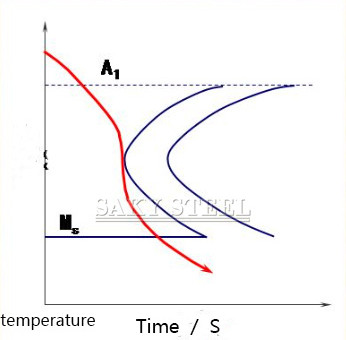

4.Makhalidwe Oziziritsa a Njira Yabwino Yozimitsa:

Kuzizira Pang'onopang'ono Pamaso Pa Kutentha kwa "Mphuno": Kuchepetsa mokwanira kupsinjika kwamafuta.

Kutentha Kwapamwamba Kwambiri Pafupi ndi Kutentha kwa "Mphuno": Kupewa kupanga mapangidwe omwe si a martensitic.

Kuzizira Pang'onopang'ono Pafupi ndi M₅ Point: Kuchepetsa kupsinjika komwe kumabwera chifukwa cha kusintha kwa martensitic.

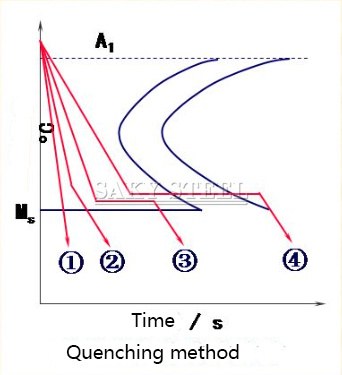

5. Njira Zozimitsira ndi Makhalidwe Awo:

①Kuzimitsa Kosavuta: Kusavuta kugwiritsa ntchito komanso koyenera kwa tinthu tating'ono tating'ono, tosavuta. Chifukwa cha microstructure ndi martensite (M).

②Kuzimitsa Kawiri: Zovuta kwambiri komanso zovuta kuziwongolera, zomwe zimagwiritsidwa ntchito ngati zitsulo zowoneka bwino zowoneka ngati kaboni wapamwamba komanso zitsulo zokulirapo. Chifukwa cha microstructure ndi martensite (M).

③Kuzimitsa Kophwanyika: Njira yovuta kwambiri, yogwiritsidwa ntchito pazitsulo zazikulu, zomangika ngati aloyi. Chifukwa cha microstructure ndi martensite (M).

④Kuzimitsa kwa Isothermal: Kumagwiritsidwa ntchito pazigawo zing'onozing'ono, zowoneka bwino zokhala ndi zofunika kwambiri. Zotsatira zake zimakhala zochepa bainite (B).

6.Zomwe Zimakhudza Kuuma

Mlingo wa hardability umadalira kukhazikika kwa supercooled austenite muzitsulo. Kukhazikika kwapamwamba kwa austenite ya supercooled, kumapangitsa kuti ikhale yolimba, komanso mosiyana.

Zomwe Zimapangitsa Kukhazikika kwa Supercooled Austenite:

Malo a C-Curve: Ngati C-curve isunthira kumanja, kuzizira kofunikira pakuzimitsa kumachepa, ndikupangitsa kuuma.

Mfungulo Yomaliza:

Chinthu chilichonse chomwe chimasintha C-curve kumanja chimawonjezera kuuma kwachitsulo.

Chofunika Kwambiri:

Mapangidwe a Chemical: Kupatula cobalt (Co), ma alloying onse osungunuka mu austenite amawonjezera kuuma.

Kuyandikira kwambiri kwa kaboni ndi kapangidwe ka eutectoid mu chitsulo cha kaboni, m'pamenenso C-curve imasunthira kumanja, ndikukulitsa kuuma.

