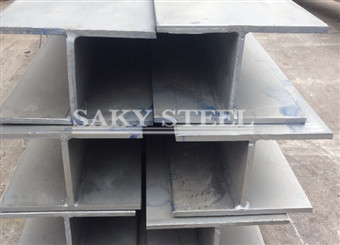

Bar Rasuk IH Keluli Tahan Karat

Penerangan ringkas:

| Spesifikasi bagikeluli tahan karat IH Beam bar: |

Spesifikasi:DIN 1025 / EN 10034

Gred:304, 304L, 316, 316L, 321

Panjang :6000, 6100 mm, 12000, 12100 mm & Panjang Diperlukan

Teknologi:Digulung Panas, Dikimpal

Kemasan Permukaan:Jeruk, Cerah, Digilap, Kasar Diputar, Kemasan NO.4, Kemasan Matt

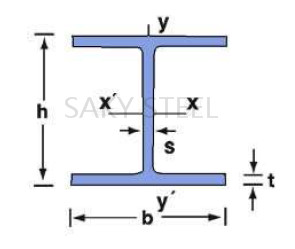

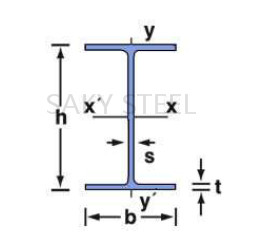

Borang :Rasuk HI

| HEB (IPB) |

MENGIKUT PENGELUARAN:DIN 1025 / EN 10034,

KUALITI KELULI: DIN 17100 / EN 10025

| BERAT BADAN | DIMENSI | ΔΙΑΤΟΜΗ | ΡΟΠΗ ΑΝΤΙΣΤΑΣΕΩΣ | ||||||||||||||||||||||

| kg / m | mm | cm2 | cm3 | ||||||||||||||||||||||

| h | b | s | t | F | Wx | Wy | |||||||||||||||||||

| 100 | 20,400 | 100 | 100 | 6,0 | 10,0 | 26,0 | 89,9 | 33,5 | |||||||||||||||||

| 120 | 26,700 | 120 | 120 | 6,5 | 11,0 | 34,0 | 144,0 | 52,9 | |||||||||||||||||

| 140 | 33,700 | 140 | 140 | 7,0 | 12,0 | 43,0 | 216,0 | 78,5 | |||||||||||||||||

| 160 | 42,600 | 160 | 160 | 8,0 | 13,0 | 54,3 | 311,0 | 111,0 | |||||||||||||||||

| 180 | 51,200 | 180 | 180 | 8,5 | 14,0 | 65,3 | 426,0 | 151,0 | |||||||||||||||||

| 200 | 61,300 | 200 | 200 | 9,0 | 15,0 | 78,1 | 570,0 | 200,0 | |||||||||||||||||

| 220 | 71,500 | 220 | 220 | 9,5 | 16,0 | 91,0 | 736,0 | 258,0 | |||||||||||||||||

| 240 | 83,200 | 240 | 240 | 10,0 | 17,0 | 106,0 | 938,0 | 327,0 | |||||||||||||||||

| 260 | 93,000 | 260 | 260 | 10,0 | 17,5 | 118,0 | 1150,0 | 395,0 | |||||||||||||||||

| 280 | 103,000 | 280 | 280 | 10,5 | 18,0 | 131,0 | 1380,0 | 471,0 | |||||||||||||||||

| 300 | 117,000 | 300 | 300 | 11,0 | 19,0 | 149,0 | 1680,0 | 571,0 | |||||||||||||||||

| 320 | 127,000 | 320 | 300 | 11,5 | 20,5 | 161,0 | 1930,0 | 616,0 | |||||||||||||||||

| 340 | 134,000 | 340 | 300 | 12,0 | 21,5 | 171,0 | 2160,0 | 646,0 | |||||||||||||||||

| 360 | 142,000 | 360 | 300 | 12,5 | 22,5 | 181,0 | 2400,0 | 676,0 | |||||||||||||||||

| 400 | 155,000 | 400 | 300 | 13,5 | 24,0 | 198,0 | 2880,0 | 721,0 | |||||||||||||||||

| 450 | 171,000 | 450 | 300 | 14,0 | 26,0 | 218,0 | 3550,0 | 781,0 | |||||||||||||||||

