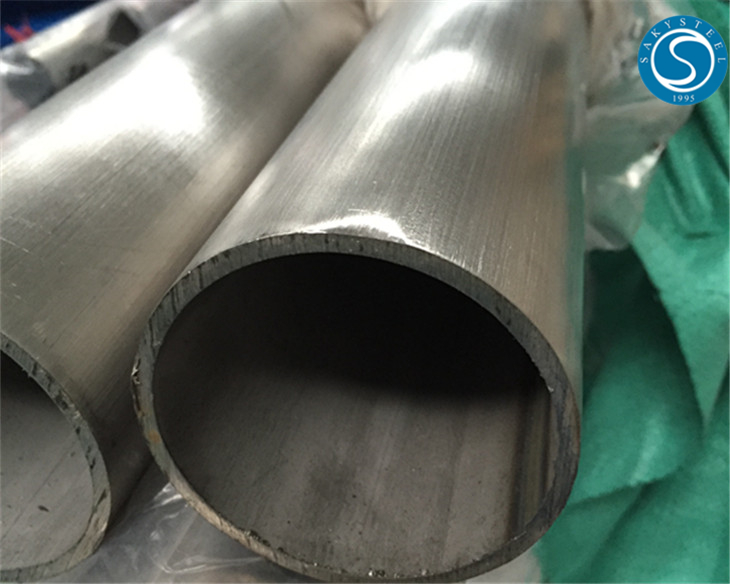

Paip Keluli Tahan Karat Digilap

Penerangan ringkas:

| Spesifikasi paip keluli tahan karat yang digilap: |

| 1. Produk | Paip Kimpalan Keluli Tahan Karat |

| 2. Bahan | 201,202,301,302,304,309,310S,316L,321,347,410,430,409Letc. |

| 3. Standard | ASTM, ASME, DIN, EN, ISO, JIS, GOST, dsb. |

| 4. Julat saiz | OD: dari 6mm hingga 1219mm (NPS dari 1/8” hingga 40”) |

| WT: dari 0.7mm hingga 38mm (Jadual dari 5S hingga XXS) | |

| Panjang: betulkan panjang atau nyahbetulkan panjang, Maks 30meter | |

| 5. Proses menghasilkan | dikimpal, lenturan panas; kimpalan rintangan; Pengembangan terma dsb. |

| 6. Permukaan | 2B,Acar,180G, 320G, Satin, Garis Rambut,400G, 500G, 600G |

| ,800G, Kemasan cermin | |

| 7. Menanda | SAKY, GRED, Lancar, Standard, Saiz, Haba NO. |

| 8. Pakej | Ikatan dengan kain kalis air di luar. |

| atau kotak papan lapis. | |

| 9. Panjang | 5.8m,6m,12m atau mengikut keperluan |

| Sifat mekanikal biasa untuk aloi keluli tahan karat 304: |

| Gred | Kekuatan Tegangan (MPa) | Kekuatan Mampatan (MPa) | Tekanan Bukti 0.2% (MPa) | Pemanjangan A5 (%) | Kekerasan Rockwell B |