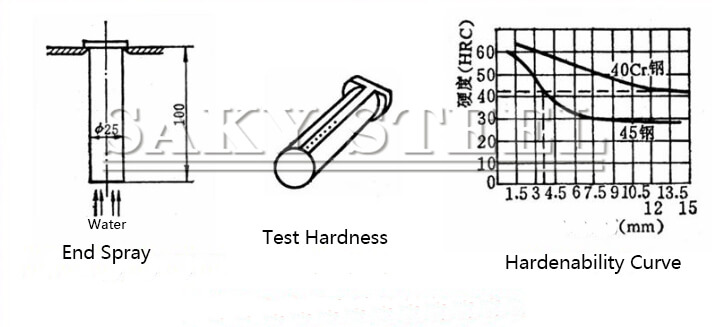

7.Kutsimikiza ndi Kuyimilira kwa Kuuma

① Mayesero Omaliza Ovuta Kwambiri: Kuuma kumayesedwa pogwiritsa ntchito njira yoyeserera yomaliza.

②Critical Quench Diameter Method: Njira yozimitsa kwambiri (D₀) imayimira kutalika kwa chitsulo chomwe chingathe kuumitsidwa kwathunthu mu sing'anga yozimitsa.

B. Kutentha

1. Tanthauzo la Kutentha

Kutentha ndi njira yopangira kutentha kumene zitsulo zozimitsidwa zimatenthedwanso kutentha pansi pa A₁ point, yomwe imakhala pa kutentha komweko, ndiyeno kuziziritsa kutentha.

2. Cholinga cha Kutentha

Chepetsani kapena Kuchotsa Kupsinjika Kwakutsalira: Kumalepheretsa kusinthika kapena kusweka kwa chogwirira ntchito.

Chepetsani kapena Chotsani Residual Austenite: Imakhazikitsa miyeso ya workpiece.

Chotsani Brittleness ya Zitsulo Zozimitsidwa: Imasintha ma microstructure ndi katundu kuti akwaniritse zofunikira za workpiece.

Chidziwitso chofunikira: Chitsulo chiyenera kutenthedwa mwamsanga pambuyo pozimitsa.

3.Kutentha Njira

1.Low Tempering

Cholinga: Kuchepetsa kupsinjika kothetsa nkhawa, kukonza kulimba kwa chogwirira ntchito, ndikukwaniritsa kulimba kwambiri komanso kukana kuvala.

Kutentha: 150 ° C ~ 250 ° C.

Kuchita: Kulimba: HRC 58 ~ 64. Kuuma kwakukulu ndi kukana kuvala.

Ntchito: Zida, zisamere pachakudya, ma fani, magawo a carburized, ndi zida zowumitsidwa pamwamba.

2.Kutentha Kwambiri

Cholinga: Kukwaniritsa kulimba kwakukulu limodzi ndi mphamvu zokwanira komanso kuuma.

Kutentha: 500 ° C ~ 600 ° C.

Magwiridwe: Kulimba: HRC 25 ~ 35. Zabwino zonse zamakina.

Ntchito: Shafts, magiya, ndodo zolumikizira, etc.

Kutentha Kwambiri

Tanthauzo: Kuzimitsa kotsatiridwa ndi kutentha kwakukulu kumatchedwa kutenthetsa kwa kutentha, kapena kungotentha chabe. Chitsulo chogwiritsidwa ntchito ndi njirayi chimakhala ndi ntchito yabwino kwambiri ndipo chimagwiritsidwa ntchito kwambiri.

Ⅳ.Surface Heat Chithandizo cha Zitsulo

A.Kuzimitsa Pamwamba pa Zitsulo

1. Tanthauzo la Kuuma Pamwamba

Kuwumitsa pamwamba ndi njira yochizira kutentha yomwe imapangidwa kuti ilimbikitse kusanjikiza kwa gawo lazogwirira ntchito poyitentha mwachangu kuti isinthe kusanjikiza kwake kukhala austenite ndikuziziritsa mwachangu. Njirayi imachitika popanda kusintha zitsulo zachitsulo kapena maziko a zinthuzo.

