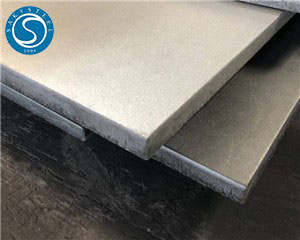

17-4PH 630 Stainless Hlau Bar

Lus piav qhia luv luv:

SAKYSTEEL cov khoom siv 17-4PH (630) stainless hlau tuav nrog lub zog zoo thiab corrosion kuj rau aerospace, marine, thiab kev lag luam siv.

Saky Steel's 17-4PH / 630 / 1.4542 yog ib qho nrov tshaj plaws thiab feem ntau siv stainless chromium-nickel alloy steels nrog tooj liab additive, nag lossis daus hardened nrog martensitic qauv. Nws yog tus cwj pwm los ntawm kev ua haujlwm siab corrosion thaum tswj cov khoom muaj zog, nrog rau hardness. Hlau tuaj yeem ua haujlwm nyob rau hauv qhov kub ntawm -29 ℃ to 343 ℃, thaum tuav cov kev ntsuas tsis zoo. Tsis tas li ntawd, cov ntaub ntawv nyob rau hauv qib no yog tus cwj pwm los ntawm qhov zoo ductility thiab lawv cov corrosion kuj yog piv rau 1.4301 / X5CrNi18-10.

17-4PH, tseem hu ua UNS S17400, yog martensitic nag lossis daus-hardening stainless hlau. Nws yog cov khoom siv ntau yam thiab siv dav hauv ntau yam kev lag luam, xws li aerospace, nuclear, petrochemical, thiab kev ua zaub mov.

17-4PH muaj lub zog siab, zoo corrosion kuj, thiab hardness zoo piv rau lwm yam stainless hlau. Nws yog sib xyaw ntawm 17% chromium, 4% npib tsib xee, 4% tooj liab, thiab ib qho me me ntawm molybdenum thiab niobium. Kev sib xyaw ntawm cov ntsiab lus no muab cov hlau nws cov khoom tshwj xeeb.

Zuag qhia tag nrho, 17-4PH yog cov khoom siv ntau yam thiab muaj txiaj ntsig zoo uas muaj qhov sib npaug zoo ntawm cov khoom siv rau ntau yam kev siv.

| Stainless Hlau Round Bar Bright Khoom Qhia: |

| Specification ntawm 630stainless hlau bar: |

Specifications:ASTM A564 / ASME SA564 Cov Lus Qhia

Qib:AISI 630 SUS630 17-4PH 1.4542 PH

Ntev:5.8M, 6M & Ntev Ntev

Round Bar Txoj kab uas hla:4.00mm txog 400mm

Bright Bar :4mm-100mm,

Kev kam rau siab:H8, H9, H10, H11, H12, H13, K9, K10, K11, K12 los yog raws li cov neeg xav tau

Qhov xwm txheej:Cold Drawn & Polished Cold Drawn, Peeled & Forged

Nto tiav:Dub, Ci, Polished, Rough tig, NO.4 Finish, Matt Finish

Daim ntawv:Round, Square, Hex (A / F), Rectangle, Billet, Ingot, Forged Etc.

Xaus:Plain End, Beveled End

| Stainless hlau Bar Qib Chemical Composition: |

| UNS npe | Hom | C | Mn | P | S | Si | Cr | Ni | Al | Mo | Ti | Cu | Lwm Yam Khoom |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| S17400 Nws | 630 | 0.07 ib | 1.00 Nws | 0.040 ib | 0.030 Nws | 1.00 Nws | 15.00–17.50 dr hab | 3.00–5.00 Nws | - | - | - | 3.00–5.00 Nws | C |

| S17700 Nws | 631 ib | 0.09 ib | 1.00 Nws | 0.040 ib | 0.030 Nws | 1.00 Nws | 16.00–18.00 Nws | 6.50–7.75 dr hab | - | - | - | - | - |

| S15700 Nws | 632 ib | 0.09 ib | 1.00 Nws | 0.040 ib | 0.030 Nws | 1.00 Nws | 14.00–16.00 Nws | 6.50–7.75 dr hab | - | 2.00–3.00 Nws | - | - | - |

| S35500 | 634 ib | 0.10–0.15 dr hab | 0.50–1.25 dr hab | 0.040 ib | 0.030 Nws | 0.50 ib | 15.00–16.00 Nws | 4.00–5.00 Nws | - | 2.50–3.25 dr hab | - | - | D |