| 304 | 520-720 | 210 | 210 | 45 Min | 92 |

| 304L | 500-670 | 200 | 45 Min | ||

| 304H | 520-720 | 210 | 45Min |

| Gred paip keluli tahan karat yang digilap: |

| taip | Gred | Gred | Komponen Kimia % | ||||

| Keluli tahan karat Austenit | C | Cr | Ni | Mn | |||

| 201 | 1Cr17Mn6Ni5N | 0.15 | 16.00-18.00 | 3.50-5.50 | 5.50-7.50 | ||

| 201L | 03Cr17Mn6Ni5N | 0.030 | 16.00-18.00 | 3.50-5.50 | 5.50-7.50 | ||

| 202 | 1Cr18Mn8Ni5N | 0.15 | 17.00-19.00 | 4.00-6.00 | 7.50-10.00 | ||

| 204 | 03Cr16Mn8Ni2N | 0.030 | 15.00-17.00 | 1.50-3.50 | 7.00-9.00 | ||

| 1Cr18Mn10Ni5Mo3N | 0.10 | 17.00-19.00 | 4.00-6.00 | 8.50-12.00 | |||

| 2Cr13Mn9Ni4 | 0.15-0.25 | 12.00-14.00 | 3.70-5.00 | 8.00-10.00 | |||

| 2Cr15Mn15Ni2N | 0.15-0.25 | 14.00-16.00 | 1.50-3.00 | 14.00-16.00 | |||

| 1Cr18Mn10Ni5Mo3N | 0.15 | 17.00-19.00 | 4.00-6.00 | 8.50-12.00 | |||

| 301 | 1Cr17Ni7 | 0.15 | 16.00-18.00 | 6.00-8.00 | 2.00 | ||

| 302 | 1Cr18Ni9 | 0.15 | 17.00-19.00 | 8.00-10.00 | 2.00 | ||

| 303 | Y1Cr18Ni9 | 0.15 | 17.00-19.00 | 8.00-10.00 | 2.00 | ||

| 303se | Y1Cr18Ni9Se | 0.15 | 17.00-19.00 | 8.00-10.00 | 2.00 | ||

| 304 | 0Cr18Ni9 | 0.07 | 17.00-19.00 | 8.00-10.00 | 2.00 | ||

| 304L | 00Cr19Ni10 | 0.030 | 18.00-20.00 | 8.00-10.00 | 2.00 | ||

| 304N1 | 0Cr19Ni9N | 0.08 | 18.00-20.00 | 7.00-10.50 | 2.00 | ||

| 304N2 | 0Cr18Ni10NbN | 0.08 | 18.00-20.00 | 7.50-10.50 | 2.00 | ||

| 304LN | 00Cr18Ni10N | 0.030 | 17.00-19.00 | 8.50-11.50 | 2.00 | ||

| 305 | 1Cr18Ni12 | 0.12 | 17.00-19.00 | 10.50-13.00 | 2.00 | ||

| 309S | 0Cr23Ni13 | 0.08 | 22.00-24.00 | 12.00-15.00 | 2.00 | ||

| 310S | 0Cr25Ni20 | 0.08 | 24.00-26.00 | 19.00-22.00 | 2.00 | ||

| 316 | 0Cr17Ni12Mo2 | 0.08 | 16.00-18.50 | 10.00-14.00 | 2.00 | ||

| 1Cr18Ni12Mo2Ti6) | 0.12 | 16.00-19.00 | 11.00-14.00 | 2.00 | |||

| 0Cr18Ni12Mo2Ti | 0.08 | 16.00-19.00 | 11.00-14.00 | 2.00 | |||

| 316L | 00Cr17Ni14Mo2 | 0.030 | 16.00-18.00 | 12.00-15.00 | 2.00 | ||

| 316N | 0Cr17Ni12Mo2N | 0.08 | 16.00-18.00 | 10.00-14.00 | 2.00 | ||

| 316N | 00Cr17Ni13Mo2N | 0.030 | 16.00-18.50 | 10.50-14.50 | 2.00 | ||

| 316J1 | 0Cr18Ni12Mo2Cu2 | 0.08 | 17.00-19.00 | 10.00-14.50 | 2.00 | ||

| 316J1L | 00Cr18Ni14Mo2Cu2 | 0.030 | 17.00-19.00 | 12.00-16.00 | 2.00 | ||

| 317 | 0Cr19Ni13Mo3 | 0.12 | 18.00-20.00 | 11.00-15.00 | 2.00 | ||

| 317L | 00Cr19Ni13Mo3 | 0.08 | 18.00-20.00 | 11.00-15.00 | 2.00 | ||

| 1Cr18Ni12Mo3Ti6 | 0.12 | 16.00-19.00 | 11.00-14.00 | 2.00 | |||

| 0Cr18Ni12Mo3Ti | 0.08 | 16.00-19.00 | 11.00-14.00 | 2.00 | |||

| 317J1 | 0Cr18Ni16Mo5 | 0.040 | 16.00-19.00 | 15.00-17.00 | 2.00 | ||

| 321 | 1Cr18Ni9Ti6 | 0.12 | 17.00-19.00 | 8.00-11.00 | 2.00 | ||

| 0Cr18Ni10Ti | 0.08 | 17.00-19.00 | 9.00-12.00 | 2.00 | |||

| 347 | 0Cr18Ni11Nb | 0.08 | 17.00-19.00 | 9.00-13.00 | 2.00 | ||

| XM7 | 0Cr18Ni9Cu3 | 0.08 | 17.00-19.00 | 8.50-10.50 | 2.00 | ||

| XM15J1 | 0Cr18Ni13Si4 | 0.08 | 15.00-20.00 | 11.50-15.00 | 2.00 | ||

| Austenit Keluli Tahan Karat Ferrite | 329J1 | 0Cr26Ni5Mo2 | 0.08 | 23.00-28.00 | 3.00-6.00 | 1.50 | 0.035 | 0.030 | 1.00-3.00 | 1.00 | - | - | 2) |

