316 Chitoliro chosapanga dzimbiri chosapanga dzimbiri

Kufotokozera Kwachidule:

| Zofotokozera zazitsulo zosapanga dzimbiri zopanda msoko: |

Mipope Yopanda Msoko & Kukula Kwamachubu :1/8″ NB – 24″ NB

Zofotokozera:ASTM A/ASME SA213, A249, A269, A312, A358, A790

Standard :ASTM, ASME

Gulu:304, 316, 321, 321Ti, 420, 430, 446, 904L, 2205, 2507

Njira:Wotentha-wodzigudubuza, wozizira

Utali:5.8M, 6M & Utali Wofunika

Diameter Yakunja:6.00 mm OD mpaka 914.4 mm OD, Kukula mpaka 24 ” NB

Thickness :0.3mm – 50 mm, SCH 5, SCH10, SCH 40, SCH 80, SCH 80S, SCH 160, SCH XXS, SCH XS

Ndandanda:SCH20, SCH30, SCH40, STD, SCH80, XS, SCH60, SCH80, SCH120, SCH140, SCH160, XXS

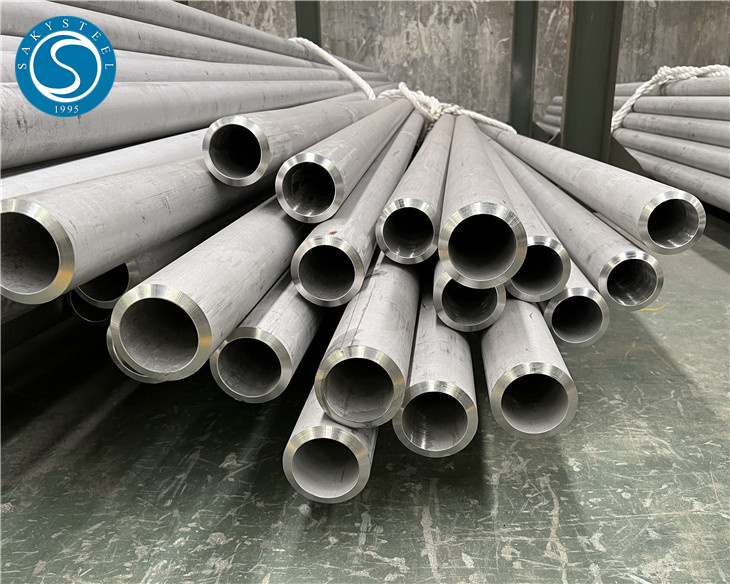

Mitundu :Mipope Yopanda Msoko

Fomu :Zozungulira, Square, Rectangle, Hydraulic, Honed Tubes

TSIRIZA :Mapeto Oyera, Mapeto A Beveled, Opondapo

| SS 316 Mapaipi Osasinthika Mapangidwe Amankhwala: |

| Gulu | C | Mn | Si | P | S | Cr | Ni |

| Chithunzi cha SS316 | 0.08 max | 2 max | 0.75 max | 0.045 kukula | 0.030 kukula | 16-18 | 0.10 |

| Katundu Wamakina a Chitoliro Chachitsulo chosapanga dzimbiri: |

| Gulu | Mphamvu ya Tensile (MPa) min | Zokolola Zamphamvu 0.2% Umboni (MPa) min | Elongation (% mu 50mm) min | Kuuma | |

| Rockwell B (HR B) max | Brinell (HB) max | ||||

| 316 | 515 | 205 | 40 | 95 | 217 |

| Njira Yopangira Mapaipi Opanda Zitsulo: |

Chithunzichi chikuwonetsa zonsenjira yopanga chitoliro chopanda msoko, yopangidwa ndi magawo asanu ndi atatu ofunika: kukonzekera zinthu, kuthira mafuta, kuthira madzi, kugaya pamwamba, kuyeretsa asidi, kujambula kozizira, kuyezetsa akupanga, ndi kuyika komaliza. Gawo lirilonse limayang'aniridwa mosamala kuti liwonetsetse kulondola kwapamwamba, kutsirizika kwapamwamba kwambiri, ndi khalidwe lamkati, kukwaniritsa zofunikira zamafakitale.

