Ⅰ.Lub ntsiab lus tseem ceeb ntawm kev kho cua sov.

A. Lub tswv yim ntawm kev kho cua sov.

Cov ntsiab lus tseem ceeb thiab kev ua haujlwm ntawmKev kho cua sov:

1. Cua sov

Lub hom phiaj yog kom tau txais cov qauv zoo ib yam thiab zoo austenite.

2. tuav

Lub hom phiaj yog los xyuas kom meej lub workpiece kom huv si thiab tiv thaiv decarburization thiab oxidation.

3. Cua txias

Lub hom phiaj yog los hloov cov austenite rau hauv cov qauv sib txawv.

Microstructures tom qab kev kho cua sov

Thaum lub sij hawm txias txias tom qab cua sov thiab tuav, lub austenite hloov mus rau hauv microstructures sib txawv nyob ntawm seb qhov txias txias. Txawv microstructures nthuav tawm cov khoom sib txawv.

B.Lub ntsiab lus ntawm kev kho cua sov.

Kev faib tawm raws li cov txheej txheem cua sov thiab cua txias, nrog rau Microstructure thiab Cov Khoom ntawm Hlau

1.Conventional Thaum tshav kub kub kev kho mob (Kev kho cua sov tag nrho): Tempering, Annealing, Normalizing, quenching

2. Kev kho cua sov saum npoo: Nto quenching, induction cua sov nto quenching, nplaim hluav taws kub deg quenching, hluav taws xob tiv tauj cua sov nto quenching.

3. Kev kho cua sov: Carburizing, Nitriding, Carbonitriding.

4.Lwm cov kev kho cua sov: Tswj cua sov kho cua sov, nqus cua sov kho, deformation kub kho.

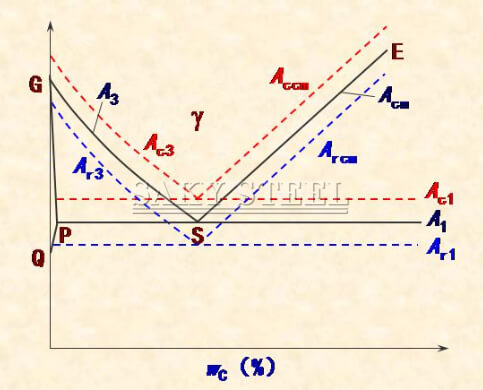

C.Critical Temperature of Steels

Qhov tseem ceeb ntawm kev hloov pauv kub ntawm cov hlau yog lub hauv paus tseem ceeb rau kev txiav txim siab cov cua sov, tuav, thiab txias txheej txheem thaum kho cua sov. Nws yog txiav txim los ntawm cov hlau-carbon theem daim duab.

Cov ntsiab lus tseem ceeb:Qhov tseeb qhov tseem ceeb ntawm kev hloov pauv kub ntawm steel ib txwm lags qab qhov theoretical tseem ceeb transformation kub. Qhov no txhais tau tias overheating yuav tsum tau thaum lub sij hawm cua sov, thiab undercooling yog tsim nyog thaum txias.

Ⅱ.Annealing thiab Normalizing hlau

1. Lub ntsiab lus ntawm Annealing

Annealing muaj cua sov hlau rau qhov kub siab tshaj lossis qis dua qhov tseem ceeb Ac₁ tuav nws ntawm qhov kub thiab txias, thiab maj mam txias nws, feem ntau hauv lub cub tawg, kom ua tiav cov qauv ze rau qhov sib npaug.

2. Lub hom phiaj ntawm Annealing

① Kho Hardness rau Machining: Ua tiav machinable hardness nyob rau hauv thaj tsam ntawm HB170 ~ 230.

②Relieve Residual Stress: Tiv thaiv kom tsis txhob deformation lossis tawg thaum cov txheej txheem tom ntej.

③Refine Grain Structure: Txhim kho microstructure.

④ Kev Npaj rau Kev Kho Mob Thaum Kawg: Tau txais granular (spheroidized) pearlite rau tom qab quenching thiab tempering.

3.Spheroidizing Annealing

Txheej txheem Specifications: Kub kub nyob ze ntawm Ac₁ point.

Lub hom phiaj: Txhawm rau spheroidize cov cementite lossis carbides hauv cov hlau, ua rau granular (spheroidized) pearlite.

