Ⅰ. Echiche bụ isi nke ọgwụgwọ okpomọkụ.

A. Echiche bụ isi nke ọgwụgwọ okpomọkụ.

Isi ihe na ọrụ nkeọgwụgwọ okpomọkụ:

1. Na-ekpo ọkụ

Ebumnuche bụ iji nweta otu na ezigbo austenite Ọdịdị.

2.Jide

Ebumnuche bụ iji hụ na workpiece na-ekpo ọkụ nke ọma yana igbochi decarburization na oxidation.

3.Cooling

Ebumnuche bụ ịgbanwe austenite ka ọ bụrụ microstructures dị iche iche.

Microstructures mgbe ọgwụgwọ okpomọkụ gasịrị

N'oge usoro jụrụ oyi mgbe kpochara ma jide ya, austenite na-agbanwe n'ime microstructures dị iche iche dabere na ọnụego jụrụ oyi. Microstructures dị iche iche na-egosipụta ihe dị iche iche.

B. Echiche bụ isi nke ọgwụgwọ okpomọkụ.

Nkewa dabere na usoro ikpo ọkụ na oyi, yana Microstructure na Njirimara nke ígwè.

1.Conventional Okpomọkụ Ọgwụ (N'ozuzu Okpomọkụ Ọgwụgwọ):Tempering,Annealing,Normalizing,Quenching

2.Surface Heat Ọgwụgwọ: N'elu ihu Quenching, Induction kpo oku n'elu ihu Quenching, ọkụ kpo oku elu elu Quenching, Electrical kọntaktị kpo oku n'elu Quenching.

3.Chemical Heat Ọgwụgwọ:Carburizing,Nitriding,Carbonitriding.

4.Other Okpomọkụ Ọgwụ: Controled Atmosphere Heat Ọgwụgwọ, Vacuum Heat Ọgwụgwọ, Deformation Okpomọkụ Ọgwụgwọ.

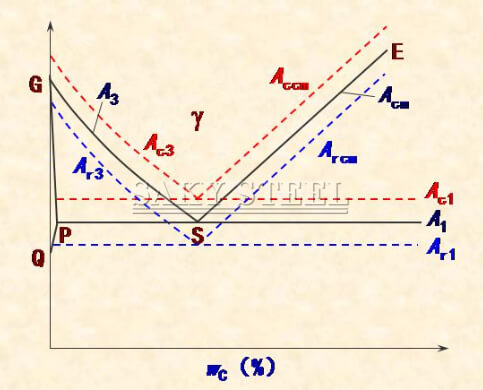

C.Critical okpomọkụ nke ígwè

Mgbanwe mgbanwe dị egwu nke ígwè bụ ihe ndabere dị mkpa maka ikpebi usoro ikpo ọkụ, njide, na oyi n'oge ọgwụgwọ okpomọkụ. A na-ekpebi ya site na eserese oge nke ígwè-carbon.

Isi mmechi:Okpomọkụ ngbanwe dị oke egwu nke igwe na-adakarị n'azụ ọnọdụ mgbanwe mgbanwe mgbanwe usoro iwu. Nke a pụtara na a na-achọ ikpo ọkụ n'oge okpomọkụ, na ịdị jụụ dị mkpa n'oge oyi.

Ⅱ.Annealing na Normalizing nke ígwè

1. Nkọwa nke Annealing

Mwepu na-agụnye igwe kpo oku na okpomọkụ dị n'elu ma ọ bụ n'okpuru ebe dị mkpa Ac₁ na-ejide ya na okpomọkụ ahụ, wee jiri nwayọọ nwayọọ mee ka ọ dị jụụ, na-emekarị n'ime ọkụ ahụ, iji nweta nhazi dị nso na nha nha.

2. Nzube nke Annealing

① Gbanwee ike maka nrụpụta: Nweta ike nke nwere ike ime n'ụdị HB170 ~ 230.

② Weghachite nchekasị fọdụrụnụ: na-egbochi nrụrụ ma ọ bụ mgbawa n'oge usoro ndị na-esote.

③Mụchaa Ọdịdị ọka: Na-emezi microstructure.

④ Nkwadebe maka ọgwụgwọ okpomọkụ ikpeazụ: na-enweta granular (spheroidized) pearlite maka nkwụsị na iwe na-esote.

3.Spheroidizing Annealing

Nkọwapụta usoro: okpomoku ikpo ọkụ dị nso ebe Ac₁.

