Rolled Ring Forging

Lus piav qhia luv luv:

Rolled nplhaib forging yog txheej txheem hlau ua haujlwm uas ua rau muaj zog, ruaj nrees nrog ntau daim ntawv thov thoob plaws ntau qhov kev lag luam.

Rolled Ring Forging:

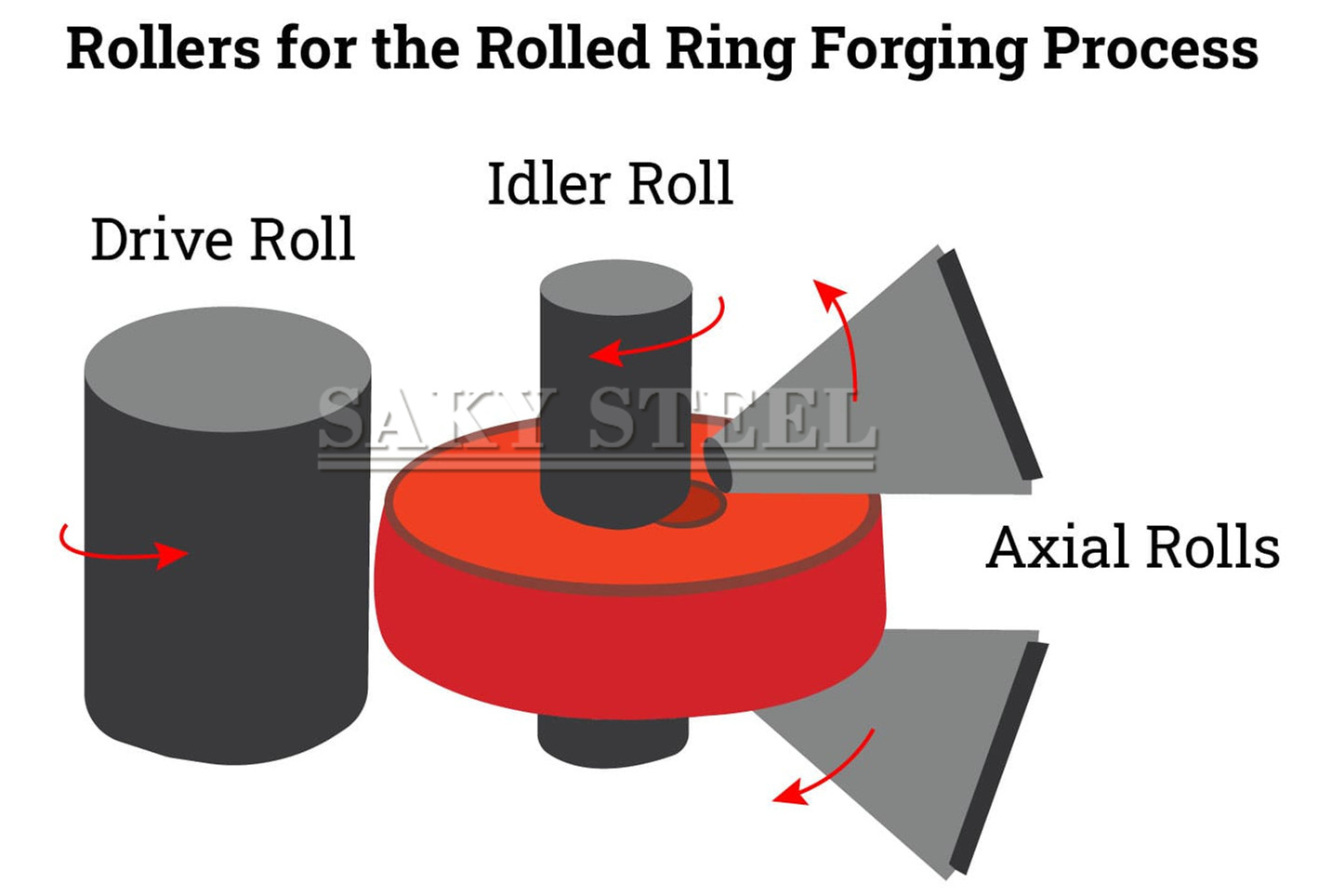

Seamless forged rings yog tsim los ntawm cov txheej txheem hu ua nplhaib dov. Cov txheej txheem no pib nrog lub voj voog hlau preform, uas yog pierced siv qhib tuag forging los tsim ib "ntiv nplhaib blocker." Lub nplhaib blocker yog tom qab ntawd rov ua kom sov rau qhov tsim nyog rau nws cov khoom qib. Thaum rhuab, nws yog positioned tshaj ib tug mandrel. Lub mandrel yog ces tsiv mus rau ib tug tsav yob, kuj hu ua ib tug huab tais yob, uas rotates nyob rau hauv siab. Qhov siab no txo cov phab ntsa thickness ntawm lub nplhaib, thaum ib txhij nce nws puab thiab sab diameters.

