Ⅰ.Babban manufar maganin zafi.

A.Babban ra'ayi na maganin zafi.

Abubuwan asali da ayyuka nazafi magani:

1. Dumama

Manufar ita ce samun tsari mai daidaituwa da lafiya austenite.

2. Rikewa

Manufar ita ce don tabbatar da aikin aikin yana da zafi sosai kuma don hana decarburization da oxidation.

3.Cikin sanyaya

Manufar ita ce a canza austenite zuwa microstructures daban-daban.

Microstructures bayan Heat Jiyya

A lokacin tsarin sanyaya bayan dumama da riƙewa, austenite yana canzawa zuwa microstructures daban-daban dangane da ƙimar sanyaya. Microstructures daban-daban suna nuna kaddarorin daban-daban.

B.Ainihin manufar maganin zafi.

Rarraba Dangane da Hanyoyi masu dumama da sanyaya, da kuma Microstructure da Abubuwan Karfe

1.Maganin Zafi na Al'ada (Maganin Jiyya na Gabaɗaya):Zazzaɓi, Annealing, Normalizing, Quenching

2.Surface Heat Jiyya:Surface Quenching,Induction dumama surface Quenching, harshen wuta dumama saman quenching, Electric lamba dumama surface Quenching.

3.Chemical Heat Jiyya:Carburizing,Nitriding,Carbonitriding.

4.Other Heat Jiyya: Sarrafa Atmosphere Heat Jiyya, Vacuum Heat Jiyya, Nakasar Zafin Magani.

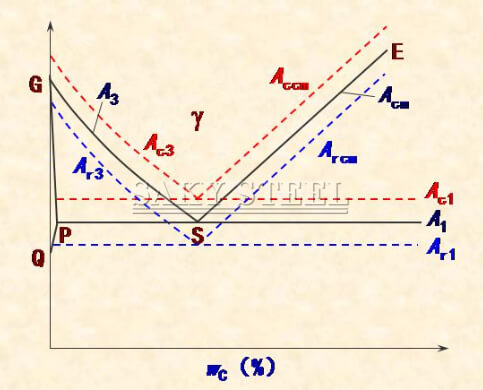

C.Mahimman Zazzabi Na Karfe

Mahimmancin canjin canjin ƙarfe na ƙarfe shine muhimmin tushe don ƙayyade hanyoyin dumama, riƙewa, da sanyaya yayin maganin zafi. An ƙaddara shi ta hanyar zane-zane na ƙarfe-carbon.

Mabuɗin Ƙarshe:Haƙiƙanin zafin canji mai mahimmanci na ƙarfe koyaushe yana baya bayan ƙa'idar zafin canji mai mahimmanci. Wannan yana nufin cewa ana buƙatar overheating lokacin dumama, kuma rashin sanyaya ya zama dole yayin sanyaya.

Ⅱ.Cewa da daidaita Karfe

1. Ma'anar Annealing

Annealing ya ƙunshi dumama karfe zuwa zafin jiki sama ko ƙasa da mahimmancin batu Ac₁ riƙe shi a wannan zafin jiki, sannan a sanyaya shi a hankali, yawanci a cikin tanderun, don cimma tsari kusa da daidaito.

2. Manufar Annealing

① Daidaita Taurin don Machining: Samun taurin machinable a cikin kewayon HB170 ~ 230.

②Sake Rage Damuwa: Yana Hana nakasawa ko tsagewa yayin matakai na gaba.

③Tace Tsarin Hatsi: Yana inganta ƙananan tsarin.

④Shiri don Maganin Zafin Ƙarshe: Ya Sami granular (spheroidized) pearlite don quenching da tempering na gaba.

3.Spheroidizing Annealing

Ƙayyadaddun tsari: Zazzabi mai zafi yana kusa da wurin Ac₁.

Manufa: Don spheroidize da siminti ko carbides a cikin karfe, haifar da granular (spheroidized) pearlite.

