Hollow Section

Short Description:

A square hollow section (SHS) refers to a type of metal profile that has a square cross-section and is hollow inside. It is commonly used in the construction and manufacturing industries for various applications due to its structural and aesthetic properties.

Hollow Structural Section:

A hollow section refers to a metal profile with a hollow core and is commonly used in various structural and engineering applications. The term "hollow section" is a broad category that encompasses various shapes, including square, rectangular, circular, and other custom shapes. These sections are designed to provide structural strength and stability while often minimizing weight.Hollow sections are often made from metals such as steel, aluminum, or other alloys.The choice of material depends on factors such as strength requirements, corrosion resistance, and the intended application.

Specifications Of steel hollow section:

| Grade | 302,304,316,430 |

| Standard | ASTM A312, ASTM A213 |

| Surface | hot rolled pickled ,polished |

| Technology | Hot Rolled , Welded,Cold Drawn |

| Out Diameter | 1/8″~32″,6mm~830mm |

| Type | Square Hollow Section (SHS),Rectangular Hollow Section (RHS),Circular Hollow Section (CHS) |

| Raw Materail | POSCO, Baosteel, TISCO, Saky Steel, Outokumpu |

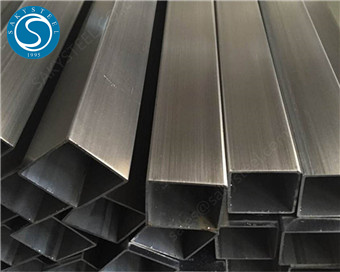

Square Hollow Section(SHS):

A Square Hollow Section (SHS) is a metal profile with a square cross-section and a hollow interior. Widely used in construction and manufacturing, SHS offers advantages such as strength-to-weight efficiency, structural versatility, and ease of fabrication. Its clean geometric shape and various sizes make it suitable for building frames, support structures, machinery, and other applications. SHS is often made from materials like steel or aluminum, adheres to industry standards, and can be treated for corrosion resistance.

Square Hollow Section (SHS) DIMENSIONS/SIZES TABLE:

