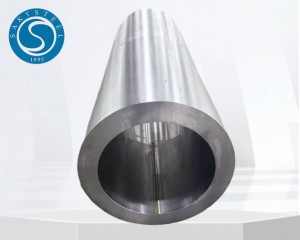

DIN 1.2311 P20 Pwm Hlau

Lus piav qhia luv luv:

DIN 1.2311 ″ yog hom pwm hlau, feem ntau hu ua P20 steel. P20 yog cov hlau tsis tshua muaj hlau uas paub txog nws txoj kev ua haujlwm zoo thiab hnav tsis kam, feem ntau siv hauv kev tsim cov pwm yas thiab cov pwm tuag-casting.

DIN 1.2311 P20 Pwm Hlau:

DIN 1.2311 P20 Mould Steel yog ib qho kev siv pwm hlau, dav siv nyob rau hauv kev tsim cov yas pwm thiab tuag-casting pwm.DIN 1.2311 P20 Mould Steel muaj kev ua tau zoo heev thiab machinability, ua rau nws yooj yim rau txheej txheem rau ntau hom pwm. DIN 1.2311 P20 Mould Steel feem ntau yog siv rau hauv ntau yam kev siv pwm xws li txhaj pwm, extrusion pwm, tuag-casting pwm, thiab pwm puag.

Specifications ntawm 1.2311 TOOL STELS:

| Qib | 1.2311, P20 |

| Txuj | ASTM A681 Cov Khoom Siv Hluav Taws Xob |

| Nto | Dub; Peeled; Polished; Tshuab; Sib tsoo; tig; Milled |

| Raw Khoom | POSCO, Baosteel, TISCO, Saky Steel, Outokumpu |

1.2311 Sib npaug Steel Qib:

| Lub teb chaws | Teb chaws USA | German | GB / T |

| Txuj | ASTM A681 Cov Khoom Siv Hluav Taws Xob | TS EN ISO 4957 Kev Tswj Xyuas Kev Nyab Xeeb | GB/T 1299 |

| Qib | P20 | 1.2311 ib | 3cr2 hmo |

P20 TOOL STEELS Chemical Composition:

| Txuj | Qib | C | Si | Mn | P | S | Cr | Mo |

| ASTM A681 Cov Khoom Siv Hluav Taws Xob | P20 | 0.28-0.40 Nws | 0.2 ~ 0.8 hli | 0.60-1.0 Nws | ≤ 0.030 | ≤ 0.030 | 1.4 ~ 2.0 | 0.3-0.55 Nws |

| GB/T 9943 | 3cr2 hmo | 0.28-0.40 Nws | 0.2 ~ 0.8 hli | 0.60-1.0 Nws | ≤ 0.030 | ≤ 0.030 | 1.4 ~ 2.0 | 0.3-0.55 Nws |

| DIN ISO4957 | 1.2311 ib | 0.35-0.45 Nws | 0.2 ~ 0.4 hli | 1.3-1.6 | ≤ 0.030 | ≤ 0.030 | 1.8-2.1 | 0.15–0.25 dr hab |

1.2311 TOOL STEELS Mechanical Properties:

| Cov khoom | Metric |

| Hardness, Brinell (Tswj) | 300 |

| Hardness, Rockwell C (Tswj) | 30 |

| Tensile Strength, Qhov kawg | 965-1030 MPa |

| Tensile zog, tawm los | 827-862 MPa |

| Elongation Thaum tawg (hauv 50 hli (2 ") | 20.00% |

| Compressive zog | ua 862mpa |

| Charpy Impact (V-Notch) | 27.1-33.9 Nws |

| Poisson tus ratio | 0.27-0.30 Nws |

| Elastic Modulus | 190-210 GPa |

Vim li cas thiaj xaiv peb?

•Koj tuaj yeem tau txais cov khoom zoo meej raws li qhov koj xav tau ntawm tus nqi tsawg kawg nkaus.

•Peb kuj muab Reworks, FOB, CFR, CIF, thiab qhov rooj rau qhov rooj tus nqi xa khoom. Peb xav kom koj ua deal rau shipping uas yuav zoo heev.

•Cov ntaub ntawv uas peb muab yog muaj tseeb tiag, txoj cai los ntawm raw cov ntaub ntawv xeem daim ntawv pov thawj mus rau qhov kawg dimensional nqe lus.

•Peb lav muab cov lus teb tsis pub dhau 24 teev (feem ntau hauv tib lub sijhawm)

•Muab SGS TUV daim ntawv qhia.

•Peb muaj siab rau peb cov neeg muas zaub. Yog tias nws yuav tsis tuaj yeem ua tau raws li koj cov kev xav tau tom qab kuaj xyuas tag nrho cov kev xaiv, peb yuav tsis ntxias koj los ntawm kev cog lus tsis tseeb uas yuav tsim kev sib raug zoo rau cov neeg siv khoom.

•Muab kev pabcuam ib-nres.

Peb Cov Kev Pabcuam

1.Quenching thiab tempering

2.Nqus cua sov kho

3. Daim iav-polished nto

4.Precision-milled tiav

4. CNC machining

5.Precision drilling

6. Txiav rau hauv me me

7.Ua tiav pwm zoo li precision

Ntim:

1. Kev ntim khoom yog qhov tseem ceeb heev tshwj xeeb tshaj yog nyob rau hauv rooj plaub ntawm kev xa khoom thoob ntiaj teb uas cov khoom xa tuaj hla ntau txoj hauv kev kom mus txog qhov kawg, yog li peb muab kev txhawj xeeb tshwj xeeb txog kev ntim khoom.

2. Saky Steel pob peb cov khoom hauv ntau txoj hauv kev raws li cov khoom lag luam. Peb ntim peb cov khoom nyob rau hauv ntau txoj kev, xws li,