| S17600 Nws | 635 ib | 0.08 ib | 1.00 Nws | 0.040 ib | 0.030 Nws | 1.00 Nws | 16.00–17.50 dr hab | 6.00–7.50 Nws | 0.40 Nws | - | - | - | - |

| S15500 Nws | XM-12 | 0.07 ib | 1.00 Nws | 0.040 ib | 0.030 Nws | 1.00 Nws | 14.00–15.50 dr hab | 3.50–5.50 Nws | - | - | - | 2.50–4.50 Nws | C |

| S13800 Nws | XM-13 | 0.05 Nws | 0.20 ib | 0.040 ib | 0.008 ib | 1.00 Nws | 12.25–13.25 dr hab | 7.50–8.50 Nws | 0.90–1.35 dr hab | 2.00–2.50 Nws | - | - | E |

| S45500 | XM-16 | 0.03 ib | 0.50 ib | 0.015 ib | 0.015 ib | 0.50 ib | 11.00–12.50 dr hab | 7.50–9.50 Nws | - | 0.50 ib | 0.90–1.40 Nws | 1.50–2.50 Nws | F |

| S45503 | - | 0.010 ib | 0.50 ib | 0.010 ib | 0.010 ib | 0.50 ib | 11.00–12.50 dr hab | 7.50–9.50 Nws | - | 0.50 ib | 1.00–1.35 dr hab | 1.50–2.50 Nws | F |

| S45000 | XM-25 | 0.05 Nws | 1.00 Nws | 0.030 Nws | 0.030 Nws | 0.50 ib | 14.00–16.00 Nws | 5.00–7.00 Nws | - | - | - | 1.25–1.75 dr hab | G |

| S46500 | - | 0.02 ib | 0.25 | 0.040 ib | 0.030 Nws | 1.00 Nws | 11.00–13.00 Nws | 10.75–11.25 dr hab | 0.15–0.50 Nws | 0.75–1.25 dr hab | - | - | E |

| wb 46910 | - | 0.030 Nws | 1.00 Nws | 0.040 ib | 0.020 ib | 1.00 Nws | 11.00–12.50 dr hab | 8.00–10.00 Nws | 0.50–1.20 dr hab | 3.0–5.0 Nws | - | 1.5-3.5 Nws | - |

| S10120 | - | 0.02 ib | 1.00 Nws | 0.040 ib | 0.015 ib | 0.25 | 11.00–12.50 dr hab | 9.00–11.00 Nws | 1.10 | 1.75–2.25 dr hab | 0.20–0.50 Nws | - | E |

| S11100 Nws | - | 0.02 ib | 0.25 | 0.040 ib | 0.010 ib | 0.25 | 11.00–12.50 dr hab | 10.25–11.25 dr hab | 1.35–1.75 dr hab | 1.75–2.25 dr hab | 0.20–0.50 Nws | - | E |

| 17-4PH Stainless Hlau Bar Sib npaug Qib: |

| STANDARD | UNS | WERKSTOFF NR. | AFNOR | JIS | EN | BS | GOST |

| 17-4 PAB | S17400 Nws | 1.4542 ib |

| 17-4PH Stainless Bar Solution Kev Kho Mob: |

| Qib | Tensile zog (MPa) min | Elongation (% hauv 50mm) min | Yield zog 0.2% Pov thawj (MPa) min | Hardness | |

| Rockwell C max | Brinell (HB) max | ||||

| 630 | - | - | - | 38 | 363 |

Reamark: Qhov A 1900 ± 25 ° F [1040 ± 15 ° C] (txias raws li yuav tsum tau qis dua 90 ° F (30 ° C))

1.4542 Mechanical Test Requirements Tom Qab Hnub Nyoog Hardening Heat Treatment:

Tensile zog:Chav tsev - ksi (MPa), Yam tsawg kawg nkaus

Yeild zog:0.2% Offset, Unit – ksi (MPa), Yam tsawg kawg nkaus

Elongation:nyob rau hauv 2 ", Unit: %, Yam tsawg kawg nkaus

Hardness:Rockwell, Maximum

17-4PH Stainless Hlau Mechanical Properties los ntawm Kev Kho Mob Kub Kub:

| H900 Nws | h925 ua | HWV 1025 | HWV 1075 | H1100 Nws | HWV 1150 | H 1150-M | |

| Qhov kawg Tensile Strength, ksi | 190 | 170 | 155 | 145 | 140 | 135 | 115 |

| 0.2% Yield zog, ksi | 170 | 155 | 145 | 125 | 115 | 105 | 75 |

| Elongation% hauv 2 "los yog 4XD | 10 | 10 | 12 | 13 | 14 | 16 | 16 |

| Kev txo qis ntawm cheeb tsam,% | 40 | 54 | 56 | 58 | 58 | 60 | 68 |

| Hardness, Brinell (Rockwell) | 388 (HWV 40) | 375 (HWV 38) | 331 (HWV 35) | 311 (HWV 32) | 302 (HWV 31) | 277 (HWV 28) | 255 (C 24) |

| Impact Charpy V-Notch, ft – lbs | | 6.8 | 20 | 27 | 34 | 41 | 75 |

| Smelting Option: |

1 EAF: Hluav taws xob Arc Rauv

2 EAF + LF + VD: Refined-smelting thiab nqus degassing

3 EAF + ESR: Electro Slag Remelting

4 EAF + PESR: tiv thaiv huab cua Electro Slag Remelting

5 VIM + PESR: Nqus induction melting

| Kev kho cua sov Option: |

1 + A: Annealed (tag nrho / mos / spheroidizing)

2 + N: Normalized

3 + NT: Normalized thiab tempered

4 + QT: quenched thiab tempered (dej / roj)

5 + AT: Kev daws teeb meem annealed

6 + P: nag lossis daus hardened

| Kev kho cua sov: |

Kev kho mob (Txoj Cai A) - Qib 630 stainless hlau yog rhuab ntawm 1040 ° C rau 0.5 h, ces cua txias rau 30 ° C. Cov ntu me me ntawm cov qib no tuaj yeem ua cov roj quenched.

Hardening - Qib 630 stainless hlau yog hnub nyoog-hardened ntawm qhov kub thiab txias kom ua tiav cov khoom siv kho tshuab. Thaum lub sij hawm tus txheej txheem, superficial discoloration tshwm sim tom qab shrinkage ntawm 0.10% rau mob H1150, thiab 0.05% rau mob H900.

| Txheem rau 17-4PH Stainless Hlau |

17-4PH stainless hlau ua raws li ntau yam ntawm cov qauv thoob ntiaj teb thiab cov lus qhia tshwj xeeb, ua kom ntseeg tau zoo thiab kev ua tau zoo thoob plaws kev lag luam xws li aerospace, lub zog, thiab kev ua tshuaj lom neeg.

| Standard Organization | Specification | Kev piav qhia |

|---|---|---|

| ASTM | ASTM A564/A564M | Txheem rau kub-dov thiab txias-tiav hnub nyoog-hardening stainless hlau tuav thiab cov duab |

| ASTM A693 Cov Khoom Siv Hluav Taws Xob | Specification rau nag lossis daus-hardening stainless hlau phaj, ntawv, thiab sawb | |

| ASTM A705 / A705M | Specification rau wrought nag lossis daus-hardening stainless thiab kub-resisting steel forging | |

| ASME | ASME SA564 / SA693 / SA705 | Sib npaug siab hlab ntsha code specifications |

| UAS (Aerospace) | TIAB SA 5643 | Aerospace spec rau bar, hlau, forgings, thiab rings nyob rau hauv 17-4PH tov-kho thiab hnub nyoog |

| TIAB SA 5622 | Phaj, ntawv, thiab strip | |

| EN / DIN | TS EN 1.4542 / DIN X5CrNiCuNb16-4 | European tsim rau 17-4PH nrog cov khoom zoo sib xws thiab cov khoom |

| UNS | UNS S17400 | Unified Numbering System npe |

| ISO | ISO 15156-3 | Kev tsim nyog rau kev siv cov khoom siv roj av hauv cov roj av qaub |

| NACE | TIAB SA 0175 | Cov khoom xav tau rau kev tiv thaiv sulfide kev nyuaj siab tawg |

| Vim li cas thiaj xaiv peb: |

1. Koj tuaj yeem tau txais cov khoom zoo meej raws li qhov koj xav tau ntawm tus nqi tsawg kawg nkaus.

2. Peb kuj muab Reworks, FOB, CFR, CIF, thiab qhov rooj rau qhov rooj tus nqi xa khoom. Peb xav kom koj ua deal rau shipping uas yuav zoo heev.

3. Cov ntaub ntawv uas peb muab yog muaj tseeb tiag, txoj cai los ntawm raw cov ntaub ntawv xeem daim ntawv pov thawj mus rau qhov kawg dimensional nqe lus.