| Size mm | kg/m | Size mm | kg/m |

| 20 x 20 x 2.0 | 1.12 | 20 x 20 x 2.5 | 1.35 |

| 25 x 25 x 1.5 | 1.06 | 25 x 25 x 2.0 | 1.43 |

| 25 X 25 X 2.5 | 1.74 | 25 X 25 X 3.0 | 2.04 |

| 30 X 30 X 2.0 | 1.68 | 30 X 30 X 2.5 | 2.14 |

| 30 X 30 X 3.0 | 2.51 | 40 x 40 x 1.5 | 1.81 |

| 40 x 40 x 2.0 | 2.31 | 40 x 40 x 2.5 | 2.92 |

| 40 x 40 x 3.0 | 3.45 | 40 x 40 x 4.0 | 4.46 |

| 40 x 40 x 5.0 | 5.40 | 50 x 50 x 1.5 | 2.28 |

| 50 x 50 x 2.0 | 2.93 | 50 x 50 x 2.5 | 3.71 |

| 50 x 50 x 3.0 | 4.39 | 50 x 50 x 4.0 | 5.72 |

| 50 x 50 x 5.0 | 6.97 | 60 x 60 x 3.0 | 5.34 |

| 60 x 60 x 4.0 | 6.97 | 60 x 60 x 5.0 | 8.54 |

| 60 x 60 x 6.0 | 9.45 | 70 x 70 x 3.0 | 6.28 |

| 70 x 70 x 3.6 | 7.46 | 70 x 70 x 5.0 | 10.11 |

| 70 x 70 x 6.3 | 12.50 | 70 x 70 x 8 | 15.30 |

| 75 x 75 x 3.0 | 7.07 | 80 x 80 x 3.0 | 7.22 |

| 80 x 80 x 3.6 | 8.59 | 80 x 80 x 5.0 | 11.70 |

| 80 x 80 x 6.0 | 13.90 | 90 x 90 x 3.0 | 8.01 |

| 90 x 90 x 3.6 | 9.72 | 90 x 90 x 5.0 | 13.30 |

| 90 x 90 x 6.0 | 15.76 | 90 x 90 x 8.0 | 20.40 |

| 100 x 100 x 3.0 | 8.96 | 100 x 100 x 4.0 | 12.00 |

| 100 x 100 x 5.0 | 14.80 | 100 x 100 x 5.0 | 14.80 |

| 100 x 100 x 6.0 | 16.19 | 100 x 100 x 8.0 | 22.90 |

| 100 x 100 x 10 | 27.90 | 120 x 120 x 5 | 18.00 |

| 120 x 120 x 6.0 | 21.30 | 120 X 120 X 6.3 | 22.30 |

| 120 x 120 x 8.0 | 27.90 | 120 x 120 x 10 | 34.20 |

| 120 X 120 X 12 | 35.8 | 120 X 120 X 12.5 | 41.60 |

| 140 X 140 X 5.0 | 21.10 | 140 X 140 X 6.3 | 26.30 |

| 140 X 140 X 8 | 32.90 | 140 X 140 X 10 | 40.40 |

| 140 X 140 X 12.5 | 49.50 | 150 X 150 X 5.0 | 22.70 |

| 150 X 150 X 6.3 | 28.30 | 150 X 150 X 8.0 | 35.40 |

| 150 X 150 X 10 | 43.60 | 150 X 150 X 12.5 | 53.40 |

| 150 X 150 X 16 | 66.40 | 150 X 150 X 16 | 66.40 |

| 180 X 180 X 5 | 27.40 | 180 X 180 X 6.3 | 34.20 |

| 180 X 180 X 8 | 43.00 | 180 X 180 X 10 | 53.00 |

| 180 X 180 X 12.5 | 65.20 | 180 X 180 X 16 | 81.40 |

| 200 X 200 X 5 | 30.50 | 200 X 200 X 6 | 35.8 |

| 200 x 200 x 6.3 | 38.2 | 200 x 200 x 8 | 48.00 |

| 200 x 200 x 10 | 59.30 | 200 x 200 x 12.5 | 73.00 |

| 200 x 200 x 16 | 91.50 | 250 x 250 x 6.3 | 48.10 |

| 250 x 250 x 8 | 60.50 | 250 x 250 x 10 | 75.00 |

| 250 x 250 x 12.5 | 92.60 | 250 x 250 x 16 | 117.00 |

| 300 x 300 x 6.3 | 57.90 | 300 x 300 x 8 | 73.10 |

| 300 x 300 x 10 | 57.90 | 300 x 300 x 8 | 90.70 |

| 300 x 300 x 12.5 | 112.00 | 300 x 300 x 16 | 142.00 |

| 350 x 350 x 8 | 85.70 | 350 x 350 x 10 | 106.00 |

| 350 x 350 x 12.5 | 132.00 | 350 x 350 x 16 | 167.00 |

| 400 x 400 x 10 | 122.00 | 400 x 400 x 12 | 141.00 |

| 400 x 400 x 12.5mm | 152.00 | 400 x 400 x 16 | 192 |

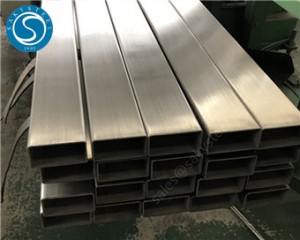

Rectangular Hollow Section(RHS):

A Rectangular Hollow Section (RHS) is a metal profile characterized by its rectangular cross-section and hollow interior. RHS is commonly employed in construction and manufacturing due to its structural efficiency and adaptability. This profile provides strength while minimizing weight, making it suitable for diverse applications such as building frames, support structures, and machinery components. Similar to Square Hollow Sections (SHS), RHS is often made from materials like steel or aluminum and follows industry standards for dimensions and specifications. Its rectangular shape and various sizes offer versatility in meeting specific engineering requirements.

