AISI 310S UNS S31008 EN 1.4845

AISI 314 UNS S31400 EN 1.4841

Types 310S SS and 314 SS are highly alloyed austenitic stainless steels designed for service at elevated temperature. The high Cr and Ni contents enable this alloy to resist oxidation in continuous service at temperatures up to 2200°F provided reducing sulfur gases are not present. In intermittent service, 310S SS can be used at temperatures up to 1900°F as it resists scaling and has a relatively low coefficient of expansion. Increased level of silicon in 314 SS further improves oxidation resistance at higher temperature. Carburizing atmosphere may reduce the total life depending on the actual conditions. However, these grades have superior resistance compared to lower-chromium-nickel grades.

These grades are used for their high-temperature oxidation resistance for applications such as furnace parts, furnace conveyer belts, insulation holding studs, etc.

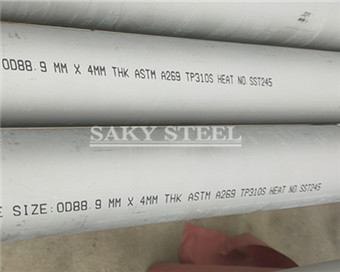

PROUDCTS AVAILABLE

See product sheet for dimensions, tolerances, finishes available and other details.

Standard Chemical Composition

|

Elements |

|

C | MN | P | S | SI | CR | NI | |

|

UNS 31000 |

AISI 310 |

Min |

|

|

|

|

|

24.00 | 19.00 |

| Max | 0.25 | 2.00 | 0.045 | 0.030 | 1.50 | 26.00 | 22.00 | ||

|

UNS 31008 |

AISI 310S |

Min |

|

|

|

|

|

24.00 | 19.00 |

| Max | 0.08 | 2.00 | 0.045 | 0.030 | 1.50 | 26.00 | 22.00 | ||

|

UNS 31400 |

AISI 314 |

Min |

|

|

|

|

1.50 | 23.00 | 19.00 |

| Max | 0.25 | 2.00 | 0.045 | 0.030 | 3.00 | 26.00 | 22.00 | ||

Nominal Mechanical Properties (annealed condition)

| Tensile Strength

ksi[MPa] |

Yield Strength

ksi[MPa] |

% Elongation

4d |

% Reduction in

Area |

|

95[655] |

45[310] |

50 | 60 |

Post time: Jun-29-2020