Siv tau ntau yam: Siv rau steels nrog eutectoid thiab hypereutectoid compositions.

4.Diffusing Annealing (Homogenizing Annealing)

Txheej txheem Specifications: Cov cua kub kub yog me ntsis hauv qab ntawm solvus kab ntawm daim duab theem.

Lub hom phiaj: txhawm rau tshem tawm kev cais tawm.

① Rau qis-carbon hlaunrog cov ntsiab lus carbon tsawg dua 0.25%, normalizing yog nyiam tshaj annealing raws li kev npaj kho cua sov.

②Rau nruab nrab-carbon steel nrog cov ntsiab lus carbon ntawm 0.25% thiab 0.50%, ob qho tib si annealing lossis normalizing tuaj yeem siv los ua kev npaj kho cua sov.

③Rau qhov nruab nrab mus rau high-carbon steel nrog cov ntsiab lus carbon ntawm 0.50% thiab 0.75%, tag nrho annealing yog pom zoo.

④ Rau siab-carbon hlaunrog cov ntsiab lus carbon ntau dua 0.75%, normalizing yog thawj zaug siv los tshem tawm lub network Fe₃C, ua raws li spheroidizing annealing.

Ⅲ.Quenching thiab Tempering ntawm Hlau

A.Quenching

1. Lub ntsiab lus ntawm quenching: quenching yuav tsum tau cua sov steel rau ib qho kub ntawm qhov kub ntawm Ac₃ lossis Ac₁ point, tuav nws ntawm qhov kub thiab txias, thiab tom qab ntawd txias nws ntawm tus nqi siab dua qhov tseem ceeb ntawm qhov txias txias los tsim martensite.

2. Lub hom phiaj ntawm Quenching: Lub hom phiaj tseem ceeb yog kom tau txais martensite (lossis qee zaum qis dua bainite) kom ua rau cov tawv tawv thiab hnav tsis kam ntawm cov hlau. Quenching yog ib qho tseem ceeb tshaj plaws kev kho cua sov txheej txheem rau hlau.

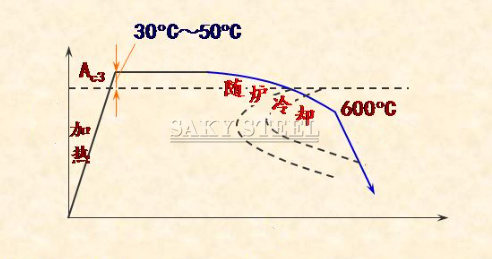

3.Kev txiav txim siab quenching kub rau ntau hom hlau

Hypoeutectoid Steel: Ac₃ + 30 ° C txog 50 ° C

Eutectoid thiab Hypereutectoid Steel: Ac₁ + 30 ° C txog 50 ° C

Alloy Steel: 50 ° C txog 100 ° C siab tshaj qhov kub tseem ceeb

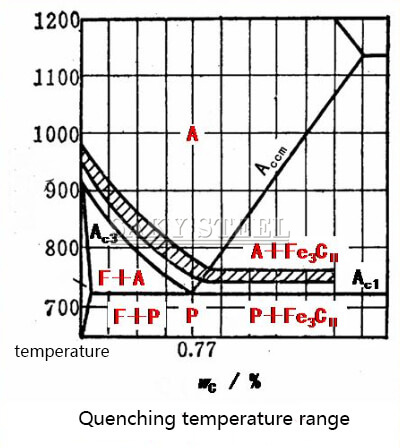

4.Cooling yam ntxwv ntawm ib qho zoo tagnrho quenching nruab nrab:

Txias Txias Ua Ntej "Ntshav" Kub: Kom txaus kom txo tau cov thermal stress.

Lub peev xwm txias txias nyob ze ntawm qhov kub "Nse": Txhawm rau kom tsis txhob muaj cov qauv uas tsis yog martensitic.

Slow Cooling Nyob ze M₅ Point: Txhawm rau txo qhov kev ntxhov siab vim los ntawm kev hloov pauv martensitic.