2. Zida Zogwiritsidwa Ntchito Pakuuma Pamwamba ndi Kumangika Kwapambuyo

Zipangizo Zogwiritsidwa Ntchito Poumitsa Pamwamba

Zida Zofananira: Chitsulo chapakati cha kaboni ndi chitsulo chapakatikati cha carbon alloy.

Chithandizo chisanachitike:Njira Yodziwika: Kutentha. Ngati zoyambira sizili zovuta, normalizing ingagwiritsidwe ntchito m'malo mwake.

Kapangidwe ka Post-Hardening

Maonekedwe a Pamwamba: Chosanjikiza chapamwamba chimapanga mawonekedwe olimba monga martensite kapena bainite, omwe amapereka kuuma kwakukulu komanso kukana kuvala.

Chikhalidwe Chachikulu: Pakatikati pa chitsulo nthawi zambiri chimakhala ndi mawonekedwe ake oyambirira, monga pearlite kapena kutentha, kutengera njira yochizira kale komanso momwe zinthu ziliri. Izi zimatsimikizira kuti pachimake chimakhalabe cholimba komanso champhamvu.

B. Makhalidwe a induction surface kuumitsa

1.Kutentha Kwambiri Kutentha Kwambiri ndi Kutentha Kwambiri: Kuwumitsa kwapamwamba kwa induction kumaphatikizapo kutentha kwapamwamba komanso kutentha kwachangu, kulola kutentha mofulumira mkati mwa nthawi yochepa.

2.Fine Austenite Grain Structure mu Surface Layer: Panthawi yotentha mofulumira ndi kuzimitsa kotsatira, pamwamba pake amapanga mbewu zabwino za austenite. Pambuyo pozimitsa, pamwamba pake imakhala ndi martensite yabwino, yomwe imakhala yolimba kwambiri 2-3 HRC kuposa kuzimitsa wamba.

3.Good Surface Quality: Chifukwa cha nthawi yotentha yotentha, malo ogwirira ntchito samakhala ovuta kwambiri ndi oxidation ndi decarburization, ndipo quenching-induced deformation imachepetsedwa, kuonetsetsa kuti malo abwino ali abwino.

4.Kutopa Kwambiri Mphamvu: Kusintha kwa gawo la martensitic pamtunda wamtunda kumapanga kupsinjika maganizo, zomwe zimawonjezera mphamvu ya kutopa kwa workpiece.

5.Kupanga Kwapamwamba Kwambiri: Kuwumitsa kwapamwamba kwa induction ndikoyenera kupanga zinthu zambiri, kumapereka magwiridwe antchito apamwamba.

C. Gulu la mankhwala kutentha mankhwala

Carburizing,Carburizing,Carburizing,Chromizing,Siliconizing,Siliconizing,Siliconizing,Carbonitriding,Borocarburizing

D. Gas Carburizing

Gas Carburizing ndi njira yomwe chogwirira ntchito chimayikidwa mu ng'anjo yotsekedwa ya gasi ndikutenthedwa kutentha komwe kumasintha chitsulo kukhala austenite. Kenako, chotengera cha carburizing chimadonthozedwa mu ng'anjo, kapena mpweya wotsekemera umalowetsedwa mwachindunji, kulola maatomu a kaboni kufalikira pamwamba pa chogwiriracho. Izi zimawonjezera kaboni (wc%) pamalo ogwirira ntchito.

√Carburizing Agents:

•Mipweya yochuluka ya Carbon: Monga gasi wa malasha, gasi wamafuta opangidwa ndi liquefied petroleum (LPG), ndi zina zotero.

•Zamadzimadzi Zachilengedwe: Monga palafini, methanol, benzene, ndi zina.

√Carburizing Process Parameters:

•Kutentha kwa Carburizing: 920~950°C.

• Carburizing Time: Zimatengera kuya komwe kufunidwa kwa carburized layer ndi kutentha kwa carburizing.

Chithandizo cha E. Kutentha Pambuyo pa Carburizing

Chitsulo chiyenera kuchitidwa kutentha pambuyo pa carburizing.