Matsakaicin Range: Ana amfani dashi don karafa tare da abubuwan eutectoid da hypereutectoid.

4. Yawaita Annealing (Homogenizing Annealing)

Ƙayyadaddun tsari: Zazzabi mai zafi yana ɗan ƙasa da layin solvus akan zanen lokaci.

Manufar: Don kawar da wariya.

①Don low-carbon karfetare da abun ciki na carbon ƙasa da 0.25%, an fi son daidaita al'ada fiye da annealing azaman maganin zafi na shiri.

②Don matsakaici-carbon karfe tare da abun ciki carbon tsakanin 0.25% da 0.50%, ko dai annealing ko normalizing za a iya amfani da matsayin shiri zafi magani.

③Don matsakaici-zuwa babban-carbon karfe tare da abun ciki na carbon tsakanin 0.50% da 0.75%, ana ba da shawarar cirewa sosai.

④ Don high-carbon karfetare da abun ciki na carbon fiye da 0.75%, ana fara amfani da al'ada don kawar da hanyar sadarwar Fe₃C, sannan kuma spheroidizing annealing.

Ⅲ.Quenching da zafin Karfe

A. Quenching

1. Ma'anar Quenching: Quenching ya haɗa da dumama karfe zuwa wani zazzabi sama da Ac₃ ko Ac₁, riƙe shi a wannan zafin jiki, sannan sanyaya shi fiye da ƙimar sanyaya mai mahimmanci don samar da martensite.

2. Manufar Quenching: Manufar farko ita ce samun martensite (ko wani lokacin ƙananan bainite) don ƙara ƙarfin ƙarfi da juriya na karfe. Quenching yana ɗaya daga cikin mahimman hanyoyin magance zafi don ƙarfe.

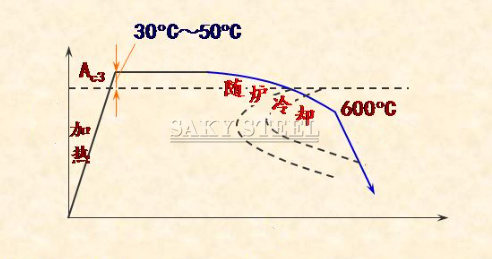

3.Yanke Yanke Zazzabi Na Ƙarfe Daban-daban

Karfe Hypoeutectoid: Ac₃ + 30°C zuwa 50°C

Eutectoid da Hypereutectoid Karfe: Ac₁ + 30 ° C zuwa 50 ° C

Alloy Karfe: 50°C zuwa 100°C sama da matsanancin zafin jiki

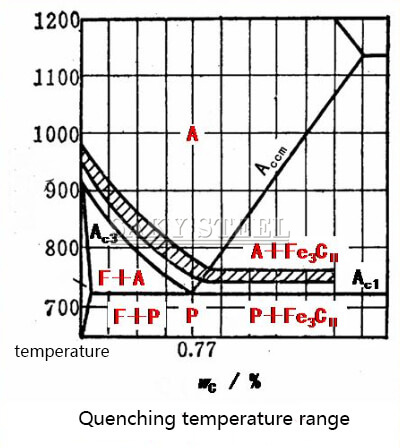

4.Cooling Halayen Matsakaici Mai Kyau:

Sanyi Sannu a hankali Kafin "Hanci" Zazzabi: Don isasshe rage zafin zafi.

Ƙarfin sanyaya Ƙarfin Kusa da Zazzabi "Hanci": Don guje wa samuwar sifofin da ba na martensitic ba.

Sanyi Sannu a hankali Kusa da Ma'anar M₅: Don rage damuwa ta hanyar canjin martensitic.

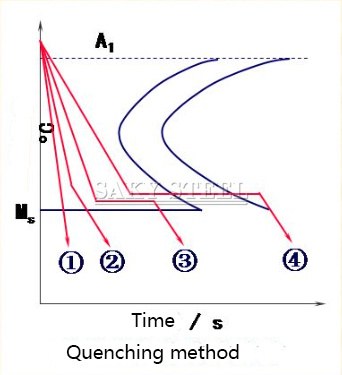

5.Hanyoyin Quenching da Halayensu:

① Sauƙaƙe Quenching: Sauƙi don aiki kuma ya dace da ƙananan kayan aiki masu sauƙi. Sakamakon microstructure shine martensite (M).

