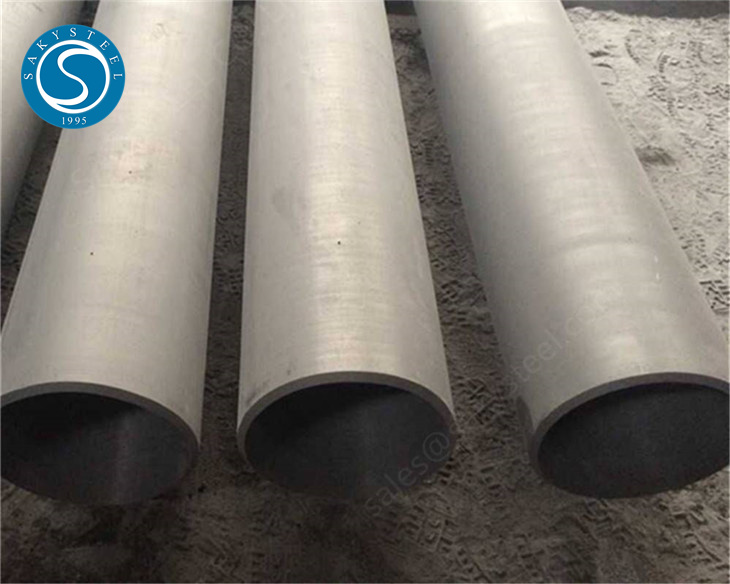

10Cr9Mo1VNbN Paipu kila ʻole

ʻO ka wehewehe pōkole:

Loaʻa i nā paipu kila 10Cr9Mo1VNbN maikaʻi loa ka wela kiʻekiʻe a me ke kūpaʻa kiʻekiʻe, e kūpono ana ia no nā kūlana hana i nā kaiapuni me ka wela a me ke kaomi.

10Cr9Mo1VNbN mau paipu hao ʻole:

ʻO 10Cr9Mo1VNbN he kila haʻahaʻa haʻahaʻa e hāʻawi ana i nā waiwai wela kiʻekiʻe maikaʻi loa a me ke kūpaʻa ʻana i ka ʻino a me ka ʻino. Hoʻohana nui ʻia ia i nā mea kanu mana, kahi e hana nui ai i ka mālama ʻana i ka hana palekana a hilinaʻi hoʻi ma lalo o nā kūlana kiʻekiʻe a me nā kūlana kiʻekiʻe. ili hoʻopau, a kiʻekiʻe toughness a me ka ductility.

Nā kikoʻī o 10Cr9Mo1VNbN Tubes:

| Papa | 10Cr9Mo1VNbN,P90 |

| Kūlana | GB 5310-2008, GB /T 5310-2017 |

| Ili | Pickled, Sandblast, Polishing, etc |

| Mahele Raw | POSCO, Baosteel, TISCO, Saky Steel, Outokumpu |

10Cr9Mo1VNbN Tube Kimia Hui:

| C | Si | Mn | P | S | Cr | Mo | Ni | Cu |

| 0.08-0.12 | 0.20-0.50 | 0.30-0.60 | 0.025 | 0.010 | 8.0-9.5 | 1.0-1.2 | 0.40 | 0.20 |

No ke aha e koho ai iā mākou?

•Hiki iā ʻoe ke loaʻa ka mea kūpono e like me kāu koi ma ka liʻiliʻi loa o ke kumu kūʻai.

•Hāʻawi pū mākou i nā Reworks, FOB, CFR, CIF, a me nā kumukūʻai hoʻopuka puka i ka puka. Manaʻo mākou iā ʻoe e hana i ka hana no ka hoʻouna ʻana e ʻoi aku ka waiwai.

•Hiki ke hōʻoia ʻia nā mea a mākou e hāʻawi ai, mai ka palapala hōʻike maka a hiki i ka ʻōlelo kikoʻī hope. (E hōʻike ʻia nā hōʻike ma ke koi)

•Ke hōʻoiaʻiʻo nei mākou e hāʻawi i kahi pane i loko o 24 mau hola (maʻamau i ka hola hoʻokahi)

•Hāʻawi i ka hōʻike SGS TUV.

•Hoʻolaʻa piha mākou i kā mākou mea kūʻai. Inā ʻaʻole hiki ke hoʻokō i kāu mau koi ma hope o ka nānā ʻana i nā koho āpau, ʻaʻole mākou e alakaʻi hewa iā ʻoe ma ka hana ʻana i nā ʻōlelo hoʻohiki wahaheʻe e hoʻokumu ai i nā pilina mea kūʻai aku.

•Hāʻawi i ka lawelawe hoʻokahi.

ʻO kā mākou lawelawe

1.Quenching a me ka tempering

2.Vacuum wela mālama

3.Mirror-polished ili

4.Precision-milled pau

4.CNC machining

5.Precision wili

6.ʻokiʻoki i nā'āpana liʻiliʻi

7. Loaʻa i ka pololei e like me ka mold

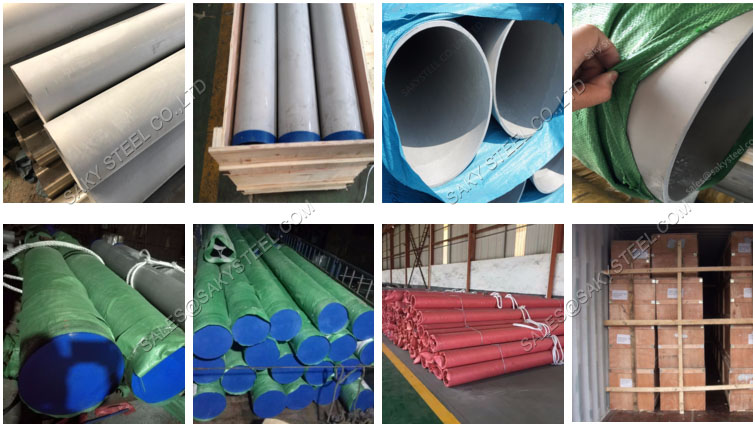

Hoʻopili:

1. He mea koʻikoʻi ka hoʻopaʻa ʻana ma ka hihia o ka hoʻouna ʻana i ka honua kahi e hele ai ka lawe ʻana ma nā ala like ʻole e hiki ai i ka hopena hope loa, no laila ke kau nei mākou i ka hopohopo kūikawā e pili ana i ka ʻeke.

2. Hoʻopili ʻo Saky Steel i kā mākou waiwai ma nā ʻano he nui e pili ana i nā huahana. Hoʻopili mākou i kā mākou huahana ma nā ʻano he nui, e like me,