Nzube: Iji spheroidize cimentite ma ọ bụ carbides na ígwè, na-akpata granular (spheroidized) pearlite.

Oke ọdabara: Ejiri ya maka nchara nwere eutectoid na hypereutectoid mejupụtara.

4.Diffusing Annealing (Homogenizing Annealing)

Nkọwapụta usoro: Okpomọkụ ikpo ọkụ dị ntakịrị n'okpuru ahịrị solvus na eserese oge.

Ebumnuche: Iji kpochapụ nkewa.

① Maka obere -carbon ígwèna ọdịnaya carbon ihe na-erughị 0.25%, a na-ahọrọ normalizing karịa ịchafụ dị ka ọgwụgwọ okpomọkụ na-akwadebe.

②N'ihi na ọkara-carbon ígwè nwere carbon ọdịnaya n'etiti 0.25% na 0.50%, ma annealing ma ọ bụ normalizing nwere ike iji dị ka nkwadebe okpomọkụ ọgwụgwọ.

③Maka igwe na-agba agba ruo elu-carbon nwere ọdịnaya carbon n'etiti 0.50% na 0.75%, a na-atụ aro ịkachasị mma.

④ Maka oke -carbon ígwèna ọdịnaya carbon karịa 0.75%, a na-ebu ụzọ mee normalizing iji kpochapụ netwọk Fe₃C, na-esote spheroidizing annealing.

Ⅲ. Nkụnye na iwe ọkụ nke igwe

A.Quenching

1. Nkọwa nke Quenching: Quenching na-agụnye ikpo ọkụ nchara na okpomọkụ dị n'elu Ac₃ ma ọ bụ Ac₁ point, na-ejide ya na okpomọkụ ahụ, wee mee ka ọ dị jụụ na ọnụego dị oke egwu karịa ka ọ dị mkpa iji mepụta martensite.

2. Ebumnuche nke Quenching: Ebumnuche bụ isi bụ ịnweta martensite (ma ọ bụ mgbe ụfọdụ bainite dị ala) iji mee ka ike sie ike ma na-eyi nguzogide ígwè. Quenching bụ otu n'ime usoro ọgwụgwọ okpomọkụ kachasị mkpa maka ígwè.

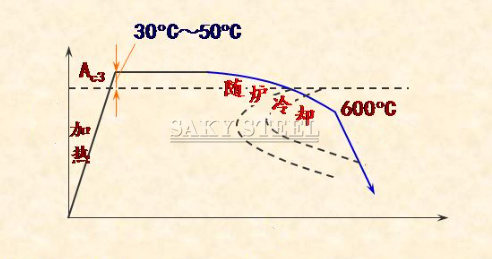

3.Determining Quenching Temperatures for different Types of steel

Steel Hypoeutectoid: Ac₃ + 30°C ruo 50°C

Eutectoid na Hypereutectoid ígwè: Ac₁ 30°C ruo 50°C

Alloy Steel: 50°C ruo 100°C n'elu oke okpomọkụ

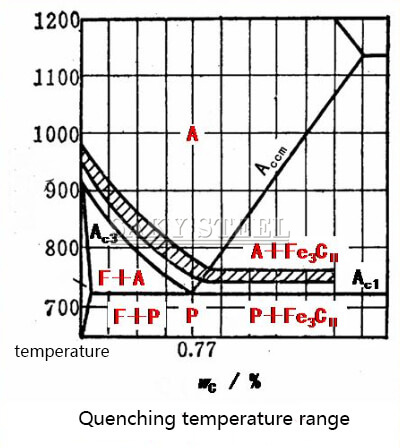

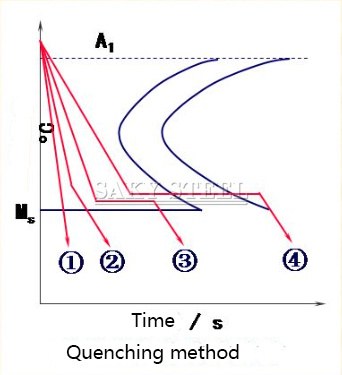

Njirimara 4.Cooling nke Ọkara Quenching kacha mma:

Ọdịda jụụ tupu “imi” okpomọkụ: Iji belata nrụgide okpomọkụ nke ọma.

Ike dị elu dị jụụ dị nso Okpomọkụ "Imi": Iji zere nguzobe nke ihe ndị na-abụghị martensitic.