② Quenching Biyu: Ƙarin rikitarwa da wahala don sarrafawa, ana amfani da shi don rikitaccen siffa mai girma-carbon karfe da manyan kayan aikin ƙarfe na gami. Sakamakon microstructure shine martensite (M).

③Broken Quenching: A mafi hadaddun tsari, amfani da manyan, hadaddun gami gami karfe workpieces. Sakamakon microstructure shine martensite (M).

④ Isothermal Quenching: An yi amfani da shi don ƙananan kayan aiki masu rikitarwa, masu siffa tare da manyan buƙatu. Sakamakon microstructure shine ƙananan bainite (B).

6.Abubuwan Da Ke Tauye Hardenability

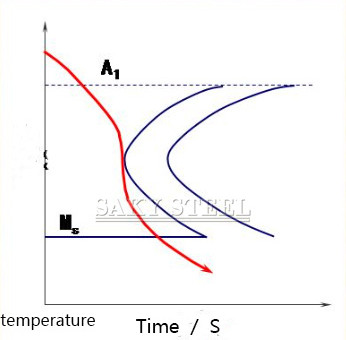

Matsayin taurin ya dogara da kwanciyar hankali na supercooled austenite a cikin karfe. Mafi girman kwanciyar hankali na supercooled austenite, mafi kyawun ƙarfin ƙarfi, kuma akasin haka.

Abubuwan Da Ke Tasirin Kwanciyar Austenite Supercooled:

Matsayin C-Curve: Idan C-curve ya canza zuwa dama, ƙimar sanyi mai mahimmanci don quenching yana raguwa, inganta ƙarfin hali.

Mabuɗin Ƙarshe:

Duk wani abu da ke juya C-curve zuwa dama yana ƙara ƙarfin ƙarfe.

Babban Abu:

Haɗin Kemikal: Ban da cobalt (Co), duk abubuwan da aka narkar da su a cikin austenite suna ƙaruwa da ƙarfi.

Mafi kusancin abun cikin carbon shine zuwa abun da ke cikin eutectoid a cikin karfen carbon, yawan C-curve yana motsawa zuwa dama, kuma mafi girma da taurin.

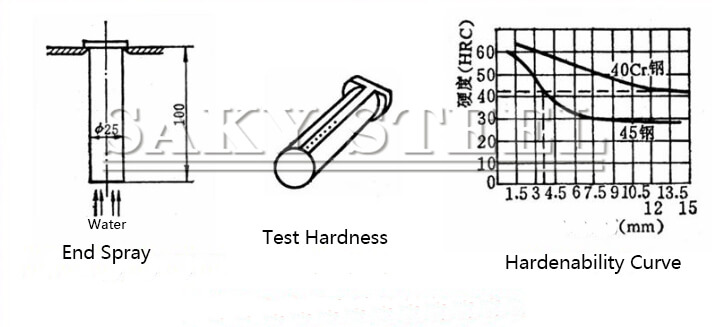

7.Kaddara da wakilci na Hardenability

① Gwajin Ƙarshen Ƙarshen Ƙarshen Ƙarshen Ƙarshe: Ana auna ƙarfin ƙarfin ta amfani da hanyar gwajin ƙarewa.

②Hanyar Mahimmancin Quench Diamita: Matsakaicin diamita mai mahimmanci (D₀) yana wakiltar matsakaicin diamita na ƙarfe wanda za'a iya taurare gabaɗaya a cikin takamaiman matsakaicin quenching.

B. Haushi

1. Ma'anar fushi

Tempering wani tsari ne na maganin zafi inda aka kashe ƙarfen da aka kashe zuwa zafin jiki da ke ƙasa da maki A₁, ana riƙe shi a wannan zafin, sannan a sanyaya zuwa zafin jiki.