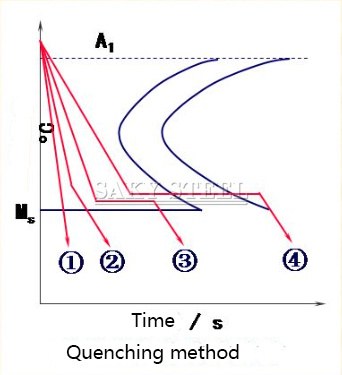

5.Quenching Methods thiab lawv cov yam ntxwv:

①Simple Quenching: Yooj yim rau kev khiav lag luam thiab haum rau me me, yooj yim-puab workpieces. Qhov tshwm sim microstructure yog martensite (M).

②Double Quenching: Ntau qhov nyuaj thiab nyuaj rau kev tswj, siv rau kev ua haujlwm zoo li cov pa roj carbon ntau thiab cov hlau loj hlau ua haujlwm. Qhov tshwm sim microstructure yog martensite (M).

③Broken Quenching: Cov txheej txheem ntau dua, siv rau cov khoom loj, nyuaj-zoo li alloy steel workpieces. Qhov tshwm sim microstructure yog martensite (M).

④ Isothermal Quenching: Siv rau me me, complex-shaped workpieces nrog siab xav tau. Qhov tshwm sim microstructure yog qis dua bainite (B).

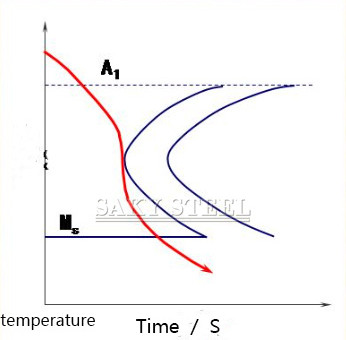

6.Qhov cuam tshuam rau Hardenability

Qib ntawm hardenability nyob ntawm qhov ruaj khov ntawm supercooled austenite hauv hlau. Qhov siab dua qhov ruaj khov ntawm supercooled austenite, qhov zoo dua qhov hardenability, thiab vice versa.

Cov yam ntxwv cuam tshuam rau kev ruaj ntseg ntawm Supercooled Austenite:

Txoj hauj lwm ntawm C-Curve: Yog hais tias C-khov hloov mus rau sab xis, qhov tseem ceeb ntawm qhov txias txias rau quenching txo, txhim kho hardenability.

Cov ntsiab lus tseem ceeb:

Txhua yam uas hloov C-khoov mus rau sab xis ua rau cov hlau hardenability.

Qhov Tseem Ceeb:

Chemical Composition: Tsuas yog cobalt (Co), tag nrho cov ntsiab lus alloying yaj hauv austenite nce hardenability.

Qhov ze ntawm cov ntsiab lus carbon yog rau cov eutectoid muaj pes tsawg leeg hauv cov hlau, ntau qhov C-nqaj hloov mus rau sab xis, thiab siab dua qhov hardenability.

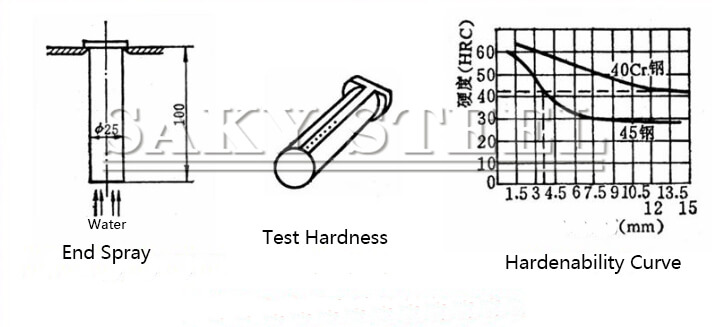

7.Kev txiav txim siab thiab sawv cev ntawm Hardenability

① End Quench Hardenability Test: Hardenability yog ntsuas siv qhov kawg-quench test method.

②Critical Quench Diameter Method: Qhov tseem ceeb quench txoj kab uas hla (D₀) sawv cev rau qhov siab tshaj plaws txoj kab uas hla ntawm cov hlau uas muaj peev xwm ua tau tag nrho hardened nyob rau hauv ib tug tshwj xeeb quenching nruab nrab.

B. Tempering

1. Txhais ntawm Tempering

Tempering yog txheej txheem kev kho cua sov uas cov hlau quenched rov qab rau qhov kub hauv qab A₁ point, tuav ntawm qhov kub thiab txias, thiab tom qab ntawd txias rau hauv chav tsev kub.

