Manufactur standard Cold Drawn Hex Bar - Stainless Steel Pipe Polished – Saky Steel

Manufactur standard Cold Drawn Hex Bar - Stainless Steel Pipe Polished – Saky Steel Detail:

Specifications of stainless steel pipe polished

| 1. Product | Stainless Steel Welded Pipe |

| 2. Material | 201,202,301,302,304,309,310S,316L,321,347,410,430,409Letc. |

| 3. Standard | ASTM, ASME, DIN, EN, ISO,JIS, GOST, etc. |

| 4. Size range | OD: from 6mm to 1219mm (NPS from 1/8” to 40”) |

| WT: from 0.7mm to 38mm (Schedule from 5S to XXS) | |

| Length: fix length or un-fix length, Max 30meters | |

| 5. Produce process | welded,hot bending;resistance welding;Thermal expansion etc. |

| 6. Surface | 2B,Pickled,180G, 320G, Satin, Hairline,400G, 500G, 600G |

| ,800G, Mirror finish | |

| 7. Marking | SAKY, GRADE, Seamless, Standard, Size, Heat NO. |

| 8. Package | Bundles with waterproof cloth outside. |

| or plywood box. | |

| 9. Length | 5.8m,6m,12m or as required |

| Typical mechanical properties for 304 stainless steel alloys | |||||

| Grade | Tensile Strength (MPa) | Compression Strength (MPa) | Proof Stress 0.2% (MPa) | Elongation A5 (%) | Hardness Rockwell B |

| 304 | 520-720 | 210 | 210 | 45 Min | 92 |

| 304L | 500-670 | 200 | 45 Min | ||

| 304H | 520-720 | 210 | 45Min | ||

Grades of stainless steel pipe polished:

