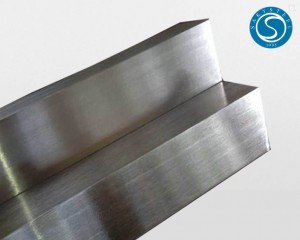

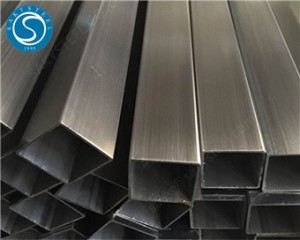

ER2209 ER2553 ER2594 Waya Wowotcherera

Kufotokozera Kwachidule:

Mtengo wa ER2209adapangidwa kuti aziwotcherera zitsulo zosapanga dzimbiri ngati 2205 (Nambala ya UNS N31803). Kulimba kwamphamvu kwambiri komanso kukana kupsinjika kwa corrosion kung'ambidwa ndi pitting kumadziwika ndi ma welds a waya. Wayayu ndi wocheperako poyerekeza ndi chitsulo choyambira kuti azitha kuwotcherera bwino.

Mtengo wa ER2553amagwiritsidwa ntchito makamaka kuwotcherera zitsulo zosapanga dzimbiri zomwe zimakhala ndi pafupifupi 25% chromium. Ili ndi microstructure ya 'duplex' yokhala ndi matrix austenite-ferrite. Aloyi ya duplex iyi imadziwika ndi kulimba kwamphamvu kwambiri, kukana kupsinjika kwa corrosion kung'ambika komanso kukana bwino pakubowola.

Mtengo wa ER2594ndi waya wowotcherera wa superduplex. Pitting Resistance Equivalent Number (PREN) ndi osachepera 40, motero amalola kuti zitsulo zowotcherera zizitchedwa superduplex zitsulo zosapanga dzimbiri. Waya wowotcherera uyu amapereka mawonekedwe ofananirako a chemistry ndi makina amakina opangira ma superduplex alloys monga 2507 ndi Zeron 100 komanso ma superduplex casting alloys (ASTM A890). Waya wowotcherera uyu wapangidwa ndi 2-3 peresenti mu Nickel kuti apereke chiŵerengero chabwino cha ferrite/austenite pakuwotcherera komalizidwa. Kapangidwe kameneka kamapangitsa kuti pakhale mphamvu zolimba komanso zopatsa mphamvu komanso kukana kwambiri kwa SCC ndi dzimbiri.

| Zofotokozera za Welding Wire Rod: |

Zofotokozera:AWS 5.9, ASME SFA 5.9

Gulu:TIG/MIG ER304 ER308L ER308L ER309L,ER2209 ER2553 ER2594

Welding waya diameter:

MIG - 0.8 mpaka 1.6 mm,

TIG - 1 mpaka 5.5 mm,

Waya wapakati - 1.6 mpaka 6.0

Pamwamba:Wowala, Wamtambo, Wopanda, Wakuda

| ER2209 ER2553 ER2594 Wowotchera waya ndodo Chemical Composition ndi Mechanical properties (saky steel): |

| Gulu | C | Mn | Si | P | S | Cr | Ni |

| ER2209 | 0.03 max | 0.5 - 2.0 | 0.9 max | 0.03 max | 0.03 max | 21.5 - 23.5 | 7.5 - 9.5 |

| Mtengo wa ER2553 | 0.04 max | 1.5 | 1.0 | 0.04 max | 0.03 max | 24.0 - 27.0 | 4.5 - 6.5 |

| Mtengo wa ER2594 | 0.03 max | 2.5 | 1.0 | 0.03 max | 0.02 max | 24.0 -27.0 | 8.0 - 10.5 |

| Chifukwa Chosankha Ife: |

1. Mutha kupeza zinthu zabwino kwambiri malinga ndi zomwe mukufuna pamtengo wotsika kwambiri.

2. Timaperekanso Reworks, FOB, CFR, CIF, ndi mitengo yobweretsera khomo ndi khomo. Tikukulangizani kuti mugwiritse ntchito zotumiza zomwe zingakhale zotsika mtengo.

3. Zida zomwe timapereka ndizotsimikizika kotheratu, kuyambira pa chiphaso choyezera zinthu mpaka pachiwonetsero chomaliza. (Malipoti awonetsa pakufunika)

4. e chitsimikizo kupereka yankho mkati 24hours(nthawi zambiri mu ola lomwelo)

5. Mutha kupeza njira zina zogulitsira, zoperekera mphero ndikuchepetsa nthawi yopanga.

6. Ndife odzipereka kwathunthu kwa makasitomala athu. Ngati sizingatheke kukwaniritsa zomwe mukufuna mutapenda zonse zomwe mungasankhe, sitidzakusocheretsani popanga malonjezo abodza omwe angapangitse ubale wabwino ndi makasitomala.

| Chitsimikizo cha Ubwino wa SAKY STEEL (kuphatikiza zonse Zowononga ndi Zosawononga): |

1. Mayeso a Visual Dimension

2. Kuwunika kwamakina monga kukhazikika, kutalika ndi kuchepetsa dera.

3. Kusanthula zotsatira

4. Kusanthula kwa mankhwala

5. Mayeso olimba

6. Kuyesa chitetezo cha pitting

7. Mayeso Olowera

8. Intergranular Corrosion Testing

9. Mayeso Olimba

10. Metallography Experimental Test

| Phukusi la SAKY STEEL'S: |

1. Kulongedza ndi kofunika kwambiri makamaka ngati katundu wapadziko lonse lapansi amadutsa munjira zosiyanasiyana kuti akafike komwe akupita, chifukwa chake timayika chidwi chapadera pakuyika.

2. Saky Steel's amanyamula katundu wathu m'njira zambiri kutengera zomwe timapanga. Timanyamula katundu wathu m'njira zingapo, monga,

Ndemanga pa Phukusi:

| Mtundu Wawaya | Kukula kwa Waya | Kulongedza | Kalemeredwe kake konse | |||||||||

| Mtengo wa MIG | φ0.8~1.6(mm) | D100mm D200mm D300mm D270mm | 1kg 5kg 12.5kg 15kg 20kg | |||||||||

| Mtengo wa TIG | φ1.6~5.5(mm) | 1 mita / Mabokosi | 5kg 10kg | |||||||||

| Waya wapakati | φ1.6~5.5(mm) | Coil kapena Drum | 30kg - 500kg | |||||||||