Njira Yochizira Kutentha Pambuyo pa Carburizing:

√Kuzimitsa + Kutentha Kwambiri

1.Kuzimitsa Kwachindunji Pambuyo Pakuzizira Kwambiri + Kutentha Kwambiri: Chogwirira ntchitocho chimakhala chokhazikika kuchokera ku kutentha kwa carburizing mpaka pamwamba pa kutentha kwa Ar₁ yapachiyambi ndikuzimitsidwa nthawi yomweyo, ndikutsatiridwa ndi kutentha kwapakati pa 160 ~ 180 ° C.

2.Kuzimitsa Kumodzi Pambuyo Kuzizira Kwambiri + Kutentha Kwambiri: Pambuyo pa carburizing, chogwirira ntchitocho chimatsitsidwa pang'onopang'ono mpaka kutentha kwa chipinda, kenako kumatenthedwa kuti chizimitse ndi kutentha pang'ono.

3.Kuzimitsa Kawiri Pambuyo pa Kuzizira Kwambiri + Kutentha Kwambiri: Pambuyo pa carburizing ndi kuzizira pang'onopang'ono, chogwirira ntchito chimakhala ndi magawo awiri a kutentha ndi kuzimitsa, ndikutsatiridwa ndi kutentha kwapansi.

Ⅴ.Chemical Heat Chithandizo cha Zitsulo

1.Tanthauzo la Chithandizo cha Kutentha kwa Chemical

Chithandizo cha kutentha kwa Chemical ndi njira yochizira kutentha momwe chitsulo chogwirira ntchito chimayikidwa mu sing'anga yogwira ntchito, kutenthedwa, ndi kusungidwa kutentha, kulola maatomu omwe ali mkatikati kuti afalikire pamtunda wa workpiece. Izi zimasintha kapangidwe ka mankhwala ndi microstructure ya workpiece pamwamba, potero kusintha katundu wake.

2.Basic Process of Chemical Heat Treatment

Kuwola: Pa kutentha, sing'anga yogwira kuwola, kutulutsa maatomu yogwira.

Mayamwidwe: Ma atomu omwe amagwira ntchito amalowetsedwa ndi pamwamba pa chitsulo ndikusungunula mu njira yolimba yachitsulo.

Kufalikira: Ma atomu ogwira ntchito omwe amatengedwa ndi kusungunuka pamwamba pa chitsulo amasamukira mkati.

Mitundu ya Induction Surface Harding

a. High-Frequency Induction Kutentha

Ma frequency apano: 250 ~ 300 kHz.

Kuzama kwa Gulu Lolimba: 0.5 ~ 2.0 mm.

Ntchito: Magiya apakati ndi ang'onoang'ono a module ndi ma shaft ang'onoang'ono mpaka apakatikati.

b.Medium-Frequency Induction Heating

Ma frequency apano: 2500 ~ 8000 kHz.

Kuzama kwa Gawo Lolimba: 2 ~ 10 mm.

Ntchito: Mitsinje yayikulu komanso magiya akulu mpaka apakatikati.

c.Kutentha kwa Mphamvu-Frequency Induction

Ma frequency apano: 50 Hz.

Kuzama kwa Gawo Lolimba: 10-15 mm.

Ntchito: Zogwirira ntchito zomwe zimafuna wosanjikiza wozama kwambiri.

3. Induction Surface Kuuma

Mfundo Yoyambira Yowumitsa Pansi Pansi

Khungu Zotsatira:

Pamene kusinthasintha kwamakono mu koyilo yolowera kumapangitsa kuti pakhale phokoso pamwamba pa chogwirira ntchito, mphamvu zambiri zomwe zimapangidwira zimakhazikika pafupi ndi pamwamba, pamene pafupifupi palibe yamakono yomwe imadutsa mkati mwa workpiece. Chodabwitsa ichi chimadziwika kuti khungu.