| 500 | 187,000 | 500 | 300 | 14,5 | 28,0 | 239,0 | 4290,0 | 842,0 | |||||||||||||||||

| 550 | 199,000 | 550 | 300 | 15,0 | 29,0 | 254,0 | 4970,0 | 872,0 | |||||||||||||||||

| 600 | 212,000 | 600 | 300 | 15,5 | 30,0 | 270,0 | 5700,0 | 902,0 | |||||||||||||||||

| 650 | 225,000 | 650 | 300 | 16,0 | 31,0 | 286,0 | 6480,0 | 932,0 | |||||||||||||||||

| 700 | 241,000 | 700 | 300 | 17,0 | 32,0 | 306,0 | 7340,0 | 963,0 | |||||||||||||||||

| 800 | 262,000 | 800 | 300 | 17,5 | 33,0 | 334,0 | 8980,0 | 994,0 | |||||||||||||||||

| 900 | 291,000 | 900 | 300 | 18,5 | 35,0 | 371,0 | 10980,0 | 1050,0 | |||||||||||||||||

| 1000 | 314,000 | 1000 | 300 | 19,0 | 36,0 | 400,0 | 12890,0 | 1090,0 | |||||||||||||||||

| HEA-IPBL: |

MENGIKUT PENGELUARAN: DIN 1025 / EN 10034,

KUALITI KELULI: DIN 17100 / EN 10025

| BERAT BADAN | DIMENSI | ΔΙΑΤΟΜΗ | ΡΟΠΗ ΑΝΤΙΣΤΑΣΕΩΣ | ||||||||||||||||||||||

| kg / m | mm | cm2 | cm3 | ||||||||||||||||||||||

| h | b | s | t | F | Wx | Wy | |||||||||||||||||||

| 100 | 16,700 | 96 | 100 | 5,0 | 8,0 | 21,2 | 72,8 | 26,8 | |||||||||||||||||

| 120 | 19,900 | 114 | 120 | 5,0 | 8,0 | 25,3 | 106,0 | 38,5 | |||||||||||||||||

| 140 | 24,700 | 133 | 140 | 5,5 | 8,5 | 31,4 | 155,0 | 55,6 | |||||||||||||||||

| 160 | 30,400 | 152 | 160 | 6,0 | 9,0 | 38,8 | 220,0 | 76,9 | |||||||||||||||||

| 180 | 35,500 | 171 | 180 | 6,0 | 9,5 | 45,3 | 294,0 | 103,9 | |||||||||||||||||

| 200 | 42,300 | 190 | 200 | 6,5 | 10,0 | 53,8 | 389,0 | 134,0 | |||||||||||||||||

| 220 | 50,500 | 210 | 220 | 7,0 | 11,0 | 64,3 | 515,0 | 178,0 | |||||||||||||||||

| 240 | 60,300 | 230 | 240 | 7,5 | 12,0 | 76,8 | 675,0 | 231,0 | |||||||||||||||||

| 260 | 68,200 | 250 | 260 | 7,5 | 12,5 | 86,8 | 836,0 | 282,0 | |||||||||||||||||

| 280 | 76,400 | 270 | 280 | 8,0 | 13,0 | 97,3 | 1010,0 | 340,0 | |||||||||||||||||

| 300 | 88,300 | 290 | 300 | 8,5 | 14,0 | 112,0 | 1260,0 | 421,0 | |||||||||||||||||

| 320 | 97,600 | 310 | 300 | 9,0 | 15,5 | 124,0 | 1480,0 | 466,0 | |||||||||||||||||

| 340 | 105,000 | 330 | 300 | 9,5 | 16,5 | 133,0 | 1680,0 | 496,0 | |||||||||||||||||

| 360 | 112,000 | 350 | 300 | 10,0 | 17,5 | 143,0 | 1890,0 | 526,0 | |||||||||||||||||

| 400 | 125,000 | 390 | 300 | 11,0 | 19,0 | 159,0 | 2310,0 | 571,0 | |||||||||||||||||

| 450 | 140,000 | 440 | 300 | 11,5 | 21,0 | 178,0 | 2900,0 | 631,0 | |||||||||||||||||

| 500 | 155,000 | 490 | 300 | 12,0 | 23,0 | 198,0 | 3550,0 | 691,0 | |||||||||||||||||

