Hot Rolled Pickled Cold Drawn 321 Stainless Steel Round Bars

Short Description:

Saky Steel’s 321 stainless steel bar, also known as UNS S32100 and Grade 321, is primarily comprised of 17% to 19% chromium, 12% nickel, .25% to 1% silicon, 2% maximum manganese, traces of phosphorus and sulfur, 5 x (c + n) .70% titanium, with the balance being iron. With regards to corrosion resistance, 321 is equivalent to Grade 304 in the annealed condition and is superior if the application involves service in the 797° to 1652° F range. Saky Steel’s Grade 321 combines high strength, resistance to scaling and phase stability with resistance to subsequent aqueous corrosion.

| Specifications of inox 321 bar hot rolled: |

| Standard | ASTM A276, A484, A479, A580, A582, JIS G4303, JIS G4311,DIN 1654-5,DIN 17440,KS D3706,GB/T 1220 |

| Material | 201,202,205,XM-19 etc. 301,303,304,304L,304H,309S,310S,314,316,316L,316Ti,317,321,321H,329,330,348 etc. 409,410,416,420,430,430F,431,440 2205,2507,S31803,2209,630,631,15-5PH,17-4PH,17-7PH,904L,F51,F55,253MA etc. |

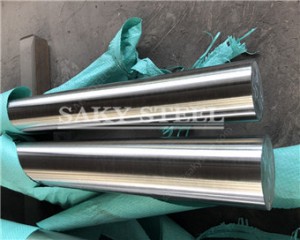

| Surface | Bright,Polishing,Pickled,Peeled,Black,Grinding |

| Technology | Cold Drawn,Hot Rolled,Forged |

| Specifications | Size: 3mm~400mm Length:5.8m,6m or as required |

| Tolerance | H9, H11, H13, K9, K11, K13 or as required |

| Stainless Steel 321 Bar Equivalent Grades: |

| STANDARD | WERKSTOFF NR. | UNS | JIS | EN |

| SS 321 | 1.4541 | S32100 | SUS 321 | X6CrNiTi18-10 |

| SS 321 Bar Chemical Composition: |

| Grade | C | Mn | Si | P | S | Cr | N | Ni | Ti |

| SS 321 | 0.08 max | 2.0 max | 1.0 max | 0.045 max | 0.030 max | 17.00 – 19.00 | 0.10 max | 9.00 – 12.00 | 5(C+N) – 0.70 max |

| SS 321 Bar Mechanical Properties: |

| Density | Melting Point | Tensile Strength | Yield Strength (0.2%Offset) | Elongation |

| 8.0 g/cm3 | 1457 °C (2650 °F) | Psi – 75000 , MPa – 515 | Psi – 30000 , MPa – 205 | 35 % |

| Part of 321 steel bar sizes: |

| Dia | Weight | Dia | Weight |

| (mm) | per metre (kg) | (in) | per metre (kg) |

| 3mm | 0.06 | 1/8″ | 0.06 |

| 4mm | 0.10 | 3/16″ | 0.14 |

| 5mm | 0.16 | 1/4″ | 0.25 |

| 6mm | 0.22 | 5/16″ | 0.39 |

| 7mm | 0.30 | 3/8″ | 0.56 |

| 8mm | 0.40 | 7/16″ | 0.77 |

| 10mm | 0.62 | 1/2″ | 1.00 |

| 12mm | 0.89 | 9/16″ | 1.22 |

| 14mm | 1.22 | 5/8″ | 1.56 |

| 15mm | 1.40 | 11/16″ | 1.89 |

| 16mm | 1.59 | 3/4″ | 2.25 |

| 18mm | 2.01 | 7/8″ | 3.07 |

| 20mm | 2.48 | 1″ | 4.03 |

| 22mm | 3.00 | 1 1/8 “ | 5.07 |

| 24mm | 3.57 | 1 1/4 “ | 6.25 |

| 25mm | 3.88 | 1 3/8″ | 7.57 |

| 30mm* | 5.58 | 1 1/2″ | 9.01 |

| 35mm | 7.60 | 1 5/8″ | 10.60 |

| 40mm* | 9.93 | 1 3/4″ | 12.20 |

| 45mm | 12.56 | 1 7/8″ | 14.10 |

| 60mm | 22.30 | 2″ | 16.00 |

| Stainless Steel Round Bar Packaging: |

Sakysteel 321 Stainless Steel Round Bar are packed and labeled according to the regulations and customer’s requests. Great care is taken to avoid any damage which might otherwise be caused during storage or transportation.

| 321 Stainless Steel Round Bars Applications: |

321 stainless steel round bars are versatile materials with a wide range of applications due to their excellent corrosion resistance, high strength, and heat resistance. Here are some common applications of 321 stainless steel round bars:

1. Aerospace: 321 stainless steel round bars are commonly used in the aerospace industry for their excellent high-temperature performance and resistance to corrosion and oxidation.

2. Chemical Processing: 321 stainless steel round bars are often used in chemical processing applications due to their excellent resistance to corrosive chemicals.

3. Heat Exchangers: 321 stainless steel round bars are commonly used in heat exchangers because of their excellent resistance to high temperatures and corrosion.

4. Power Generation: 321 stainless steel round bars are often used in power generation equipment due to their excellent heat resistance and strength.

5. Medical Equipment: 321 stainless steel round bars are also used in medical equipment and devices because of their high resistance to corrosion and their biocompatibility.

6. Automotive Industry: 321 stainless steel round bars are used in automotive exhaust systems due to their excellent heat resistance and resistance to corrosion.

7. Food Processing: 321 stainless steel round bars are used in food processing equipment due to their excellent resistance to corrosion and their non-reactive properties.

8. Marine Industry: 321 stainless steel round bars are used in marine applications because of their excellent corrosion resistance in saltwater environments.

Overall, 321 stainless steel round bars are an excellent material for a wide range of applications due to their combination of high strength, heat resistance, and corrosion resistance.