Mirror Stainless Steel Sheet

Short Description:

| Specifications of stainless steel sheet: |

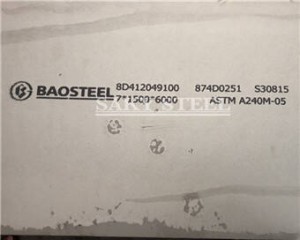

Specifications : ASTM A240 / ASME SA240

Grade: 3Cr12, 304L, 316L, 309, 309S, 321,347, 347H, 410, 420,430

Width : 1000mm, 1219mm, 1500mm, 1800mm, 2000mm, 2500mm, 3000mm, 3500mm, etc

Length :2000mm, 2440mm, 3000mm, 5800mm, 6000mm, etc

Thickness : 0.3 mm to 30 mm

Technology : Hot rolled plate (HR), Cold rolled sheet (CR)

Surface Finish : 2B, 2D, BA, NO.1, NO.4, NO.8, 8K, mirror, hair line, sand blast, Brush, SATIN (Met with Plastic Coated) etc.

Raw Materail: POSCO, Acerinox, Thyssenkrup, Baosteel, TISCO, Arcelor Mittal, Saky Steel, Outokumpu

Form : Coils, Foils, Rolls, Plain Sheet, Shim Sheet, Perforated Sheet, Chequered Plate, Strip, Flats, etc.

| Surface of CR stailess steel sheet: |

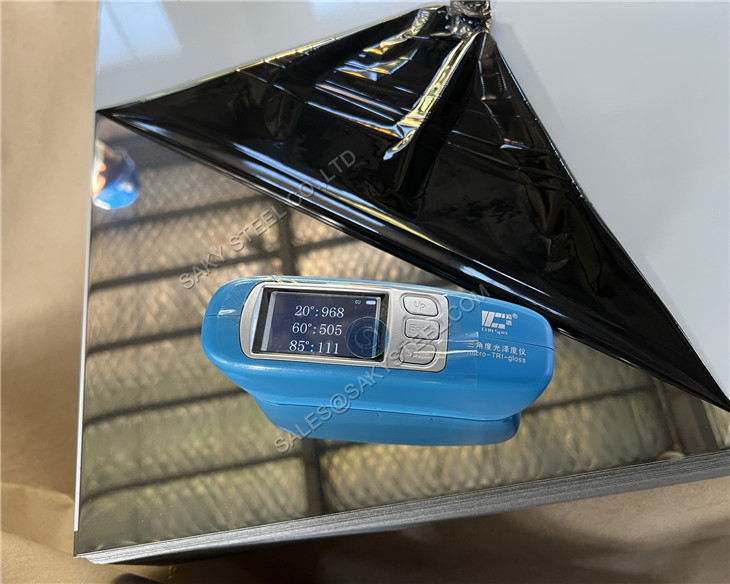

| Mirror Steel Plate Surface Finish Test: |

The gloss meter is used to evaluate the reflectivity and polishing quality of mirror stainless steel sheets.

It provides accurate, repeatable data to ensure each sheet meets high mirror finish standards.

1. Mirror Grade Evaluation

Measures surface gloss (GU). A 20° gloss value above 950 GU confirms a true mirror finish.

2. Objective Inspection

Replaces visual judgment with precise numerical data, ensuring standardized and reliable quality control.

3. Consistent Production Quality

Gloss readings are taken during each polishing stage to maintain uniform brightness and surface smoothness across all batches.

4. Quality Certification

Gloss results are included in inspection reports to prove high reflectivity, enhance brand image, and build customer trust.

5. Process Comparison

Used to compare different materials (304, 316L) or polishing methods (mechanical, electrolytic) for the best surface performance.

|

|

| Stainless Steel sheet Surface Roughness Test: |

The Mitutoyo Surface Roughness Tester is used to measure the smoothness and polishing precision of mirror stainless steel sheets.

It provides accurate Ra (Roughness Average) values in micrometers (μm), reflecting the microscopic texture of the surface.

Main Functions

-

Evaluate Polishing Quality

Detects micro scratches and surface waviness to confirm whether the sheet reaches the mirror finish (No.8) standard.

