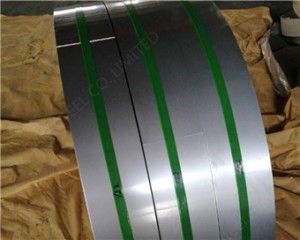

C67s CK67 C67 1.1231 CK68 XC68 70cr2 AISI 1065 Caij nplooj ntoos hlav Steel Strips

Lus piav qhia luv luv:

| Specifications ntawm Spring Steel Sawb: |

| Qib | C67, XC68 |

| Txuj | EN BS 10132-4 C67S 1.1231 |

| Thickness | 0.10-5.0 hli |

| Dav | 10-600 hli |

| Daim ntawv | Steel Coils Strips |

| Hardness | mos, 1/4H, 1/2H, FH thiab lwm yam. |

| CHEMICAL COMPOSITION NTAWMStainless Spring Steel Sawb: |

| Qib | C | Mn | Si | S | Cu | Ni | Cr | Mo | P |

| C67 S | 0.65-0.73 Nws | 0.6-0.9 hli | 0.15-0.35 dr hab | 0.025 max | - | 0.4 max | 0.4 max | 0.1 max | 0.025 max |

| CK 68 | 0.6-0.75 Nws | 0.7 max | 0.2-0.45 Nws | 0.025 max | - | - | - | - | 0.025 max |

| 70c2 ua | 0.65-0.70 Nws | 0.75-0.90 Nws | 0.2-0.30 Nws | 0.030 max | - | - | 0.55-0.70 Nws | - | 0.030 max |

| C67s Stainless Hlau Caij nplooj ntoos hlav sawbMechanical Properties |

| Qib | Tensile zog (MPa) min | Yield zog 0.2% Pov thawj (MPa) min | Elongation (% hauv 50mm) min |

| c67s ua | 670-900 Nws | 450-600 Nws | 2% -10% |

| Rau quenched thiab tempered txias dov strips, muaj ntau yam ua tiav nto: |

Qhov saum npoo tiav ntawm annealed C67S 1.1231 steel strips tom qab txias dov thiab annealing nyob rau hauv ib qho chaw tswj yuav tsum ci, uas tshwm sim los ntawm dov thiab annealing txheej txheem.

1.Grey/Annealed Oxide Finish: Qhov no tiav yog unpolished thiab khaws cia ib tug natural grey tsos nrog ib tug oxide txheej.

2.Bright Tempered (Unpolished): Nyob rau hauv cov ntaub ntawv no, lub steel sawb tseem unpolished tab sis pom ib tug kaj tsos vim lub tempering txheej txheem.

3.Polished Finish: Qhov kev ua tiav no yog ua tiav los ntawm kev siv cov txheej txheem zoo li kev sib tsoo zoo lossis txhuam txhuam kom tsim tau ib qho chaw du thiab muaj kev cuam tshuam.

4.Polished thiab Coloured Finish: Qhov kev ua tiav no suav nrog kev kho cua sov los tsim cov xim tshwj xeeb, xws li annealed lossis daj xim, los ntawm cov txheej txheem oxidization.

| Vim li cas thiaj xaiv peb: |

1. Koj tuaj yeem tau txais cov khoom zoo meej raws li qhov koj xav tau ntawm tus nqi tsawg kawg nkaus.

2. Peb kuj muab Reworks, FOB, CFR, CIF, thiab qhov rooj rau qhov rooj tus nqi xa khoom. Peb xav kom koj ua deal rau shipping uas yuav zoo heev.

3. Cov ntaub ntawv uas peb muab yog muaj tseeb tiag, txoj cai los ntawm raw cov ntaub ntawv xeem daim ntawv pov thawj mus rau qhov kawg dimensional nqe lus.

4. e lav muab cov lus teb tsis pub dhau 24 teev (feem ntau hauv tib lub sijhawm)

5. Muab SGS TUV daim ntawv qhia.

6. Peb muaj siab rau peb cov neeg muas zaub. Yog tias nws yuav tsis tuaj yeem ua tau raws li koj cov kev xav tau tom qab kuaj xyuas tag nrho cov kev xaiv, peb yuav tsis ntxias koj los ntawm kev cog lus tsis tseeb uas yuav tsim kev sib raug zoo rau cov neeg siv khoom.

7. Muab kev pabcuam ib-nres

| SAKY STEEL'S Quality Assurance (nrog rau kev puas tsuaj thiab tsis muaj kev puas tsuaj): |

1. Visual Dimension Test

2. Kev tshuaj xyuas cov tshuab xws li tensile, Elongation thiab txo qhov chaw.

3. Kev soj ntsuam cuam tshuam

4. Tshuaj ntsuam xyuas

5. Kev sim hardness

6. Pitting tiv thaiv kev xeem

7. Kev Xeem Penetrant

8. Intergranular Corrosion Test

9. Kev Ntsuas Roughness

10. Metallography Experimental Test

| SAKY STEEL'S Packing: |

1. Kev ntim khoom yog qhov tseem ceeb heev tshwj xeeb tshaj yog nyob rau hauv rooj plaub ntawm kev xa khoom thoob ntiaj teb uas cov khoom xa tuaj hla ntau txoj hauv kev kom mus txog qhov kawg, yog li peb muab kev txhawj xeeb tshwj xeeb txog kev ntim khoom.

2. Saky steel pob peb cov khoom hauv ntau txoj hauv kev raws li cov khoom lag luam. Peb ntim peb cov khoom nyob rau hauv ntau txoj kev, xws li