304 316 pipa baja tahan karat

Katrangan singkat:

| Spesifikasi sakapipa stainless steel:: |

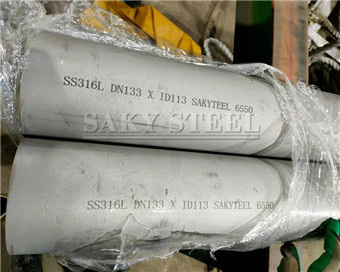

Ukuran Pipa & Tabung Seamless:1/8″ NB – 12″ NB

Spesifikasi:ASTM A/ASME SA213, A249, A269, A312, A358, A790

Standar:ASTM, ASME

kelas:304.310, 310S, 314, 316.316L, 321.347, 904L, 2205, 2507

Teknik:Digulung panas, ditarik kadhemen

dawa:5.8M, 6M, 12M & Dibutuhake Length

Diameter njaba:6,00 mm OD nganti 914,4 mm OD

kekandelan :0,6 mm kanggo 12,7 mm

Jadwal:SCH. 5, 10, 20, 30, 40, 60, 80, 100, 120, 140, 160, XXS

Jinis:Pipa Seamless

Formulir :Round, Square, Rectangle, Hydraulic, Honed Tube

Pungkasan:Ujung Polos, Ujung Beveled, Tapak

| Stainless Steel 316 / 316L Pipa Mulus Kelas Setara: |

| STANDAR | WERKSTOFF NR. | UNS | JIS | BS | AFNOR | EN |

| SS 304 | 1.4301 | S30400 | SUS 304 | 304S1 | 58E | |

| SS 316 | 1.4401 | S31600 | SUS 316 | 304S11 | - | 58E |

| SS 304 / 316L Pipa Seamless Komposisi Kimia lan Sifat Mekanik: |

| sasmita | C | Mn | Si | P | S | Cr | Mo | Ni |

| S30400 | 0,08 maks | 2.0 maks | 1.00 maks | 0,045 maks | 0,030 maks | 18.00 – 20.00 | 8.00 – 11.00 | |

| S31600 | 0,035 maks | 2.0 maks | 1.00 maks | 0,045 maks | 0,030 maks | 16.00 – 18.00 | 2.00 – 3.00 | 10.00 – 14.00 |

| sasmita | Titik Lebur | Kekuwatan Tensile | Kekuwatan Ngasilake (0,2% Offset) |

| 304 | 1040 °C (1900 °F) | MPa - 515 | MPa - 205 |

| 316 | 1100-1170 °C (2010-2140 °F) | MPa - 515 | MPa - 205 |

| Apa Pilih Kita |

1. Sampeyan bisa njaluk materi sampurna miturut requirement ing rega paling bisa.

2. Kita uga nawakake Reworks, FOB, CFR, CIF, lan door to door prices delivery. Disaranake sampeyan supaya menehi hasil kanggo pengiriman sing bakal cukup ekonomis.

3. Bahan sing diwenehake bisa diverifikasi kanthi lengkap, saka sertifikat tes bahan mentah nganti pernyataan dimensi pungkasan. (Laporan bakal ditampilake ing syarat)

4. e njamin menehi respon sajrone 24 jam (biasane ing jam sing padha)

5. Sampeyan bisa entuk alternatif saham, pangiriman pabrik kanthi nyilikake wektu manufaktur.

6. We are kebak darmabakti kanggo kita pelanggan. Yen ora bisa nyukupi syarat sampeyan sawise mriksa kabeh pilihan, kita ora bakal nyasarké sampeyan kanthi janji palsu sing bakal nggawe hubungan pelanggan sing apik.

| Jaminan Kualitas (kalebu ngrusak lan ora ngrusak): |

1. Tes Dimensi Visual

2. Mechanical mriksa kaya tensile, Elongation lan abang saka area.

3. Tes gedhe-gedhe

4. Analisis ujian kimia

5. Tes kekerasan

6. Tes pangayoman pitting

7. Flaring Testing

8. Water-Jet Test

9. Tes Penetrant

10. Tes X-ray

11. Intergranular Corrosion Testing

12. Analisis dampak

13. Eddy saiki mriksa

14. Analisis hidrostatik

15. Uji Eksperimental Metalografi

| Packaging: |

1. Packing cukup penting utamané ing cilik saka kiriman internasional kang consignment liwat macem-macem saluran kanggo nggayuh tujuan pokok, supaya kita sijine badhan khusus bab packaging.