Nji nwayọ nwayọ nso nso M₅ Point: Iji belata nchekasị nke mgbanwe martensitic na-ebute.

5.Quenching Ụzọ na njirimara ha:

① Dị Mfe Quenching: Ọ dị mfe iji rụọ ọrụ ma dabara maka obere ọrụ arụ ọrụ dị mfe. Ihe si na microstructure pụta bụ martensite (M).

② Quenching ugboro abụọ: mgbagwoju anya ma sie ike ijikwa, ejiri ya mee ihe dị mgbagwoju anya nke nwere nnukwu carbon carbon na nnukwu alloy steel workpieces. Ihe si na microstructure pụta bụ martensite (M).

③ Nkwụsị agbaji: Usoro dị mgbagwoju anya, nke a na-eji maka nnukwu ígwè arụ ọrụ dị mgbagwoju anya. Ihe si na microstructure pụta bụ martensite (M).

④ Isothermal Quenching: A na-eji ya maka obere ọrụ arụ ọrụ dị mgbagwoju anya nwere nnukwu ihe achọrọ. Ihe microstructure na-esi na ya pụta bụ bainite dị ala (B).

6.Ihe na-emetụta ike ike

Ọkwa nke ike siri ike na-adabere na nkwụsi ike nke austenite supercooled na ígwè. Nke dị elu nke nkwụsi ike nke supercooled austenite, nke ka mma nke hardenability, na ntụgharị.

Ihe ndị na-emetụta nkwụsi ike nke Supercooled Austenite:

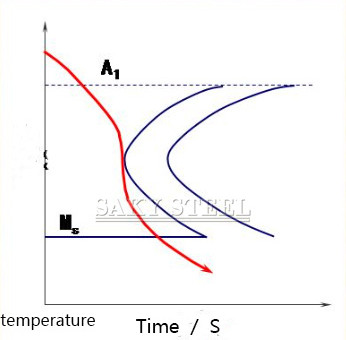

Ọnọdụ nke C-Curve: Ọ bụrụ na C-curve na-atụgharị gaa n'aka nri, ọnụ ọgụgụ dị egwu dị egwu maka ịkwụsị na-ebelata, na-eme ka ike sie ike.

Isi mmechi:

Ihe ọ bụla nke na-atụgharị C-curve gaa n'aka nri na-eme ka ígwè sie ike.

Isi ihe:

Ngwakọta kemịkalụ: Ewezuga cobalt (Co), ihe niile na-agbaze na-agbaze na austenite na-abawanye ike.

Ka ihe dị n'ime carbon dị nso na eutectoid mejupụtara na carbon ígwè, ka C-curve na-atụgharị gaa n'aka nri, na-esiwanye ike karị.

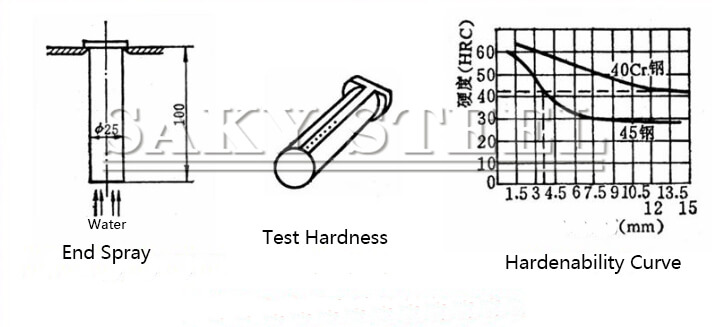

7.Mkpebi na nnọchite anya ike ike

① Ọgwụgwụ Quench Hardenability Ule: A na-atụ ike ike site na iji usoro nnwale njedebe.

② Ụzọ dị egwu Quench dayameta: Dayameta nkwụsị dị oke egwu (D₀) na-anọchite anya dayameta kachasị nke ígwè nwere ike ịgbasi ike zuru oke na usoro nkwụsịtụ.

B. Iwe ọkụ

1. Nkọwa nke iwe ọkụ

Tempering bụ usoro ọgwụgwọ okpomọkụ ebe a na-eme ka ígwè menyụọ ka ọ bụrụ okpomọkụ dị n'okpuru ebe A₁, na-ejide ya na okpomọkụ ahụ, wee mee ka ọ dị jụụ n'ime ụlọ.