4. e lav muab cov lus teb tsis pub dhau 24 teev (feem ntau hauv tib lub sijhawm)

5. Koj tuaj yeem tau txais cov khoom lag luam, cov khoom xa tuaj nrog lub sijhawm tsim khoom tsawg.

6. Peb muaj siab rau peb cov neeg muas zaub. Yog tias nws yuav tsis tuaj yeem ua tau raws li koj cov kev xav tau tom qab kuaj xyuas tag nrho cov kev xaiv, peb yuav tsis ntxias koj los ntawm kev cog lus tsis tseeb uas yuav tsim kev sib raug zoo rau cov neeg siv khoom.

| SAKY STEEL'S Quality Assurance (nrog rau kev puas tsuaj thiab tsis muaj kev puas tsuaj) |

1. Visual Dimension Test

2. Kev tshuaj xyuas cov tshuab xws li tensile, Elongation thiab txo qhov chaw.

3. Ultrasonic kuaj

4. Tshuaj ntsuam xyuas

5. Kev sim hardness

6. Pitting tiv thaiv kev xeem

7. Kev Xeem Penetrant

8. Intergranular Corrosion Test

9. Kev soj ntsuam cuam tshuam

10. Metallography Experimental Test

| Ntim |

1. Kev ntim khoom yog qhov tseem ceeb heev tshwj xeeb tshaj yog nyob rau hauv rooj plaub ntawm kev xa khoom thoob ntiaj teb uas cov khoom xa tuaj hla ntau txoj hauv kev kom mus txog qhov kawg, yog li peb muab kev txhawj xeeb tshwj xeeb txog kev ntim khoom.

2. Saky Steel pob peb cov khoom hauv ntau txoj hauv kev raws li cov khoom lag luam. Peb ntim peb cov khoom nyob rau hauv ntau txoj kev, xws li,

17-4PH, 630 thiab X5CrNiCuNb16-4 / 1.4542 yog muab nyob rau hauv daim ntawv ntawm round tuav, cov ntawv txheeb, tiaj tus tuav thiab txias-dov strip. Cov khoom siv dav siv hauv aerospace, marine, ntawv, lub zog, offshore thiab zaub mov industries rau hnyav-duty tshuab Cheebtsam, bushings, turbine hniav, couplings, screws, tsav shafts, ceev, ntsuas li.

1. Aerospace Kev Lag Luam

-

Turbine cav Cheebtsam (impellers, ncej, vaj tse)

-

Kev tsaws iav qhov chaw

-

Fasteners (bolts, txiv ntseej) thiab cov khoom sib txuas

-

Hydraulic system Cheebtsam

2. Kev lag luam roj thiab roj

-

Cov cuab yeej downhole (drill rods, valve rooj, yeeb nkab fittings)

-

Corrosion-resistant valve qhov chaw

-

Cov khoom siv roj av (cov twj tso kua mis, cov vaj tse, cov nplhaib sib khi)

3. Kev Lag Luam Kev Lag Luam

-

Cov twj tso kua mis thiab cov li qub siv nyob rau hauv qhov chaw acidic

-

Thaum tshav kub kub exchangers thiab siab hlab ntsha

-

Reactors thiab agitator ncej

-

Fittings rau cia tank

4. Khoom noj khoom haus & Khoom siv kho mob

-

Khoom noj khoom haus-qib pwm thiab tsav cov khoom

-

Cheebtsam rau high-pressure sterilizers

-

Cov cuab yeej phais thiab cov cuab yeej kho mob (yuav tsum tau ntawv pov thawj)

-

Qhov chaw rau kev kho mob siab tswj tshuab

5. Marine thiab Offshore Engineering

-

Propeller shafts thiab propulsion assemblies

-

Seawater twj shafts thiab sealing Cheebtsam

-

Fasteners thiab structural connectors nyob rau hauv lub nkoj hulls

-

Corrosion-resistant Cheebtsam rau offshore platforms

6. Nuclear thiab lub zog tsim

-

Fasteners rau nuclear reactor qauv

-

Tube pob kev txhawb nqa rau cov khoom siv hluav taws xob

-

Hydraulic valve rods thiab twj tso kua mis lub cev

-

High-temperature valve qhov chaw

7. Pwm thiab Tooling Industry

-

Txhaj pwm thav duab

-

High-lub zog tsim shafts thiab kev txhawb nqa

-

Qhia cov ncej thiab bushings rau stamping pwm

8. General Machinery & Automation

-

Cov khoom sib kis xws li iav shafts, couplings, thiab spindles

-

Mechanical rails thiab positioning rods nyob rau hauv automation systems

-

Muaj hydraulic piston pas nrig