Rectangular Hollow Section (RHS) DIMENSIONS/SIZES TABLE:

| Size mm | kg/m | Size mm | kg/m |

| 40 x 20 x 2.0 | 1.68 | 40 x 20 x 2.5 | 2.03 |

| 40 x 20 x 3.0 | 2.36 | 40 x 25 x 1.5 | 1.44 |

| 40 x 25 x 2.0 | 1.89 | 40 x 25 x 2.5 | 2.23 |

| 50 x 25 x 2.0 | 2.21 | 50 x 25 x 2.5 | 2.72 |

| 50 x 25 x 3.0 | 3.22 | 50 x 30 x 2.5 | 2.92 |

| 50 x 30 x 3.0 | 3.45 | 50 x 30 x 4.0 | 4.46 |

| 50 x 40 x 3.0 | 3.77 | 60 x 40 x 2.0 | 2.93 |

| 60 x 40 x 2.5 | 3.71 | 60 x 40 x 3.0 | 4.39 |

| 60 x 40 x 4.0 | 5.72 | 70 x 50 x 2 | 3.56 |

| 70 x 50 x 2.5 | 4.39 | 70 x 50 x 3.0 | 5.19 |

| 70 x 50 x 4.0 | 6.71 | 80 x 40 x 2.5 | 4.26 |

| 80 x 40 x 3.0 | 5.34 | 80 x 40 x 4.0 | 6.97 |

| 80 x 40 x 5.0 | 8.54 | 80 x 50 x 3.0 | 5.66 |

| 80 x 50 x 4.0 | 7.34 | 90 x 50 x 3.0 | 6.28 |

| 90 x 50 x 3.6 | 7.46 | 90 x 50 x 5.0 | 10.11 |

| 100 x 50 x 2.5 | 5.63 | 100 x 50 x 3.0 | 6.75 |

| 100 x 50 x 4.0 | 8.86 | 100 x 50 x 5.0 | 10.90 |

| 100 x 60 x 3.0 | 7.22 | 100 x 60 x 3.6 | 8.59 |

| 100 x 60 x 5.0 | 11.70 | 120 x 80 x 2.5 | 7.65 |

| 120 x 80 x 3.0 | 9.03 | 120 x 80 x 4.0 | 12.00 |

| 120 x 80 x 5.0 | 14.80 | 120 x 80 x 6.0 | 17.60 |

| 120 x 80 x 8.0 | 22.9 | 150 x 100 x 5.0 | 18.70 |

| 150 x 100 x 6.0 | 22.30 | 150 x 100 x 8.0 | 29.10 |

| 150 x 100 x 10.0 | 35.70 | 160 x 80 x 5.0 | 18.00 |

| 160 x 80 x 6.0 | 21.30 | 160 x 80 x 5.0 | 27.90 |

| 200 x 100 x 5.0 | 22.70 | 200 x 100 x 6.0 | 27.00 |

| 200 x 100 x 8.0 | 35.4 | 200 x 100 x 10.0 | 43.60 |

| 250 x 150 x 5.0 | 30.5 | 250 x 150 x 6.0 | 38.2 |

| 250 x 150 x 8.0 | 48.0 | 250 x 150 x 10 | 59.3 |

| 300 x 200 x 6.0 | 48.10 | 300 x 200 x 8.0 | 60.50 |

| 300 x 200 x 10.0 | 75.00 | 400 x 200 x 8.0 | 73.10 |

| 400 x 200 x 10.0 | 90.70 | 400 x 200 x 16 | 142.00 |

Circular Hollow Sections(CHS):

A Circular Hollow Section (CHS) is a metal profile distinguished by its circular cross-section and hollow interior. CHS is widely used in construction and engineering applications, offering advantages such as structural strength, torsional rigidity, and ease of fabrication. This profile is often employed in scenarios where a circular shape is advantageous, such as in columns, poles, or structural elements requiring symmetrical load distribution.