2. Ebumnuche nke iwe iwe

Belata ma ọ bụ kpochapụ nchekasị fọdụrụnụ: na-egbochi nrụrụ ma ọ bụ mgbawa nke workpiece.

Belata ma ọ bụ kpochapụ Austenite fọdụrụnụ: Na-eme ka akụkụ nke workpiece guzosie ike.

Wepụ Brittleness nke Quenched Steel: na-edozi microstructure na akụrụngwa iji gboo ihe ndị ọrụ ahụ chọrọ.

Ihe dị mkpa: ígwè kwesịrị ịdị ọkụ ozugbo emenyụchara.

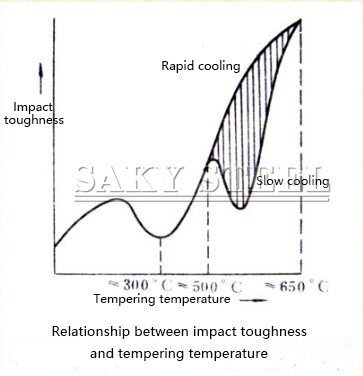

3. Usoro iwe ọkụ

1.Obere iwe

Nzube: Iji belata quenching nchekasị, melite ike nke workpiece, na nweta elu ike ike na eyi iguzogide.

Okpomọkụ: 150°C ~ 250°C.

Arụmọrụ: ike: HRC 58 ~ 64. Elu ike na eyi iguzogide.

Ngwa: Ngwa, ebu, bearings, carburized akụkụ, na elu-ike siri ike.

2.High Tempering

Ebumnuche: Iji nweta ike siri ike yana ike zuru oke na ike.

Okpomọkụ: 500°C ~ 600°C.

Arụmọrụ: ike: HRC 25 ~ 35. Ezi n'ozuzu n'ibu Njirimara.

Ngwa: Ogwe, gia, mkpanaka njikọ, wdg.

Nchacha ọkụ

Nkọwa: A na-akpọ nkwụsị ọkụ na-esochi okpomọkụ dị elu, nchacha ọkụ, ma ọ bụ nanị iwe ọkụ. Igwe a na-agwọ site na usoro a nwere ọmarịcha arụmọrụ n'ozuzu ya ma na-ejikarị ya eme ihe.

Ⅳ.Ngwọta Ọkụ n'elu igwe

A. Ngwunye igwe dị elu

1. Nkọwa nke Mgbochi Elu

Ịdị ike nke dị n'elu bụ usoro ọgwụgwọ okpomọkụ emebere iji wusie oyi akwa nke ihe arụ ọrụ ike site na ikpo ọkụ ngwa ngwa iji gbanwee oyi akwa elu ka ọ bụrụ austenite wee mee ka ọ dị jụụ ngwa ngwa. A na-eme usoro a n'ebughị ụzọ gbanwee ihe mejupụtara kemịkalụ nke ígwè ma ọ bụ isi nhazi nke ihe.

2. Ihe eji eme ihe maka ime ihe ike na elu elu na nhazi ihe nrụgide

Akụrụngwa eji eme ka ike dị elu

Ihe ndị a na-ahụkarị: Carbon steel na ọkara carbon alloy steel.

Tupu ọgwụgwọ: Usoro a na-ahụkarị: iwe ọkụ. Ọ bụrụ na ihe ndị bụ isi adịghị mkpa, enwere ike iji normalizing kama.

Ọdịdị Post-Hardening

Ọdịdị dị n'elu: N'elu oyi akwa na-emepụta ihe siri ike dị ka martensite ma ọ bụ bainite, nke na-enye ike siri ike ma na-eyi nguzogide.

Nhazi isi: Isi nke nchara n'ozuzu na-ejigide nhazi mbụ ya, dị ka pearlite ma ọ bụ ọnọdụ dị ọkụ, dabere na usoro ọgwụgwọ tupu oge na ihe onwunwe nke isi ihe. Nke a na-eme ka o doo anya na isi ahụ na-edobe ezigbo ike na ike.

B.Amara nke induction elu hardening

1.High Heating Temperature and Rapid Temperature Rise: Induction elu hardening na-agụnye okpomọkụ dị elu na ọkụ ọkụ ngwa ngwa, na-enye ohere maka ikpo ọkụ ngwa ngwa n'ime obere oge.