2. Manufar Fushi

Rage ko Kawar da Rage Damuwa: Yana hana nakasawa ko tsattsage kayan aikin.

Rage ko Kawar da ragowar Austenite: Yana daidaita girman aikin aikin.

Kawar da Karfe Karfe: Yana daidaita microstructure da kaddarorin don biyan buƙatun aikin aikin.

Muhimmiyar sanarwa: Karfe ya kamata a huce da sauri bayan ya mutu.

3.Tsarin zafi

1.Rashin fushi

Manufa: Don rage quenching danniya, inganta taurin na workpiece, da kuma cimma babban taurin da sa juriya.

Zazzabi: 150°C ~ 250°C.

Ayyuka: Hardness: HRC 58 ~ 64. Babban taurin da juriya.

Aikace-aikace: Kayan aiki, gyaggyarawa, bearings, carburized sassa, da abubuwan da aka taurare.

2.Mai Girma

Manufar: Don cimma babban tauri tare da isasshen ƙarfi da taurin.

Zazzabi: 500°C ~ 600°C.

Ayyuka: Hardness: HRC 25 ~ 35. Kyakkyawan kayan aikin injiniya gabaɗaya.

Aikace-aikace: Shafts, Gears, haɗa sanduna, da dai sauransu.

Gyaran zafi

Ma'anar: Quenching yana biye da yanayin zafi mai zafi ana kiransa refining thermal, ko kuma kawai mai zafi. Karfe da aka yi wa wannan tsari yana da kyakkyawan aiki gabaɗaya kuma ana amfani da shi sosai.

Ⅳ.Maganin Zafin Karfe

A.Surface Quenching na Karfe

1. Ma'anar Tauraruwar Sama

Tauraruwar saman wani tsari ne na maganin zafi wanda aka ƙera don ƙarfafa saman saman kayan aiki ta hanyar ɗumama shi da sauri don canza saman saman zuwa austenite sannan kuma da sauri sanyaya shi. Ana aiwatar da wannan tsari ba tare da canza sinadarai na karfe ko ainihin tsarin kayan ba.

2. Kayayyakin da Ake Amfani da su Don Ƙarfafa Fassara da Tsarin Ƙarfafawa

Kayayyakin da Ake Amfani da su don Tauraruwar Sama

Abubuwan Haƙiƙa: Matsakaicin ƙarfe na carbon da matsakaicin carbon gami karfe.

Pre-Jiyya:Tsarin Hankali: Tsari. Idan ainihin kaddarorin ba su da mahimmanci, ana iya amfani da al'ada maimakon.

Tsarin Bayan-Hardening

Tsarin Sama: Layer Layer yawanci yana samar da tsari mai tauri kamar martensite ko bainite, wanda ke ba da tauri mai ƙarfi da juriya.

Tsarin Mahimmanci: Jigon ƙarfe gabaɗaya yana riƙe da ainihin tsarin sa, kamar pearlite ko yanayin zafi, ya danganta da tsarin riga-kafi da kaddarorin kayan tushe. Wannan yana tabbatar da cewa ainihin yana kula da kyau da ƙarfi.

B.Halayen induction hardening surface

1.High Heating Temperature and Fast Temperature Rise: Induction surface hardening yawanci ya haɗa da yanayin zafi mai zafi da saurin dumama, ƙyale saurin dumama cikin ɗan gajeren lokaci.

2.Fine Austenite Grain Structure a cikin Surface Layer: A lokacin da sauri dumama da kuma m quenching tsari, da surface Layer samar da kyau austenite hatsi. Bayan quenching, saman farko ya ƙunshi kyakkyawan martensite, tare da taurin yawanci 2-3 HRC sama da quenching na al'ada.