2. Lub hom phiaj ntawm Tempering

Txo lossis tshem tawm cov kev ntxhov siab uas seem: Tiv thaiv kom tsis txhob deformation lossis tawg ntawm lub workpiece.

Txo lossis tshem tawm cov Austenite Residual: Stabilizes qhov ntev ntawm lub workpiece.

Tshem tawm Brittleness ntawm Quenched Steel: Kho cov microstructure thiab cov khoom kom tau raws li cov haujlwm ua haujlwm.

Lus Cim Tseem Ceeb: Hlau yuav tsum tau tempered tam sim ntawd tom qab quenching.

3. Cov txheej txheem Tempering

1. Tsawg Tempering

Lub hom phiaj: txhawm rau txo qis kev ntxhov siab, txhim kho lub zog ntawm cov khoom ua haujlwm, thiab ua tiav siab hardness thiab hnav tsis kam.

Kub: 150 ° C ~ 250 ° C.

Kev Ua Haujlwm: Hardness: HRC 58 ~ 64. Siab hardness thiab hnav tsis kam.

Daim ntaub ntawv: Cov cuab yeej, pwm, bearings, carburized qhov chaw, thiab nto-hardened Cheebtsam.

2. High Tempering

Lub hom phiaj: kom ua tiav siab toughness nrog rau lub zog txaus thiab hardness.

Kub: 500 ° C ~ 600 ° C.

Kev ua tau zoo: Hardness: HRC 25 ~ 35. Zoo tag nrho cov khoom siv kho tshuab.

Daim ntawv thov: Shafts, gears, txuas rods, thiab lwm yam.

Thermal Refining

Txhais: quenching ua raws li qhov kub-kub tempering yog hu ua thermal refining, los yog tsuas yog tempering. Hlau kho los ntawm cov txheej txheem no muaj kev ua tau zoo tag nrho thiab yog siv dav.

Ⅳ.Kev kho cua sov ntawm cov hlau

A.Surface Quenching ntawm Steels

1. Kev txhais ntawm Deg Hardening

Surface hardening yog txheej txheem kev kho cua sov tsim los ntxiv dag zog rau txheej txheej ntawm lub workpiece los ntawm cua sov sai heev los hloov cov txheej txheej saum npoo rau hauv austenite thiab tom qab ntawd txias nws sai. Cov txheej txheem no yog ua tiav yam tsis hloov cov hlau cov tshuaj muaj pes tsawg leeg lossis cov qauv ntawm cov khoom siv.

2. Cov khoom siv rau Deg Hardening thiab Post-Hardening Structure

Cov khoom siv rau Deg Hardening

Cov khoom siv: Cov pa roj carbon steel nruab nrab thiab nruab nrab carbon alloy steel.

Kev Kho Mob Ua Ntej: Txheej Txheem: Tempering. Yog tias cov khoom tseem ceeb tsis tseem ceeb, normalizing tuaj yeem siv hloov pauv.

Post-Hardening Structure

Surface Structure: Cov txheej saum npoo feem ntau tsim cov qauv tawv xws li martensite lossis bainite, uas muab siab tawv thiab hnav tsis kam.

Core Structure: Cov tub ntxhais ntawm cov hlau feem ntau khaws nws cov qauv qub, xws li pearlite lossis tempered lub xeev, nyob ntawm cov txheej txheem ua ntej kho thiab cov khoom ntawm cov khoom siv hauv paus. Qhov no ua kom ntseeg tau tias cov tub ntxhais muaj qhov zoo toughness thiab lub zog.

B. Yam ntxwv ntawm induction nto hardening

1.High Heating Temperature and Rapid Temperature Rise: Induction deg hardening feem ntau cuam tshuam nrog cov cua kub kub thiab cov cua kub ceev ceev, tso cai rau cua sov ceev hauv lub sijhawm luv luv.

2.Fine Austenite Grain Structure nyob rau hauv Deg Txheej: Thaum lub sij hawm cua kub ceev thiab cov txheej txheem quenching tom ntej, txheej txheej saum npoo tsim cov nplej zoo austenite. Tom qab quenching, qhov chaw feem ntau muaj nplua martensite, nrog hardness feem ntau 2-3 HRC siab dua li cov pa quenching.

3.Zoo Nto Zoo: Vim lub sij hawm cua sov luv, lub workpiece nto tsis tshua muaj oxidation thiab decarburization, thiab quenching-induced deformation yog tsawg, kom ntseeg tau zoo nto zoo.