RCircular Hollow Section (CHS) DIMENSIONS/SIZES TABLE:

| Nominal Bore mm | Outside diameter mm | Thickness mm | Weight kg/m |

| 15 | 21.3 | 2.00 | 0.95 |

| 2.60 | 1.21 | ||

| 3.20 | 1.44 | ||

| 20 | 26.9 | 2.30 | 1.38 |

| 2.60 | 1.56 | ||

| 3.20 | 1.87 | ||

| 25 | 33.7 | 2.60 | 1.98 |

| 3.20 | 0.24 | ||

| 4.00 | 2.93 | ||

| 32 | 42.4 | 2.60 | 2.54 |

| 3.20 | 3.01 | ||

| 4.00 | 3.79 | ||

| 40 | 48.3 | 2.90 | 3.23 |

| 3.20 | 3.56 | ||

| 4.00 | 4.37 | ||

| 50 | 60.3 | 2.90 | 4.08 |

| 3.60 | 5.03 | ||

| 5.00 | 6.19 | ||

| 65 | 76.1 | 3.20 | 5.71 |

| 3.60 | 6.42 | ||

| 4.50 | 7.93 | ||

| 80 | 88.9 | 3.20 | 6.72 |

| 4.00 | 8.36 | ||

| 4.80 | 9.90 | ||

| 100 | 114.3 | 3.60 | 9.75 |

| 4.50 | 12.20 | ||

| 5.40 | 14.50 | ||

| 125 | 139.7 | 4.50 | 15.00 |

| 4.80 | 15.90 | ||

| 5.40 | 17.90 | ||

| 150 | 165.1 | 4.50 | 17.80 |

| 4.80 | 18.90 | ||

| 5.40 | 21.30 | ||

| 150 | 168.3 | 5.00 | 20.1 |

| 6.3 | 25.2 | ||

| 8.00 | 31.6 | ||

| 10.00 | 39 | ||

| 12.5 | 48 | ||

| 200 | 219.1 | 4.80 | 25.38 |

| 6.00 | 31.51 | ||

| 8.00 | 41.67 | ||

| 10.00 | 51.59 | ||

| 250 | 273 | 6.00 | 39.51 |

| 8.00 | 52.30 | ||

| 10.00 | 64.59 | ||

| 300 | 323.9 | 6.30 | 49.36 |

| 8.00 | 62.35 | ||

| 10.00 | 77.44 |

Features & Benefits:

• The design of hollow sections allows for maintaining structural strength while minimizing weight.This design enables hollow sections to provide high structural strength when bearing loads, suitable for projects where weight considerations are important.

• Hollow sections, by forming voids within the cross-section, can effectively utilize materials and reduce unnecessary weight.This structural design helps lower material costs while maintaining sufficient structural strength.

• Due to their enclosed shape, hollow sections exhibit excellent torsional and bending rigidity.This property ensures stable performance when facing twisting or bending loads.

• Hollow sections can be manufactured through processes like cutting and welding, and they are easy to connect.This convenient manufacturing and connection process helps simplify construction and manufacturing, improving efficiency.

• Hollow sections include not only square, rectangular, and circular shapes but also various custom shapes based on specific needs.This flexibility makes hollow sections suitable for a wide range of engineering and manufacturing applications.

• Hollow sections are typically made of metals such as steel, aluminum, and various alloys.This diversity allows hollow sections to meet the material characteristics required for different engineering projects.