| 1Cr18Ni11Si4AlTi | 0.10-0.18 | 17.50-19.50 | 10.–120.. | 0.80 | 0.035 | 0.030 | - | 3.40-4.00 | - | - | Al 0.10-0.30; Ti 0.40-0.70 | ||

| 00Cr18Ni5MoSi2 | 0.030 | 18.00-19.50 | 4.50-5.50 | 1.00-2.00 | 0.035 | 0.030 | 2.50-3.00 | 1.30-2.00 | - | - | - | ||

| Keluli Tahan Karat Ferrite | 405 | 0Cr13Al | 0.08 | 11.50-14.50 | 3) | 1.00 | 0.035 | 0.030 | - | 1.00 | - | - | Al 0.10-0.30 |

| 410L | 00Cr12 | 0.030 | 11.00-13.00 | 3) | 1.00 | 0.035 | 0.030 | - | 1.00 | - | - | - | |

| 430 | 1Cr17 | 0.12 | 16.00-18.00 | 3) | 1.25 | 0.035 | 0.030 | - | 0.75 | - | - | - | |

| 430F | Y1Cr17 | 0.12 | 16.00-18.00 | 3) | 1.00 | 0.035 | 0.15 | 1) | 1.00 | - | - | - | |

| 434 | 1Cr17Mo | 0.12 | 16.00-18.00 | 3) | 1.00 | 0.035 | 0.030 | 0.75-1.25 | 1.00 | - | - | - | |

| 447J1 | 00Cr30Mo2 | 0.010 | 28.50-32.00 | - | 0.40 | 0.035 | 0.030 | 1.50-2.50 | 0.40 | - | 0.015 | - | |

| XM27 | 00Cr27Mo | 0.010 | 25.00-27.50 | - | 0.40 | 0.035 | 0.030 | 0.75-1.50 | 0.40 | - | 0.015 | - |

| Keluli tahan karat martensit | 403 | 1Cr12 | 0.15 | 11.50-13.00 | 3) | 1.00 | 0.035 | 0.030 | - | 0.50 | - | - | - |

| 410 | 1Cr13 | 0.15 | 11.50-13.50 | 3) | 1.00 | 0.035 | 0.030 | - | 1.00 | - | - | - | |

| 405 | 0Cr13 | 0.08 | 11.50-13.50 | 3) | 1.00 | 0.035 | 0.030 | - | 1.00 | - | - | - | |

| 416 | Y1Cr13 | 0.15 | 12.00-14.00 | 3) | 1.25 | 0.035 | 0.15 | 1) | 1.00 | - | - | - | |

| 410J1 | 1Cr13Mo | 0.08-0.18 | 11.50-14.00 | 3) | 1.00 | 0.035 | 0.030 | 0.30-0.60 | 0.60 | - | - | - | |

| 420J1 | 2Cr13 | 0.16-0.25 | 12.00-14.00 | 3) | 1.00 | 0.035 | 0.030 | - | 1.00 | - | - | - | |

| 420J2 | 3Cr13 | 0.26-0.35 | 12.00-14.00 | 3) | 1.00 | 0.035 | 0.030 | - | 1.00 | - | - | - | |

| 420F | Y3Cr13 | 0.26-0.40 | 12.00-14.00 | 3) | 1.25 | 0.035 | 0.15 | 1) | 1.00 | - | - | - | |

| 3Cr13Mo | 0.28-0.35 | 12.00-14.00 | 3) | 1.00 | 0.035 | 0.030 | 0.50-1.00 | 0.80 | - | - | - | ||

| 4Cr13 | 0.36-0.45 | 12.00-14.00 | 3) | 0.80 | 0.035 | 0.030 | - | 0.60 | - | - | - | ||

| 431 | 1Cr17Ni2 | 0.11-0.17 | 16.00-18.00 | 1.50-2.50 | 0.80 | 0.035 | 0.030 | - | 0.80 | - | - | - | |

| 440A | 7Cr17 | 0.60-0.75 | 16.00-18.00 | 3) | 1.00 | 0.035 |