3.Good Surface Quality: Saboda da short dumama lokaci, da workpiece surface ne kasa yiwuwa ga hadawan abu da iskar shaka da kuma decarburization, da kuma quenching-jawo nakasawa ne minimized, tabbatar da kyau surface quality.

4.High Gaji ƙarfi: The martensitic lokaci canji a cikin surface Layer haifar matsa lamba, wanda qara gajiya ƙarfi na workpiece.

5.High Production Efficiency: Induction surface hardening ya dace da taro samar, miƙa high aiki yadda ya dace.

C.Rarraba maganin zafi na sinadarai

Carburizing, Carburizing, Carburizing, Chromizing, Siliconizing, Siliconizing, Siliconizing, Carbonitriding, Borocarburizing

D. Gas Carburizing

Gas Carburizing wani tsari ne inda aka sanya kayan aiki a cikin tanderun da aka rufe da iskar gas kuma mai zafi zuwa zafin jiki wanda ke canza ƙarfe zuwa austenite. Sa'an nan, wani carburizing wakili ne dripped a cikin tanderun, ko wani carburizing yanayi da aka kai tsaye gabatar, kyale carbon zarra su yadu a cikin surface Layer na workpiece. Wannan tsari yana ƙara abun cikin carbon (wc%) akan farfajiyar aikin.

√Waɗanda ke Kawo Karɓa:

• Gas mai arzikin Carbon: Kamar Gas Gas, Gas Gas mai Liquefied (LPG), da sauransu.

•Magungunan ruwa: Kamar kananzir, methanol, benzene, da sauransu.

√ Ma'auni Tsari:

• Zazzabi mai ɗaukar nauyi: 920 ~ 950 ° C.

• Lokacin Carburizing: Ya dogara da zurfin da ake so na carburized Layer da zafin jiki na carburizing.

E. Maganin Zafi Bayan Carburizing

Karfe dole ne a sha magani mai zafi bayan carburizing.

Tsarin Maganin Zafi Bayan Carburizing:

√Quenching + Rawan Zazzabi

1.Direct Quenching Bayan Pre-Cooling + Low-Temperature Tempering: The workpiece ne pre-sanyaya daga carburizing zafin jiki zuwa kawai sama da core ta Ar₁ zafin jiki sa'an nan nan da nan quenched, bi da low-zazzabi tempering a 160 ~ 180 ° C.

2.Single Quenching Bayan Pre-Cooling + Low-Temperature Tempering: Bayan carburizing, da workpiece ne sannu a hankali sanyaya zuwa dakin zafin jiki, sa'an nan reheated for quenching da low-zazzabi tempering.

3.Double Quenching Bayan Pre-Cooling + Low-Temperature Tempering: Bayan carburizing da jinkirin sanyaya, da workpiece undergoes biyu matakai na dumama da quenching, bi da low-zazzabi tempering.

Ⅴ.Maganin Zafin Karfe

1.Ma'anar Maganin Zafin Sinadari

Chemical zafi magani ne mai zafi magani tsari a cikin abin da wani karfe workpiece aka sanya a cikin wani takamaiman aiki matsakaici, mai tsanani, da kuma gudanar a zazzabi, kyale da aiki atoms a cikin matsakaici don yada cikin surface na workpiece. Wannan yana canza sinadaran abun da ke ciki da microstructure na saman workpiece, ta haka yana canza kaddarorin sa.

2.Basic Tsarin Maganin Zafin Sinadari

Rushewa: A lokacin dumama, matsakaicin aiki yana bazuwa, yana sakin kwayoyin halitta masu aiki.

Absorption: Abubuwan zarra masu aiki suna adsorbed da saman karfe kuma suna narke cikin ingantaccen bayani na karfe.

Watsawa: Abubuwan zarra masu aiki suna tsotsewa da narkar da su akan saman karfe suna ƙaura zuwa ciki.

Nau'o'in Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarƙashin Ƙarfafawa

a.High-Frequency Induction Dumama

Mitar halin yanzu: 250 ~ 300 kHz.

Hardened Layer Zurfin: 0.5 ~ 2.0 mm.