Chemical Composition Of cold formed hollow section:

| Grade | C | Mn | P | S | Si | Cr | Ni | Mo |

| 301 | 0.15 | 2.0 | 0.045 | 0.030 | 1.0 | 16-18.0 | 6.0-8.0 | - |

| 302 | 0.15 | 2.0 | 0.045 | 0.030 | 1.0 | 17-19 | 8.0-10.0 | - |

| 304 | 0.15 | 2.0 | 0.045 | 0.030 | 1.0 | 18.0-20.0 | 8.0-10.5 | - |

| 304L | 0.030 | 2.0 | 0.045 | 0.030 | 1.0 | 18-20.0 | 9-13.5 | - |

| 316 | 0.045 | 2.0 | 0.045 | 0.030 | 1.0 | 10-18.0 | 10-14.0 | 2.0-3.0 |

| 316L | 0.030 | 2.0 | 0.045 | 0.030 | 1.0 | 16-18.0 | 12-15.0 | 2.0-3.0 |

| 430 | 0.12 | 1.0 | 0.040 | 0.030 | 0.75 | 16-18.0 | 0.60 | - |

Mechanical properties :

| Grade | Tensile Strength ksi[MPa] | Yiled Strengtu ksi[MPa] |

| 304 | 75[515] | 30[205] |

| 304L | 70[485] | 25[170] |

| 316 | 75[515] | 30[205] |

| 316L | 70[485] | 25[170] |

Hollow section FAQ Guide :

Why Choose us ?

• You can get the perfect material according to your requirement at the least possible price.

• We also offer Reworks, FOB, CFR, CIF, and door to door delivery prices. We suggest you to do deal for shipping which will be quite economical.

• The materials we provide are completely verifiable, right from raw material test certificate to the final dimensional statement.(Reports will show on requirement)

• We guarantee to give a response within 24hours(usually in the same hour)

• Provide SGS TUV report.

• We are fully dedicated to our customers. If it will not possible to meet your requirements after examining all options, we will not mislead you by making false promises which will create good customer relations.

• Provide one-stop service.

what is hollow section?

A hollow section refers to a metal profile with a voided interior, coming in shapes like square, rectangular, circular, or custom designs. Commonly made from steel, aluminum, or alloys, hollow sections are widely used in construction and manufacturing. They provide strength with minimal weight, efficient material distribution, and versatility in applications such as building frames, machinery components, and more. Hollow sections are adaptable, easily fabricated, and often standardized based on dimensions and specifications, making them essential in various engineering and structural projects.

What are hollow tubes with circular cross section?

Hollow tubes with a circular cross-section, often known as circular hollow sections (CHS), are cylindrical structures with an empty interior. Commonly made from materials like steel or aluminum, these tubes find widespread use in construction and manufacturing. Their circular shape provides uniform stress distribution, making them suitable for applications such as columns, poles, and structural supports. Circular tubes offer good torsional and bending rigidity, are easily fabricated through cutting and welding, and often adhere to standardized dimensions for consistency and compatibility. With versatility and adaptability, these tubes play a crucial role in various industries, including construction and machinery.

What is the difference between hollow section and I beam?

Hollow sections are metal profiles with a hollow interior, available in shapes like square, rectangular, or circular, commonly used in construction and manufacturing. They derive strength from the outer edges of the section.I-beams, on the other hand, have an I-shaped cross-section with a solid flange and web. Widely used in construction, I-beams distribute weight along the length of the structure, providing strength throughout. The choice between them depends on specific structural requirements and design considerations.

Our Clients

Feedbacks From Our Clients

Hollow sections are typically made of metals such as steel, aluminum, and various alloys.This diversity allows hollow sections to meet the material characteristics required for different engineering projects.The geometric shapes of hollow sections often have more aesthetic appeal than solid sections, making them suitable for projects where design and aesthetics are considerations.Due to their more efficient use of materials, hollow sections can reduce resource waste, aligning with environmentally friendly practices.

Packing:

1. Packing is quite important especially in a case of international shipments in which consignment pass through various channels to reach the ultimate destination, so we put special concern regarding packaging.

2. Saky Steel's pack our goods in numerous ways based on the products. We pack our products in multiple ways, such as,