Specifications ntawm Seamless Rolled Ring Forging:

| Qib | 304, 316, 321 thiab lwm yam. |

| Loj | Customized |

| Nto | Polishing, sandblasting, electroplating, thiab lwm yam |

| Raw Khoom | POSCO, Baosteel, TISCO, Saky Steel, Outokumpu |

Rolled Ring Forging yog dab tsi?

Rolled nplhaib forging yog txheej txheem hlau ua haujlwm uas pib nrog lub voj voog, preformed hlau daim, uas yog chim siab thiab pierced los tsim ib tug zoo li lub khob noom cookie. Cov khoom no yog tom qab ntawd rhuab mus rau qhov kub siab tshaj nws qhov recrystallization point thiab muab tso rau hauv ib lub mandrel los yog idler.Tus idler directs lub pierced torus rau ib tug tsav roller, uas uniformly rotates thiab siv siab los txo cov phab ntsa thickness thaum expanding lub puab thiab sab diameters. Cov txheej txheem no ua rau muaj kev tsim ntawm lub nplhaib seamless dov.Seamless hlau rings uas tsim los ntawm dov nplhaib forging tuaj yeem sib txawv me me thiab feem ntau siv rau hauv cov cuab yeej siv tshuab, turbines, kav dej, thiab cov hlab ntsha siab. Txoj kev forging no ho txhim kho cov khoom siv ntawm cov hlau, khaws cia nws cov qauv nplej thaum shaping nws.

Vim li cas thiaj xaiv peb?

•Koj tuaj yeem tau txais cov khoom zoo meej raws li qhov koj xav tau ntawm tus nqi tsawg kawg nkaus.

•Peb kuj muab Reworks, FOB, CFR, CIF, thiab qhov rooj rau qhov rooj tus nqi xa khoom. Peb xav kom koj ua deal rau shipping uas yuav zoo heev.

•Cov ntaub ntawv uas peb muab yog muaj tseeb tiag, txoj cai los ntawm raw cov ntaub ntawv xeem daim ntawv pov thawj mus rau qhov kawg dimensional nqe lus.

•Peb lav muab cov lus teb tsis pub dhau 24 teev (feem ntau hauv tib lub sijhawm)

•Muab SGS TUV daim ntawv qhia.

•Peb muaj siab rau peb cov neeg muas zaub. Yog tias nws yuav tsis tuaj yeem ua tau raws li koj cov kev xav tau tom qab kuaj xyuas tag nrho cov kev xaiv, peb yuav tsis ntxias koj los ntawm kev cog lus tsis tseeb uas yuav tsim kev sib raug zoo rau cov neeg siv khoom.

•Muab kev pabcuam ib-nres.

Peb Cov Kev Pabcuam

1.Quenching thiab tempering

2.Nqus cua sov kho

3. Daim iav-polished nto

4.Precision-milled tiav

4. CNC machining

5.Precision drilling

6. Txiav rau hauv me me

7.Ua tiav pwm zoo li precision

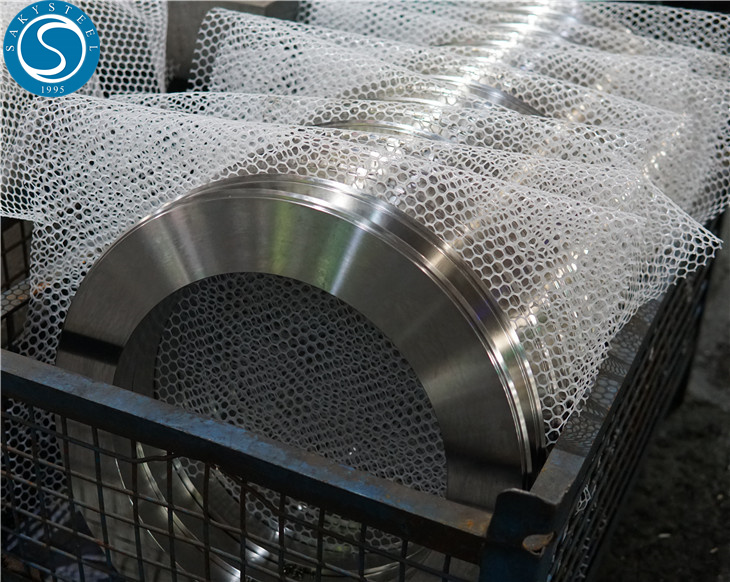

Ntim:

1. Kev ntim khoom yog qhov tseem ceeb heev tshwj xeeb tshaj yog nyob rau hauv rooj plaub ntawm kev xa khoom thoob ntiaj teb uas cov khoom xa tuaj hla ntau txoj hauv kev kom mus txog qhov kawg, yog li peb muab kev txhawj xeeb tshwj xeeb txog kev ntim khoom.

2. Saky Steel pob peb cov khoom hauv ntau txoj hauv kev raws li cov khoom lag luam. Peb ntim peb cov khoom nyob rau hauv ntau txoj kev, xws li,