4.High Fatigue Strength: Lub martensitic theem transformation nyob rau hauv lub nto txheej generates compressive kev nyuaj siab, uas ua rau kom lub zog qaug zog ntawm lub workpiece.

5.High Production Efficiency: Induction nto hardening yog tsim rau huab hwm coj ntau lawm, muab kev ua haujlwm siab.

C.Classification ntawm tshuaj kho cua sov

Carburizing, Carburizing, Carburizing, Chromizing, Siliconizing, Siliconizing, Siliconizing, Carbonitriding, Borocarburizing

D. Gas Carburizing

Gas Carburizing yog txheej txheem uas ib qho chaw ua haujlwm tau muab tso rau hauv lub tshuab hluav taws xob kaw thiab ua kom sov rau qhov kub uas hloov cov hlau mus rau hauv austenite. Tom qab ntawd, tus neeg sawv cev carburizing yog dripped rau hauv lub qhov cub, los yog ib qho chaw carburizing yog qhia ncaj qha, tso cai rau cov pa roj carbon atom mus rau hauv txheej txheej ntawm workpiece. Cov txheej txheem no nce cov ntsiab lus carbon (wc%) ntawm qhov chaw ua haujlwm.

√ Carburizing Agents:

•Carbon-nplua nuj Gases: xws li thee roj, liquefied petroleum gas (LPG), thiab lwm yam.

•Organic kua: xws li kerosene, methanol, benzene, thiab lwm yam.

√ Carburizing txheej txheem Parameter:

•Carburizing kub: 920 ~ 950 ° C.

• Lub Sijhawm Carburizing: Nyob ntawm qhov xav tau qhov tob ntawm carburized txheej thiab qhov kub ntawm carburizing.

E. Kev kho cua sov tom qab Carburizing

Hlau yuav tsum tau kho cua sov tom qab carburizing.

Kev kho cua sov txheej txheem tom qab Carburizing:

√Quenching + Tsawg-kub Tempering

1.Direct quenching Tom qab Pre-Cooling + Low-Temperature Tempering: Lub workpiece yog pre-txias los ntawm lub carburizing kub mus rau saum toj no cov tub ntxhais lub Ar₁ kub thiab ces quenched tam sim ntawd, ua raws li qhov kub-temperature ntawm 160 ~ 180 ° C.

2.Single Quenching Tom qab Pre-Cooling + Low-Temperature Tempering: Tom qab carburizing, lub workpiece yog maj mam txias rau hauv chav tsev kub, ces reheated rau quenching thiab low-temperature tempering.

3.Double quenching Tom qab Pre-Cooling + Low-Temperature Tempering: Tom qab carburizing thiab txias txias, lub workpiece undergoes ob theem ntawm cua sov thiab quenching, ua raws li los ntawm low-temperature tempering.

Ⅴ.Chemical Heat Treatment of Steels

1.Definition of Chemical Heat Treatment

Kev kho cua sov tshuaj yog txheej txheem kev kho cua sov uas cov hlau ua haujlwm tau muab tso rau hauv ib qho nruab nrab active, rhuab, thiab tuav ntawm qhov kub thiab txias, tso cai rau cov active atoms nyob rau hauv nruab nrab diffuse rau saum npoo ntawm lub workpiece. Qhov no hloov cov tshuaj muaj pes tsawg leeg thiab microstructure ntawm lub workpiece nto, yog li hloov nws cov khoom.

2.Basic txheej txheem ntawm kev kho cua sov

Decomposition: Thaum tshav kub kub, lub active nruab nrab decomposes, tso active atoms.

Absorption: Cov active atoms yog adsorbed los ntawm cov hlau nto thiab yaj mus rau hauv cov khoom tov ntawm cov hlau.

Diffusion: Cov active atoms absorbed thiab yaj nyob rau saum npoo ntawm cov hlau tsiv mus rau sab hauv.

Hom Induction Surface Hardening

a.High-Frequency induction cua sov

Tam sim no Zaus: 250 ~ 300 kHz.

Hardened Txheej Qhov tob: 0.5 ~ 2.0 hli.

Daim ntawv thov: nruab nrab thiab me module gears thiab me me mus rau nruab nrab-qhov loj shafts.

b. Nruab nrab-Frequency Induction Cua sov

Tam sim no Zaus: 2500 ~ 8000 kHz.