2.Fine Austenite Grain Structure in the Surface Layer: N'oge ọkụ ọkụ ngwa ngwa na usoro nkwụsị na-esote, oyi akwa dị n'elu na-emepụta ọka austenite dị mma. Mgbe emenyụchara, elu ahụ na-enwekarị ọmarịcha martensite, nke siri ike na-adịkarị 2-3 HRC dị elu karịa nkwụsị nke mbụ.

3.Good Surface Quality: N'ihi obere oge kpo oku, elu workpiece na-adịkarị mfe na oxidation na decarburization, na nkwụsị nke na-eme ka a na-eme ka ọ ghara ịdị na-ebelata, na-eme ka ọdịdị elu dị mma.

4.High Ike ike ọgwụgwụ: The martensitic frasi mgbanwe na n'elu oyi akwa site compressive nrụgide, nke na-abawanye ike ike ọgwụgwụ nke workpiece.

5.High Production Efficiency: Induction elu hardening dị mma maka mmepụta oke, na-enye ọrụ arụmọrụ dị elu.

C.Nhazi nke ọgwụgwọ okpomọkụ kemịkal

Carburizing, Carburizing, Carburizing, Chromizing, Siliconizing, Siliconizing, Siliconizing, Carbonitriding, Borocarburizing

D. Gas Carburizing

Gas Carburizing bụ usoro ebe a na-etinye workpiece n'ime ọkụ ọkụ carburizing gas mechiri emechi ma kpoo ọkụ na okpomọkụ nke na-agbanwe ígwè ahụ n'ime austenite. Mgbe ahụ, a carburizing gị n'ụlọnga na-dripped n'ime ọkụ, ma ọ bụ a carburizing ikuku na-kpọmkwem ozugbo, ikwe ka carbon atom gbasaa n'ime elu oyi akwa nke workpiece. Usoro a na-abawanye ọdịnaya carbon (wc%) na elu workpiece.

√ Ndị na-ebu ibu:

• Gases bara ụba nke carbon: Dị ka coal gas, gas petroleum gas (LPG), wdg.

• Mmiri ara ehi: Dị ka kerosene, methanol, benzene, wdg.

√Usoro usoro ịkwọ ụgbọ mmiri:

• Okpomọkụ Carburizing: 920 ~ 950°C.

• Oge Carburizing: Na-adabere na omimi achọrọ nke oyi akwa carburized na okpomọkụ carburizing.

E.Heat Ọgwụgwọ Mgbe Carburizing

Steel ga-enweta ọgwụgwọ okpomọkụ mgbe carburizing gasịrị.

Usoro ọgwụgwọ okpomọkụ Mgbe Carburizing:

√Quenching + Okpomọkụ dị ala

1.Direct Quenching Mgbe Pre-Cooling + Low-Temperature Tempering: The workpiece bụ tupu mma si carburizing okpomọkụ ka dị n'elu isi nke Ar₁ okpomọkụ na mgbe ahụ ozugbo quenched, sochiri ala-okpomọkụ tempering na 160 ~ 180 ° C.

2.Single Quenching Mgbe Pre-Cooling + Low-Temperature Tempering: Mgbe carburizing, na workpiece ji nwayọọ nwayọọ mma ka ụlọ okpomọkụ, mgbe ahụ reheated maka quenching na ala-okpomọkụ tempering.

3.Double Quenching Mgbe Pre-Cooling + Low-Temperature Tempering: Mgbe carburizing na ngwa ngwa jụrụ, na workpiece undergoes abụọ nkebi nke kpo oku na quenching, sochiri ala-okpomọkụ tempering.

Ⅴ. Ọgwụgwọ Igwe Ọkụ nke igwe

1.Definition of Chemical Heat Treatment

Chemical okpomọkụ ọgwụgwọ bụ okpomọkụ ọgwụgwọ usoro nke a ígwè workpiece na-etinye na a kpọmkwem arụ ọrụ ọkara, kpụ ọkụ n'ọnụ, na ẹkenịmde ke okpomọkụ, ikwe ka ndị na-arụ ọrụ atọm na-ajụ na-agbasa n'ime elu nke workpiece. Nke a na-agbanwe ihe mejupụtara kemịkalụ na microstructure nke elu workpiece, si otú ahụ na-agbanwe akụrụngwa ya.

2.Basic usoro nke Chemical okpomọkụ ọgwụgwọ

Nbibi: N'oge kpo oku, onye na-arụ ọrụ na-arụ ọrụ na-emebi, na-ahapụ atom ndị na-arụ ọrụ.

