1.Stainless steel capillary tube pipe concept:

I. Used in automation instrument signal tubes, automation instrument wire protection tubes, etc., building materials with good flexibility, corrosion resistance, high temperature resistance, abrasion resistance, tensile resistance, water resistance and excellent electromagnetic shielding performance.

II. It has a certain degree of tensile strength to prevent the damage of the hose from exposing the lines laid inside the hose, and the axial tension can withstand more than 6 times the nominal inner diameter.

Specification: outer diameter:0.8 to 8mm wall thickness: 0.1-2.0mm

Material: SUS316L, 316, 321, 310, 310S, 304, 304L, 302, 301, 202, 201, etc.

2. Applications:

As a raw material, Stainless steel capillary tubes are widely used in various fields such as chemical industry, petroleum, electronics, accessories, medical treatment, aerospace, air conditioning, medical equipment, kitchen appliances, pharmacy, water supply equipment, food machinery, power generation, boilers and so on.

1): Medical equipment industry, injection needle tube, puncture needle tube, medical industrial tube.

2):Industrial electric heating pipe,Stainless industrial oil pipe

3): Temperature sensor tube, sensor tube, barbecue tube, thermometer tube, thermostat tube, instrumentation tube, thermometer stainless steel tube.

4): Pen tube, core protection tube, pen tube for pen manufacturing industry.

5): Various electronic microtubes, optical fiber accessories, optical mixers, small diameter stainless steel capillaries

6): Watch industry, mother-to-child communication, raw ear rods, watch band accessories, jewellery punching needles

7): Various antenna tubes, car tail antenna tubes, whip antenna tubes, extension pointers, mobile phone extension tubes, miniature antenna tubes, laptop antennas, stainless steel antennas.

8): Stainless steel tube for laser engraving equipment.

9): Fishing tackle tube, fishing rod tube

10): Various catering industry pipes, pipes for conveying materials.

3.Flow chart:

Raw materials =>Stainless Steel Strips=>Welding=> Wall reduction => Reduced caliber => Straighten=>Cutting => Package => Shipping

4.Cutting technology of stainless steel capillary tube:

I.Grinding wheel cutting: This is currently the most used cutting method. As the name suggests, it uses a grinding wheel as a cutting tool to cut stainless steel on and on it; it is also the cheapest cutting method, but because of its cutting A lot of burrs will be generated, so the deburring process is needed in the later stage. Some customers have no requirements for pipe burrs. This method is the simplest and lowest cost.

II.Wire cutting: It is to let the stainless steel capillary tube wire on the wire cutting machine, but this method will cause discoloration of the nozzle. In the case of more demanding buyers, it needs to be processed by later processing, such as polishing and grinding. Wire cutting is rough

Metal circular saw cutting: The cutting effect of this cutting technology is not too big, and several pieces can be cut together, which is very efficient; but the disadvantage is that the chips are easy to stick to the tool, so you must be very careful in selecting the saw blade .

Laser cutting: The quality of the stainless steel capillary tube cut by laser is the best. The nozzle has no burrs, precise size, and the material near the cut is not affected. It has high efficiency, zero consumables, safety and environmental protection and zero pollution. It can be operated automatically when it is powered on. , Save labor. It is generally suitable for customers who have higher requirements on the quality of pipe fittings and smaller dimensional errors, and are mostly used in precision instruments.

Manufacturers generally use grinding wheels for cutting tubes. Medical needle tubes are not suitable for laser cutting or wire cutting. The incisions are not well cut by grinding wheels.

Different cutting methods will have corresponding advantages and disadvantages, depending on the needs of customers. In addition, the quality of the cutting equipment and the proficiency of the cutting technicians are also affected by the quality of the stainless steel pipe.

5.Specific case presentation:

I.316 Stainless Steel precision tube:

Product use: These tubes are used to make machines that inject gas into the meat, and the bending is to prevent the meat from entering the machine and making the machine jam

II. 304 Stainless Steel Needle Tube:

III. Medical probe Stainless Steel capillary tubes:

IV: Medical syringe needle:

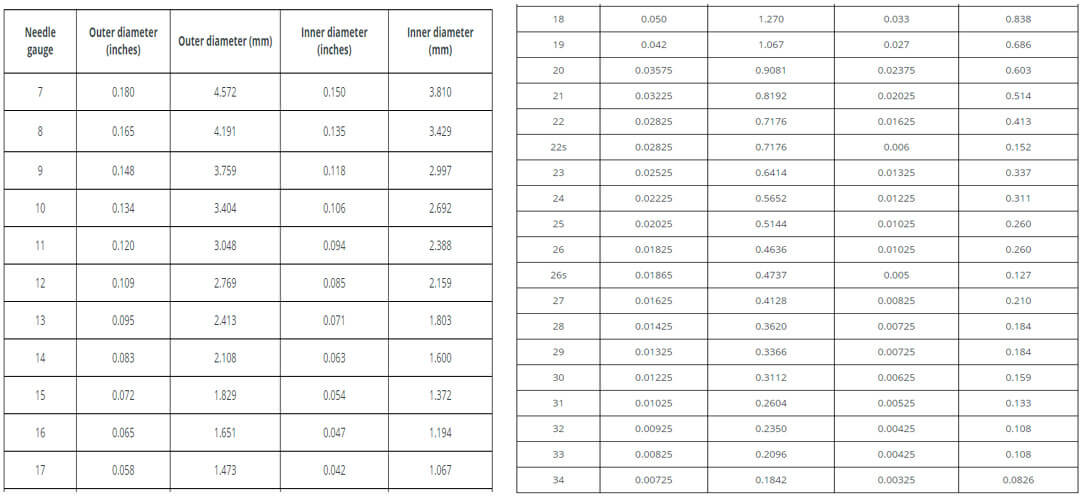

6.Capillary Tubes GAUGE-Comparison Table:

Post time: Jul-06-2021