Hardened Txheej Qhov tob: 2 ~ 10mm.

Daim ntaub ntawv: Cov ncej loj dua thiab loj rau nruab nrab module gears.

c.Power-Frequency induction cua sov

Tam sim no Zaus: 50 Hz.

Hardened Txheej Qhov tob: 10 ~ 15mm.

Daim ntaub ntawv: Workpieces yuav tsum tau ib tug sib sib zog nqus hardened txheej.

3. Induction Surface Hardening

Lub hauv paus ntsiab lus ntawm Induction Surface Hardening

Cov nyhuv ntawm daim tawv nqaij:

Thaum alternating tam sim no nyob rau hauv induction kauj induces ib tug tam sim no nyob rau saum npoo ntawm lub workpiece, feem ntau ntawm induced tam sim no yog concentrated nyob ze ntawm lub nto, thaum yuav luag tsis muaj tam sim no dhau los ntawm sab hauv ntawm lub workpiece. Qhov tshwm sim no hu ua cov nyhuv ntawm daim tawv nqaij.

Lub hauv paus ntsiab lus ntawm Induction Surface Hardening:

Raws li cov nyhuv ntawm daim tawv nqaij, qhov chaw ntawm lub workpiece yog rhuab mus rau lub austenitizing kub (nce mus rau 800 ~ 1000 ° C nyob rau hauv ob peb feeb), thaum lub sab hauv ntawm lub workpiece tseem yuav luag unheated. Tom qab ntawd lub workpiece yog txias los ntawm dej txau, ua tiav qhov tawv tawv.

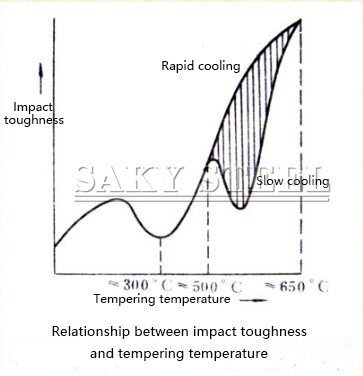

4.Temper Brittleness

Tempering Brittleness hauv Quenched Steel

Tempering brittleness yog hais txog qhov tshwm sim uas qhov cuam tshuam toughness ntawm quenched steel ho txo qis thaum tempered ntawm qee qhov kub.

Thawj Hom Tempering Brittleness

Qhov kub thiab txias: 250 ° C txog 350 ° C.

Yam ntxwv: Yog tias quenched steel yog tempered nyob rau hauv qhov kub thiab txias, nws muaj peev xwm tsim tau hom tempering brittleness, uas tsis tuaj yeem tshem tawm.

Kev daws: Tsis txhob tempering quenched steel nyob rau hauv qhov ntsuas kub no.

Thawj hom tempering brittleness tseem hu ua low-temperature tempering brittleness lossis irreversible tempering brittleness.

Ⅵ.Tempering

1.Tempering yog txheej txheem kev kho cua sov kawg uas ua raws li quenching.

Vim li cas quenched Steels xav tau Tempering?

Microstructure Tom Qab Quenching: Tom qab quenching, lub microstructure ntawm hlau feem ntau muaj martensite thiab residual austenite. Ob leeg yog metastable theem thiab yuav hloov nyob rau hauv tej yam kev mob.

Cov khoom ntawm Martensite: Martensite yog tus cwj pwm los ntawm kev ua haujlwm siab, tab sis kuj muaj siab brittleness (tshwj xeeb tshaj yog nyob rau hauv high-carbon koob zoo li martensite), uas tsis ua tau raws li qhov yuav tsum tau ua rau ntau daim ntawv thov.

Cov yam ntxwv ntawm Martensitic Transformation: Kev hloov pauv mus rau martensite tshwm sim sai heev. Tom qab quenching, lub workpiece muaj cov seem sab hauv uas tuaj yeem ua rau deformation lossis tawg.

Xaus: Lub workpiece tsis tuaj yeem siv ncaj qha tom qab quenching! Tempering yog tsim nyog los txo cov kev ntxhov siab sab hauv thiab txhim kho lub zog ntawm lub workpiece, ua kom nws haum rau kev siv.

