A na-ekewakarị igwe anaghị agba nchara na-ekpo ọkụ na-emekarị n'ime ụdị atọ, 309S, 310S na 253MA, a na-ejikarị ígwè na-ekpo ọkụ na-emepụta ihe ọkụkụ, turbines uzuoku, ụlọ ọrụ mmepụta ihe na ụgbọ elu, petrochemical na ụlọ ọrụ mmepụta ihe ndị ọzọ na-arụ ọrụ dị elu.

1.309s: (OCr23Ni13) igwe anaghị agba nchara

Njirimara: Ọ nwere ike idi kpo oku ugboro ugboro n'okpuru 980 ℃, na elu okpomọkụ ike, oxidation iguzogide na carburizing iguzogide.

Ngwa: ọkụ ihe onwunwe, ike ga-eji rụpụta ọkụ ígwè akụkụ, Ya elu chromium na nickel ọdịnaya ana achi achi ezi corrosion iguzogide na ọxịdashọn resistance.

E jiri ya tụnyere austenitic 304 alloy, ọ dị ntakịrị ike na ụlọ okpomọkụ. Na ndụ n'ezie, ọ nwere ike na-ekpo ọkụ ugboro ugboro na 980 Celsius C iji nọgide na-arụ ọrụ nkịtị.310s: (0Cr25Ni20) igwe anaghị agba nchara.

2.310s: (OCr25Ni20) igwe anaghị agba nchara

Njirimara: Igwe anaghị agba nchara chromium-nickel austenitic nwere ezigbo igwe igwe dị elu yana ezigbo nguzogide corrosion na mgbasa ozi oxidizing. Kwesịrị ekwesị maka mmepụta nke ihe ọkụ ọkụ dị iche iche, okpomọkụ kachasị elu 1200 ℃, na-aga n'ihu na-eji okpomọkụ 1150 ℃.

Ngwa: ihe ọkụ ọkụ, ihe eji eme ihe nchacha ụgbọala.

310S igwe anaghị agba nchara bụ a ukwuu corrosion-eguzogide austenitic igwe anaghị agba nchara alloy na-eji dị iche iche elu okpomọkụ na corrosive gburugburu. Ọ bụ nhọrọ magburu onwe ya maka ngwa na petrochemical, kemịkalụ, na ụlọ ọrụ na-ekpo ọkụ, yana maka ihe ọkụ ọkụ na ngwa ndị ọzọ dị elu. Efere igwe anaghị agba nchara 310S bụ mpempe akwụkwọ dị larịị, dị gịrịgịrị sitere na alloy a akọwapụtara.

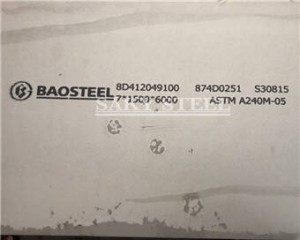

3.253MA (S30815) igwe anaghị agba nchara efere

Njirimara: 253MA bụ igwe anaghị agba nchara Austenitic na-eguzogide okpomọkụ emebere maka ngwa chọrọ ike creep na ezigbo nguzogide corrosion. Ya na-arụ ọrụ okpomọkụ nso bụ 850-1100 ℃.

253MA bụ kpọmkwem ụdị igwe anaghị agba nchara nke emebere maka ngwa okpomọkụ dị elu. Ọ na-enye ezigbo nguzogide oxidation, sulfidation, na carburization na okpomọkụ dị elu. Nke a na-eme ka ọ dị mma maka iji ya na ụlọ ọrụ dị iche iche, gụnyere ndị metụtara okpomọkụ na corrosion, dị ka petrochemical, ike ike, na ụlọ ọkụ ọkụ.Mpempe akwụkwọ 253MA dị gịrịgịrị, ihe dị larịị nke emere site na alloy a. A na-eji ha na ngwa dị iche iche ebe nchikota nke oke okpomọkụ na nguzogide corrosion dị mkpa. Enwere ike igbutu mpempe akwụkwọ ndị ahụ ma guzobe n'ụdị dị iche iche iji mezuo ihe achọrọ maka ọrụ.

Mpempe akwụkwọ 253MA, Plates Chemical Composition

| Ọkwa | C | Cr | Mn | Si | P | S | N | Ce | Fe | Ni |

| 253MA | 0.05-0.10 | 20.0-22.0 | 0.80 kacha | 1.40-2.00 | 0.040 kacha | 0.030 kacha | 0.14-0.20 | 0.03-0.08 | Nhazi | 10.0-12.0 |

253MA Plate Mechanical Njirimara

| Ike ọdụdọ | Ike Mpụta (0.2% kwụsịrị) | Mgbatị (na 2 in.) |

| Psi: 87,000 | Psi 45000 | 40% |

253MA Plate Corrosion eguzogide na isi ojiji gburugburu:

1.Corrosion Resistance: 253MA na-etu ọnụ nke ọma oxidation resistance, elu-okpomọkụ corrosion eguzogide, na ịrịba elu-okpomọkụ n'ibu ike. Ọ dị irè karịsịa n'ime oke okpomọkụ nke 850 ruo 1100 ° C.

2.Temperature Range: Maka ịrụ ọrụ kachasị mma, 253MA kacha mma maka ojiji n'ime okpomọkụ nke 850 ruo 1100 ° C. Na okpomọkụ n'etiti 600 na 850 Celsius, mgbanwe nhazi na-eme, na-eduga n'ibelata mmetụta siri ike na okpomọkụ ụlọ.

3.Mechanical Strength: Nke a alloy karịrị nkịtị igwe anaghị agba nchara, dị ka 304 na 310S, na okwu nke obere oge tensile ike dị iche iche okpomọkụ site n'elu 20%.

4.Chemical Composition: 253MA nwere ihe mejupụtara kemịkalụ kwesịrị ekwesị nke na-enye ya arụmọrụ pụrụ iche na oke okpomọkụ nke 850-1100 Celsius. Ọ na-egosipụta nguzogide oxidation dị oke elu, na-egbochi okpomọkụ ruo 1150 Celsius. Ọ na-enyekwa nguzogide na-akpụ akpụ na ike mgbaji.

5.Corrosion Resistance: Na mgbakwunye na ike okpomọkụ ya dị elu, 253MA na-egosiputa nguzogide dị mma maka nkwụsị okpomọkụ dị elu na ahịhịa ahịhịa na ọtụtụ ikuku gas.

6.Strength: Ọ nwere nnukwu mkpụrụ ike na ike tensile na elu okpomọkụ.

7.Formability na Weldability: 253MA mara maka ezigbo nhazi, weldability, na machinability.

Oge nzipu: Ọkt-09-2023