The fusing method of a stainless steel wire rope generally refers to the welding or connection technology used during the connection, joint or termination of the wire rope.

1.Ordinary Melting

Definition: Ordinary melting involves heating the contact area of the steel wire rope to a high temperature, causing it to melt and fuse. The melted part solidifies as it cools, forming a strong connection, typically used for the rope's joint section.

Characteristics: Ordinary melting is commonly used for high-strength connections, and the welded area typically has a strength similar to or slightly lower than the wire rope itself. It is suitable for most steel wire rope joint requirements, and the joint formed is generally very durable.

2. Soldering

Definition: Soldering involves using a low-temperature alloy (such as tin) to melt and bond the steel wire rope’s joint area. The temperature used in soldering is relatively low and is typically employed for smaller diameter or lighter load ropes, or for applications requiring electrical conductivity.

Characteristics: The strength of a soldered joint is typically lower than ordinary melting, making it more suitable for applications that don’t involve heavy loads. The advantage of soldering is that it operates at a lower temperature, which prevents damage to the material. However, its downside is that the joint's strength is generally lower.

3. Spot Welding

Definition: Spot welding is a process where electrical current is passed through the wire rope's joint area, generating heat to melt and connect two parts. This process typically forms one or more small spot connections, often used for connecting multiple wires or the ends of steel ropes.

Characteristics: Spot welding is suitable for smaller steel wire rope joints. Due to the small welding area, it is generally used for lighter load applications. The advantage is fast connection, but the welding strength depends on the area of the joint.

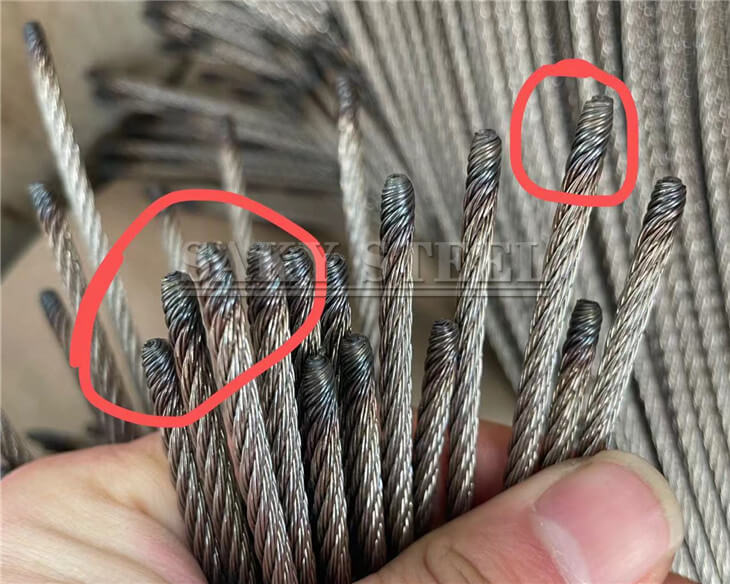

4. Rectangular Melting

Definition: Rectangular melting is a method where the ends of the steel wire rope are melted and then formed into a rectangular shape to create the connection. This method is used when a specific shape or sealing effect is required.

Characteristics: Rectangular melting involves melting and re-forming the joint into a rectangular structure, providing a stronger connection. It is typically used in applications requiring stronger or more secure jointing, especially for high-strength steel wire rope connections.

Summary

These melting or welding methods each have their advantages and disadvantages. The appropriate method is selected based on the specific application:

• Ordinary melting is suitable for strong connections that need to withstand higher loads.

• Soldering is better for lighter load applications, especially where low-temperature welding is required.

• Spot welding is used for quick connections, typically in smaller steel wire rope joints.

• Rectangular melting is ideal for creating specific joint shapes and providing enhanced stability.

Post time: Jan-07-2025