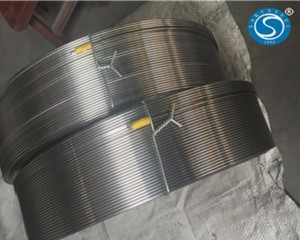

Mig wire rod

Short Description:

Sakysteel’s products have excellent welding performance and mechanical properties, mainly for pressure vessels, construction machinery, shipbuilding, petrochemical and other industries. Related products through the CCS, ABS, LR, GL, NK, CE, DB, TUV, CWB certification.

| Specifications of Stainless steel welding wire: |

| Product Name | Mig wire e71t-11 | |

| Standard | ASTM A240,GB/T3280-2007,JIS4304-2005,ASTM A167,EN10088-2-2005,etc | |

| Electrode Grades | ER308H, ER308L, ER316L, ER317L, ER318, ER318Si, ER309L, ER309Si, ER310 etc | |

| Type | Spring,Tiny,Tig,Mig,Welding | |

| Surface | Bright, Cloudy,Plain,Black | |

| Hardness | Soft, Soft Annealed, 1⁄4 Hard, 1⁄2 Hard, 3⁄4 Hard, Full Hard, Spring Hard |

|

| Package | TIG WELDING WIRE | 5kg (10 lbs) plastic tubes Cut Length in wooden boxes of 500-1000 kgs (1000-2000 lbs) In tabular carrier coils of 300-1000 kgs (650-2200 lbs) HDPE wrapped coils of 100-200 kgs (200-500 lbs) |

| WELDING WIRE |

1. 12.50 & 15 kg in precision layer wound in plastic/metallic spools. 2. Pail packing in fibre drums of 100-250 kgs (200-500 lbs) |

|

| MOQ | 1 Ton | |

| Payment term | TT,L/C,western Union | |

| Application | Filter Cages, Umbrella Spokes, Ball Bearings, Scrubbers, Wedge Wire Screens, Wiper Assembly, Vineyards, Needles, Tie Hooks, Welded Wire MEsh |

|

| Why Choose Us : |

1. You can get the perfect material according to your requirement at the least possible price.

2. We also offer Reworks, FOB, CFR, CIF, and door to door delivery prices. We suggest you to do deal for shipping which will be quite economical.

3. The materials we provide are completely verifiable, right from raw material test certificate to the final dimensional statement.(Reports will show on requirement)

4. e guarantee to give a response within 24hours(usually in the same hour)

5. You can get stock alternatives, mill deliveries with minimizing manufacturing time.

6. We are fully dedicated to our customers. If it will not possible to meet your requirements after examining all options, we will not mislead you by making false promises which will create good customer relations.

| SAKY STEEL’S Quality Assurance (including both Destructive and Non-Destructive) : |

1. Visual Dimension Test

2. Mechanical examining like tensile, Elongation and reduction of area.

3. Impact analysis

4. Chemical examination analysis

5. Hardness test

6. Pitting protection test

7. Penetrant Test

8. Intergranular Corrosion Testing

9. Roughness Testing

10. Metallography Experimental Test