For premium mirror surfaces, Ra ≤ 0.05 μm is typically required. -

Ensure Surface Consistency

Used during each polishing stage to maintain stable and uniform roughness values across all production batches. -

Support Quality Certification

The Ra results are recorded in inspection reports to verify that the surface finish meets ISO 4287 / JIS B0601 standards. -

Complement Gloss Measurement

Together with gloss meter testing, it provides a complete evaluation of both surface reflectivity and smoothness, ensuring true mirror quality.

| Description of Astm A240 ss sheet: |

| Category | Model | Thickness | Surface |

| Austenitic Steel | 201/202 | 0.5-80mm | 2B,NO.4,NO.1 |

| Austenitic Steel | 304J1/304/321/316L | 0.4-12mm | 2B,BA,NO.4,HL,NO.1 |

| Super-austenitic Steel | 317L | 0.5-20mm | 2B,NO.4,HL,NO.1 |

| Super-austenitic Steel | 904L | 1.5-50mm | 2B,NO.4,HL,NO.1 |

| Heat-resistant Steel | 309S | 0.5-40mm | 2B,NO.4,HL,NO.1 |

| Heat-resistant Steel | 310S | 0.8-40mm | 2B,NO.4,HL,NO.1 |

| 6-Mo Steel | 254SMO | 0.6-20mm | Tisco,Outokump VDM |

| Duplex stainless steel | 2205/31803 | 1.5-60mm | Tisco,Janpan,Europe |

| Duplex stainless steel | 2507/S32750 | 3.0-30mm | Tisco,Janpan,Europe |

| Nickel-base Alloys | Incoloy 800/800HT | 3.0-50mm | Nippon/VDM |

| Nickel-base Alloys | Incoloy 825(N08825) | 0.8-30mm | Nippon/ATI/SMC/VDM |

| Nickel-base Alloys | Inconel 600(N06600) | 1.5-45mm | Nippon/SMC/VDM/ATI |

| Nickel-base Alloys | Inconel 625(N06625) | 0.8-12mm | HAYNES/SMC/VDM |

| Nickel-base Alloys | Monel 400/K-500 | 3.0-20mm | Nippon Yakin Kogyo |

| Nickel-base Alloys | Hastelloy C-276/C-22/B | 1.0-50mm | ATI/SMC/HAYNES/VDM |

| Titanium | TA2/Gr2 | 4.0-20mm | Baosteel/Wtt/Baoti |

| Ferritic stainless steel | 409L | 0.4-2.5mm | 2B,2D |

| Ferritic stainless steel | 430 | 0.4-3.0mm | 2B,BA,NO.4,HL,NO.1 |

| Ferritic stainless steel | 443 | 0.4-2.0mm | 2B,KB |

| Ferritic stainless steel | 436L/439/444/441 | 0.5-3.0mm | 2B |

Production Flow about 304 316L mirror stainless steel sheet

Raw materials are sending to hot rolling units for rolling into different sizes

Hot rolled material is annealing in cold; rolled annealing furnace and pickling in acid.

All mill rolls are grinded on precision grinding machine with proper chamfering after first shiftoperation.

All sheets are pickled in different tanks and dried on brush roll machine before dispatched.

These sheets are again annealing and are sent to straighten machine for straightening.

Inspections are done at various stages. Keep proper control overall internal process via rolling,annealin and pickling by our experienced staff

| Mirror Stainless Steel Sheet Packaging: |

Sakysteel mirror Stainless Steel Sheetare packed and labeled according to the regulations and customer’s requests. Great care is taken to avoid any damage which might otherwise be caused during storage or transportation.

Application–ss sheet plate

Stainless steels of various kinds are used in thousands of applications. The following gives a flavour of the full range:

1.Domestic– cutlery, sinks, saucepans, washing machine drums, microwave oven liners, razor blades

2.Transport– exhaust systems, car trim/grilles, road tankers, ship containers, ships chemical tankers,refuse vehicles

3.Oil and Gas– platform accommodation, cable trays, subsea pipelines.

4.Medical– Surgical instruments, surgical implants, MRI scanners.

5.Food and Drink – Catering equipment, brewing, distilling, food processing.

6.Water – Water and sewage treatment, water tubing, hot water tanks.

7.General– springs, fasteners (bolts, nuts and washers), wire.

8.Chemical/Pharmaceutical– pressure vessels, process piping.

9.Architectural/Civil Engineering – cladding, handrails, door and window fittings, street furniture,structural sections,reinforcement bar, lighting columns, lintels, masonry supports