diameteripun gedhe Seamless pipa Stainless Steel

Katrangan singkat:

| Spesifikasi pipa baja tahan karat mulus: |

| 1. Standar: | ASTM A312 A213 A269 A511 A789 A790, JIS3463, JIS3459, DIN2462, DIN17456 |

| 2. Kelas: | 304,310S,316,316L,321,321H,317L,904L,2205, lsp |

| 3. Range OD: | 200-800 mm |

| 4. Range Ketebalan Tembok: | SCH-5S, SCH-10S, SCH-20S, SCH-40 |

| 5. Rampung lumahing: | Pickled, Padhang, Sandblast, Polishing, etc |

| 6. Teknik: | Digulung panas, ditarik kadhemen |

| 7. Tes: | Analisis Kimia, Tes Listrik Hidrostatik utawa Ora Ngrusak, Tes Korosi Intergranular, Tes Flaring,Tes Flattening,Tes Flange, Tes Ukuran Butiran, Tes Udhara ing Banyu, Tes Ultrasonik, Tes Eddy Saiki |

| 8. Packing: | Buntelan. Kasus Plywood. End Caps ing Loro Ends |

| Komposisi kimia: |

| sasmita | C | Mn | Si | P | S | Cr | Mo | Ni | N |

| 201 | .15 Maks | 5.5 - 7.5 | 1.00 Maks | .060 Maks | .030 Maks | 16 - 18 | 3.5-5.5 | .25 Maks | |

| 202 | .15 Maks | 5.5 - 7.5 | 1.00 Maks | .060 Maks | .030 Maks | 16 - 18 | 3.5-5.5 | .25 Maks | |

| 301 | 0,15 maks | 2.00 maks | 1.00 maks | 0,045 maks | 0,030 maks | 16-18 | 6–8 | 0.10 | |

| 302 | 0.15 | 2.00 maks | 0.75 | 0.05 | 0.03 | 17–19 | - | 8–10 | 0.10 |

| 302B | 0.15 | 2.00 maks | 2.0–3.0 | 0.05 | 0.03 | 17–19 | - | 8–10 | - |

| 304 | 0.08 | 2.00 maks | 0.75 | 0.05 | 0.03 | 18-20 | - | 8-10.5 | 0.10 |

| 304L | 0.03 | 2.00 maks | 0.75 | 0.05 | 0.03 | 18-20 | 6–12 | 0.10 | |

| 304H | 0.04-0.01 | 2.00 maks | 0.75 | 0.05 | 0.03 | 18-20 | 8-10.5 | - | |

| 310 | 0.25 | 2.00 maks | 1.50 | 0.05 | 0.03 | 24-26 | - | 19-22 | - |

| 310S | 0.08 | 2.00 maks | 1.50 | 0.05 | 0.03 | 24-26 | - | 19-22 | - |

| 316 | 0.08 | 2.00 maks | 0.75 | 0.05 | 0.03 | 16-15 | 2–3 | 10–14 | 0.10 |

| 316L | 0.03 | 2.00 maks | 0.75 | 0.05 | 0.03 | 16-18 | 2–3 | 10–14 | 0.10 |

| 321 | 0.08 | 2.00 maks | 0.75 | 0.05 | 0.03 | 17–19 | 9–12 | 0.10 | |

| 410 | .080-.150 | 1.00 maks | 1.00 Maks | 0.04 | 0,030 maks | 11.5-13.5 | 0,75 maks |

| Pipa Stainless Steel Diameter Besar JIS G3468, CNS 13517 Spesifikasi: |

| Nominal | Nominal | Njaba | SCH-5S | SCH-10S | SCH-20S | SCH-40 |

| Dhiameter | Dhiameter | Dhiameter (mm) | Ketebalan Dinding Nominal (mm) | Ketebalan Dinding Nominal (mm) | Ketebalan Dinding Nominal (mm) | Ketebalan Dinding Nominal (mm) |