2.Qhov txawv ntawm Hardenability thiab Hardening Capacity:

Hardenability:

Hardenability yog hais txog lub peev xwm ntawm cov hlau kom ua tiav qhov tob ntawm hardening (qhov tob ntawm txheej hardened) tom qab quenching. Nws nyob ntawm cov hlau muaj pes tsawg leeg thiab cov qauv, tshwj xeeb tshaj yog nws cov ntsiab lus alloying thiab hom hlau. Hardenability yog ib qho kev ntsuas ntawm qhov zoo npaum li cas cov hlau tuaj yeem ua rau nws cov thickness thaum lub sij hawm quenching.

Hardness (Hardening Capacity):

Hardness, los yog hardening muaj peev xwm, hais txog lub siab tshaj plaws hardness uas yuav ua tau tiav nyob rau hauv cov hlau tom qab quenching. Nws yog feem ntau cuam tshuam los ntawm cov ntsiab lus carbon ntawm cov hlau. Cov ntsiab lus carbon ntau dua feem ntau ua rau muaj peev xwm ua tau zoo dua, tab sis qhov no tuaj yeem raug txwv los ntawm cov hlau alloying ntsiab lus thiab cov txiaj ntsig ntawm cov txheej txheem quenching.

3. Hardenability ntawm hlau

√ Lub tswv yim ntawm Hardenability

Hardenability yog hais txog lub peev xwm ntawm cov hlau kom ua tiav qhov tob ntawm martensitic hardening tom qab quenching los ntawm austenitizing kub. Hauv cov ntsiab lus yooj yim, nws yog lub peev xwm ntawm cov hlau los tsim martensite thaum quenching.

Kev ntsuas Hardenability

Qhov loj ntawm hardenability yog qhia los ntawm qhov tob ntawm lub hardened txheej tau raws li cov kev cai tshwj xeeb tom qab quenching.

Hardened Layer Depth: Qhov no yog qhov tob ntawm qhov chaw ntawm lub workpiece mus rau thaj tsam uas tus qauv yog ib nrab martensite.

Common Quenching Media:

• Dej

Cov yam ntxwv: Kev lag luam muaj peev xwm ua kom txias txias, tab sis muaj qhov cua txias siab nyob ze ntawm qhov kub kub, uas tuaj yeem ua rau txias heev.

Daim ntawv thov: Feem ntau yog siv rau carbon steels.

Dej ntsev: Ib qho kev daws ntawm ntsev los yog alkali hauv dej, uas muaj peev xwm ua kom txias dua ntawm qhov kub thiab txias piv rau dej, ua rau nws haum rau carbon steels.

• Roj

Cov yam ntxwv: Muab cov cua txias qeeb qeeb ntawm qhov kub thiab txias (ze ntawm lub boiling point), uas ua tau zoo txo qhov nyiam deformation thiab tawg, tab sis muaj peev xwm ua kom txias qis ntawm qhov kub thiab txias.

Daim ntawv thov: Haum rau alloy steels.

Hom: suav nrog quenching roj, tshuab roj, thiab roj diesel.

Thaum tshav kub kub

Lub sij hawm cua sov muaj ob qho tib si qhov cua sov (lub sij hawm coj mus txog qhov xav tau kub) thiab lub sij hawm tuav (lub sij hawm tuav ntawm lub hom phiaj kub).

Lub hauv paus ntsiab lus rau kev txiav txim siab lub sij hawm cua sov: xyuas kom meej qhov kub thiab txias faib thoob plaws hauv lub workpiece, ob qho tib si sab hauv thiab sab nraud.

Xyuas kom tiav austenitization thiab tias cov austenite tsim yog ib yam thiab zoo.

Lub hauv paus rau Kev Txiav Txim Lub Sij Hawm Kub: Feem ntau kwv yees siv cov qauv empirical lossis txiav txim siab los ntawm kev sim.

Quenching Media

Ob Qhov Tseem Ceeb:

a.Cooling Rate: Cov cua txias ntau dua txhawb kev tsim ntawm martensite.

b.Residual Stress: Cov cua txias ntau dua ua rau muaj kev ntxhov siab ntau ntxiv, uas tuaj yeem ua rau muaj kev xav ntau dua rau kev deformation thiab tawg hauv qhov chaw ua haujlwm.