Absorption: Atọm ndị na-arụ ọrụ na-adaba n'elu igwe ma gbazee n'ime ngwọta siri ike nke ígwè.

Mgbasa: Atọm na-arụ ọrụ na-etinye obi ma gbazee n'elu igwe na-akwaga n'ime ime.

Ụdị nke Induction elu elu ike ike

a.Elu-ugboro oku iwebata

Ugboro ugbu a: 250 ~ 300 kHz.

Omimi oyi akwa siri ike: 0.5 ~ 2.0 mm.

Ngwa: Ọkara na obere modul gia na obere ogwe osisi dị obere.

b.Ọkara-ugboro oku nnabata

Ugboro ugbu a: 2500 ~ 8000 kHz.

Omimi oyi akwa siri ike: 2 ~ 10 mm.

Ngwa: ogwe ndị buru ibu na nnukwu modul modul gia.

c.Ike-ugboro ugboro ntinye oku

Ugboro ugbu a: 50 Hz.

Omimi oyi akwa siri ike: 10 ~ 15 mm.

Ngwa: Workpieces chọrọ akwa oyi akwa siri ike.

3. Induction elu elu harddening

Ụkpụrụ bụ isi nke ikesi elu elu nnabata

Mmetụta akpụkpọ:

Mgbe a ọzọ ugbu a na induction eriri igwe na-eme ka a ugbu a n'elu nke workpiece, ihe ka ọtụtụ n'ime ndị na-akpali ugbu a na-etinye uche n'akụkụ elu, ebe ọ fọrọ nke nta ka ọ dịghị ugbu a na-agafe n'ime ime nke workpiece. A maara ihe a dị ka mmetụta akpụkpọ ahụ.

Ụkpụrụ nke Ịgbasi Ike n'elu Mwebata:

Dabere na mmetụta akpụkpọ ahụ, elu nke workpiece na-ekpo ọkụ ngwa ngwa na okpomọkụ austenitizing (na-ebili ruo 800 ~ 1000 Celsius C n'ime sekọnd ole na ole), ebe ime nke workpiece na-anọgide na-enweghị ọkụ. The workpiece na-ahụ mma site na mmiri spraying, nweta elu hardening.

4. Iwe iwe ọkụ

Ọkụ na-ekpo ọkụ n'ime igwe anaghị agba nchara

Ọkụkụ nkụja na-ezo aka na ihe omume ebe mmetụta siri ike nke ígwè emenyụ emenyụ na-ebelata nke ukwuu mgbe iwe dị ọkụ na ụfọdụ okpomọkụ.

Ụdị mbụ nke iwe ọkụ

Oke okpomọkụ: 250°C ruo 350°C.

Àmà: Ọ bụrụ na ígwè emenyụ ọkụ na-adị n'ime oke okpomọkụ a, ọ ga-abụ na ọ ga-etolite ụdị ọkụ ọkụ a, nke a na-apụghị ikpochapụ.

Ngwọta: Zenarị nchara agbanyụọ n'ime oke okpomọkụ a.

Ụdị nke mbụ nke iwe ọkụ ka a na-akpọkwa dị ka obere okpomọkụ tempering brittleness ma ọ bụ irreversible tempering brittleness.

Ⅵ. Na-ewe iwe

1.Tempering bụ usoro ọgwụgwọ okpomọkụ ikpeazụ nke na-esote quenching.

Gịnị mere ígwè kụnwụsịrị ji chọọ iwe ọkụ?

Microstructure Mgbe Quenching: Mgbe emechara, microstructure nke ígwè na-enwekarị martensite na austenite fọdụrụnụ. Ha abụọ bụ usoro metastable ga-agbanwe n'okpuru ọnọdụ ụfọdụ.

Ngwongwo nke Martensite: A na-eji Martensite mara oke ike mana ọ dịkwa oke nhịahụ (karịsịa na agịga carbon dị elu dị ka martensite), nke na-emezughị ihe achọrọ maka ọtụtụ ngwa.

Njirimara nke mgbanwe Martensitic: Mgbanwe na martensite na-eme ngwa ngwa. Mgbe emenyụchara, ọrụ ahụ nwere nrụgide dị n'ime ya nke nwere ike ibute nrụrụ ma ọ bụ mgbawa.