Aikace-aikace: Matsakaici da ƙananan gear module da ƙanana zuwa matsakaita masu girma dabam.

b.Matsakaici-Mitsin Jigilar Dumama

Mitar halin yanzu: 2500 ~ 8000 kHz.

Hardened Layer Zurfin: 2 ~ 10 mm.

Aikace-aikace: Manyan shafts da manya zuwa matsakaicin kayan aiki.

c.Yawan Ƙarfi Mai Dumamawa

Mitar Yanzu: 50 Hz.

Hardened Layer Zurfin: 10 ~ 15 mm.

Aikace-aikace: Kayan aiki na buƙatar Layer mai tauri mai zurfi sosai.

3. Ƙarfafa Ƙarfafawar Jigilar Induction

Tushen Ƙa'idar Ƙarfafa Tauraron Sama

Tasirin Fata:

Lokacin da madaidaicin halin yanzu a cikin induction coil ya haifar da wani halin yanzu a saman kayan aikin, yawancin abubuwan da aka jawo suna tattara su kusa da saman, yayin da kusan babu halin yanzu da ke wucewa ta cikin kayan aikin. An san wannan sabon abu da tasirin fata.

Ƙa'idar Ƙarfafa Ƙarfafa Sama:

Dangane da tasirin fata, saman kayan aikin yana da sauri mai tsanani zuwa zafin jiki na austenitizing (tashi zuwa 800 ~ 1000 ° C a cikin 'yan seconds), yayin da ciki na workpiece ya kasance kusan unheated. A workpiece ne sa'an nan sanyaya da ruwa spraying, cimma saman taurare.

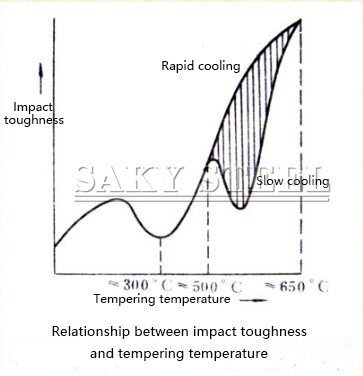

4. Tashin hankali

Ƙunƙarar Ƙarfafawa a Ƙarfe Mai Ƙarfe

Ƙunƙarar zafin jiki yana nufin abin da ya faru inda tasirin taurin karfen da aka kashe yana raguwa sosai lokacin da aka yi zafi a wasu yanayin zafi.

Nau'in Farko na Haushi

Yanayin Zazzabi: 250 ° C zuwa 350 ° C.

Halaye: Idan karfe yana da zafi a cikin wannan kewayon zafin jiki, yana da yuwuwar haɓaka irin wannan nau'in tashin hankali, wanda ba za a iya kawar da shi ba.

Magani: Guji zafin wutan ƙarfe a cikin wannan kewayon zafin jiki.

Nau'in tashin hankali na farko kuma an san shi da ƙarancin zafin jiki ko rashin iya jurewa.

Ⅵ.Mai zafi

1.Tempering shine tsarin maganin zafi na ƙarshe wanda ke biye da quenching.

Me yasa Karfe Ke Bukatar Haushi?

Microstructure Bayan Quenching: Bayan quenching, microstructure na karfe yawanci ya ƙunshi martensite da saura austenite. Dukansu matakai ne masu daidaitawa kuma za su canza a ƙarƙashin wasu yanayi.

Kayayyakin Martensite: Martensite yana da ƙayyadaddun tauri mai ƙarfi amma kuma yana da ƙarfi sosai (musamman a cikin allurar carbon-kamar martensite), wanda baya cika buƙatun aiki don aikace-aikace da yawa.

Halayen Canjin Martensitic: Canji zuwa martensite yana faruwa da sauri. Bayan quenching, workpiece yana da ragowar damuwa na ciki wanda zai iya haifar da lalacewa ko fashewa.

