17-4PH 630 Chalybis Inoxidabilis Virga

Descriptio Brevis:

SAKYSTEEL virgas chalybis inoxidabilis 17-4PH (630) praebet, praeclara robore et resistentia corrosionis ad usum aëronauticum, maritimum, et industrialem.

Chalybs Saky Steel 17-4PH / 630 / 1.4542 inter chalybes inoxidabiles chromii-niccoli cum additivo cupri, praecipitatione induratus et structura martensitica, inter populares et frequentissime adhibitos numeratur. Magna resistentia corrosionis insignitur, proprietatibus tamen firmitatis, inter quas duritiam, excellens servatis. Chalybs, temperaturas inter -29°C et 343°C tolerare potest, parametris relative bonis retinens. Praeterea, materiae huius gradus ductilitate relative bona insignitae sunt, et resistentia corrosionis cum 1.4301 / X5CrNi18-10 comparabilis est.

17-4PH, etiam UNS S17400 appellatum, est chalybs inoxidabilis martensiticus, praecipitatione durans. Materia versatilis est et late adhibita in variis industriis, ut in industria aëronautica, nucleari, petrochemica, et in ciborum processu.

17-4PH, comparatus aliis chalybibus inoxidabilibus, magnam firmitatem, bonam resistentiam corrosionis, et bonam duritiam habet. Mixtura est 17% chromii, 4% niccoli, 4% cupri, et parvae quantitatis molybdeni et niobii. Haec elementorum coniunctio chalybi proprietates suas singulares dat.

Summa summarum, 17-4PH est materia valde versatilis et utilis quae bonum aequilibrium proprietatum ad amplam applicationum varietatem offert.

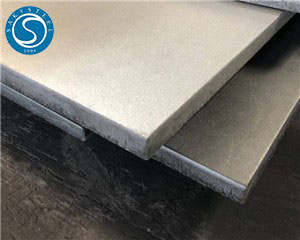

| Virga Rotunda Chalybis Inoxidabilis, Producta Splendida, Ostentatio: |

| Specificationes 630virga chalybis inoxidabilis: |

Specificationes:ASTM A564 /ASME SA564

Gradus:AISI 630 SUS630 17-4PH 1.4542 PH

Longitudo:5.8M, 6M et Longitudo Requisita

Diameter Vectis Rotundae:4.00 mm ad 400 mm

Taberna Clara :4mm – 100mm,

Tolerantia:H8, H9, H10, H11, H12, H13, K9, K10, K11, K12 vel secundum requisita clientium

Status:Frigide Tractum et Politum Frigide Tractum, Decorticatum et Fusatum

Superficies Finis:Niger, Splendens, Politus, Versus Asper, Finis No.4, Finis Matt

Forma:Rotundus, Quadratus, Hexagonalis (A/F), Rectangulus, Tubus ligneus, Massa fusa, Fabricatus etc.

Finis:Extremum Planum, Extremum Oblinatum

| Gradus Vectis Chalybis Inoxidabilis Compositio Chemica: |

| Designatio UNS | Typus | C | Mn | P | S | Si | Cr | Ni | Al | Mo | Ti | Cu | Alia Elementa |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| S17400 | DCXXX | 0.07 | 1.00 | 0.040 | 0.030 | 1.00 | 15.00–17.50 | 3.00–5.00 | – | – | – | 3.00–5.00 | C |

| S17700 | DCXXXI | 0.09 | 1.00 | 0.040 | 0.030 | 1.00 | 16.00–18.00 | 6.50–7.75 | – | – | – | – | – |

| S15700 | DCXXXII | 0.09 | 1.00 | 0.040 | 0.030 | 1.00 | 14.00–16.00 | 6.50–7.75 | – | 2.00–3.00 | – | – | – |

| S35500 | DCXXXIV | 0.10–0.15 | 0.50–1.25 | 0.040 | 0.030 | 0.50 | 15.00–16.00 | 4.00–5.00 | – | 2.50–3.25 | – | – | D |