Mmechi: Enweghị ike iji workpiece ozugbo emechara! Iwe ọkụ dị mkpa iji belata nrụgide dị n'ime ma melite ike nke workpiece, na-eme ka ọ dị mma maka ojiji.

2. Ọdịiche n'etiti ike ike na ike ike:

Ike ike:

Hardenability na-ezo aka n'ikike nke ígwè iji nweta ụfọdụ omimi nke siri ike (ihe omimi nke oyi akwa) mgbe emechara. Ọ na-adabere na nhazi na nhazi nke ígwè ahụ, karịsịa ihe ndị na-ejikọta ya na ụdị ígwè. Ịdị ike bụ ihe nleba anya ka nchara ahụ nwere ike isi sie ike n'ogologo ya n'oge usoro nkwụsị.

Isi Ike (Ike Nrụsi Ike):

Ike ike, ma ọ bụ ike ike, na-ezo aka na ike siri ike nke enwere ike nweta na nchara mgbe emechara. Ọ na-emetụta nke ukwuu site na ọdịnaya carbon nke ígwè. Ọdịnaya carbon dị elu n'ozuzu na-eduga n'ike siri ike dị elu, mana nke a nwere ike kpachie ya site na ihe na-eme ka ígwè na ịdị irè nke usoro imenyụ.

3.Herdenability nke ígwè

√ Echiche nke ike siri ike

Hardenability na-ezo aka na ike nke ígwè iji nweta ụfọdụ omimi nke hardening martensitic mgbe ọ kwụsịrị site na austenitizing okpomọkụ. N'okwu dị mfe, ọ bụ ikike nke ígwè ịmepụta martensite n'oge quenching.

Ntụle ike ike

A na-egosi oke ike ike site na omimi nke oyi akwa siri ike enwetara n'okpuru ọnọdụ akọwapụtara mgbe emechara.

Omimi oyi akwa siri ike: Nke a bụ omimi site na elu nke workpiece na mpaghara ebe ihe owuwu ahụ bụ ọkara martensite.

Mgbasa ozi na-emenyụkarị:

• Mmiri

Àgwà: Akụ na ụba nwere ike jụrụ oyi, mana ọ nwere oke jụrụ oyi n'akụkụ ebe a na-esi esi mmiri, nke nwere ike ibute oke jụrụ oyi.

Ngwa: A na-ejikarị ígwè carbon.

Mmiri Nnu: Ngwọta nke nnu ma ọ bụ alkali na mmiri, nke nwere ikike dị jụụ na okpomọkụ dị elu ma e jiri ya tụnyere mmiri, na-eme ka ọ dị mma maka ígwè carbon.

• Mmanụ

Àmà: Na-enye ọnụ ọgụgụ dị nwayọọ nwayọọ nwayọọ na okpomọkụ dị ala (n'akụkụ ebe a na-esi esi esi), nke na-ebelata nke ọma nrụrụ na mgbawa, mana ọ nwere ike ịjụ oyi na okpomọkụ dị elu.

Ngwa: Kwesịrị ekwesị maka nchara alloy.

Ụdị: Gụnyere mmanụ na-emenyụ ọkụ, mmanụ igwe, na mmanụ dizel.

Oge ikpo ọkụ

Oge ikpo ọkụ na-agụnye ma ọnụego kpo oku (oge a na-ewe iji ruo okpomọkụ a chọrọ) na oge njide (oge a na-edobe na ọnọdụ okpomọkụ).

Ụkpụrụ maka ikpebi oge ikpo ọkụ: Gbaa mbọ hụ na nkesa otu okpomọkụ n'ime ụlọ ọrụ, ma n'ime ma n'èzí.

Gbaa mbọ hụ na austenitization zuru oke yana na austenite guzobere bụ otu ma dị mma.

Ndabere maka ikpebi oge ikpo ọkụ: A na-eme atụmatụ site na iji usoro ihe atụ ma ọ bụ kpebisie ike site na nnwale.

Mgbasa mgbasa ozi

Akụkụ abụọ bụ isi:

a.Cooling Rate: Ọnụego jụrụ oyi dị elu na-akwalite nhazi nke martensite.

b.Residual Nchekasị: A elu jụrụ ọnụego na-abawanye residual nchegbu, nke nwere ike iduga a ukwuu ọchịchọ maka deformation na cracking na workpiece.