Kammalawa: Ba za a iya amfani da aikin ba kai tsaye bayan quenching! Tempering ya zama dole don rage damuwa na ciki da inganta ƙarfin aikin aikin, yana sa ya dace da amfani.

2.Bambanci Tsakanin Hardenability da Ƙarfin Ƙarfi:

Hardenability:

Hardenability yana nufin ikon ƙarfe don cimma wani zurfin taurin (zurfin daɗaɗɗen Layer) bayan quenching. Ya dogara da nau'in karfe da tsarinsa, musamman abubuwan da ke haɗa shi da nau'in karfe. Hardenability shine ma'auni na yadda ƙarfe zai iya yin taurare a duk lokacin kauri yayin aikin kashewa.

Tauri (Ƙarfin Ƙarfin):

Tauri, ko ƙarfin ƙarfi, yana nufin iyakar taurin da za'a iya samu a cikin ƙarfe bayan quenching. An fi rinjaye shi da abun cikin carbon na karfe. Mafi girman abun ciki na carbon gabaɗaya yana kaiwa zuwa mafi girman yuwuwar taurin, amma ana iya iyakance wannan ta abubuwan haɗakar da ƙarfe da tasirin aikin kashewa.

3.Taurin Karfe

√Ma'anar Hardenability

Hardenability yana nufin ƙarfin ƙarfe don cimma wani zurfin taurin martensitic bayan quenching daga zafin jiki na austenitizing. A cikin mafi sauƙi, shine ikon ƙarfe don samar da martensite a lokacin quenching.

Auna Hardenability

Girman taurin yana nuna zurfin taurin Layer da aka samu a ƙarƙashin ƙayyadaddun yanayi bayan quenching.

Zurfin Hardened Layer: Wannan shine zurfin daga saman kayan aikin zuwa yankin da tsarin ya kasance rabin martensite.

Media Quenching gama gari:

•Ruwa

Halaye: Tattalin arziki tare da ƙarfin sanyaya mai ƙarfi, amma yana da ƙimar sanyi mai girma kusa da wurin tafasa, wanda zai iya haifar da sanyaya mai yawa.

Aikace-aikace: Yawanci ana amfani da su don carbon steels.

Ruwan Gishiri: Maganin gishiri ko alkali a cikin ruwa, wanda ke da ƙarfin sanyaya a yanayin zafi mai yawa idan aka kwatanta da ruwa, yana sa ya dace da karafan carbon.

•Mai

Halaye: Yana ba da ƙarancin sanyaya a hankali a ƙananan yanayin zafi (kusa da wurin tafasa), wanda ya rage yadda ya kamata don lalatawa da fashewa, amma yana da ƙananan ƙarfin sanyaya a yanayin zafi.

Aikace-aikace: Dace da gami karfe.

Nau'o'i: Ya haɗa da man da ake kashewa, man inji, da man dizal.

Lokacin dumama

Lokacin dumama ya ƙunshi duka adadin dumama (lokacin da aka ɗauka don isa yanayin zafin da ake so) da lokacin riƙewa (lokacin da aka kiyaye a zafin da aka yi niyya).

Ka'idoji don Ƙayyadaddun Lokacin Zafafawa:Tabbatar rarraba yawan zafin jiki iri ɗaya a cikin kayan aikin, ciki da waje.

Tabbatar da cikakken ingantawa da kuma cewa austenite da aka kafa daidai ne kuma yana da kyau.

Tushen Ƙayyade Lokacin Zafafawa: Yawancin lokaci ana ƙididdigewa ta amfani da ƙididdiga masu ƙarfi ko ƙaddara ta hanyar gwaji.

Mai Rarraba Media

Hanyoyi guda biyu masu mahimmanci:

a.Cooling Rate: Matsayin sanyaya mafi girma yana haɓaka samuwar martensite.

b.Residual Stress: A mafi girma sanyaya kudi ƙara saura danniya, wanda zai iya haifar da mafi girma hali ga nakasawa da fatattaka a cikin workpiece.