| S17600 | DCXXXV | 0.08 | 1.00 | 0.040 | 0.030 | 1.00 | 16.00–17.50 | 6.00–7.50 | 0.40 | – | – | – | – |

| S15500 | XM-12 | 0.07 | 1.00 | 0.040 | 0.030 | 1.00 | 14.00–15.50 | 3.50–5.50 | – | – | – | 2.50–4.50 | C |

| S13800 | XM-13 | 0.05 | 0.20 | 0.040 | 0.008 | 1.00 | 12.25–13.25 | 7.50–8.50 | 0.90–1.35 | 2.00–2.50 | – | – | E |

| S45500 | XM-16 | 0.03 | 0.50 | 0.015 | 0.015 | 0.50 | 11.00–12.50 | 7.50–9.50 | – | 0.50 | 0.90–1.40 | 1.50–2.50 | F |

| S45503 | – | 0.010 | 0.50 | 0.010 | 0.010 | 0.50 | 11.00–12.50 | 7.50–9.50 | – | 0.50 | 1.00–1.35 | 1.50–2.50 | F |

| S45000 | XM-25 | 0.05 | 1.00 | 0.030 | 0.030 | 0.50 | 14.00–16.00 | 5.00–7.00 | – | – | – | 1.25–1.75 | G |

| S46500 | – | 0.02 | 0.25 | 0.040 | 0.030 | 1.00 | 11.00–13.00 | 10.75–11.25 | 0.15–0.50 | 0.75–1.25 | – | – | E |

| S46910 | – | 0.030 | 1.00 | 0.040 | 0.020 | 1.00 | 11.00–12.50 | 8.00–10.00 | 0.50–1.20 | 3.0–5.0 | – | 1.5–3.5 | – |

| S10120 | – | 0.02 | 1.00 | 0.040 | 0.015 | 0.25 | 11.00–12.50 | 9.00–11.00 | 1.10 | 1.75–2.25 | 0.20–0.50 | – | E |

| S11100 | – | 0.02 | 0.25 | 0.040 | 0.010 | 0.25 | 11.00–12.50 | 10.25–11.25 | 1.35–1.75 | 1.75–2.25 | 0.20–0.50 | – | E |

| Gradus Aequivalentes Vectis Chalybis Inoxidabilis 17-4PH: |

| NORMA | UNS | OPIFICIUM NUM. | AFNOR | JIS | EN | BS | GOST |

| 17-4PH | S17400 | 1.4542 |

| Curatio solutionis virgae inoxidabilis 17-4PH: |

| Gradus | Robur tensile (MPa) min | Elongatio (% in 50mm) min | Robur cessionis 0.2% probationis (MPa) min. | Duritia | |

| Rockwell C max | Brinell (HB) maximus | ||||

| DCXXX | - | - | - | XXXVIII | 363 |

Renotatio: Conditio A 1900±25°F [1040±15°C] (refrigerandum si opus est infra 90°F (30°C))

1.4542 Requisita Probationis Mechanicae Post Curam Caloris Durescentiae Aetatis:

Robur tensile:Unitas – ksi (MPa), Minimum

Robur Cedendi:0.2 % Offset , Unit - ksi (MPa) , Minimum

Elongatio:in 2″, Unitas: %, Minimum

Duritia:Rockwell, Maximus

Proprietates Mechanicae Chalybis Inoxidabilis 17-4PH per Tractationem Caloris:

| H 900 | H 925 | H 1025 | H 1075 | H 1100 | H 1150 | H 1150-M | |

| Robur Tensilis Maximum, ksi | 190 | CLXX | CLV | 145 | 140 | 135 | 115 |

| Robur cessionis 0.2%, ksi | CLXX | CLV | 145 | 125 | 115 | 105 | 75 |

| Elongatio % in 2″ vel 4XD | 10 | 10 | 12 | 13 | 14 | 16 | 16 |

| Reductio Areae, % | 40 | 54 | 56 | 58 | 58 | 60 | 68 |

| Duritia, Brinell (Rockwell) | 388 (C 40) | 375 (C 38) | 331 (C 35) | 311 (C 32) | 302 (C 31) | 277 (C 28) | 255 (C 24) |

| Impactus Charpy V-Notch, pedum – librarum | | 6.8 | 20 | 27 | 34 | 41 | 75 |

| Optio Fusionis: |

1 EAF: Fornax Arcus Electrici

2 EAF+LF+VD: Fusio raffinata et degassatio vacui

3 EAF+ESR: Refusionem Scoriae Electroliticae

4 EAF+PESR: atmosphaera protectiva Refusionem Scoriae Electroliticae

5 VIM+PESR: Fusio per inductionem vacui

| Optio curationis caloris: |

1 +A: Recoctum (plenum/molle/sphaeroidizans)

2 +N: Normalizatum

3 +NT: Normalizatum et temperatum

4 +QT: Extinctum et temperatum (aqua/oleum)

5 +AT: Solutione recoctum

6 +P: Praecipitatione induratum

| Tractatio Caloris: |

Solutio tractata (Conditio A) — Chalybes inoxidabiles gradus 630 ad 1040°C per 0.5 horas calefiunt, deinde aere ad 30°C refrigerantur. Parvae partes horum graduum oleo extingui possunt.

Durificatio — Chalybes inoxidabiles gradus 630 per aetatem durantur temperaturis humilibus ut proprietates mechanicae requisitae consequantur. Per processum, discoloratio superficialis fit, deinde contractio 0.10% pro condicione H1150, et 0.05% pro condicione H900.

| Normae pro Chalybe Inoxidabili 17-4PH |

Chalybs inoxidabilis 17-4PH amplissimae varietati normarum et specificationum internationalium obtemperat, qualitatem et efficaciam certam per industrias sicut aerospatialem, energiae, et processus chemici praestans.