Mfundo Yoyimitsa Pansi pa Induction:

Malingana ndi zotsatira za khungu, pamwamba pa workpiece imatenthedwa mofulumira kutentha kwa austenitizing (kukwera mpaka 800 ~ 1000 ° C mumasekondi pang'ono), pamene mkati mwa workpiece imakhalabe yosasunthika. The workpiece ndiye utakhazikika ndi kupopera madzi madzi, kukwaniritsa pamwamba kuumitsa.

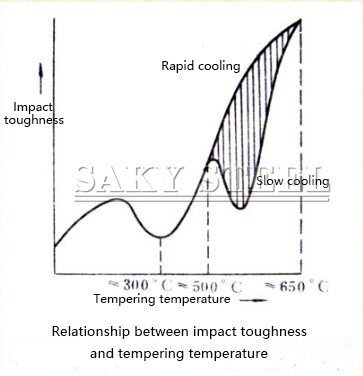

4.Kukwiya Kwambiri

Kuwotcha Kutentha mu Zitsulo Zozimitsidwa

Tempering brittleness imatanthawuza chodabwitsa chomwe kulimba kwachitsulo chozimitsidwa kumachepa kwambiri chikatenthedwa pa kutentha kwina.

Mtundu Woyamba wa Kutentha kwa Brittleness

Kutentha kwapakati: 250 ° C mpaka 350 ° C.

Makhalidwe: Ngati chitsulo chozimitsidwa chikatenthedwa mkati mwa kutentha uku, ndizotheka kwambiri kukhala ndi mtundu woterewu wa brittleness, womwe sungathe kuthetsedwa.

Yankho: Pewani kutenthetsa zitsulo zozimitsidwa mkati mwa kutentha uku.

Mtundu woyamba wa brittleness brittleness umadziwikanso kuti kutentha kwapang'onopang'ono kapena brittleness yosasinthika.

Ⅵ.Kutentha

1.Tempering ndi njira yomaliza yochizira kutentha yomwe imatsatira kuzimitsa.

N'chifukwa Chiyani Zitsulo Zozimitsidwa Zimafunika Kutenthedwa?

Microstructure Pambuyo Kuzimitsa: Pambuyo kuzimitsa, microstructure yachitsulo imakhala ndi martensite ndi otsalira austenite. Onse ndi magawo metastable ndipo adzasintha pansi zinthu zina.

Katundu wa Martensite:Martensite imadziwika ndi kuuma kwambiri komanso kulimba kwambiri (makamaka mu singano yamphamvu ya carbon-ngati martensite), yomwe simakwaniritsa zofunikira pakugwiritsa ntchito zambiri.

Makhalidwe a Kusintha kwa Martensitic: Kusintha kwa martensite kumachitika mwachangu kwambiri. Pambuyo pozimitsa, chogwiriracho chimakhala ndi zotsalira zamkati zomwe zingayambitse kuwonongeka kapena kusweka.

Kutsiliza: Chogwirira ntchito sichingagwiritsidwe ntchito mwachindunji mukatha kuzimitsa! Kutentha ndikofunikira kuti muchepetse kupsinjika kwamkati ndikuwongolera kulimba kwa workpiece, kuti ikhale yoyenera kugwiritsidwa ntchito.

2.Kusiyana Pakati pa Kuuma ndi Kuwumitsa Mphamvu:

Kuwumitsa :

Hardenability amatanthauza kuthekera kwachitsulo kukwaniritsa kuya kwina kwa kuuma (kuya kwa wosanjikiza wowuma) pambuyo pozimitsa. Zimatengera kapangidwe ka chitsulo ndi kapangidwe kake, makamaka ma alloying ake komanso mtundu wachitsulo. Kuuma ndi muyeso wa momwe chitsulo chimatha kuumitsa mu makulidwe ake panthawi yozimitsa.

