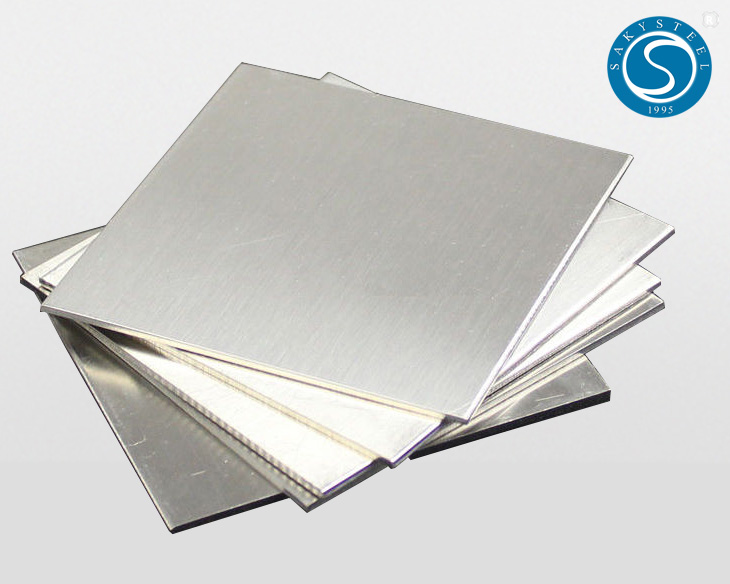

317 Pepala lachitsulo chosapanga dzimbiri

Kufotokozera Kwachidule:

| Zofotokozera zachitsulo chosapanga dzimbiri pepala: |

Zofotokozera:ASTM A240 / ASME SA240

Gulu:304L, 316L, 317, 317L, 409L, 321,347, 347H, 410, 420, 253SMA, 254SMO, 2205

M'lifupi:1000mm, 1219mm, 1500mm, 1800mm, 2000mm, 2500mm, 3000mm, 3500mm, etc.

Utali:2000mm, 2440mm, 3000mm, 5800mm, 6000mm, etc.

Makulidwe:0.3 mpaka 60 mm

Surface Finish :Hot adagulung'undisa mbale (HR), Cold adagulung'undisa pepala (CR), 2B, 2D, BA, NO.1, NO.4, NO.8, 8K, galasi, Chofufuzidwa, embossed, tsitsi mzere, mchenga kuphulika, burashi, etching, SATIN (Anakumana ndi Pulasitiki TACHIMATA) etc.

Fomu :Ma coils, Zolembapo, Mipukutu, Mapepala Oyera, Mapepala a Shim, Mapepala Obowoleza, Mbale Wopendekera, Mzere, Ma Flats, Chopanda kanthu (Mzunguli), mphete (Flange) etc.

| Mapepala a Stainless Steel 317/317L & Plate Equivalent Grades: |

| ZOYENERA | Mbiri ya WERKSTOFF NR. | UNS | JIS | EN |

| Chithunzi cha SS317 | 1.4449 | S31700 | Mtengo wa 317 | - |

| Mtengo wa SS317L | 1.4438 | S31703 | Mtengo wa 317L | X2CrNiMo18-15-4 |

| Mapepala a SS 317 / 317L, Mapepala Opangidwa ndi Ma Chemicals ndi Mawotchi: |

| Maphunziro | C | Mn | Si | P | S | Cr | Mo | Ni | Fe |

| Chithunzi cha SS317 | 0.08 max | 2.0 max | 1.0 max | 0.045 kukula | 0.030 kukula | 18.00 - 20.00 | 3.00 - 4.00 | 11.00 - 15.00 | 57.845 mphindi |

| Mtengo wa SS317L | 0.035 kukula | 2.0 max | 1.0 max | 0.045 kukula | 0.030 kukula | 18.00 - 20.00 | 3.00 - 4.00 | 11.00 - 15.00 | 57.89 mphindi |

| Kuchulukana | Melting Point | Kulimba kwamakokedwe | Mphamvu Zokolola (0.2% Offset) | Elongation |

| 7.9g/cm3 | 1400 °C (2550 °F) | Psi – 75000 , MPa – 515 | Psi – 30000, MPa – 205 | 35 % |

| Chifukwa Chosankha Ife: |

1. Mutha kupeza zinthu zabwino kwambiri malinga ndi zomwe mukufuna pamtengo wotsika kwambiri.

2. Timaperekanso Reworks, FOB, CFR, CIF, ndi mitengo yobweretsera khomo ndi khomo. Tikukulangizani kuti mugwiritse ntchito zotumiza zomwe zingakhale zotsika mtengo.

3. Zida zomwe timapereka ndizotsimikizika kotheratu, kuyambira pa chiphaso choyezera zinthu mpaka pachiwonetsero chomaliza. (Malipoti awonetsa pakufunika)

4. e chitsimikizo kupereka yankho mkati 24hours(nthawi zambiri mu ola lomwelo)

5. Mutha kupeza njira zina zogulitsira, zoperekera mphero ndikuchepetsa nthawi yopanga.

6. Ndife odzipereka kwathunthu kwa makasitomala athu. Ngati sizingatheke kukwaniritsa zomwe mukufuna mutapenda zonse zomwe mungasankhe, sitidzakusocheretsani popanga malonjezo abodza omwe angapangitse ubale wabwino ndi makasitomala.

| Chitsimikizo cha Ubwino wa SAKY STEEL (kuphatikiza zonse Zowononga ndi Zosawononga): |

1. Mayeso a Visual Dimension

2. Kuwunika kwamakina monga kukhazikika, kutalika ndi kuchepetsa dera.

3. Kusanthula zotsatira

4. Kusanthula kwa mankhwala

5. Mayeso olimba

6. Kuyesa chitetezo cha pitting

7. Mayeso Olowera

8. Intergranular Corrosion Testing

9. Mayeso Ovuta

10. Metallography Experimental Test

| Phukusi la SAKY STEEL'S: |

1. Kulongedza ndi kofunika kwambiri makamaka ngati katundu wapadziko lonse lapansi amadutsa munjira zosiyanasiyana kuti akafike komwe akupita, chifukwa chake timayika chidwi chapadera pazonyamula.

2. Saky Steel's amanyamula katundu wathu m'njira zambiri kutengera zomwe timapanga. Timanyamula katundu wathu m'njira zingapo, monga,

Mapulogalamu:

1. Chemical Processing

2. Kukonza Chakudya - zipangizo ndi kusunga

3. Petroleum Refining - madzimadzi chothandizira akulimbana mayunitsi, polythionic asidi ntchito

4. Kupanga Mankhwala

5. Zinyalala Kutentha Kubwezeretsa - recuperators