Ana kera bututun bakin ƙarfe maras sumul ta amfani da matakai da yawa, gami da:

- narkewa: Mataki na farko shine narkar da bakin karfe a cikin tanderun baka na wutan lantarki, sannan a tace shi kuma a yi masa magani da allura daban-daban don cimma abubuwan da ake so.

- Ci gaba da yin Simintin gyare-gyare: Ana zuba narkakken karfen a cikin injin ci gaba da yin simintin, wanda ke samar da ingantaccen “billet” ko “fulawa” wanda ke da siffa da girman da ake bukata.

- Dumama: Ƙaƙƙarfan billet ɗin ana dumama shi a cikin tanderu zuwa zafin jiki tsakanin 1100-1250 ° C don sa ya zama mai lalacewa kuma a shirye don ƙarin sarrafawa.

- Huda: Za a huda billet ɗin da aka zafafa tare da madaidaicin madauri don ƙirƙirar bututu mai zurfi. Ana kiran wannan tsari "hudawa."

- Mirgina: Sannan ana mirgina bututun mai rami akan injin niƙa don rage diamita da kaurin bango zuwa girman da ake buƙata.

- Maganin zafi: Daga nan sai a yi maganin bututun da ba shi da sumul don inganta ƙarfinsa da taurinsa. Wannan ya haɗa da dumama bututu zuwa zafin jiki tsakanin 950-1050C, sannan saurin sanyaya cikin ruwa ko iska.

- Ƙarshe: Bayan maganin zafi, ana gyara bututun da ba shi da kyau, a yanke shi zuwa tsayi, kuma a gama shi ta hanyar gogewa ko tsintsawa don cire duk wani datti na saman da kuma inganta bayyanarsa.

- Gwaji: Mataki na ƙarshe shine gwada bututu don kaddarorin daban-daban, kamar taurin ƙarfi, ƙarfi, da daidaiton girma, don tabbatar da ya dace da ƙa'idodin da ake buƙata.

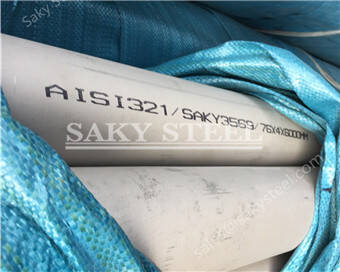

Da zarar bututun ya wuce duk gwajin da ake buƙata, yana shirye don aikawa zuwa abokan ciniki. Dukkanin tsarin ana kulawa da hankali kuma ana sarrafa shi don tabbatar da bututun da ba shi da kyau ya dace da ka'idodin ingancin da ake buƙata.

Lokacin aikawa: Fabrairu-15-2023