Kulimba (Kuwumitsa Kuthekera):

Kuuma, kapena kuuma mphamvu, kumatanthauza kuuma kwakukulu komwe kungapezeke muzitsulo pambuyo pozimitsa. Zimakhudzidwa kwambiri ndi mpweya wa carbon muzitsulo. Mpweya wochuluka wa carbon nthawi zambiri umabweretsa kuuma kwakukulu, koma izi zikhoza kuchepetsedwa ndi ma alloying azitsulo ndi mphamvu ya kuzimitsa.

3.Kuuma kwa Zitsulo

√Lingaliro la Kuuma

Hardenability amatanthauza kuthekera kwachitsulo kukwaniritsa kuya kwina kwa martensitic kuumitsa pambuyo pozimitsa kutentha kwa austenitizing. M'mawu osavuta, ndi kuthekera kwachitsulo kupanga martensite pakuzimitsa.

Kuyeza kwa Kuuma

Kukula kwa kuuma kumasonyezedwa ndi kuya kwa wosanjikiza woumitsidwa wopezedwa pansi pazikhalidwe zotchulidwa pambuyo pozimitsa.

Kuzama Kwambiri Kwambiri: Uku ndiko kuya kuchokera pamwamba pa chogwirira ntchito kupita kudera lomwe kapangidwe kake ndi theka la martensite.

Common Quenching Media:

•Madzi

Makhalidwe: Yachuma komanso kuziziritsa mwamphamvu, koma imakhala ndi kuzizira kwambiri pafupi ndi malo otentha, zomwe zingayambitse kuzizira kwambiri.

Ntchito: Amagwiritsidwa ntchito ngati zitsulo za kaboni.

Madzi amchere: Njira yothetsera mchere kapena alkali m'madzi, yomwe imakhala ndi mphamvu yozizirira kwambiri pa kutentha kwakukulu poyerekeza ndi madzi, zomwe zimapangitsa kuti zikhale zoyenera zitsulo za carbon.

•Mafuta

Makhalidwe: Amapereka kuzizira pang'onopang'ono pa kutentha kotsika (pafupi ndi malo otentha), zomwe zimachepetsa bwino chizolowezi cha kupunduka ndi kusweka, koma zimakhala ndi kuzizira kochepa pa kutentha kwakukulu.

Ntchito: Yoyenera zitsulo za alloy.

Mitundu: Zimaphatikizapo mafuta azimitsira, mafuta a makina, ndi mafuta a dizilo.

Kutentha Nthawi

Nthawi yotentha imakhala ndi kutentha kwa kutentha (nthawi yomwe imatengedwa kuti ifike kutentha komwe kukufunika) ndi nthawi yogwira (nthawi yosungidwa pa kutentha komwe mukufuna).

Mfundo Zodziwira Nthawi Yowotcha: Onetsetsani kutentha kofananako pagawo lonse la ntchito, mkati ndi kunja.

Onetsetsani kuti austenitization wathunthu ndi kuti austenite anapanga ndi yunifolomu ndi zabwino.

Maziko Odziwira Nthawi Yowotcha: Nthawi zambiri amayesedwa pogwiritsa ntchito njira zoyeserera kapena kutsimikiziridwa poyesera.

Kutsitsa Media

Mbali Ziwiri Zofunikira:

a.Kuzizira Kwambiri: Kuzizira kwapamwamba kumalimbikitsa kupanga martensite.

b.Residual Stress: Kuzizira kwapamwamba kumawonjezera kupsinjika kotsalira, komwe kungayambitse chizolowezi chachikulu cha deformation ndi kusweka kwa workpiece.

Ⅶ.Kukhazikika

1. Tanthauzo la Normalizing

Normalizing ndi njira yochizira kutentha yomwe chitsulo chimatenthedwa kutentha kwa 30 ° C mpaka 50 ° C pamwamba pa kutentha kwa Ac3, komwe kumagwiritsidwa ntchito kutentha, ndiyeno mpweya utakhazikika kuti upeze microstructure pafupi ndi dziko lofanana. Poyerekeza ndi annealing, normalizing imakhala ndi kuzizira kwachangu, zomwe zimapangitsa kuti pearlite ikhale yabwino kwambiri (P) ndi mphamvu zapamwamba ndi kuuma.