Ⅶ.Normalizing

1. Kev txhais ntawm Normalizing

Normalizing yog txheej txheem kev kho cua sov uas cov hlau tau rhuab mus rau qhov kub ntawm 30 ° C mus rau 50 ° C saum toj no qhov kub ntawm Ac3, tuav ntawm qhov kub thiab txias, thiab tom qab ntawd cua txias kom tau txais ib qho microstructure ze rau lub xeev sib npaug. Piv rau annealing, normalizing muaj qhov txias dua, ua rau cov qauv zoo dua pearlite (P) thiab muaj zog dua thiab hardness.

2. Lub hom phiaj ntawm Normalizing

Lub hom phiaj ntawm normalizing yog zoo ib yam li cov annealing.

3. Kev siv ntawm Normalizing

• Tshem tawm cov kev sib txuas ntawm cov cementite thib ob.

• Ua raws li qhov kawg kev kho cua sov rau cov khoom uas yuav tsum tau qis dua.

• Ua raws li kev npaj kho cua sov rau qis thiab nruab nrab carbon structural steel los txhim kho machinability.

4.Type of Annealing

Thawj Hom Annealing:

Lub Hom Phiaj thiab Kev Ua Haujlwm: Lub hom phiaj tsis yog los txhawb kev hloov pauv theem tab sis hloov cov hlau los ntawm lub xeev tsis sib npaug mus rau lub xeev sib npaug.

Hom:

•Diffusion Annealing: Lub hom phiaj kom homogenize muaj pes tsawg leeg los ntawm kev tshem tawm kev cais tawm.

•Recrystallization Annealing: Restores ductility los ntawm kev tshem tawm cov teebmeem ntawm kev ua hauj lwm hardening.

•Stress Relief Annealing: Txo cov kev ntxhov siab sab hauv yam tsis hloov lub microstructure.

Thib Ob Hom Annealing:

Lub Hom Phiaj thiab Kev Ua Haujlwm: Lub hom phiaj los hloov cov microstructure thiab cov khoom, ua tiav pearlite-dominated microstructure. Hom no kuj ua kom ntseeg tau tias qhov kev faib tawm thiab cov qauv ntawm pearlite, ferrite, thiab carbides ua tau raws li cov cai tshwj xeeb.

Hom:

•Full Annealing: Ua kom sov cov hlau saum lub Ac3 kub thiab maj mam txias nws los tsim cov qauv pearlite.

• Tsis tiav Annealing: Ua kom sov cov hlau ntawm Ac1 thiab Ac3 qhov kub thiab txias kom hloov cov qauv ib nrab.

•Isothermal Annealing: Ua kom sov cov hlau kom siab dua Ac3, ua raws li kev ua kom txias sai rau qhov ntsuas kub ntawm isothermal thiab tuav kom ua tiav cov qauv xav tau.

•Spheroidizing Annealing: Ua cov qauv spheroidal carbide, txhim kho machinability thiab toughness.

Ⅷ.1.Definition of Heat Treatment

Kev kho cua sov yog hais txog cov txheej txheem uas cov hlau yog rhuab, tuav ntawm qhov kub thiab txias, thiab tom qab ntawd txias thaum nyob rau hauv ib qho khoom siv los hloov nws cov qauv sab hauv thiab microstructure, yog li ua tiav cov khoom xav tau.

2. Cov yam ntxwv ntawm kev kho cua sov

Kev kho cua sov tsis hloov cov duab ntawm lub workpiece; Hloov chaw, nws hloov cov qauv sab hauv thiab microstructure ntawm cov hlau, uas nyob rau hauv lem hloov cov hlau cov khoom.

3.Lub hom phiaj ntawm kev kho cua sov

Lub hom phiaj ntawm kev kho cua sov yog txhawm rau txhim kho cov khoom siv hluav taws xob lossis kev ua haujlwm ntawm cov hlau (los yog cov khoom ua haujlwm), siv tag nrho cov peev txheej ntawm cov hlau, txhim kho cov khoom ua haujlwm zoo, thiab txuas ntxiv nws lub neej kev pab cuam.

4. Cov ntsiab lus tseem ceeb

Txawm hais tias cov khoom siv tuaj yeem txhim kho los ntawm kev kho cua sov yog qhov tseem ceeb ntawm seb puas muaj kev hloov pauv hauv nws cov microstructure thiab cov qauv thaum lub sij hawm cua sov thiab cua txias.

Post lub sij hawm: Aug-19-2024