| A | B | |||||

| 150 | 6 | 165.2 | 2.8 | 3.4 | 5 | 7.1 |

| 200 | 8 | 216.3 | 2.8 | 4 | 6.5 | 8.2 |

| 250 | 10 | 267.4 | 3.4 | 4 | 6.5 | 9.3 |

| 300 | 12 | 318.5 | 4 | 4.5 | 6.5 | 10.3 |

| 350 | 14 | 355.6 | 4 | 5 | 8 | 11.1 |

| 400 | 16 | 406.4 | 4.5 | 5 | 8 | 12.7 |

| 450 | 18 | 457.2 | 4.5 | 5 | 8 | 14.3 |

| 500 | 20 | 508 | 5 | 5.5 | 9.5 | 15.1 |

| 550 | 22 | 558.8 | 5 | 5.5 | 9.5 | 15.9 |

| 600 | 24 | 609.6 | 5.5 | 6.5 | 9.5 | 17.5 |

| 650 | 26 | 660.4 | 5.5 | 8 | 12.7 | - |

| 700 | 28 | 711.2 | 5.5 | 8 | 12.7 | - |

| 750 | 30 | 762 | 6.5 | 8 | 12.7 | - |

| 800 | 32 | 812.8 | - | 8 | 12.7 | - |

| 850 | 34 | 863.6 | - | 8 | 12.7 | - |

| 900 | 36 | 914.4 | - | 8 | 12.7 | - |

| 1000 | 40 | 1016 | - | 9.5 | 14.3 | - |

| 1050 | 42 | 1066.8 | Nalika dimensi liyane saka sing diwenehi ing tabel ndhuwur-kasebut dibutuhake, ukuran cangkang ditemtokake minangka disepakati antarane panuku lan pabrikan (sakysteel) | |||

| | | | | | | ||||

| 1650 | 66 | 1676.4 | ||||

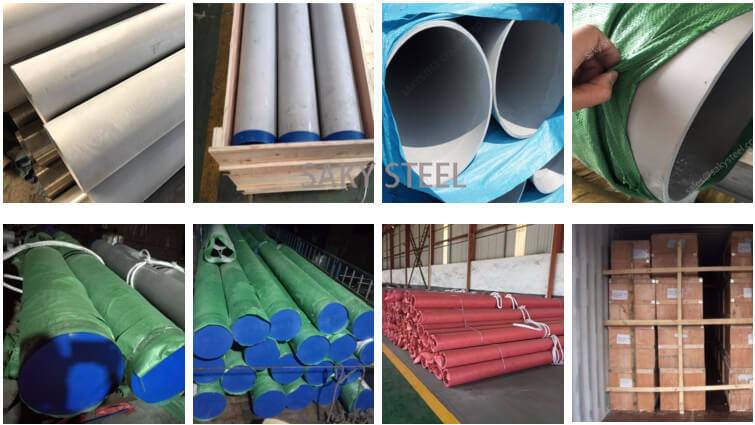

| Packing & Pengiriman: |

Informasi Kemasan pipa stainless steel mulus:

PVC packing, karton packing, utawa minangka request customer kasus kayu.

Inner packing: 1 kantong plastik (polythene) / potong, lan 500kgs dikemas ing siji bundel.

Packing njaba: kertas Kraft, kasus kayu utawa miturut panjalukan pelanggan.

Pipa Stainless Steel Diameter Gedhe kudu teka kanthi aman, cepet lan tanpa karusakan ing panggonan sing dituju ing endi wae ing jagad iki.

Pengepakan uga minangka bagean penting saka jaminan kualitas.

Aplikasi:

Sakysteel utamané dipigunakaké minangka pipa pengeboran kanggo geologi petroleum, pipa retak kanggo industri petrokimia, pipa ketel, pipa bantalan lan pipa struktur presisi dhuwur kanggo mobil, traktor lan penerbangan.