| Ordinatio Standardis | Specificatio | Descriptio |

|---|---|---|

| ASTM | ASTM A564 / A564M | Norma pro virgis et formis chalybis inoxidabilis, calidis laminatis et frigidis peractis, aetate durioribus |

| ASTM A693 | Specificatio laminae, tabulae, et fasciae chalybis inoxidabilis praecipitatione durantis | |

| ASTM A705 / A705M | Specificatio pro fabricatione chalybis inoxidabilis et calori resistente, praecipitatione durans, fabricata | |

| ASME | ASME SA564 / SA693 / SA705 | Specificationes codicis vasis pressionis aequivalentes |

| AMS (Aerospatialis) | AMS 5643 | Specificatio aerospatialis pro vectibus, filis metallicis, partibus forgiatis, et anulis in 17-4PH solutione tractatis et maturatis. |

| AMS 5622 | Lamina, charta, et fascia | |

| EN / DIN | EN 1.4542 / DIN X5CrNiCuNb16-4 | Designatio Europaea pro 17-4PH cum simili compositione et proprietatibus |

| UNS | UNS S17400 | Designatio Systematis Numerationis Unificati |

| ISO | ISO 15156-3 | Aptitudo ad usum in apparatu agrorum petrolei in ambitu gasis acidi |

| NACE | MR0175 | Requisita materiae ad resistentiam fissurarum tensionis sulfidi |

| Cur Nos Eligas: |

1. Materiam perfectam secundum necessitatem tuam minimo pretio adipisci potes.

2. Pretia etiam "Reworks", FOB, CFR, CIF, et traditionis ostium ad ostium offerimus. Suademus ut pactum vecturae facias, quod satis oeconomicum erit.

3. Materiae quas praebemus omnino verificabiles sunt, ab ipso certificato probationis materiae rudis ad declarationem dimensionalem finalem. (Relationes secundum requisitum apparebunt)

4. spondemus responsum intra horas viginti quattuor daturum esse (plerumque eadem hora).

5. Alternativas ex promptu, traditiones officinarum cum tempore fabricationis minimo accipere potes.

6. Clientibus nostris plene dediti sumus. Si, omnibus optionibus examinatis, postulatis vestris satisfacere non poterit, vos non decipiemus falsis promissis, quae bonas necessitudines cum clientibus creabunt.

| Cura Qualitatis SAKY STEEL (tam Destructivam quam Non Destructivam comprehendens) |

1. Examen Dimensionis Visualis

2. Examinatio mechanica ut tensio, elongatio et areae reductio.

3. Examen ultrasonicum

4. Analysis examinationis chemicae

5. Examen duritiae

6. Examen tutelae contra foveas

7. Examen Penetrationis

8. Examen Corrosionis Intergranularis

9. Analysis impactus

10. Experimentum Metallographiae

| Involucrum |

1. Involucrum magni momenti est, praesertim in casu vecturarum internationalium ubi consignatio per varias vias transeunt ad destinationem finalem perveniendum, itaque curam specialem de involucris ponimus.

2. Saky Steel merces nostras multis modis secundum producta convasat. Nos merces nostras multis modis convasamus, exempli gratia,

Materia 17-4PH, 630 et X5CrNiCuNb16-4 / 1.4542 in forma virgarum rotundarum, laminarum, virgarum planarum et taeniarum frigide laminatarum praebetur. Materia late in industriis aëronauticis, maritimis, chartaceis, energiae, maritimis et cibariis adhibetur pro componentibus machinarum gravium, manicarum, alarum turbinarum, copularum, cochlearum, axium motoriorum, nucum, instrumentorum mensurae.

1. Industria Aerospatialis

-

Partes turbinarum (impellatores, axes, receptacula)

-

Partes apparatus advectionis

-

Clavi (clauli, nuces) et connectores structurales

-

Partes systematis hydraulici

2. Industria Petrolei et Gasii

-

Instrumenta in puteo (virgae terebrantes, sedes valvularum, iuncturae tuborum)

-

Partes valvulae corrosioni resistentes

-

Partes instrumentorum petroliferorum (axis antliae, receptacula, anuli obturantes)

3. Industria Chemica Processuum

-

Antliae et valvae in ambitu acido adhibitae

-

Permutatores caloris et vasa pressionis

-

Reactoria et axes agitatorum

-

Instrumenta ad cisternas repositionis

4. Ciborum Processus et Instrumenta Medica

-

Formae et partes impulsorias aptae cibo

-

Partes pro sterilizatoribus altae pressionis

-

Instrumenta chirurgica et instrumenta medica (certificatio requiritur)

-

Partes systematum medicorum pressionis moderandae

5. Ingeniaria Maritima et Extra Littoralis

-

Axes propulsores et coetus propulsores

-

Axes antliae aquae marinae et partes obturantes

-

Nexus et connectores structurales in carinis navium

-

Partes corrosioni resistentes pro suggestis maritimis

6. Generatio Energiae Nuclearis et Energiae

-

Adhaesores structurarum reactorum nuclearium

-

Sustentamenta fasciculi tuborum pro permutatoribus caloris

-

Virgae valvulae hydraulicae et corpora antliae

-

Partes valvulae altae temperaturae

7. Industria Formarum et Instrumentorum

-

Formae iniectae

-

Axes et fulcra formantia altae firmitatis

-

Pali ductores et buxae ad formas imprimendas

8. Machinae Generales et Automatio

-

Partes transmissionis, ut axes dentatae, copulae, et fusi

-

Ferriviae mechanicae et virgae positionis in systematibus automationis

-

Virgae pistonis hydraulicae industriales