| 550 | 166,000 | 540 | 300 | 12,5 | 24,0 | 212,0 | 4150,0 | 721,0 | |||||||||||||||||

| 600 | 178,000 | 590 | 300 | 13,0 | 25,0 | 226,0 | 4790,0 | 751,0 | |||||||||||||||||

| 650 | 190,000 | 640 | 300 | 13,5 | 26,0 | 242,0 | 5470,0 | 782,0 | |||||||||||||||||

| 700 | 204,000 | 690 | 300 | 14,5 | 27,0 | 260,0 | 6240,0 | 812,0 | |||||||||||||||||

| 800 | 224,000 | 790 | 300 | 15,0 | 28,0 | 286,0 | 7680,0 | 843,0 | |||||||||||||||||

| 900 | 252,000 | 890 | 300 | 16,0 | 30,0 | 320,0 | 9480,0 | 903,0 | |||||||||||||||||

| 1000 | 272,000 | 990 | 300 | 16,5 | 31,0 | 347,0 | 11190,0 | 934,0 | |||||||||||||||||

| IPE BEAMS |

MENGIKUT PENGELUARAN: DIN 1025 / EN 10034

KUALITI KELULI: DIN 17100 / EN 10025

| BERAT BADAN | DIMENSI | ΔΙΑΤΟΜΗ | ΡΟΠΗ ΑΝΤΙΣΤΑΣΕΩΣ | ||||||||||||||||||||||

| kg / m | mm | cm2 | cm3 | ||||||||||||||||||||||

| h | b | s | t | F | Wx | Wy | |||||||||||||||||||

| 80 | 6,000 | 80 | 46 | 3,8 | 5,2 | 7,64 | 20,0 | 3,69 | |||||||||||||||||

| 100 | 8,100 | 100 | 55 | 4,1 | 5,7 | 10,30 | 34,2 | 5,79 | |||||||||||||||||

| 120 | 10,400 | 120 | 64 | 4,4 | 6,3 | 13,20 | 53,0 | 8,65 | |||||||||||||||||

| 140 | 12,900 | 140 | 73 | 4,7 | 6,9 | 16,40 | 77,3 | 12,30 | |||||||||||||||||

| 160 | 15,800 | 160 | 82 | 5,0 | 7,4 | 20,10 | 109,0 | 16,70 | |||||||||||||||||

| 180 | 18,800 | 180 | 91 | 5,3 | 8,0 | 23,90 | 146,0 | 22,20 | |||||||||||||||||

| 200 | 22,400 | 200 | 100 | 5,6 | 8,5 | 28,50 | 194,0 | 28,50 | |||||||||||||||||

| 220 | 26,200 | 220 | 110 | 5,9 | 9,2 | 33,40 | 252,0 | 37,30 | |||||||||||||||||

| 240 | 30,700 | 240 | 120 | 6,2 | 9,8 | 39,10 | 324,0 | 47,30 | |||||||||||||||||

| 270 | 36,100 | 270 | 135 | 6,6 | 10,2 | 45,90 | 429,0 | 62,20 | |||||||||||||||||

| 300 | 42,200 | 300 | 150 | 7,1 | 10,7 | 53,80 | 557,0 | 80,50 | |||||||||||||||||

| 330 | 49,100 | 330 | 160 | 7,5 | 11,5 | 62,60 | 713,0 | 98,50 | |||||||||||||||||

| 360 | 57,100 | 360 | 170 | 8,0 | 12,7 | 72,70 | 904,0 | 123,00 | |||||||||||||||||

| 400 | 66,300 | 400 | 180 | 8,6 | 13,5 | 84,50 | 1160,0 | 146,00 | |||||||||||||||||

| 450 | 77,600 | 450 | 190 | 9,4 | 14,6 | 98,80 | 1500,0 | 176,00 | |||||||||||||||||

| 500 | 90,700 | 500 | 200 | 10,2 | 16,0 | 116,00 | 1930,0 | 214,00 | |||||||||||||||||

| 550 | 106,000 | 550 | 210 | 11,1 | 17,2 | 134,00 | 2440,0 | 254,00 | |||||||||||||||||

| 600 | 122,000 | 600 | 220 | 12,0 | 19,0 | 156,00 | 3070,0 | 308,00 | |||||||||||||||||