Ⅶ.Daidaitawa

1. Ma'anar daidaitawa

Normalizing wani tsari ne na maganin zafi wanda ake dumama karfe zuwa zafin jiki na 30°C zuwa 50°C sama da zafin AC3, ana gudanar da shi a wannan zafin, sannan a sanyaya iska don samun microstructure kusa da yanayin daidaito. Idan aka kwatanta da annealing, daidaitawa yana da saurin sanyaya, yana haifar da mafi kyawun tsarin lu'u-lu'u (P) da ƙarfi da ƙarfi.

2. Manufar daidaitawa

Dalilin daidaitawa yana kama da na annealing.

3. Aikace-aikace na Normalizing

• Kawar da siminti na sakandare mai hanyar sadarwa.

• Yi aiki a matsayin maganin zafi na ƙarshe don sassan da ƙananan buƙatu.

• Yi aiki azaman magani mai zafi don ƙarami da matsakaicin tsarin ƙarfe don haɓaka machinability.

4.Nau'in Annealing

Nau'in Farko na Annealing:

Makasudi da Aiki: Manufar ba shine don haifar da sauyi na lokaci ba amma don canza karfe daga yanayin rashin daidaituwa zuwa daidaitaccen yanayi.

Nau'u:

•Diffusion Annealing: Yana nufin daidaita abun da ke ciki ta hanyar kawar da rarrabuwa.

• Recrystallization Annealing: Yana maido da ductility ta hanyar kawar da tasirin taurin aiki.

•Taimakon Taimakon Danniya: Yana rage damuwa na ciki ba tare da musanya microstructure ba.

Nau'i Na Biyu na Annealing:

Makasudi da Aiki: Yana nufin canza tsarin ƙayyadaddun ƙayyadaddun ƙayyadaddun ƙayyadaddun ƙayyadaddun ƙayyadaddun ƙayyadaddun ƙayyadaddun ƙayyadaddun ƙirar lu'u-lu'u. Wannan nau'in kuma yana tabbatar da cewa rarrabawa da ilimin halittar jiki na pearlite, ferrite, da carbides sun cika takamaiman buƙatu.

Nau'u:

• Cikakkun buƙatun: Yana dumama karfe sama da zafin AC3 sannan a hankali ya sanyaya shi don samar da tsari na lu'ulu'u iri ɗaya.

• Rashin cikawa: Yana dumama karfe tsakanin AC1 da AC3 yanayin zafi don canza wani bangare na tsarin.

•Isothermal Annealing: Yana dumama karfe zuwa sama da Ac3, sannan kuma saurin sanyaya zuwa zafin jiki na isothermal da rike don cimma tsarin da ake so.

•Spheroidizing Annealing: Yana samar da tsarin spheroidal carbide, inganta injina da tauri.

Ⅷ.1.Ma'anar Maganin Zafi

Maganin zafi yana nufin tsarin da ake dumama karfe, a riƙe shi a wani takamaiman zafin jiki, sannan a sanyaya yayin da yake cikin yanayi mai ƙarfi don canza tsarin cikinsa da ƙananan ƙwayoyin cuta, ta yadda ake samun abubuwan da ake so.

2.Halayen Maganin Zafi

Maganin zafi ba ya canza siffar aikin aiki; a maimakon haka, yana canza tsarin ciki da ƙananan tsarin ƙarfe, wanda hakan ya canza fasalin ƙarfe.

3.Manufar Maganin Zafi

Manufar maganin zafi shine haɓaka kayan aikin injiniya ko sarrafa kayan ƙarfe (ko kayan aiki), cikakken amfani da yuwuwar ƙarfe, haɓaka ingancin aikin, da tsawaita rayuwar sabis.

4. Mabuɗin Ƙarshe

Ko za a iya inganta kaddarorin kayan ta hanyar maganin zafi ya dogara sosai akan ko akwai canje-canje a cikin ƙananan tsarin sa da tsarin sa yayin aikin dumama da sanyaya.

Lokacin aikawa: Agusta-19-2024