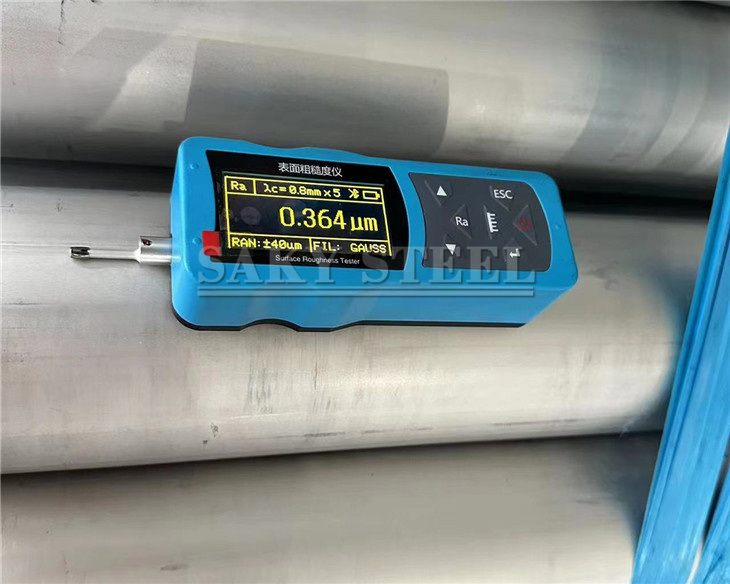

| 316 Stainless Steel Pipe Raughness test: |

Ku SAKY STEEL timayesa kuuma mwamphamvu pa mapaipi achitsulo chosapanga dzimbiri kuti tiwonetsetse kuti pamakhala malo osalala komanso osasinthika omwe amakwaniritsa miyezo yapadziko lonse lapansi. Kuvuta kwa chitoliro ndichinthu chofunikira kwambiri chomwe chimakhudza kukana kwa dzimbiri kwakuyenda bwino komanso magwiridwe antchito onse pamapulogalamu ovuta.

Timagwiritsa ntchito zida zolondola kuyeza makulidwe apamwamba kuwonetsetsa kuti mapaipi onse amakwaniritsa zofunikira za kasitomala kuti azitha kusalala komanso kumaliza. Mapaipi athu ndi abwino kwa mafakitale opanga zakudya zam'madzi komanso zamapangidwe komwe kumayenera kukhala koyenera.

|  |

| Kuyesa Pamwamba Papaipi Yopanda Zitsulo: |

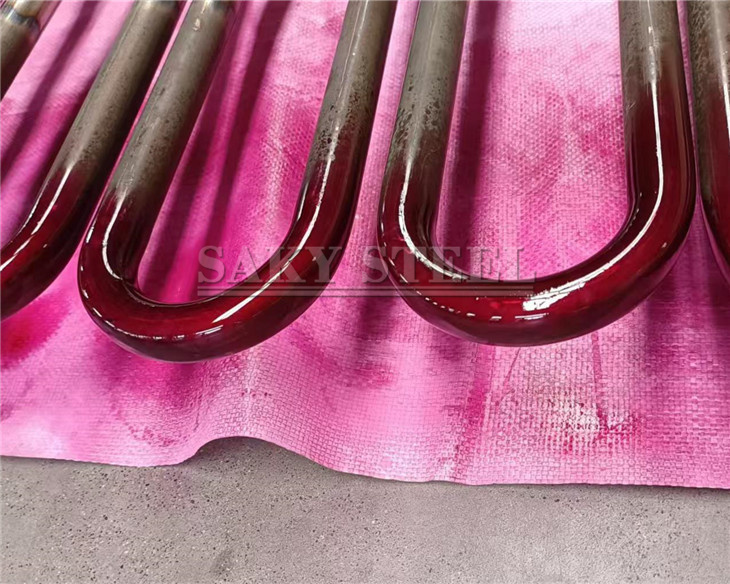

Kutha kwapaipi yazitsulo zosapanga dzimbiri ndikofunikira kwambiri pakuchita bwino komanso mawonekedwe. Ku SAKY STEEL timayendetsa mosamalitsa kukongola kwa pamwamba kudzera mumayendedwe apamwamba kwambiri. Chithunzichi chikuwonetsa kufananitsa bwino pakati pa mapaipi oyipa okhala ndi zolakwika zowoneka bwino komanso mapaipi athu abwino okhala ndi kumaliza kosalala komanso kofanana.