2. Saky Steel ngemas barang-barang kita kanthi macem-macem cara adhedhasar produk. Kita ngemas produk kanthi macem-macem cara, kayata,

Dibungkus nyusut

kothak karton

Palet kayu

Kothak kayu

Krat kayu

| Aplikasi: |

1. Perusahaan Kertas & Pulp

2. Aplikasi Tekanan Dhuwur

3. Industri Minyak lan Gas

4. Kilang Kimia

5. Pipa

6. Aplikasi Suhu Dhuwur

7. Pipa Banyu Lin

8. Pembangkit Listrik Tenaga Nuklir

9. Industri Pangolahan lan Susu

10. Boiler & Penukar Panas

| Rincian liyane: |

| SN | (GB) | (DIN) | (JIS) | AISI/ASTM | UNS | SAE | (ISO) |

| 1 | 1Cr17Mn6Ni5N | SUS201 | 201 | S20100 | 30201 | A-2 | |

| 2 | 1Cr18Mn8Ni5N | X8CrMnNi189 | SUS202 | 202 | S20200 | 30202 | A-3 |

| 3 | 1Cr18Mn10Ni5Mo3N | ||||||

| 4 | 2Cr13Mn9Ni4 | ||||||

| 5 | 1Cr17Ni7 | X12CrNi17.7 | SUS301 | 301 | S30100 | 30301 | 14 |

| 6 | 1Cr17Ni8 | X12CrNi17.7 | SUS301J1 | ||||

| 7 | 1Cr18Ni9 | X12CrNi18.8 | SUS302 | 302 | S30200 | 30302 | 12 |

| 8 | Y1Cr18Ni9 | X12CrNiSi18.8 | SUS303 | 303 | S30300 | 30303 | 17 |

| 9 | Y1Cr18Ni9Se | SUS303Se | 303Se | S30323 | 30303Se | 17 | |

| 10 | 1Cr18Ni9Si3 | X12CrNiSi18.8 | SUS302B | 302B | S30215 | 30302B | |

| 11 | 0Cr18Ni9 | X5CrNi18.9 | SUS304 | 304 | S30400 | 30304 | 11 |

| 12 | 00Cr18Ni10 | X2CrNi18.9 | SUS304L | 304L | S30403 | 30304L | 10 |

| 13 | 0Cr19Ni9N | SUS404N1 | 304N | S30451 | |||

| 14 | 0Cr19Ni10NbN | X5CrNiNb18.9 | SUS304N2 | XM21 | S30452 | ||

| 15 | 00Cr18Ni10N | X2CrNiN18.10 | SUS304LN | 304LN | S30453 | ||

| 16 | 1Cr18Ni12 | X5CrNi19.11 | SUS305 | 305 | S30500 | 30305 | 13 |

| 17 | 0Cr18Ni12 | X5CrNi19.11 | |||||

| 18 | 0Cr23Ni13 | X7CrNi23.14 | SUS309S | ||||

| 19 | 0Cr25Ni20 | SUS310S | |||||

| 20 | 0Cr17Ni12Mo2 | X5CrNiMo18.10 | SUS316 | 316 | S31600 | 30316 | 20,20a |

| 21 | 1Cr17Ni12Mo2 | ||||||

| 22 | 0Cr18Ni12Mo2Ti | X10CrNiMoTi18.10 | |||||

| 23 | 1Cr18Ni12Mo2Ti | X10CrNiMoTi18.10 | |||||

| 24 | 00Cr17Ni14Mo2 | X2CrNiMo18.10 | SUS316L | 316L | S31603 | 30316L | 19,19a |

| 25 | 0Cr17Ni12Mo2N | SUS316N | 316N | S31651 | |||

| 26 | 00Cr17Ni13Mo2N | X2CrNiMoNi18.12 | SUS316LN | 316LN | S31653 | ||

| 27 | 0Cr18Ni12Mo2Cu2 | SUS316J1 | |||||

| 28 | 00Cr18Ni14Mo2Cu2 | SUS316J11 |