2. Cholinga cha Normalizing

Cholinga cha normalizing ndi chofanana ndi annealing.

3. Ntchito za Normalizing

• Chotsani simenti yachiwiri ya networked.

• Kutumikira monga chomaliza kutentha mankhwala kwa mbali ndi zofunika otsika.

• Khalani ngati kukonzekera kutentha mankhwala otsika ndi sing'anga mpweya structural zitsulo kusintha machinability.

4. Mitundu ya Annealing

Mtundu Woyamba wa Annealing:

Cholinga ndi Ntchito: Cholinga sikuyambitsa kusintha kwa gawo koma kusintha zitsulo kuchokera ku dziko losalinganika kupita ku dziko loyenera.

Mitundu:

• Diffusion Annealing: Cholinga chake ndikupangitsa kuti pakhale tsankho pochotsa tsankho.

• Recrystallization Annealing: Kubwezeretsanso ductility pochotsa zotsatira za kuuma kwa ntchito.

• Kuchepetsa Kupsinjika Maganizo: Kumachepetsa kupsinjika kwamkati popanda kusintha mawonekedwe a microstructure.

Mtundu Wachiwiri wa Annealing:

Cholinga ndi Ntchito: Ikufuna kusintha mawonekedwe ang'onoang'ono ndi katundu, kukwaniritsa mawonekedwe oyendetsedwa ndi pearlite. Mtundu uwu umatsimikiziranso kuti kugawidwa ndi morphology ya pearlite, ferrite, ndi carbides kumakwaniritsa zofunikira zenizeni.

Mitundu:

• Full Annealing: Kutenthetsa chitsulo pamwamba pa kutentha kwa Ac3 ndiyeno kuziziritsa pang'onopang'ono kuti apange mawonekedwe ofanana a pearlite.

• Annealing Yosakwanira: Kutenthetsa chitsulo pakati pa kutentha kwa Ac1 ndi Ac3 kuti asinthe pang'ono kapangidwe kake.

• Isothermal Annealing: Imatenthetsa chitsulo pamwamba pa Ac3, kutsatiridwa ndi kuzizira kofulumira mpaka kutentha kwa isothermal ndikugwira kuti mukwaniritse zomwe mukufuna.

• Spheroidizing Annealing: Amapanga mawonekedwe a spheroidal carbide, kuwongolera machinability ndi kulimba.

Ⅷ.1.Tanthauzo la Chithandizo cha Kutentha

Chithandizo cha kutentha chimatanthawuza njira yomwe zitsulo zimatenthedwa, zomwe zimachitika pa kutentha kwapadera, ndiyeno zitakhazikika pamene zili zolimba kuti zisinthe mawonekedwe ake amkati ndi microstructure, potero kukwaniritsa zofunikira.

2.Makhalidwe a Chithandizo cha Kutentha

Chithandizo cha kutentha sichimasintha mawonekedwe a workpiece; m'malo mwake, amasintha mawonekedwe amkati ndi microstructure yachitsulo, zomwe zimasintha zitsulo zachitsulo.

3.Cholinga cha Chithandizo cha Kutentha

Cholinga cha kutentha kutentha ndi kukonza makina kapena processing katundu wa zitsulo (kapena workpieces), kugwiritsa ntchito mokwanira kuthekera kwa chitsulo, kupititsa patsogolo ubwino wa workpiece, ndi kuwonjezera moyo wake utumiki.

4.Mapeto Ofunikira

Kaya katundu wa chinthu akhoza kusinthidwa kudzera mu chithandizo cha kutentha kumadalira kwambiri ngati pali kusintha kwa microstructure ndi kapangidwe kake panthawi ya kutentha ndi kuzizira.

Nthawi yotumiza: Aug-19-2024