Ⅶ.Normalizing

1. Nkọwa nke Normalizing

Normalizing bụ usoro ọgwụgwọ okpomọkụ nke ígwè na-ekpo ọkụ na okpomọkụ 30 ° C ruo 50 ° C n'elu okpomọkụ Ac3, na-ejide ya na okpomọkụ ahụ, wee mee ka ikuku dị jụụ iji nweta microstructure dị nso na steeti nhata. E jiri ya tụnyere mgbakasị ahụ, normalizing nwere ngwa ngwa jụrụ oyi, na-ebute nhazi pearlite kacha mma (P) na ike dị elu na ike.

2. Nzube nke Normalizing

Nzube nke normalizing yiri nke annealing.

3. Ngwa nke Normalizing

• Wepụ cimentite nke abụọ nke netwọk.

• Na-eje ozi dị ka ọgwụgwọ okpomọkụ ikpeazụ maka akụkụ ndị nwere obere ihe achọrọ.

• Na-eme dị ka ihe na-akwadebe okpomọkụ ọgwụgwọ maka obere na ọkara carbon structural ígwè iji melite machinability.

4.Types of Annealing

Ụdị nke mbụ nke mgbakasị ahụ:

Ebumnuche na Ọrụ: Ebumnuche abụghị ime mgbanwe mgbanwe nke oge kama ka ọ gbanwee nchara site na ọnọdụ na-adịghị mma gaa na ọnọdụ kwesịrị ekwesị.

Ụdị:

• Mgbasa mgbasa: Ebumnobi ime ka ihe mejupụtara ya na-ekpochapụ nkewa.

• Recrystallization Annealing: Na-eweghachite ductility site na iwepụ mmetụta nke ịrụsi ọrụ ike.

• Mbelata ihe mgbakasị ahụ: Na-ebelata nrụgide dị n'ime na-agbanweghị microstructure.

Ụdị nke abụọ nke mgbakasị ahụ:

Ebumnuche na Ọrụ: Ebumnuche ịgbanwe microstructure na akụrụngwa, na-enweta microstructure na-achịkwa pearlite. Ụdị a na-ahụkwa na nkesa na morphology nke pearlite, ferrite, na carbides na-emezu ihe a chọrọ.

Ụdị:

• Mkpokọta zuru ezu: Na-ekpo ọkụ nchara n'elu AC3 okpomọkụ wee jiri nwayọọ nwayọọ mee ka ọ dị jụụ iji mepụta otu ụdị pearlite.

• Mkpuchi na-ezughị ezu: Na-ekpo ọkụ nchara n'etiti okpomọkụ Ac1 na Ac3 iji gbanwee akụkụ ahụ.

• Isothermal Annealing: Na-ekpo ọkụ nchara n'elu Ac3, na-esote ngwa ngwa oyi na okpomọkụ nke isothermal na ijide iji nweta usoro achọrọ.

• Spheroidizing Annealing: Na-emepụta ihe owuwu spheroidal carbide, na-emeziwanye igwe na ịdị ike.

Ⅷ.1.Nkọwa ọgwụgwọ okpomọkụ

Ọgwụgwọ okpomọkụ na-ezo aka na usoro nke metal na-ekpo ọkụ, na-ejide ya na okpomọkụ dị iche iche, wee mee ka ọ dị jụụ mgbe ọ nọ n'ọnọdụ siri ike iji gbanwee nhazi nke ime ya na microstructure, si otú ahụ nweta ihe ndị a chọrọ.

2.Amara nke ọgwụgwọ okpomọkụ

Ọgwụgwọ okpomọkụ adịghị agbanwe ọdịdị nke workpiece; kama, ọ na-agbanwe usoro ime na microstructure nke ígwè ahụ, nke na-eme ka ọ gbanwee ihe ndị dị nchara.

3.Ebumnobi nke ọgwụgwọ okpomọkụ

Ebumnuche nke ọgwụgwọ okpomọkụ bụ iji melite n'ibu ma ọ bụ nhazi Njirimara nke ígwè (ma ọ bụ workpieces), n'ụzọ zuru ezu nagide ikike nke ígwè, welie àgwà nke workpiece, na ịgbatị ya ọrụ ndụ.

4.Igodo mmechi

Ma enwere ike imeziwanye ihe onwunwe site na ọgwụgwọ okpomọkụ na-adabere nke ọma ma enwere mgbanwe na microstructure na nhazi ya n'oge usoro ikpo ọkụ na oyi.

Oge nzipu: Ọgọst-19-2024