| Type | Grade | Grade | Chemical Component % | ||||

| Austenitic stainless steel | C | Cr | Ni | Mn | |||

| 201 | 1Cr17Mn6Ni5N | =0.15 | 16.00-18.00 | 3.50-5.50 | 5.50-7.50 | ||

| 201L | 03Cr17Mn6Ni5N | =0.030 | 16.00-18.00 | 3.50-5.50 | 5.50-7.50 | ||

| 202 | 1Cr18Mn8Ni5N | =0.15 | 17.00-19.00 | 4.00-6.00 | 7.50-10.00 | ||

| 204 | 03Cr16Mn8Ni2N | =0.030 | 15.00-17.00 | 1.50-3.50 | 7.00-9.00 | ||

| 1Cr18Mn10Ni5Mo3N | =0.10 | 17.00-19.00 | 4.00-6.00 | 8.50-12.00 | |||

| 2Cr13Mn9Ni4 | 0.15-0.25 | 12.00-14.00 | 3.70-5.00 | 8.00-10.00 | |||

| 2Cr15Mn15Ni2N | 0.15-0.25 | 14.00-16.00 | 1.50-3.00 | 14.00-16.00 | |||

| 1Cr18Mn10Ni5Mo3N | =0.15 | 17.00-19.00 | 4.00-6.00 | 8.50-12.00 | |||

| 301 | 1Cr17Ni7 | =0.15 | 16.00-18.00 | 6.00-8.00 | =2.00 | ||

| 302 | 1Cr18Ni9 | =0.15 | 17.00-19.00 | 8.00-10.00 | =2.00 | ||

| 303 | Y1Cr18Ni9 | =0.15 | 17.00-19.00 | 8.00-10.00 | =2.00 | ||

| 303se | Y1Cr18Ni9Se | =0.15 | 17.00-19.00 | 8.00-10.00 | =2.00 | ||

| 304 | 0Cr18Ni9 | =0.07 | 17.00-19.00 | 8.00-10.00 | =2.00 | ||

| 304L | 00Cr19Ni10 | =0.030 | 18.00-20.00 | 8.00-10.00 | =2.00 | ||

| 304N1 | 0Cr19Ni9N | =0.08 | 18.00-20.00 | 7.00-10.50 | =2.00 | ||

| 304N2 | 0Cr18Ni10NbN | =0.08 | 18.00-20.00 | 7.50-10.50 | =2.00 | ||

| 304LN | 00Cr18Ni10N | =0.030 | 17.00-19.00 | 8.50-11.50 | =2.00 | ||

| 305 | 1Cr18Ni12 | =0.12 | 17.00-19.00 | 10.50-13.00 | =2.00 | ||

| 309S | 0Cr23Ni13 | =0.08 | 22.00-24.00 | 12.00-15.00 | =2.00 | ||

| 310S | 0Cr25Ni20 | =0.08 | 24.00-26.00 | 19.00-22.00 | =2.00 | ||

| 316 | 0Cr17Ni12Mo2 | =0.08 | 16.00-18.50 | 10.00-14.00 | =2.00 | ||

| 1Cr18Ni12Mo2Ti6) | =0.12 | 16.00-19.00 | 11.00-14.00 | =2.00 | |||

| 0Cr18Ni12Mo2Ti | =0.08 | 16.00-19.00 | 11.00-14.00 | =2.00 | |||

| 316L | 00Cr17Ni14Mo2 | =0.030 | 16.00-18.00 | 12.00-15.00 | =2.00 | ||

| 316N | 0Cr17Ni12Mo2N | =0.08 | 16.00-18.00 | 10.00-14.00 | =2.00 | ||

| 316N | 00Cr17Ni13Mo2N | =0.030 | 16.00-18.50 | 10.50-14.50 | =2.00 | ||

| 316J1 | 0Cr18Ni12Mo2Cu2 | =0.08 | 17.00-19.00 | 10.00-14.50 | =2.00 | ||

| 316J1L | 00Cr18Ni14Mo2Cu2 | =0.030 | 17.00-19.00 | 12.00-16.00 | =2.00 | ||

| 317 | 0Cr19Ni13Mo3 | =0.12 | 18.00-20.00 | 11.00-15.00 | =2.00 | ||

| 317L | 00Cr19Ni13Mo3 | =0.08 | 18.00-20.00 | 11.00-15.00 | =2.00 | ||

| 1Cr18Ni12Mo3Ti6 | =0.12 | 16.00-19.00 | 11.00-14.00 | =2.00 | |||

| 0Cr18Ni12Mo3Ti | =0.08 | 16.00-19.00 | 11.00-14.00 | =2.00 | |||

| 317J1 | 0Cr18Ni16Mo5 | =0.040 | 16.00-19.00 | 15.00-17.00 | =2.00 | ||

| 321 | 1Cr18Ni9Ti6 | =0.12 | 17.00-19.00 | 8.00-11.00 | =2.00 | ||

| 0Cr18Ni10Ti | =0.08 | 17.00-19.00 | 9.00-12.00 | =2.00 | |||

| 347 | 0Cr18Ni11Nb | =0.08 | 17.00-19.00 | 9.00-13.00 | =2.00 | ||

| XM7 | 0Cr18Ni9Cu3 | =0.08 | 17.00-19.00 | 8.50-10.50 | =2.00 | ||

| XM15J1 | 0Cr18Ni13Si4 | =0.08 | 15.00-20.00 | 11.50-15.00 | =2.00 | ||

| Austenite Ferrite Stainless Steel |

329J1 | 0Cr26Ni5Mo2 | =0.08 | 23.00-28.00 | 3.00-6.00 | =1.50 | =0.035 | =0.030 | 1.00-3.00 | =1.00 | - | - | 2) |

| 1Cr18Ni11Si4AlTi | 0.10-0.18 | 17.50-19.50 | 10.–120.. | =0.80 | =0.035 | =0.030 | - | 3.40-4.00 | - | - | Al 0.10-0.30; Ti 0.40-0.70 | ||

| 00Cr18Ni5MoSi2 | =0.030 | 18.00-19.50 | 4.50-5.50 | 1.00-2.00 | =0.035 | =0.030 | 2.50-3.00 | 1.30-2.00 | - | - | - | ||

| Ferrite Stainless Steel | 405 | 0Cr13Al | =0.08 | 11.50-14.50 | 3) | =1.00 | =0.035 | =0.030 | - | =1.00 | - | - | Al 0.10-0.30 |

| 410L | 00Cr12 | =0.030 | 11.00-13.00 | 3) | =1.00 | =0.035 | =0.030 | - | =1.00 | - | - | - | |

| 430 | 1Cr17 | =0.12 | 16.00-18.00 | 3) | =1.25 | =0.035 | =0.030 | - | =0.75 | - | - | - | |

| 430F | Y1Cr17 | =0.12 | 16.00-18.00 | 3) | =1.00 | =0.035 | =0.15 | 1) | =1.00 | - | - | - | |

| 434 | 1Cr17Mo | =0.12 | 16.00-18.00 | 3) | =1.00 | =0.035 | =0.030 | 0.75-1.25 | =1.00 | - | - | - | |

| 447J1 | 00Cr30Mo2 | =0.010 | 28.50-32.00 | - | =0.40 | =0.035 | =0.030 | 1.50-2.50 | =0.40 | - | =0.015 | - | |

| XM27 | 00Cr27Mo | =0.010 | 25.00-27.50 | - | =0.40 | =0.035 | =0.030 | 0.75-1.50 | =0.40 | - | =0.015 | - |

| Martensite stainless steel | 403 | 1Cr12 | =0.15 | 11.50-13.00 | 3) | =1.00 | =0.035 | =0.030 | - | =0.50 | - | - | - |

| 410 | 1Cr13 | =0.15 | 11.50-13.50 | 3) | =1.00 | =0.035 | =0.030 | - | =1.00 | - | - | - | |

| 405 | 0Cr13 | =0.08 | 11.50-13.50 | 3) | =1.00 | =0.035 | =0.030 | - | =1.00 | - | - | - | |

| 416 | Y1Cr13 | =0.15 | 12.00-14.00 | 3) | =1.25 | =0.035 | =0.15 | 1) | =1.00 | - | - | - | |