| IPN: |

Cerun Bebibir Rasuk Standard Eropah IPN:14%

| Saiz Siri 型号 | Kedalaman X Lebar D X B | Unit Berat 单位重量 | Ketebalan 厚度 | Jejari 半径 | |||||||||||||||||||||

| Web t | Bebibir T | Akar r1 | Jari kaki r2 | ||||||||||||||||||||||

| mm | kg/m | mm | mm | mm | mm | ||||||||||||||||||||

| IPN 80 | 80 X 42 | 5.94 | 3.9 | 5.9 | 3.9 | 2.3 | |||||||||||||||||||

| IPN 100 | 100 x 50 | 8.34 | 4.5 | 6.8 | 4.5 | 2.7 | |||||||||||||||||||

| IPN 120 | 120 x 58 | 11.1 | 5.1 | 7.7 | 5.1 | 3.1 | |||||||||||||||||||

| IPN 140 | 140 x 66 | 14.3 | 5.7 | 8.6 | 5.7 | 3.4 | |||||||||||||||||||

| IPN 160 | 160 x 74 | 17.9 | 6.3 | 9.5 | 6.3 | 3.8 | |||||||||||||||||||

| IPN 180 | 180 x 82 | 21.9 | 6.9 | 10.4 | 6.9 | 4.1 | |||||||||||||||||||

| IPN 200 | 200 x 90 | 26.2 | 7.5 | 11.3 | 7.5 | 4.5 | |||||||||||||||||||

| IPN 220 | 220 x 98 | 31.1 | 8.1 | 12.2 | 8.1 | 4.9 | |||||||||||||||||||

| IPN 240 | 240 x 106 | 36.2 | 8.7 | 13.1 | 8.7 | 5.2 | |||||||||||||||||||

| IPN 260 | 260 x 113 | 41.9 | 9.4 | 14.1 | 9.4 | 5.6 | |||||||||||||||||||

| IPN 280 | 280 x 119 | 47.9 | 10.1 | 15.2 | 10.1 | 6.1 | |||||||||||||||||||

| IPN 300 | 300 x 125 | 54.2 | 10.8 | 16.2 | 10.8 | 6.5 | |||||||||||||||||||

| IPN 320 | 320 x 131 | 61.0 | 11.5 | 17.3 | 11.5 | 6.9 | |||||||||||||||||||

| IPN 340 | 340 x 137 | 68.0 | 12.2 | 18.3 | 12.2 | 7.3 | |||||||||||||||||||

| IPN 360 | 360 x 143 | 76.1 | 13 | 19.5 | 13 | 7.8 | |||||||||||||||||||

| IPN 380 | 380 x 149 | 84.0 | 13.7 | 20.5 | 13.7 | 8.2 | |||||||||||||||||||

| IPN 400 | 400 x 155 | 92.4 | 14.4 | 21.6 | 14.4 | 8.6 | |||||||||||||||||||

| IPN 450 | 450 x 170 | 115 | 16.2 | 24.3 | 16.2 | 9.7 | |||||||||||||||||||

| IPN 500 | 500 x 185 | 141 | 18 | 27 | 18 | 10.8 | |||||||||||||||||||

| IPN 550 | 550 x 200 | 166 | 19 | 30 | 19 | 11.9 | |||||||||||||||||||

| Pembungkusan: |

1. Pembungkusan agak penting terutamanya dalam kes penghantaran antarabangsa di mana konsainan melalui pelbagai saluran untuk sampai ke destinasi utama, jadi kami memberi perhatian khusus mengenai pembungkusan.

2. Saky Steel membungkus barangan kami dalam pelbagai cara berdasarkan produk. Kami membungkus produk kami dalam pelbagai cara, seperti,

Aplikasi:

Rasuk IH keluli tahan karat yang dikeluarkan oleh sakysteel boleh digunakan dalam peralatan pemprosesan makanan, terutamanya dalam pembuatan bir, pemprosesan susu & pembuatan wain. Bangku dapur, singki, palung, peralatan dan perkakas. Panel seni bina, pagar & trim. Bekas kimia, termasuk untuk pengangkutan Penukar Haba. Anyaman atau penapisan penapisan & pemerlombongan. Pengikat berulir.