Mipope yathu yachitsulo chosapanga dzimbiri ilibe ming'alu ya ming'alu ndi zizindikiro zowotcherera zomwe zimatsimikizira kulimba kwa dzimbiri komanso kudalirika. Mapaipiwa amagwiritsidwa ntchito kwambiri m'madzi am'madzi komanso m'mapangidwe omwe amafunikira kukhulupirika kwapamtunda.

| Mayeso a PT: |

SAKY STEEL imapanga kuyesa kolowera kwa PT pamapaipi achitsulo chosapanga dzimbiri ndi zigawo zina monga gawo lathu lokhazikika lowongolera. PT ndi njira yoyesera yosawononga yomwe imagwiritsidwa ntchito kuti izindikire zolakwika zapamtunda monga ming'alu ya porosity ndi inclusions zomwe sizikuwoneka ndi maso.

Oyang'anira athu ophunzitsidwa amagwiritsa ntchito zida zapamwamba zolowera komanso zopanga kuti zitsimikizire zolondola komanso zodalirika. Njira zonse za PT zimatsata miyezo yapadziko lonse lapansi komanso zomwe kasitomala amatsimikizira chitetezo ndi magwiridwe antchito.

|  |

| Chifukwa Chosankha Ife : |

1. Mutha kupeza zinthu zabwino kwambiri malinga ndi zomwe mukufuna pamtengo wotsika kwambiri.

2. Timaperekanso Reworks, FOB, CFR, CIF, ndi mitengo yobweretsera khomo ndi khomo. Tikukulangizani kuti mugwiritse ntchito zotumiza zomwe zingakhale zotsika mtengo.

3. Zida zomwe timapereka ndizotsimikizika kotheratu, kuyambira pa chiphaso choyezera zinthu mpaka pachiwonetsero chomaliza. (Malipoti awonetsa pakufunika)

4. e chitsimikizo kupereka yankho mkati 24hours(nthawi zambiri mu ola lomwelo)

5. Mutha kupeza njira zina zogulitsira, zoperekera mphero ndikuchepetsa nthawi yopanga.

6. Ndife odzipereka kwathunthu kwa makasitomala athu. Ngati sizingatheke kukwaniritsa zomwe mukufuna mutapenda zonse zomwe mungasankhe, sitidzakusocheretsani popanga malonjezo abodza omwe angapangitse ubale wabwino ndi makasitomala.

| Chitsimikizo cha Ubwino (kuphatikiza zonse Zowononga ndi Zosawononga): |

1. Mayeso a Visual Dimension

2. Kuwunika kwamakina monga kukhazikika, kutalika ndi kuchepetsa dera.

3. Kuyesa kwakukulu

4. Kusanthula kwa mankhwala

5. Mayeso olimba

6. Kuyesa chitetezo cha pitting

7. Kuyesa kwa Flaring

8. Mayeso a Madzi-Jet

9. Mayeso Olowera

10. Mayeso a X-ray

11. Intergranular Corrosion Testing

12. Kusanthula zotsatira

13. Eddy panopa kufufuza

14. Kusanthula kwa Hydrostatic

15. Metallography Experimental Test

| Kuyika: |

1. Kulongedza ndi kofunika kwambiri makamaka ngati katundu wapadziko lonse lapansi amadutsa munjira zosiyanasiyana kuti akafike komwe akupita, chifukwa chake timayika chidwi chapadera pazonyamula.

2. Saky Steel's amanyamula katundu wathu m'njira zambiri kutengera zomwe timapanga. Timanyamula katundu wathu m'njira zingapo, monga,

Mapulogalamu:

1. Makampani a Paper & Pulp

2. Mapulogalamu Othamanga Kwambiri

3. Makampani a Mafuta ndi Gasi

4. Chemical Refinery

5. Chitoliro

6. Kutentha Kwambiri Kugwiritsa Ntchito

7. Chitoliro cha Madzi

8. Zomera Zanyukiliya

9. Kukonza Chakudya ndi Mafakitale a Mkaka

10. Boiler & Heat Exchangers