| 410J1 | 1Cr13Mo | =0.08-0.18 | 11.50-14.00 | 3) | =1.00 | =0.035 | =0.030 | 0.30-0.60 | =0.60 | - | - | - | |

| 420J1 | 2Cr13 | 0.16-0.25 | 12.00-14.00 | 3) | =1.00 | =0.035 | =0.030 | - | =1.00 | - | - | - | |

| 420J2 | 3Cr13 | 0.26-0.35 | 12.00-14.00 | 3) | =1.00 | =0.035 | =0.030 | - | =1.00 | - | - | - | |

| 420F | Y3Cr13 | 0.26-0.40 | 12.00-14.00 | 3) | =1.25 | =0.035 | =0.15 | 1) | =1.00 | - | - | - | |

| 3Cr13Mo | 0.28-0.35 | 12.00-14.00 | 3) | =1.00 | =0.035 | =0.030 | 0.50-1.00 | =0.80 | - | - | - | ||

| 4Cr13 | 0.36-0.45 | 12.00-14.00 | 3) | =0.80 | =0.035 | =0.030 | - | =0.60 | - | - | - | ||

| 431 | 1Cr17Ni2 | 0.11-0.17 | 16.00-18.00 | 1.50-2.50 | =0.80 | =0.035 | =0.030 | - | =0.80 | - | - | - | |

| 440A | 7Cr17 | 0.60-0.75 | 16.00-18.00 | 3) | =1.00 | =0.035 |

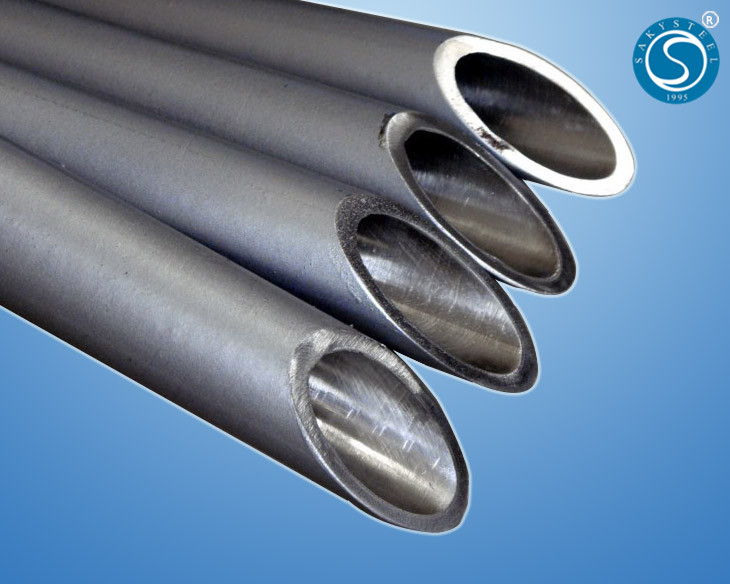

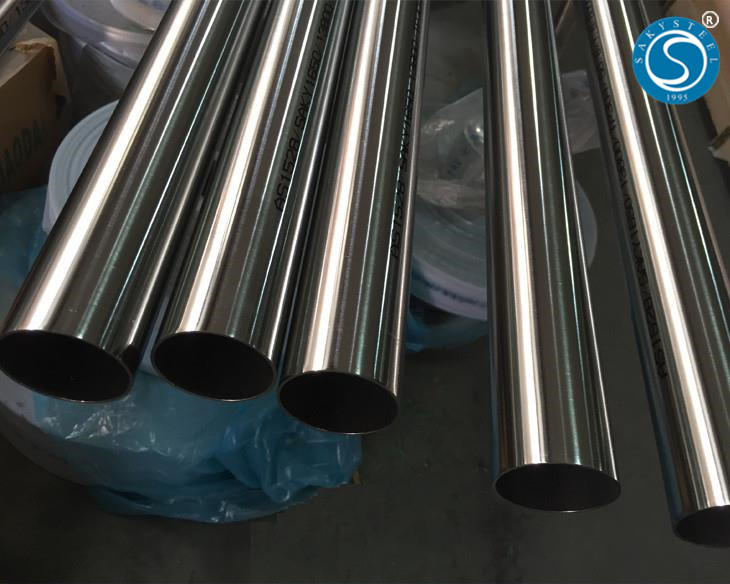

Product detail pictures:

Related Product Guide:

Stainless Steel Bars – Production, Importance, and Uses

Stainless Steel Bar Tops In the Great British Pub

We always think and practice corresponding to the change of circumstance, and grow up. We aim at the achievement of a richer mind and body and the living for Manufactur standard Cold Drawn Hex Bar - Stainless Steel Pipe Polished – Saky Steel, The product will supply to all over the world, such as: Pretoria , Plymouth , Melbourne , We are seeking the chances to meet all the friends from both at home and abroad for the win-win cooperation. We sincerely hope to have long-term cooperation with all of you on the bases of mutual benefit and common development.

It is a very good, very rare business partners, looking forward to the next more perfect cooperation!